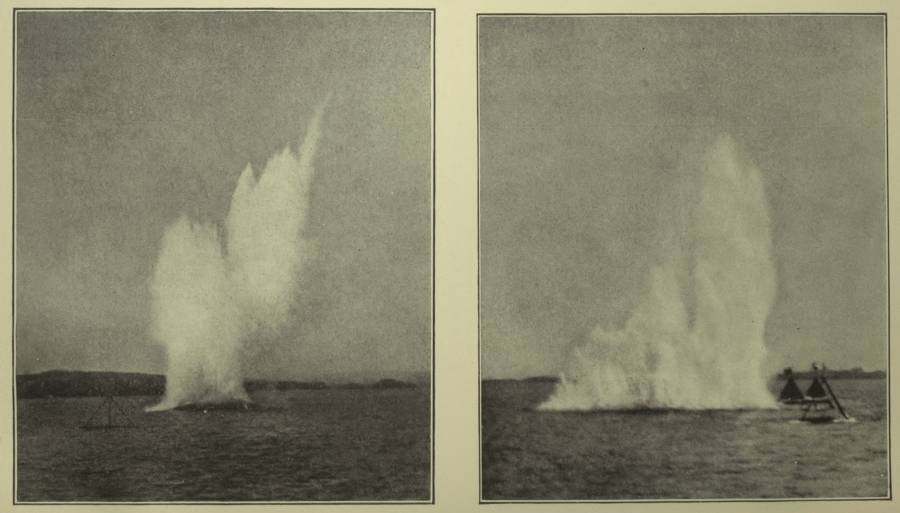

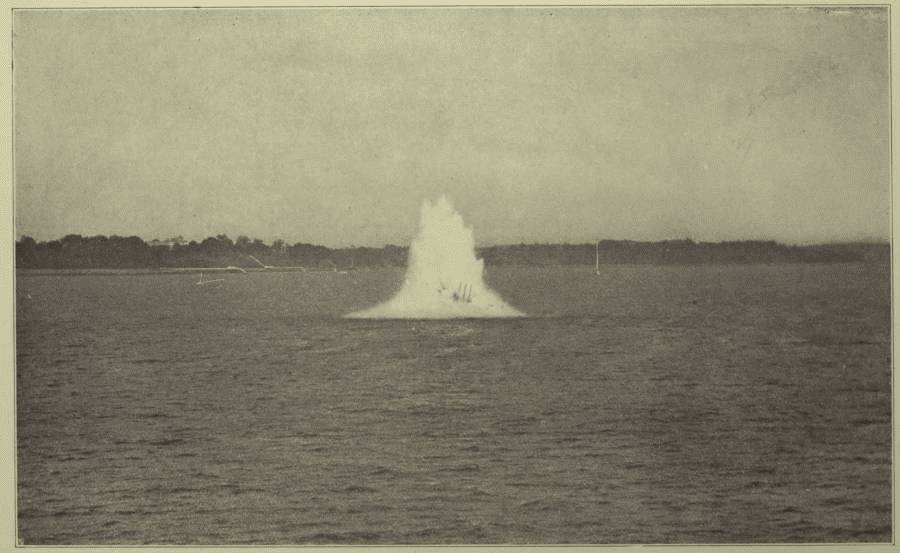

[Frontispiece.]

WORKS OF CAPTAIN H. E. CLOKE

The Gunner's Examiner.

Third Edition, Revised and Enlarged. 8vo, viii + 206 pages, 109 figures. Cloth, $1.50.

The Enlisted Specialists' Examiner.

8vo, vi + 186 pages, 146 figures. Cloth, $2.00 net.

PREPARED BY

HAROLD E. CLOKE

Captain Coast Artillery Corps, U. S. A.

THIRD EDITION, REVISED AND ENLARGED.

FIRST THOUSAND

NEW YORK

JOHN WILEY AND SONS

London: CHAPMAN AND HALL, Limited

1908

Copyright, 1905, 1906, 1908,

BY

HAROLD E. CLOKE

The Scientific Press

Robert Drummond and Company

New York

Owing to the practical impossibility of a student of gunnery obtaining ready access to all the books, pamphlets, circulars, orders, etc., necessary to fit him for the examinations as required by General Orders of the War Department for first- and second-class gunners, and also owing to the extreme difficulty the average enlisted man has in comprehending the technical language in which these books, pamphlets, etc., are couched,—provided he does by some stroke of good fortune come into possession of some of them,—the author has been impelled to compile this work.

Effort has been made to eliminate all subjects that are not included in the requirements of G. O. 141, 1904, yet being particular that it contain all such subjects as an examining board might fairly construe to be within the interest and scope of the order.

As the art of gunnery changes from year to year, and the scope of gunner's examinations changes likewise, it is intended that this book be revised and published accordingly.

The preparation of this book was suggested to the author by the members of his company—the 61st Coast Artillery.

As is well known, the first publication of a text-book is liable to contain a few technical errors. The author will be grateful for any information of such a character concerning this work.

The author is indebted to Brigadier-General William Crozier for supplying him with many pamphlets issued by the Ordnance Department; to First Lieutenant W. K. Moore for correction of proof and other matters; and to Master Electrician C. M. Beer, Artillery Corps, for photographs.

Fort Totten, N. Y., February, 1905.

In this edition the author has endeavored to make all the corrections which were suggested to him during the past year, and to add to the book descriptions, etc., of the new range-board, the deflection-board, several later types of guns, and a brief discourse on the loading, planting, and care of submarine mines according to the new and adopted system.

The author desires to thank Captain R. P. Davis for his revision of the "torpedo gunnery" contained in the work.

Fort Totten, N. Y., November, 1905.

As was stated in the preface of the first edition, this book will be revised from year to year as the rules of gunnery change, and this revision is made merely to bring the book up to date.

It is intended in this revision to conform strictly to G. O. 105, 1907, and to add to the book only such matter as will assist enlisted men of the Coast Artillery Corps to pass their examinations for first or second-class gunners.

The chapter on submarine mining is almost completely revised, for the reason that the new system has undergone many more radical changes within the past few years than has gunnery in the Coast Artillery.

Several additions in mortar gunnery have been made in order to keep pace with the rapid and remarkable development of this arm of Coast Artillery.

Fort Totten, New York, March, 1908.

| CHAPTER I. | |

| PAGE | |

| Extracts from G. O. 105, May 11, 1907 | 1 |

| Schedule of Examination for Gunners | 2 |

| Syllabus of Examination for Gunners | 3 |

| Second-class Gunners | 4 |

| First-class Gunners | 6 |

| Torpedo-company Gunners | 9 |

| Examination for Second-class Gunners | 11 |

| General Information | 11 |

| Service of the Piece | 11 |

| 12-inch B. L. R., Disappearing Carriage | 13 |

| 12-inch B. L. R., Mounted on Non-disappearing Carriage | 26 |

| 8-inch Non-disappearing | 30 |

| 12-inch Mortar, Model 1896 | 33 |

| 6-inch Disappearing | 37 |

| Nomenclature and General Description | 41 |

| Breech-blocks, Recoil-cylinders, etc. | 44 |

| Care of Guns and Carriages | 66 |

| Powders, Projectiles, Primers, and Fuses | 73 |

| Cordage, Blocks, Tackle, Gins, Shears, etc. | 88 |

| Knots and Hitches | 91 |

| Splices | 95 |

| Rigging-tackles | 96 |

| Gins | 98 |

| Shears | 99 |

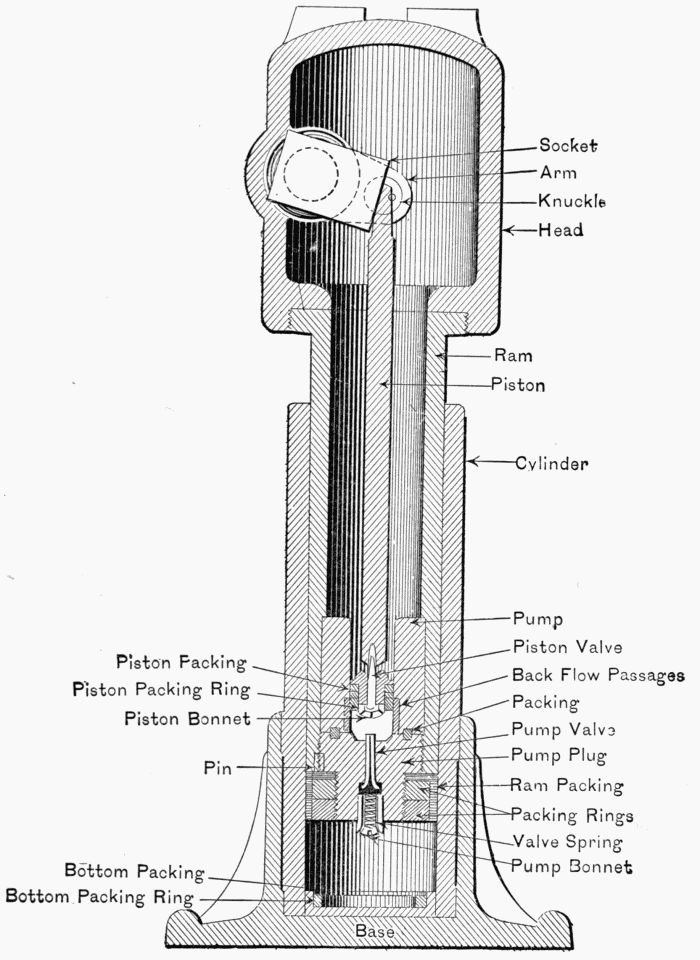

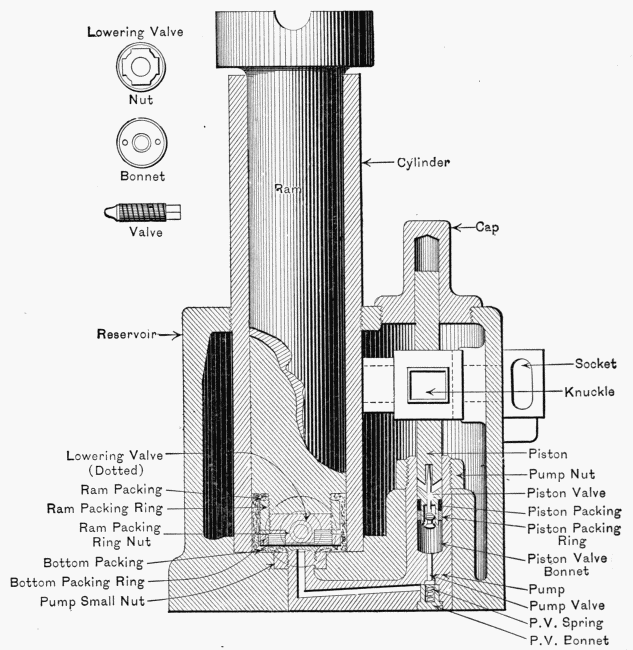

| Hydraulic Jacks | 102 |

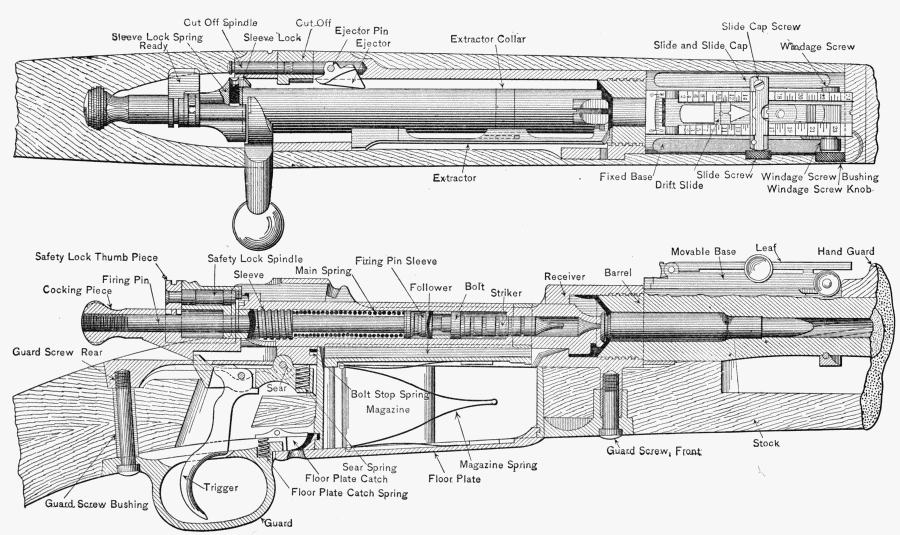

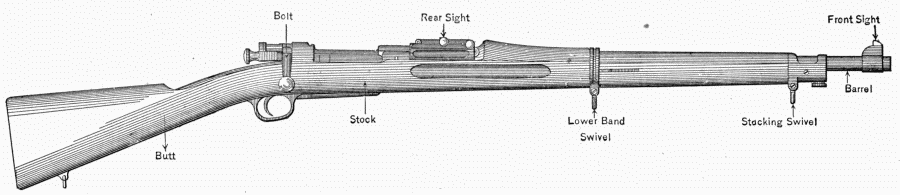

| U. S. Magazine Rifle Description etc. | 105 |

| CHAPTER II.[viii] | |

| Examination of First-class Gunners | 111 |

| (a) The Azimuth Instrument and Definitions | 111 |

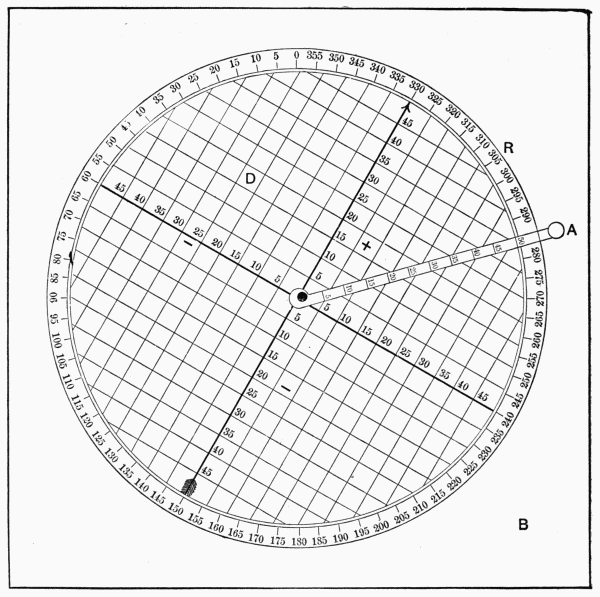

| (b) The Plotting-board | 116 |

| The Range-board | 123 |

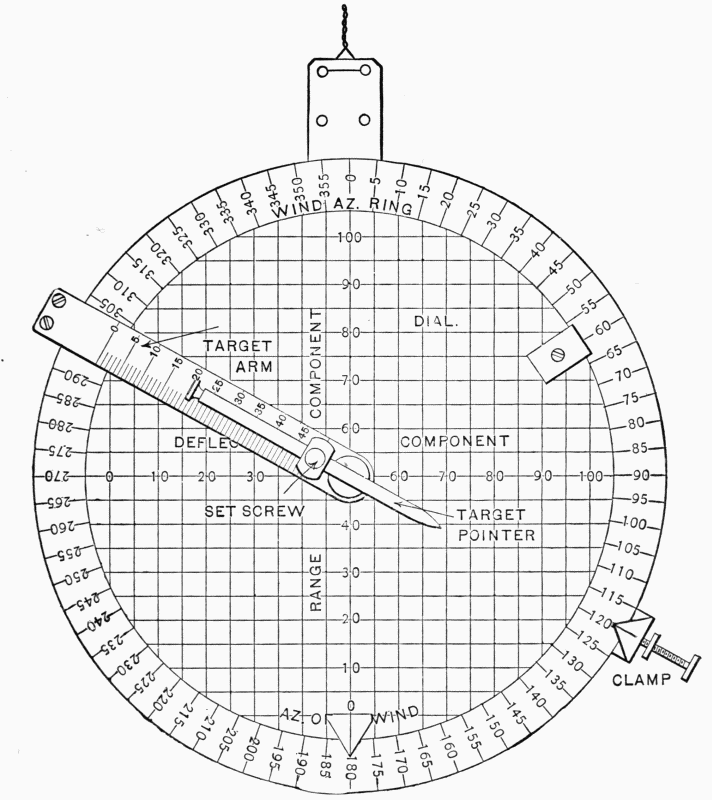

| The Deflection-board | 128 |

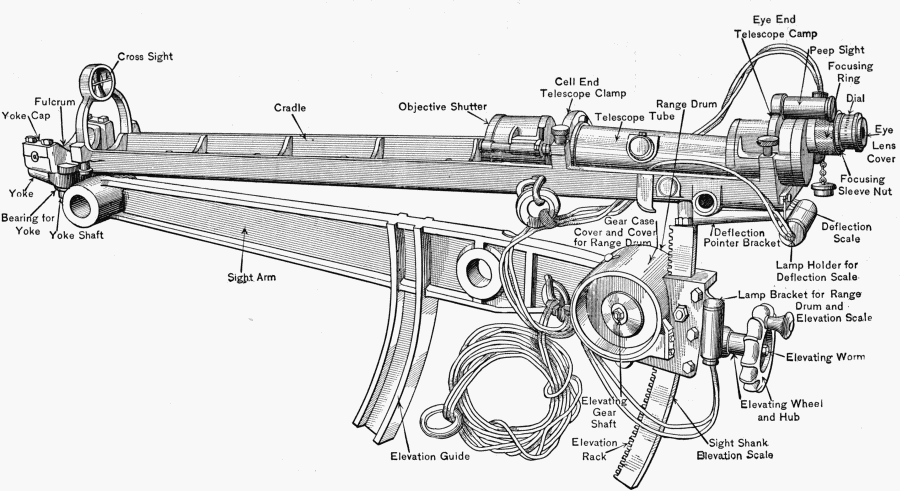

| The Telescopic Sight | 136 |

| Wind Component | 145 |

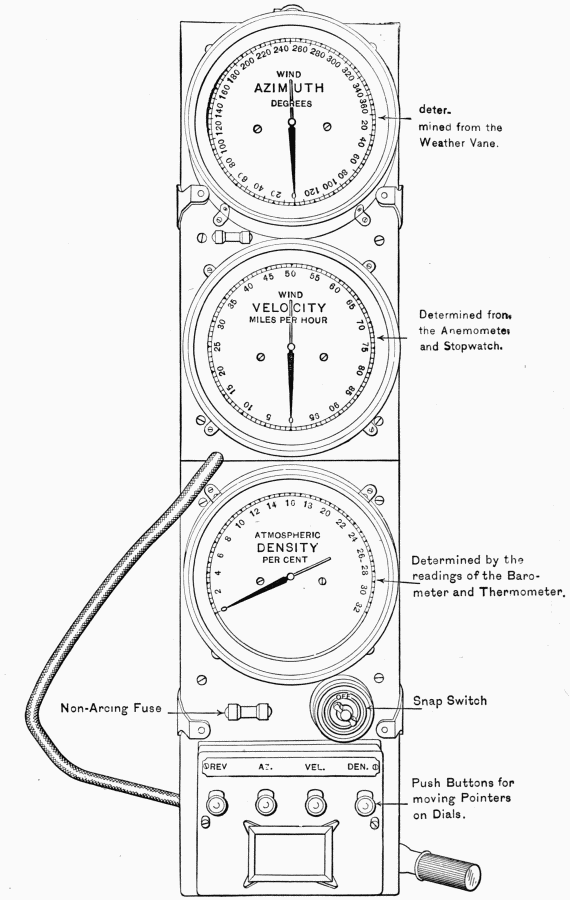

| The Aeroscope | 146 |

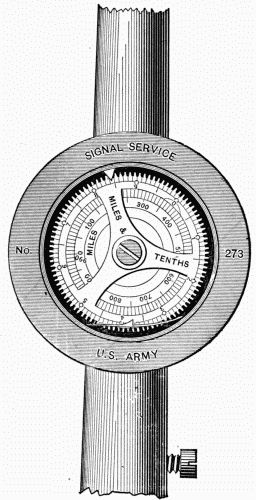

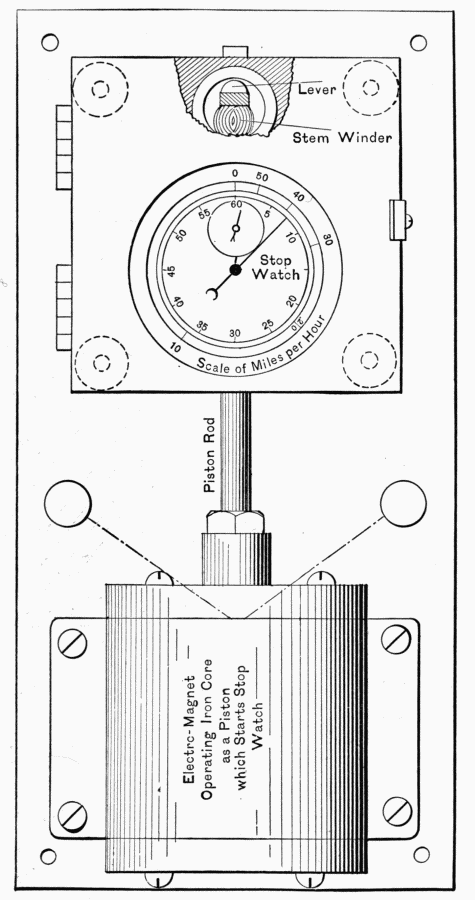

| Anemometer | 149 |

| Electric Stop-watch | 149 |

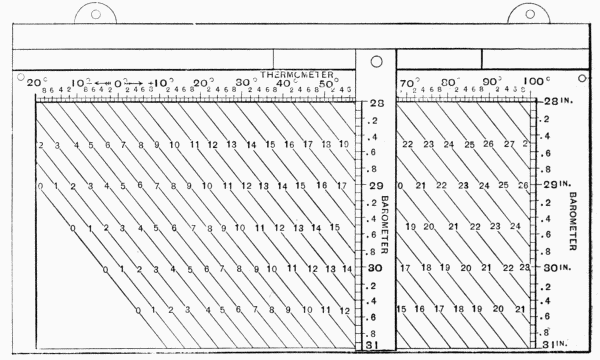

| The Atmosphere-board | 150 |

| Special Apparatus for Mortars | 151 |

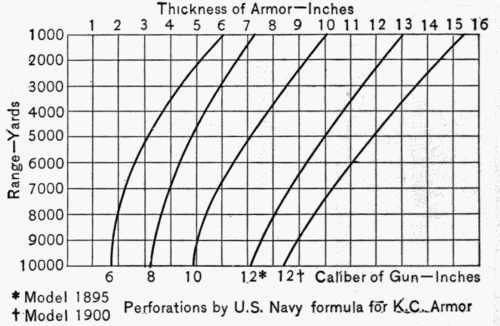

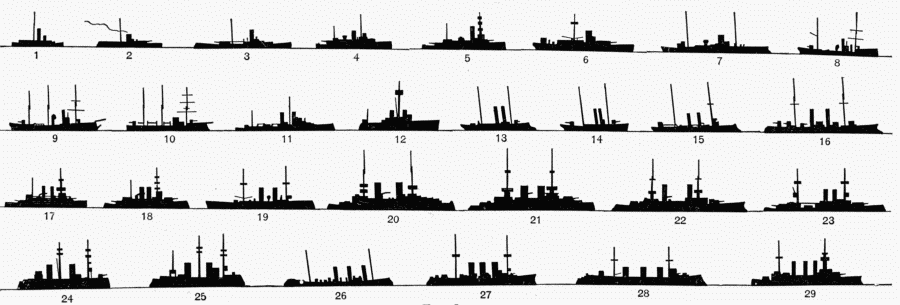

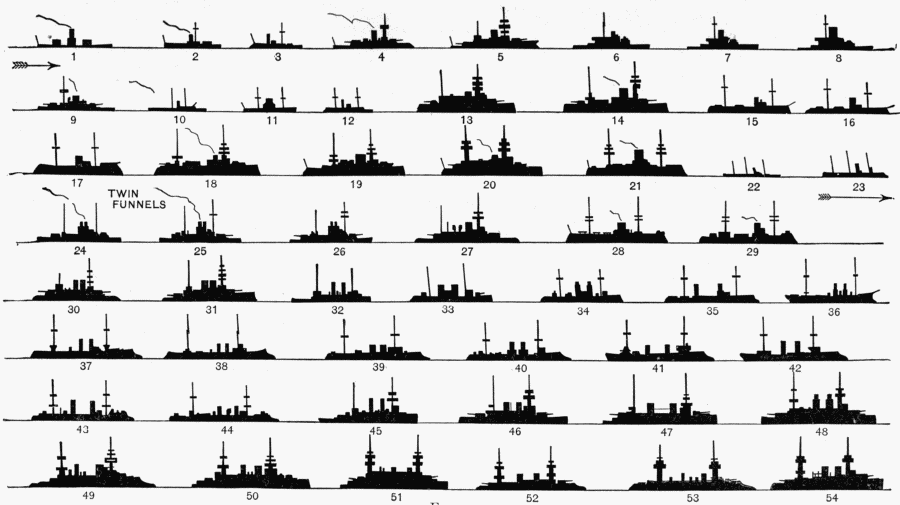

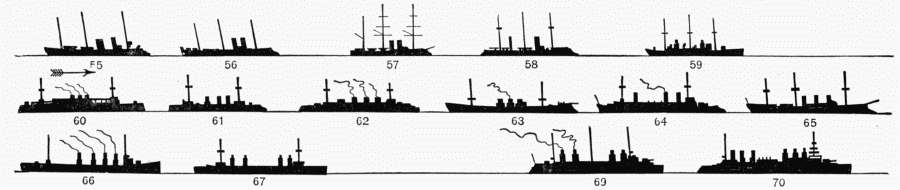

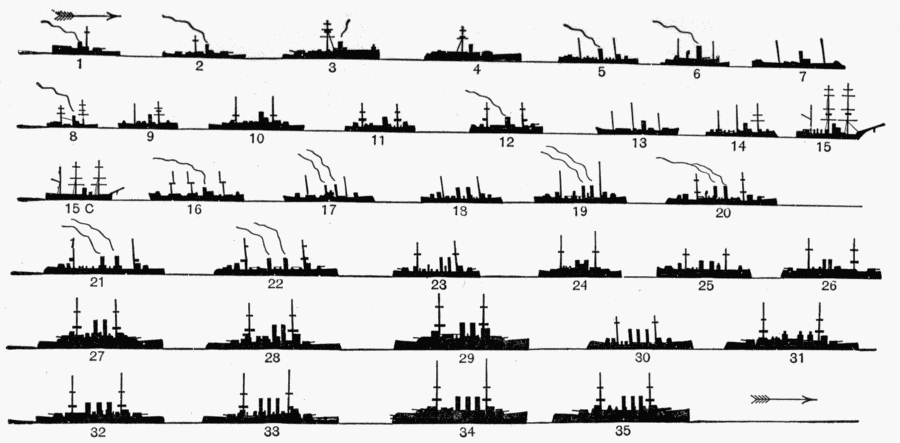

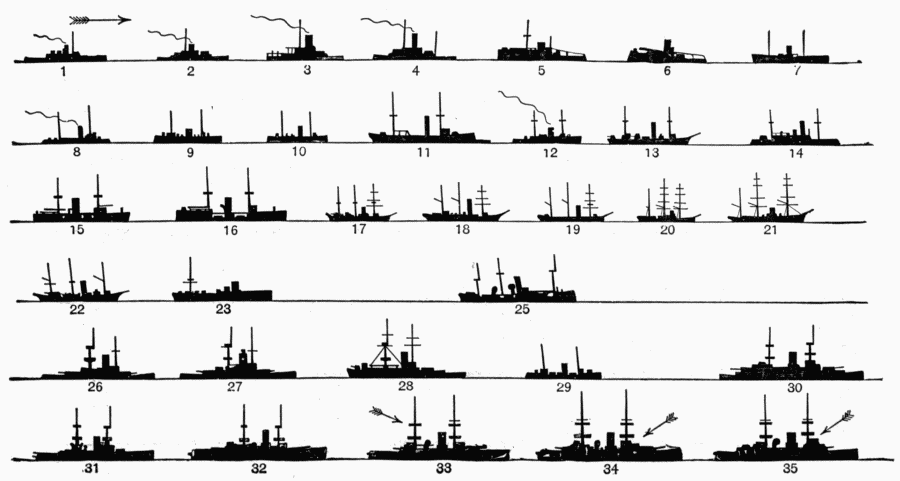

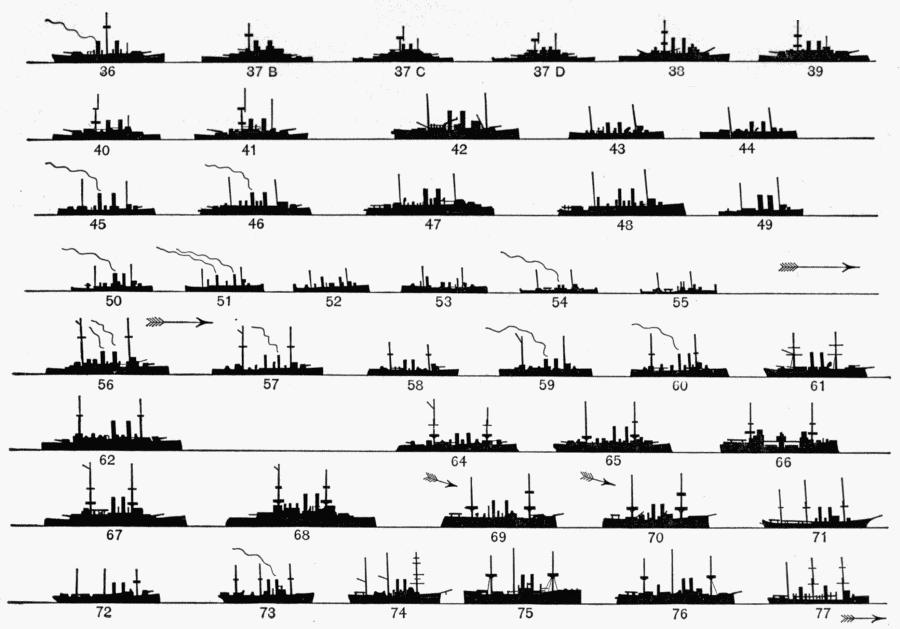

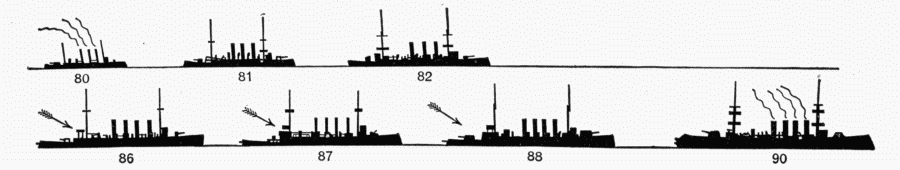

| Battle-ships, Armor, etc. | 151 |

| Examination for Torpedo-company Gunners | 169 |

| Second-class Gunners | 169 |

| Service of the Piece, Nomenclature | 169 |

| Duties in the Loading-room | 174 |

| Duties on the Water | 181 |

| Magazine Rifle, Description, etc. | 186 |

| First-class Gunners | 186 |

| Care and Preservation of Mine Material | 186 |

| Handling High Explosives | 189 |

| The Azimuth Instrument and Plotting-board | 190 |

| Storage Batteries | 190 |

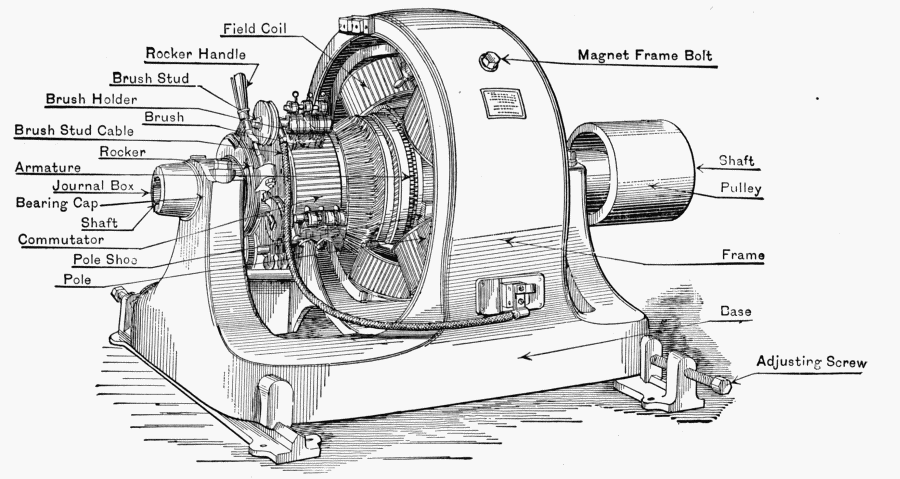

| Generators | 190 |

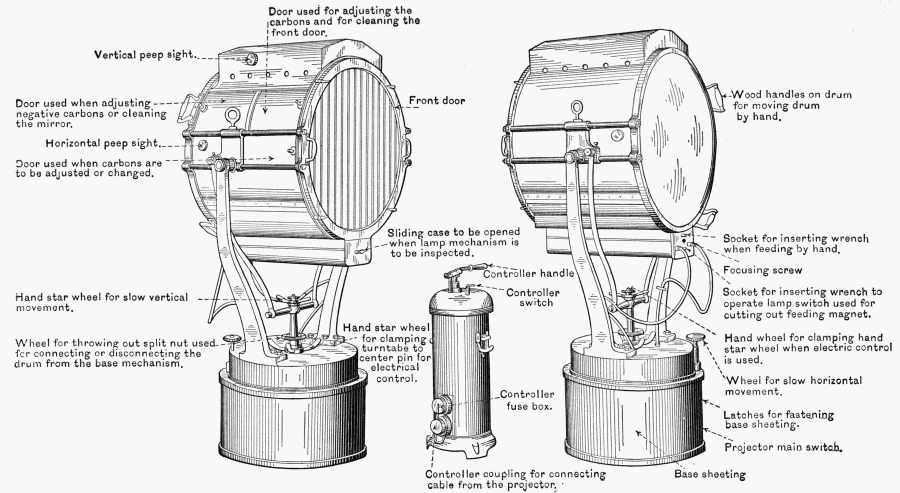

| Searchlights | 190 |

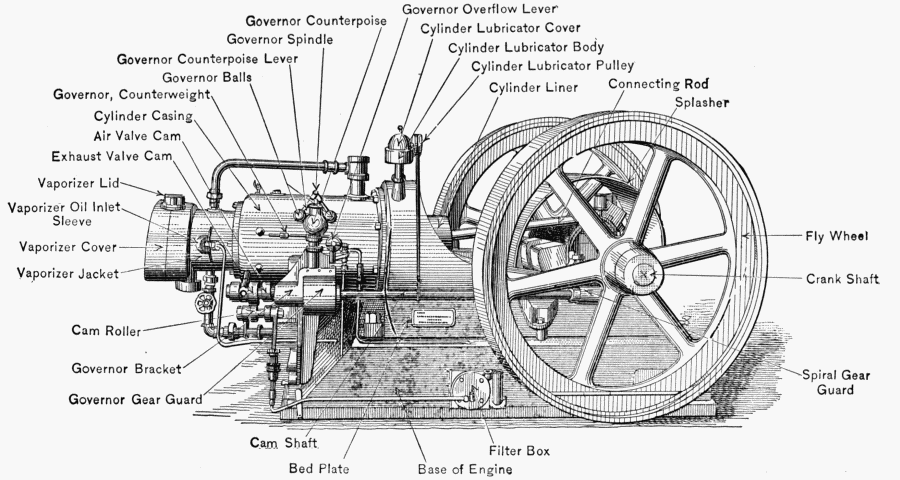

| Oil-engines | 195 |

| Apparatus and Operation of Casemate Switchboard | 198 |

144. A candidate to be eligible for qualification as first-class gunner must have previously qualified as second-class gunner, though both qualifications may be made at the same examination.

145. Boards of examination shall be convened annually in each artillery district by the district commander, to meet within one month after the expiration of the indoor instruction period. Separate boards may be convened for the examination of candidates for first and second-class gunners and also for the posts attached to the artillery district. All boards shall consist of three artillery officers, selected with reference to their special qualifications for this duty; provided, that when a member of the board is a company commander he will, during the examination of candidates from his company, be replaced by an officer of another company. Where travel is necessary the selection of an officer for this duty will be made subject to the approval of the authority competent to order the necessary journeys.

146. Each company commander will, previous to the commencement of the examination, submit to the adjutant a duly signed list, in the triplicate, giving the full names, arranged in[2] muster-roll order, of all the men in his company who are to be examined for first or second-class gunners, with the statement that he believes that each man so presented is capable of qualifying in the class designated. These lists will be transmitted to the senior member of the board by the post commander.

147. In determining the qualifications of candidates credit shall be given for practical knowledge of subjects rather than for text-book answers to questions.

148. For candidates in companies assigned to gun defence:

| For second-class gunners— | |

| (a) Service of the piece | 25 |

| (b) Guns and carriages | 25 |

| (c) Powders, projectiles, primers, and fuses | 25 |

| (d) Cordage, gins, shears, jacks | 15 |

| (e) U. S. magazine rifle | 10 |

| —— | |

| 100 | |

| For first-class gunners— | |

| (a) The azimuth instrument | 20 |

| (b) Duties in the plotting-room | 50 |

| (c) Aiming and laying guns and mortars | 15 |

| (d) Elementary gunnery | 5 |

| (e) Warships | 10 |

| —— | |

| 100 |

149. The examination of candidates for first-class gunners of organizations assigned exclusively to rapid-fire guns not provided with separate position-finding system shall include the following head in lieu of that given above under (b):

(b) Subcaliber firing 50

150. The examination of candidates for first-class gunners shall be held as far as practicable at such places as the material or equipment pertaining to the subject in hand is located, i.e., at the guns or in the plotting-rooms.

151. The examination in subjects (a), (b), (c) for second-class gunners and in subjects (a), (b), (c) and (d) for first-class gunners shall be confined to the material of the battery and its accessories to which the company is assigned. If no azimuth instrument is included in the battery equipment, the instrument used in the company instruction shall be used in the examination. If for any cause beyond the power of the battery commander any part of this equipment has been removed from his control and has not been available for instruction for at least two months previous to the examination, such material shall form no part of the examination.

152. For candidates in companies and detachments assigned to mine defence:

| For second-class gunners— | |

| (a) Ammunition, nomenclature, and service of guns assigned | |

| to the company of which the candidate is a member | 15 |

| (b) Material of and duties in the loading room (except | |

| electrical principles involved) | 35 |

| (c) Material for and duties on water | 30 |

| (d) Cordage | 10 |

| (e) U. S. magazine rifle | 10 |

| —— | |

| 100 | |

| For first-class gunners— | |

| (a) Care and preservation of mine material | 20 |

| (b) Handling high explosives | 20 |

| (c) Knowledge and use of the azimuth instrument | |

| and plotting-board | 20 |

| (d) Batteries, generators, and searchlights assigned to | |

| the company of which candidate is a member | 20 |

| (e) Apparatus and operation of switchboard and care | |

| and use of telephone | 20 |

| —— | |

| 100 |

153. The qualifying mark for classification as first or second-class gunner shall be in each case not less than an average of 75 per centum. Whenever, during the progress of the examination of a candidate for either grade, the sum of the marks received on subjects in which he has already been examined, increased by the maximum allowed for the remaining subjects, is less than 75, his examination will be discontinued.

154. Instruction in the course for first or second-class gunner will be given to such men as the company commander may consider capable of mastering the prescribed schedules.

155. Men not receiving instruction in the gunners' classes will perform such duties at their batteries or elsewhere during the hours for instruction as their company commander, with the approval of the post commander, may direct.

156. The board shall keep a record of its marks during the examination, but these marks shall not be published in orders. The record of each company shall be sent to the artillery district commander as soon as possible after the completion of the examination, to be published immediately. The report of the board to be published in orders shall contain the names of those who have qualified as first and second-class gunners and recite the date of the report, which will be the date of the completion of the company examination in each case, the names being arranged for each organization in each class in muster-roll order.

The following syllabus gives the outline of the scope of the examination of candidates for gunners in companies assigned to gun defense. While the indoor instruction in any subject need not be limited to what is indicated in this syllabus, the examination of candidates for gunners shall be confined thereto.

(a) Service of the Piece.

Questions on the service of the piece and nomenclature of the piece to which organization is assigned. If the company is assigned to pieces of different calibers, the candidate will be examined upon the piece of the caliber selected by the company commander. Examining boards are cautioned not to attach too much importance to nomenclature, where a candidate shows a knowledge of the practical use of the part under examination.

(b) Guns and Carriages.

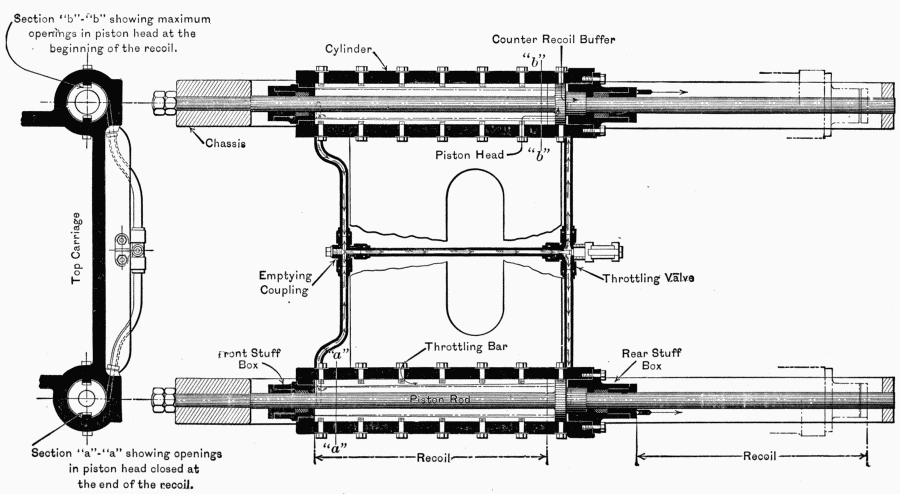

Explain briefly how a breech-block of a heavy gun or mortar is dismantled; having a breech-block completely dismantled (not dismounted), how it is assembled and adjusted for firing; how old packing is removed from recoil-cylinders, and how they are repacked; how recoil-cylinders are filled. Object, care, and use of throttling-valve for guns and by-pass valve for mortars. Parts and surfaces of guns and carriages to be oiled; how much oil to use, and how it is used. Adjustment of grease-cups. In the case of rapid-fire guns explain how to adjust firing mechanism, percussion, and electric (if so equipped).

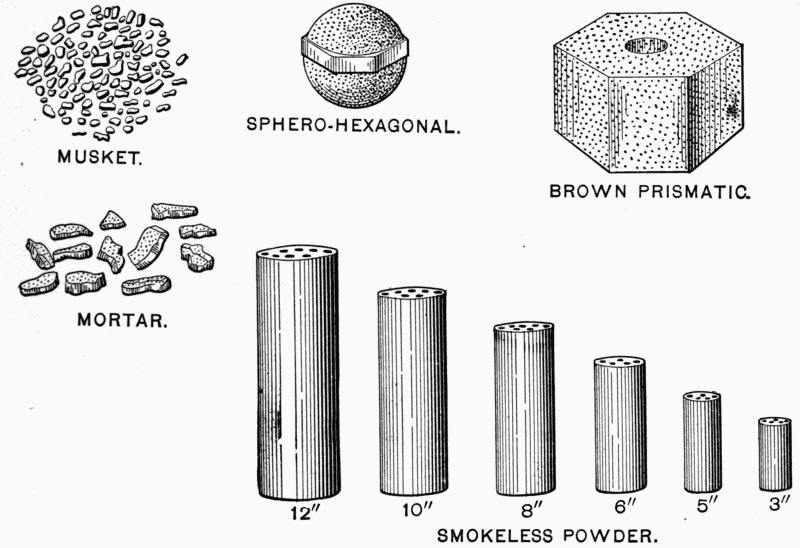

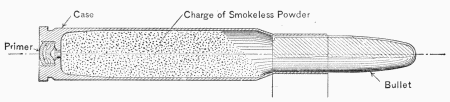

(c) Powders, Projectiles, Primers, Fuses.

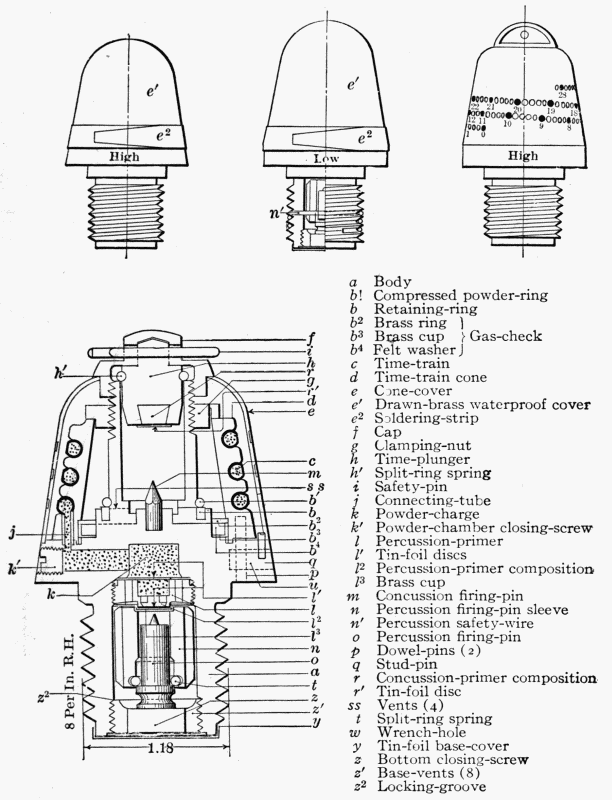

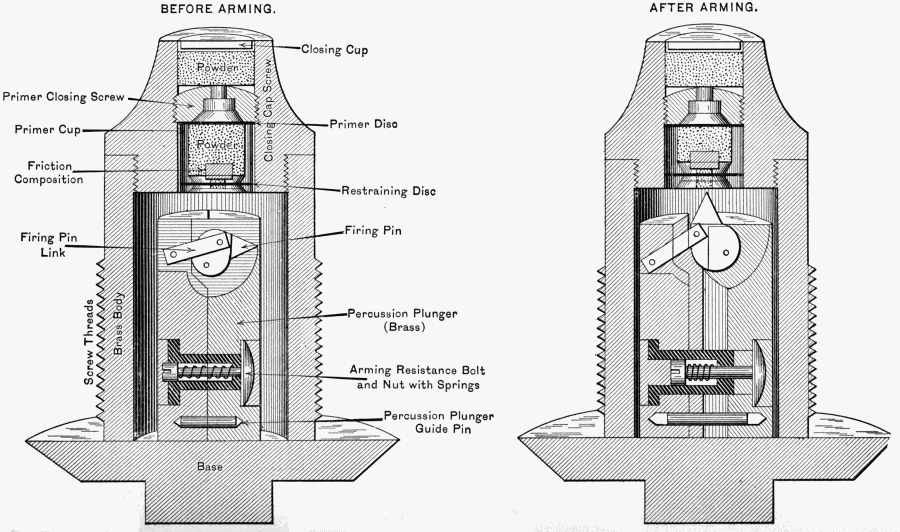

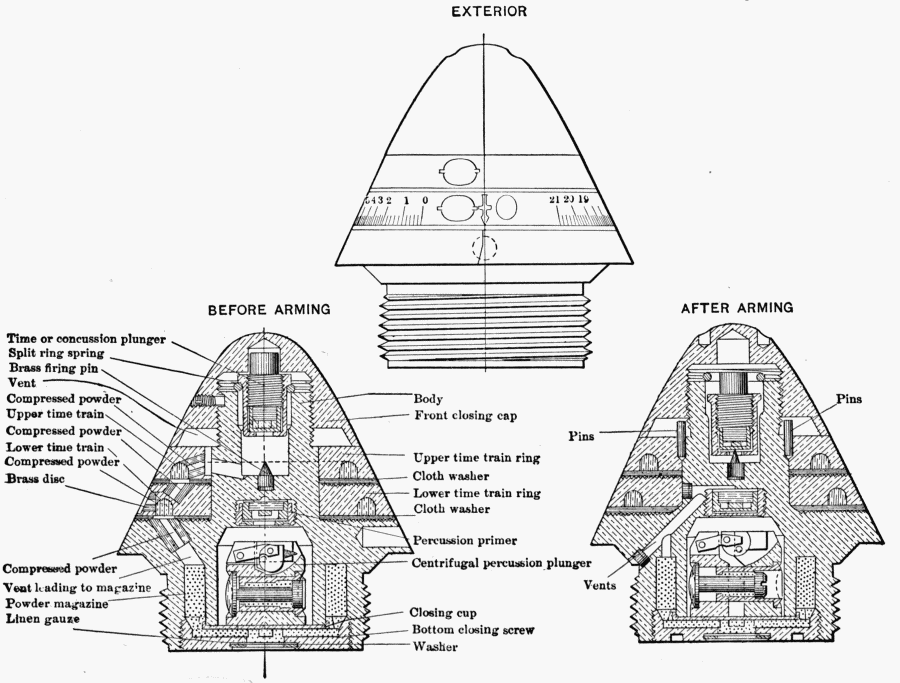

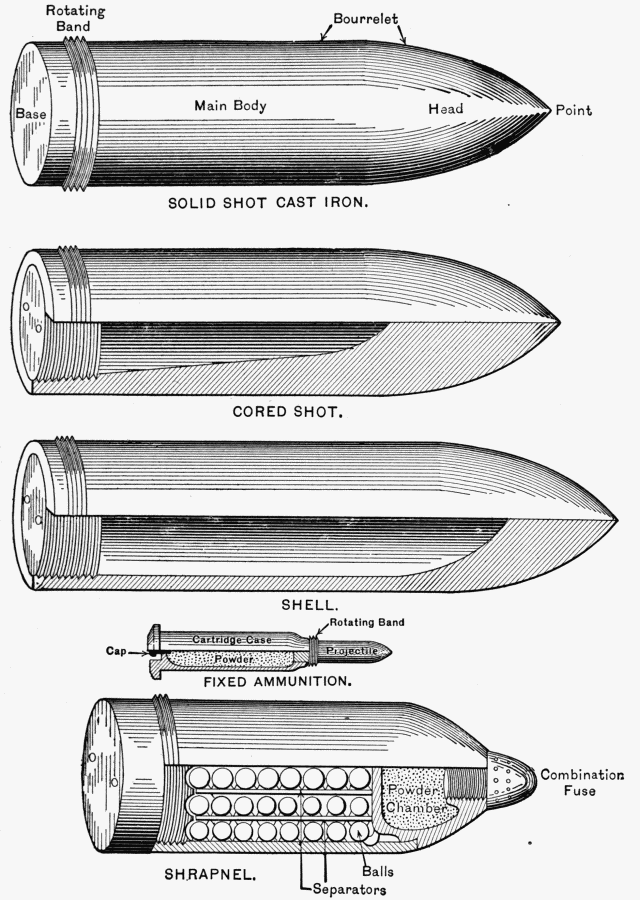

Examination: Name the kind of powder used in the pieces of battery to which organization is assigned; give the weights of service charges and corresponding muzzle velocities of these pieces; also the lowest and highest muzzle velocities of the steel and cast-iron mortars, if assigned to mortar battery. Name the projectiles used in the pieces and give their weights. Tell how to distinguish from the painting of projectiles used, its kind, armor-piercing quality, and nature of bursting charge. Point out the cap, the ogive, the bourrelet, the body, the base, the rotating band, the fuse hole of a projectile.

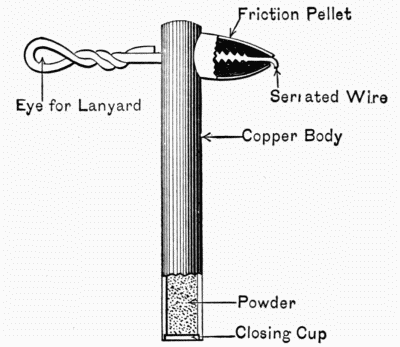

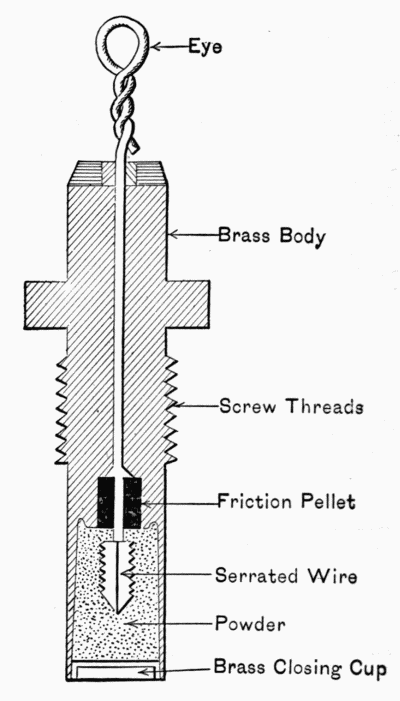

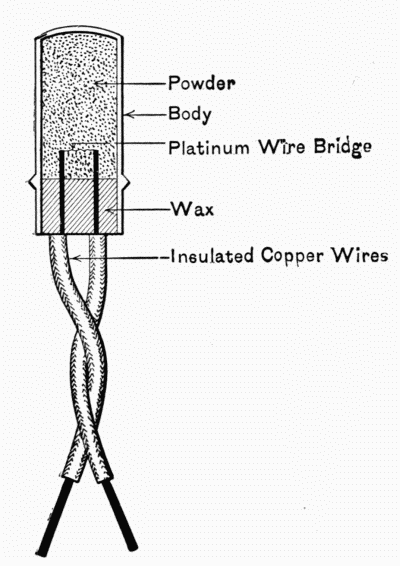

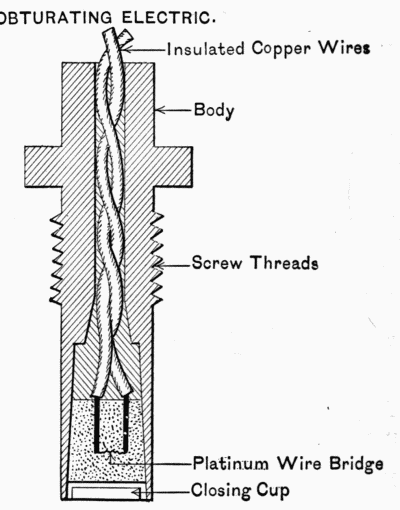

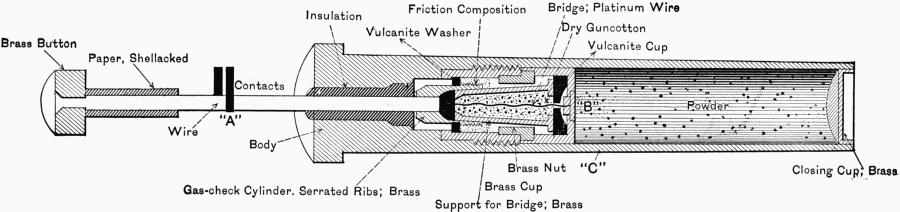

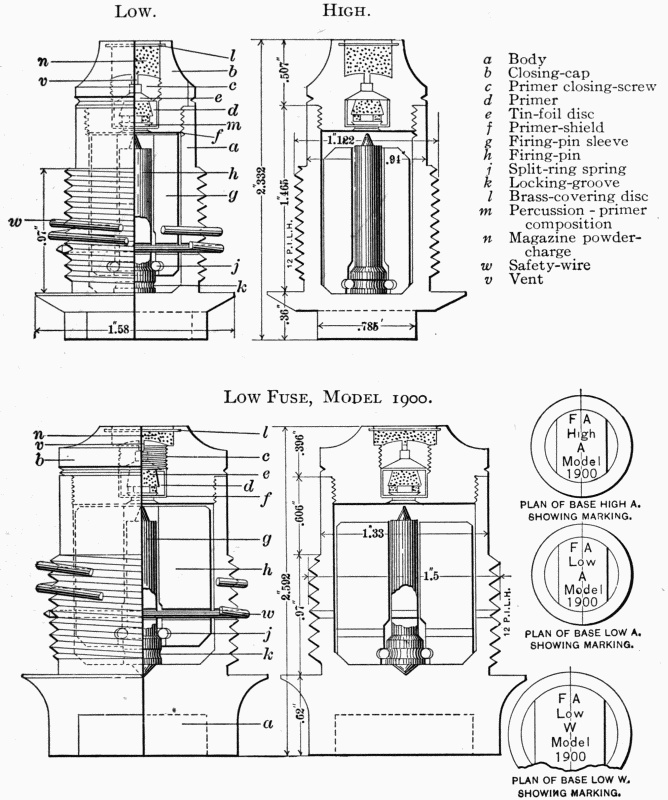

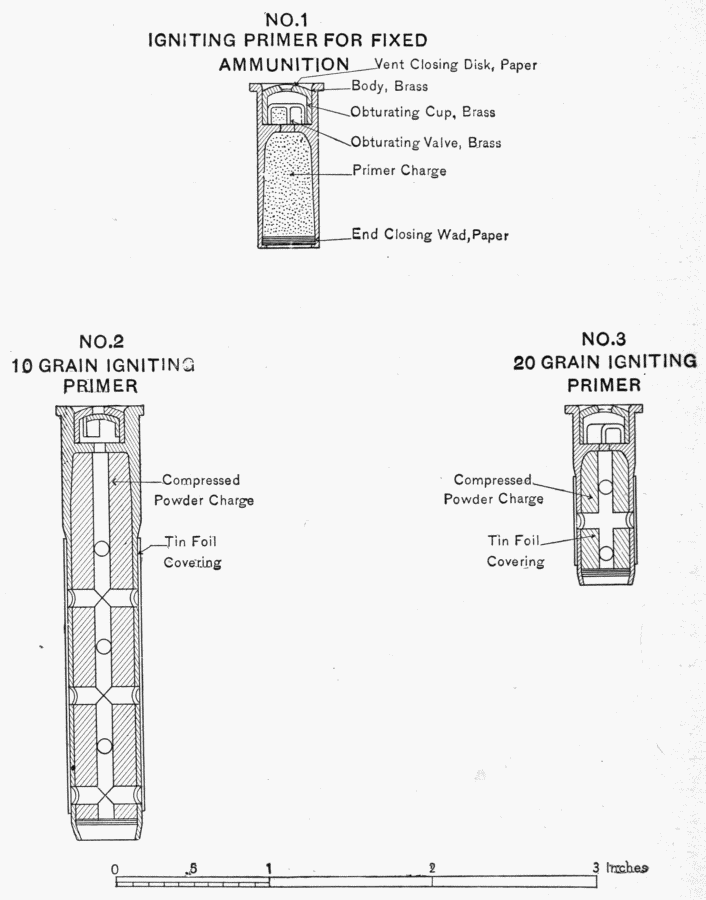

Name each kind of fuse used in the battery (ring resistance, centrifugal, combination, detonating, see Ordnance Department[6] pamphlet No. 1727); tell how it is inserted to make a tight joint. Name the different kinds of primers used in the battery. Friction, electric, combination (electric-friction), percussion, igniting. Reload a drill primer. (Ordnance Department pamphlet No. 1881.)

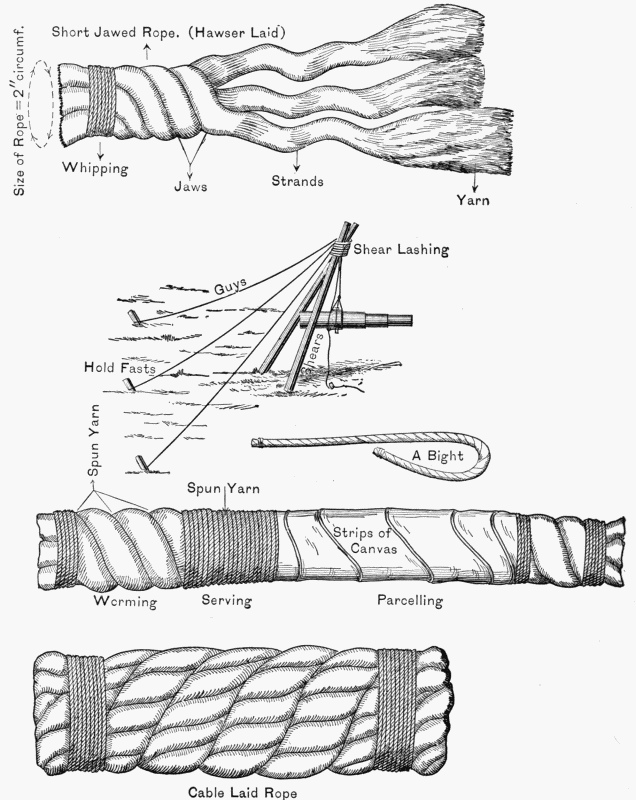

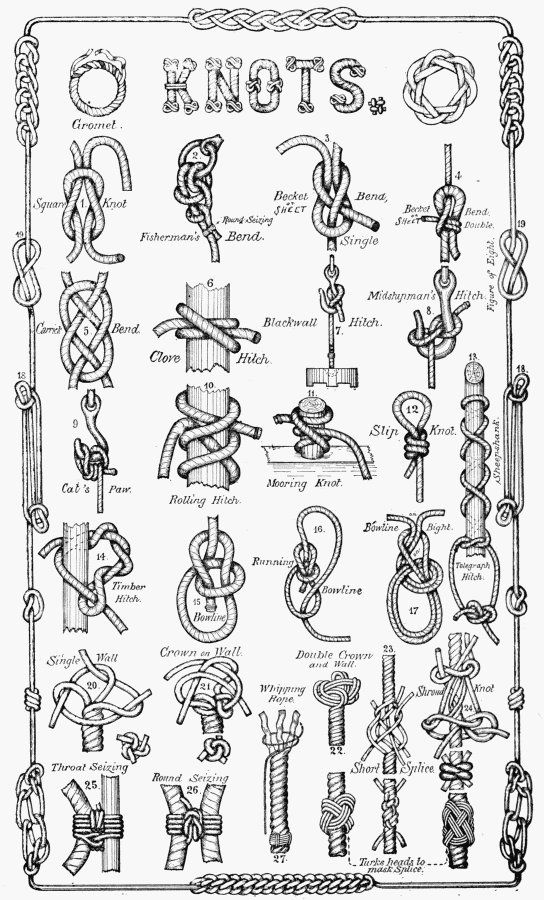

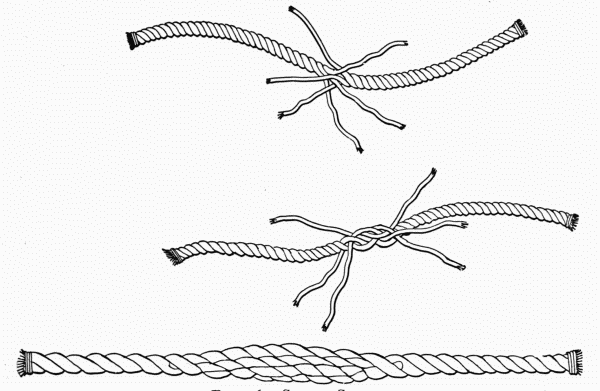

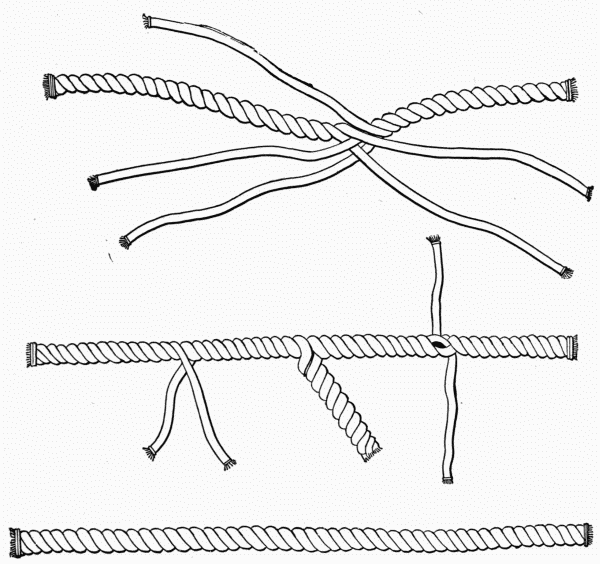

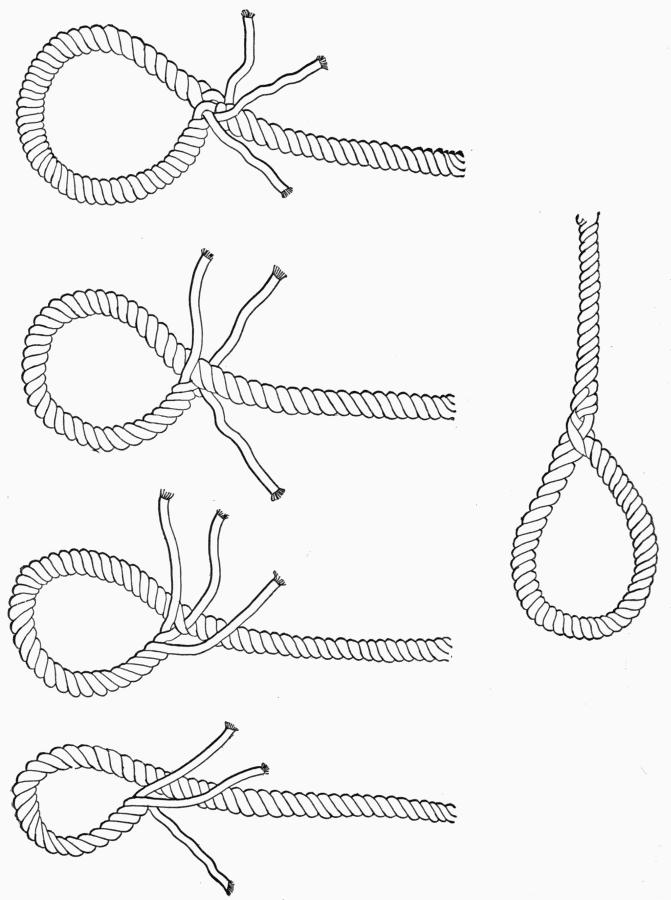

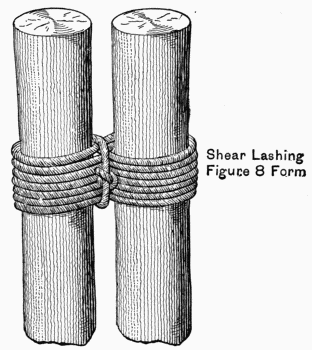

(d) Cordage.

How is the size of a rope denoted? How do you serve a rope? Make a square knot; a bowline; rolling hitch; blackwall hitch; round turn and two half hitches; clove hitch. What is a strap or sling, and what is its use? Make a shear lashing. Mouse a hook and explain for what purpose used.

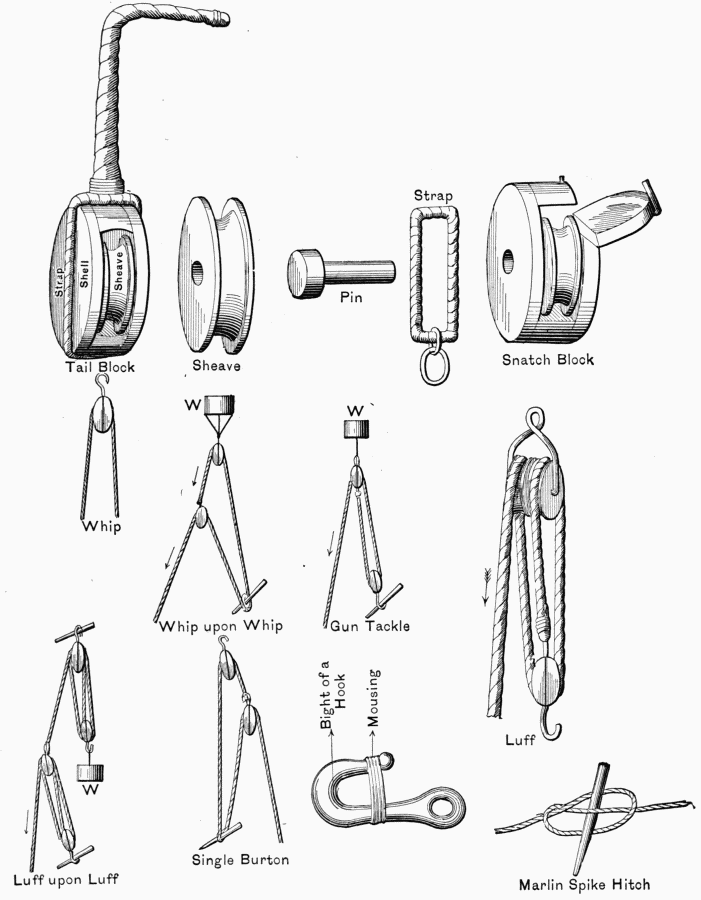

Point out the shell, sheave, pin, strap of a block, and describe the different kinds (single, double, treble, snatch, and tail blocks). Point out the running part; the standing part; the fall of a tackle.

Rig the following: Whip, gun tackle, luff, single burton.

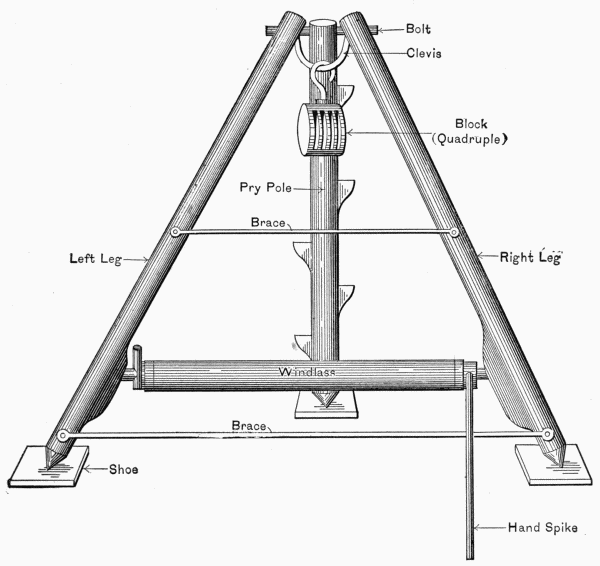

Gins.—Name the different parts of a garrison-gin. Explain briefly how it is assembled and raised (the drill is not required). How can the upper block be placed in position after the gin has been raised?

Sheares.—What do sheares consist of, how are they rigged and raised, and what are they used for? How and when is the tackle made fast? How are sheares held in position after being raised?

Hydraulic Jacks.—For what is a hydraulic jack used? What liquids are used in the jack? How is it filled and emptied? How is the jack cared for when not in use? Show how to use the jack when lifting a heavy weight; in lowering a heavy weight; use of the claw in connection with the jack.

(e) U. S. Magazine Rifle.—Nomenclature of the piece, kind and weight of powder used, description and weight of projectile, muzzle velocity. Setting of sight for range and deflection.

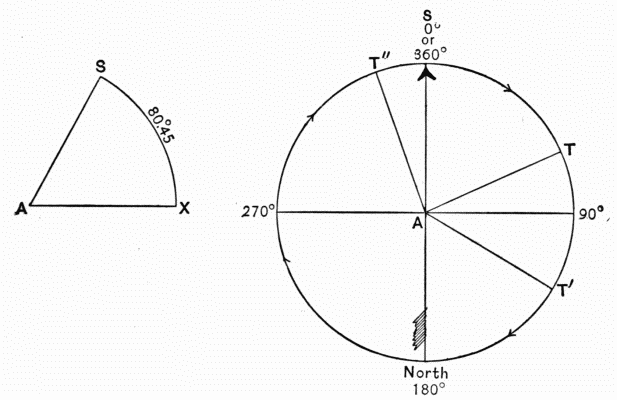

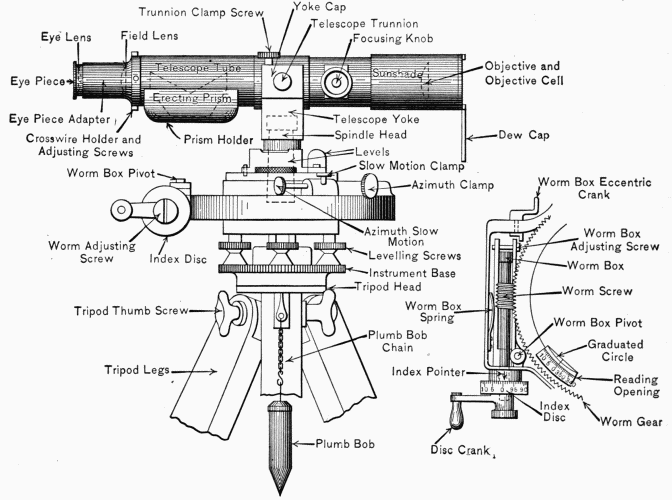

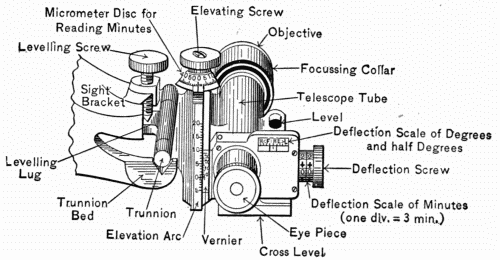

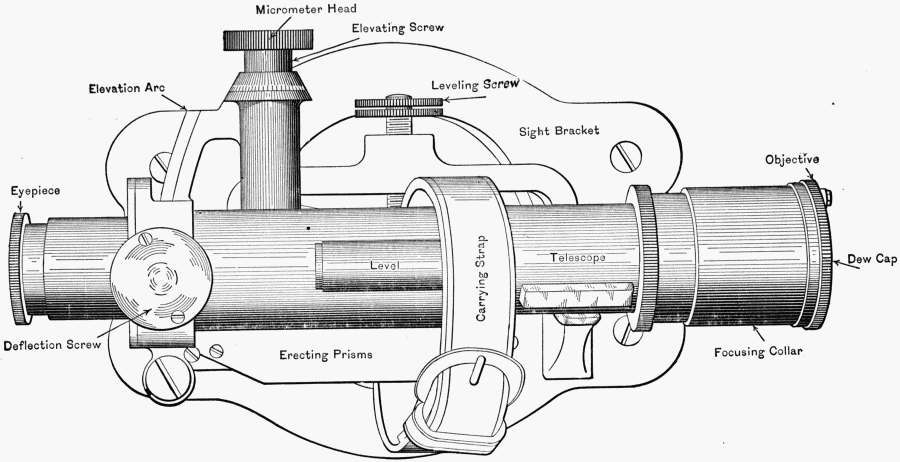

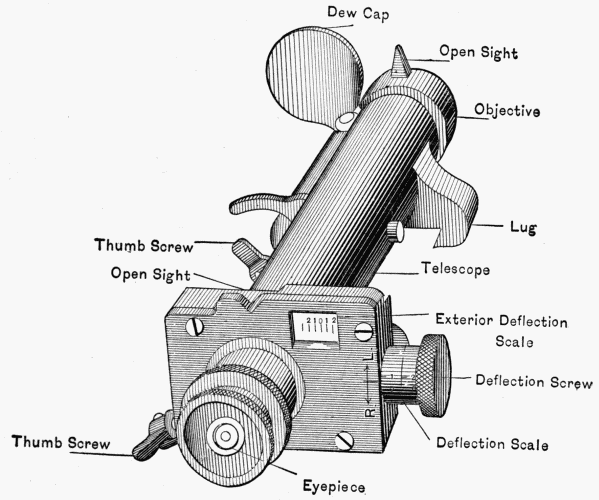

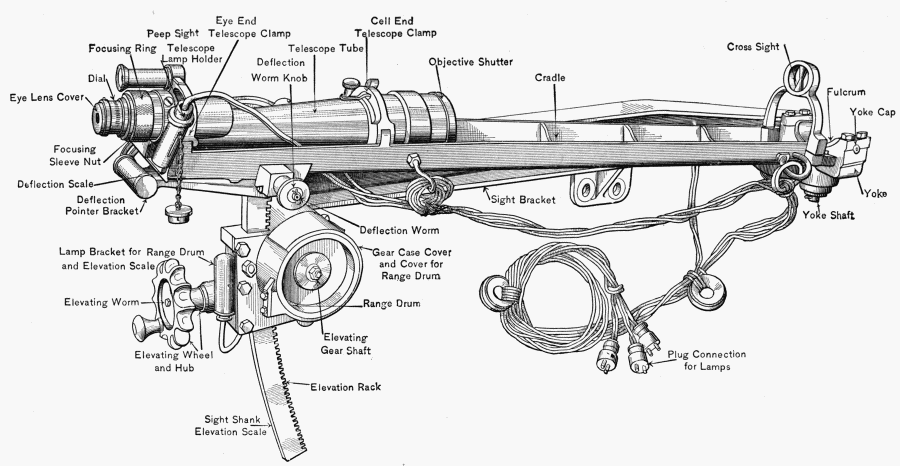

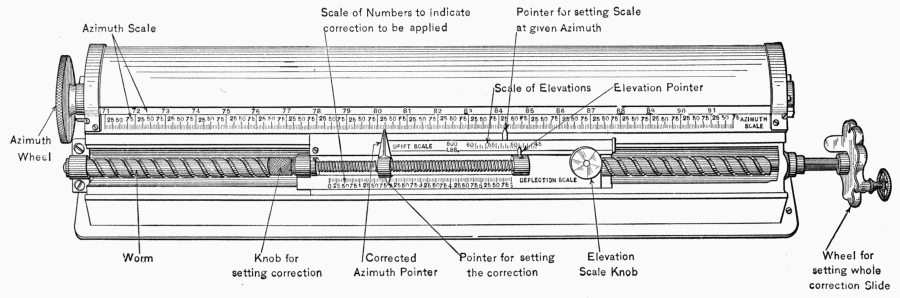

(a) Azimuth Instrument (pattern in use by the company for instruction), definition of angles, horizontal angles, vertical angle, angle measured by the instrument, leveling and orientation; focussing the telescope. Graduation of the instrument: Set up the instrument over a given point and orient it from sufficient data; direct the telescope successively on a series of points and read their azimuths with accuracy.

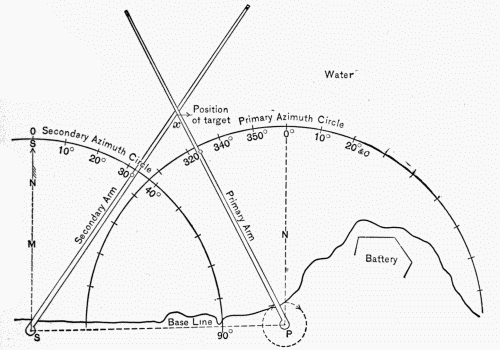

(b) The Plotting-room (for guns).

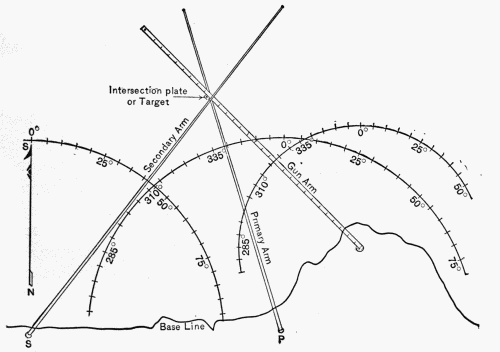

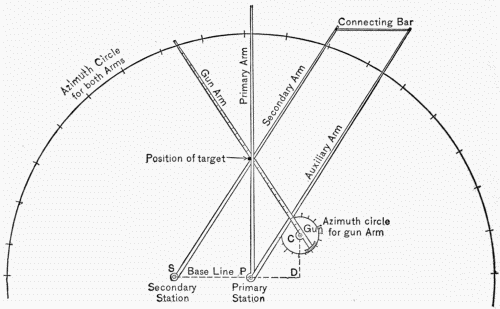

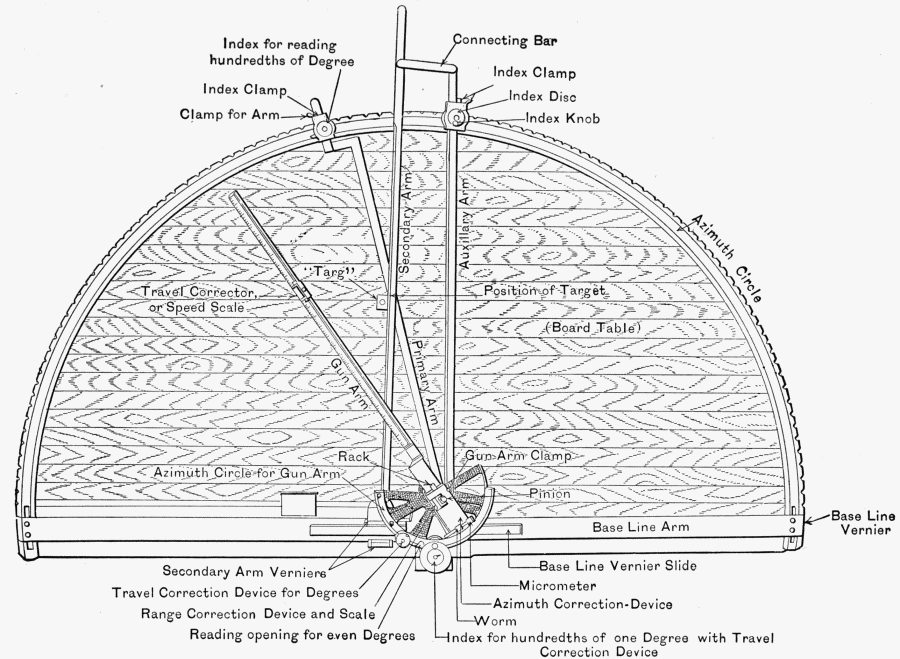

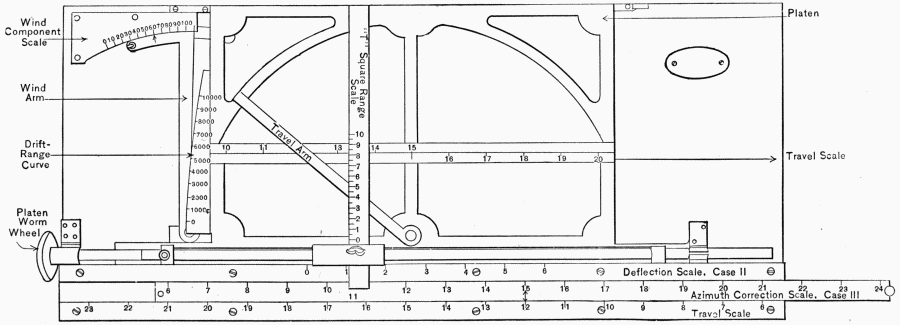

1. Plotting-board.—Point out the following: Primary and secondary stations, directing gun, displacement, gun-arm, travel-scale, azimuth-correction scale, tally dials, range-correction scale.

Lay off a distance of so many yards on the board; conversely, tell the distance in yards between two given points on the board.

The azimuths of a fixed target from the primary and secondary station being given, locate the corresponding point on the board, and give its azimuths and range, from the directing gun or directing point.

The azimuths of a fixed target from the primary and secondary stations being given, locate the corresponding point on the board and determine its range and azimuth from the directing gun or point.

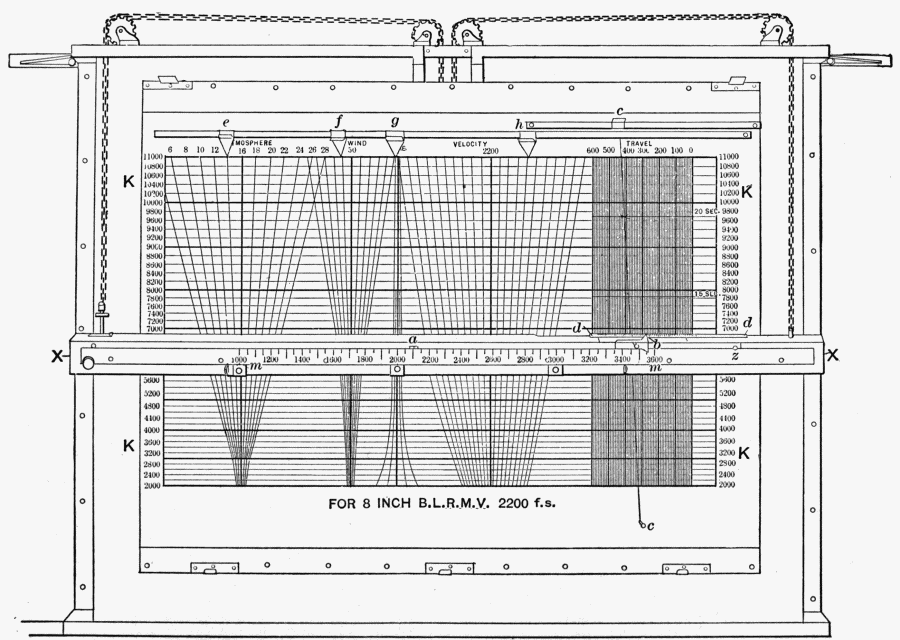

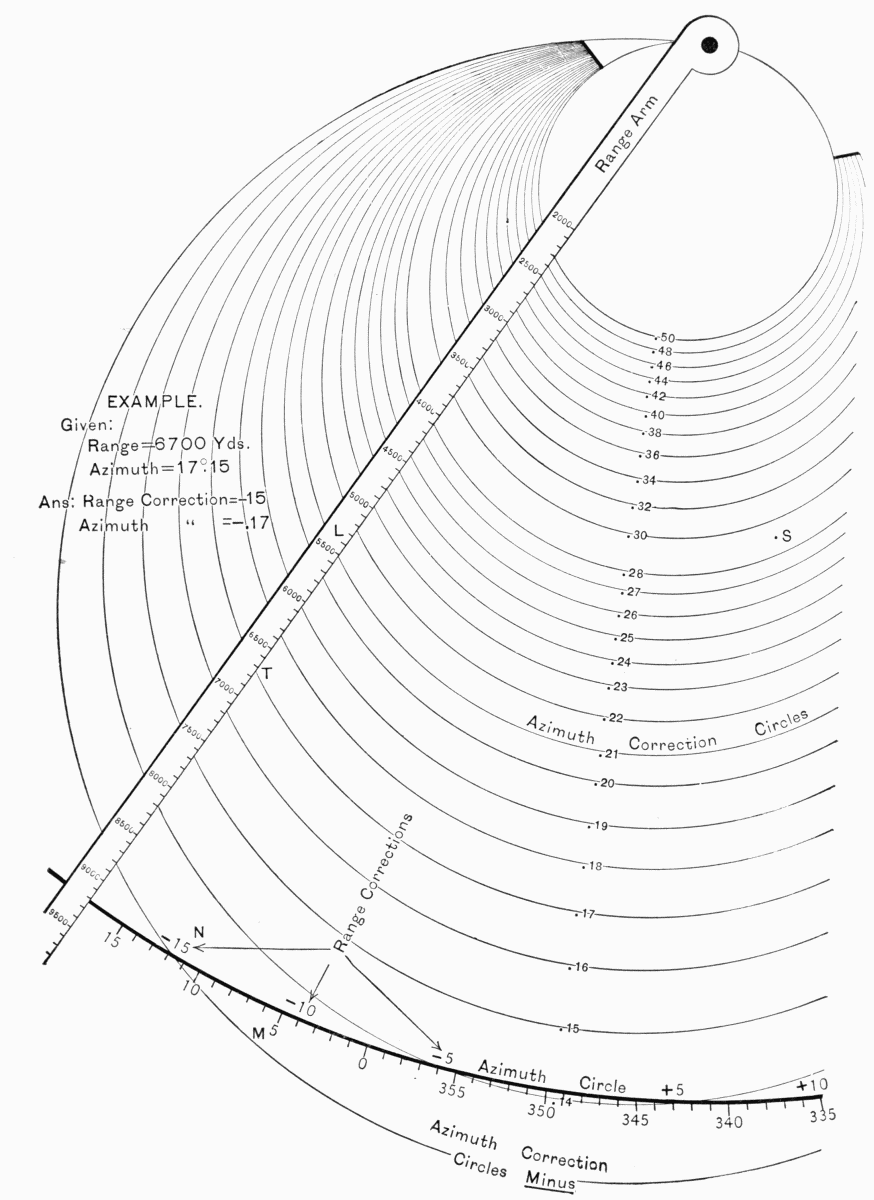

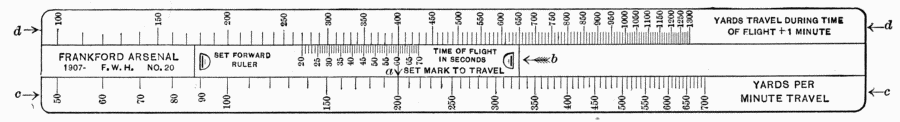

2. Range Board.—Show how to make the range corrections for atmosphere, wind, tide, muzzle velocity, travel, and how this range correction is applied to the range-correction scale.

3. Deflection Board.—Show how to make deflection correction for wind, drift, and travel. Show how to make azimuth correction in Case 3 for wind, drift, travel, and how this correction is applied to azimuth correction scale.

What data are sent to the guns in Case 1, Case 2, and Case 3?

The plotting-room (for mortars).

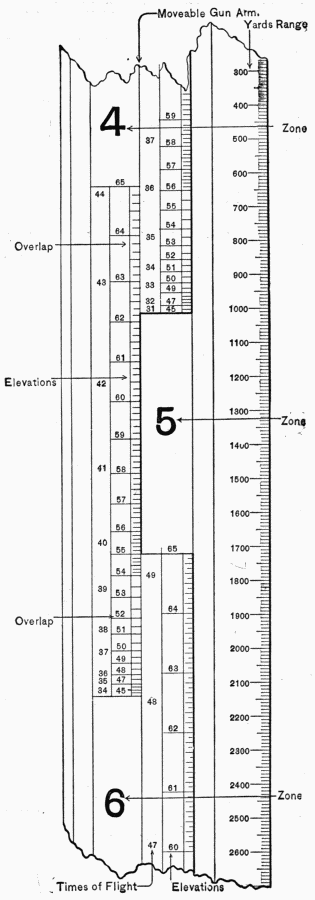

1. Plotting-board.—Point out the following: Primary and secondary stations, directing point, gun-arm, gun-arm azimuth circle, displacement, powder zones, elevation, times of flight.

Lay off a distance of so many yards on the board; conversely tell the distance between two given points on the board.

The range and azimuth of a fixed point (from primary station) being given, locate the corresponding point on the board. Tell the zone, elevation for firing at this point, and its azimuth from the directing point. The azimuth of a fixed target from the primary and secondary stations being given, locate the corresponding point on the board and determine its range and azimuth from the directing point.

2. Show how a target is tracked, how to get travel, how the time of flight is used, how to get predicted point, how to get set-forward point. What is the predicted point used for? What is the set-forward point used for? What data are sent to the pit and what to the B. C. station? Show how range corrections are made.

3. Drift Device (for deflection board if issued).—Show how to make arbitrary and drift corrections.

(c) Aiming and Laying Guns or Mortars.

1. For Rapid-fire Guns.—Set and read the sight for given elevations and deflections; aim the gun at some object; show how elevating and traversing hand-wheels are used; explain the use of the deflection scale for firing right and firing left. What is Case 1?

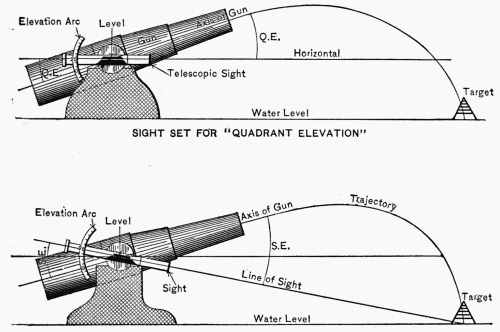

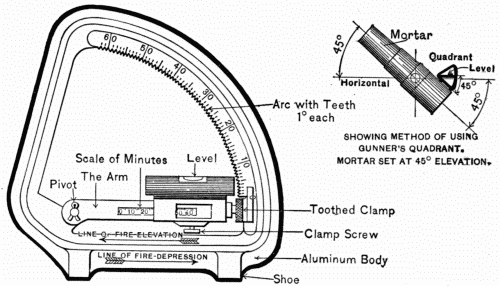

2. For Mortars.—Use of the gunner's quadrant, setting and reading the instrument, when and how placed when used with mortars. With the data received from the plotting room lay the piece. What is Case 3?

3. For Heavy Guns.—(Heavy guns refer to 8-inch, 10-inch, and 12-inch rifles and other guns which are provided with a system of vertical and horizontal position finders.) Name the principal parts of the telescopic sight (one used for instruction purposes); show how it is used. Its readings for elevation and[9] deflection, east count of its scales. Place it on the Hagood tripod mount, level it; set it for given elevation and deflection.

4. Use of Difference Chart.—An example like the following will be given: Range 4500 yards, azimuth 210. Put down the corrected range and azimuth.

Examination in the foregoing subject (c) to be confined to the authorized systems in use by the company during the year and to the complete equipment of the battery to which the company is assigned.

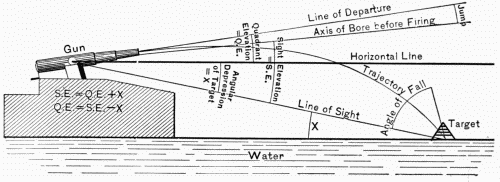

(d) Elementary Gunnery.—Axis of the bore; line of departure; line of sight; drift; muzzle velocity; quadrant elevation; sight elevation; angle of fall; jump; trajectory; time of flight.

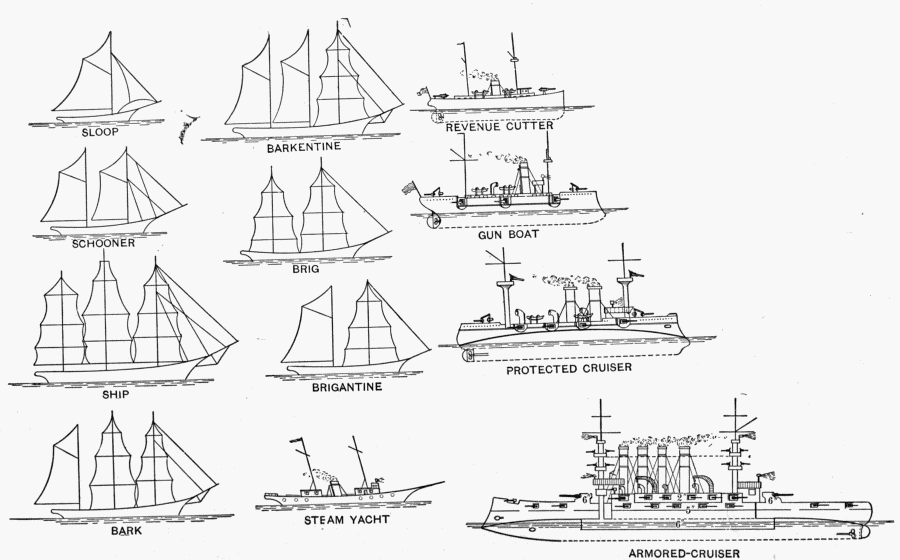

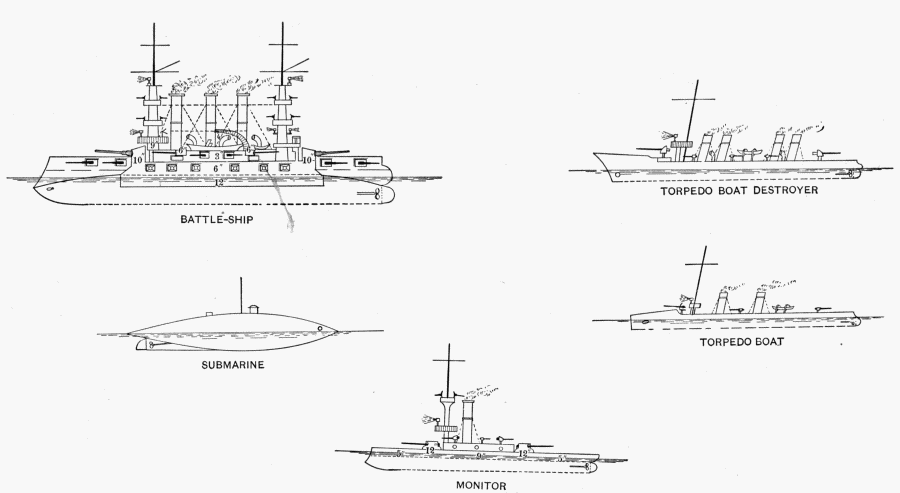

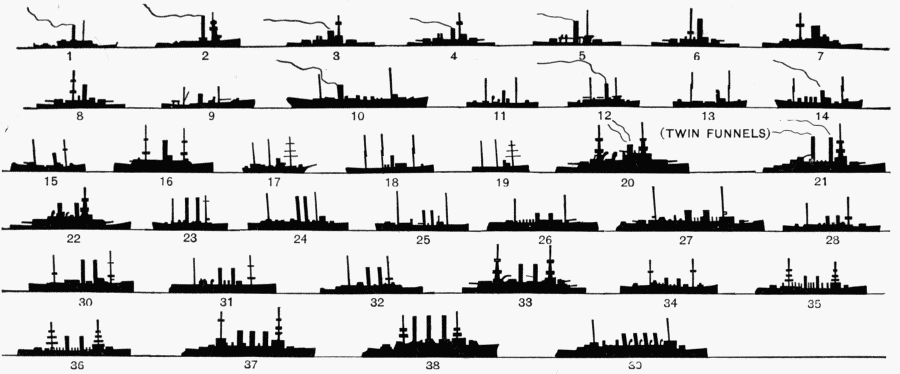

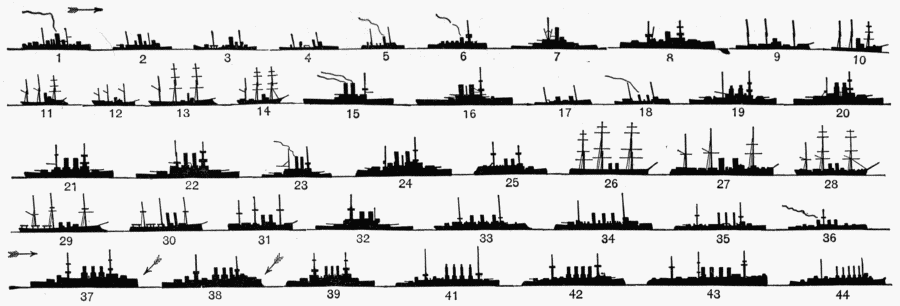

(e) General Features of Warships.—General features of battleships (broad beam compared to length, low freeboard, general massive appearance, large turrets fore and aft, heavy guns, heavy armor, generally moderate speed).

Armored cruisers: (High freeboard, narrow beam compared to length, medium armor, medium turrets, medium guns, high speed).

Protected cruisers: (Fine lines, moderate size, no armor, medium guns usually with shields, protective deck).

Torpedo-boat destroyers: (High bow, generally great speed, light guns, no armor).

Torpedo boats: (Small size, high speed, no armor).

The following head will take the place of subject (b) in the examination of candidates for first-class gunners of organizations assigned exclusively to rapid-fire guns:

(b) Subcaliber Firing.—The 15-pounder gun and subcaliber attachment will be used. The target will be Target X, miniature target, page 25, Small-arms Firing Regulations, 1906, pasted on a screen of sufficient size to catch all the shots, preferably the screen used for small-arms Target A; range about 95 feet, where six minutes on the scale is equal to 2 inches at the target; method of scoring as prescribed for small-arms practice.

During the test one member of the board will be at the target and will personally superintend the marking.

The preliminary shots will be fired under direction of the examining board until three hits have been obtained with the same elevation and deflection. The center of impact of these three shots will be referred to the horizontal and vertical axes through the bulls'-eye of the target and its coordinates carefully measured. This center of impact will not be on the miniature target and may be changed by the board as often as they deem necessary during the examination. These measurements, with the elevation and deflection used, will be given to the candidate, who will be required to make corrections corresponding to the distance of the center of impact from the bull's-eye. Each candidate will fire five shots, the piece being thrown off the target between shots. Each shot will be marked as fired, the candidate making such changes in elevation and deflection as he may deem necessary before firing the next shot. The ratio of the candidates' score to the maximum score possible will determine the credit, the maximum credit being 20.

After this test the candidate will fire at the fixed subcaliber target anchored at about 500 yards, without knowing the exact distance, five rounds under service conditions in one minute and thirty seconds. Three sighting shots will be allowed each candidate preceding the latter test. Each hit on the material target counts 6.

The following syllabus gives the outline of the scope of the examination of candidates for gunner in companies and detachments assigned to mine defense. It is not intended that the theoretical instruction in any subject shall be limited to what is indicated in this syllabus, but the examination for candidates for gunners will be closely confined thereto.

(a) Ammunition, Nomenclature, and Service of Guns assigned to the Company of which the Candidate is a Member.

Duties of the cannoneer and nomenclature of the piece to which assigned. (Note: If not assigned to a piece, or if the company is assigned to different pieces of different calibers, the candidate will be examined upon the piece of the caliber selected by the company commander.)

Describe the ammunition and name all the projectiles used for the piece upon which examined.

(b) Material of and Duties in the Loading Room (except electrical principles involved).

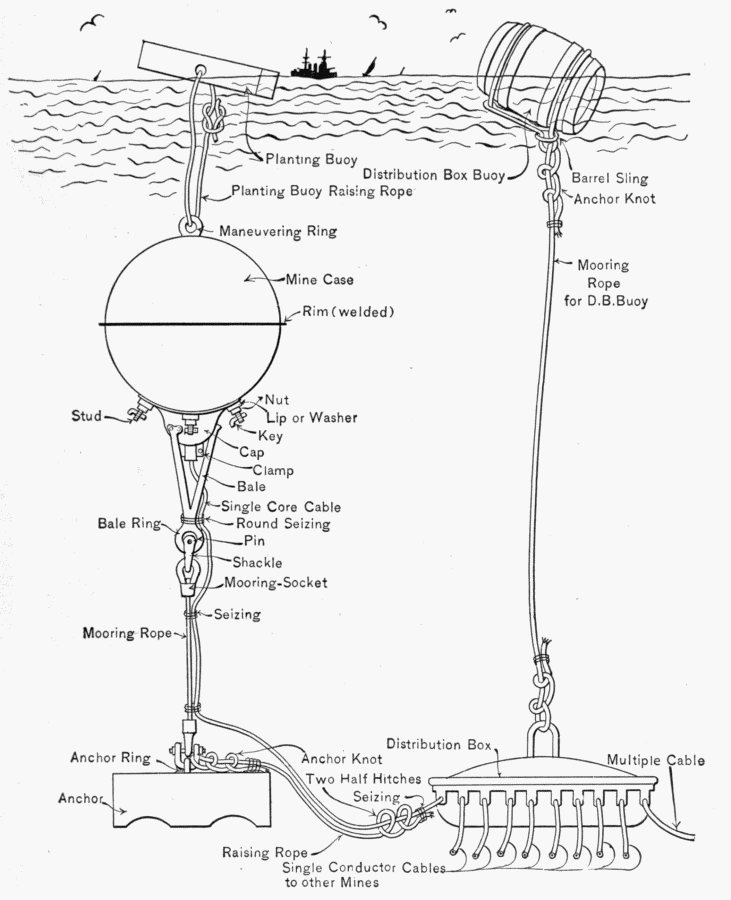

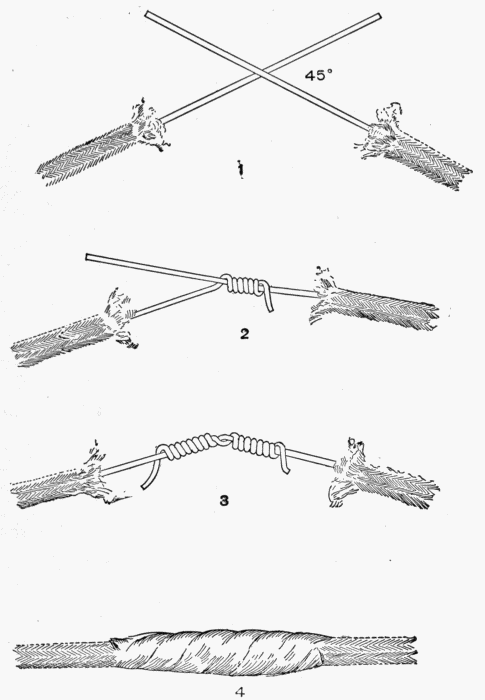

What apparatus is used in making a Turk's head? A telegraph joint? A joint to be used under water? Name all the parts of an assembled mine. Name all the parts of a compound plug and explain how to load one. What is a cut-out plug? Explain how to prepare a cut-out plug and box. What apparatus is used in preparing a compound plug? How are mines numbered? How are mooring pipes prepared, and what are the rules for lengths of mine cables and of mooring ropes?

(c) Material for and Duties on the Water.

What apparatus is taken out in the grand-junction box-boat? How and in what way are the cores of cable numbered? How is a mine, together with its attachments, arranged on a boat for planting? Name the apparatus on the boat used in planting and raising mines. What are the duties in the triple-junction box-boat in planting and in raising mines, and what precaution is taken so that cables may be distinguished when box is raised? Explain how soundings for a triple group are made.

(d) Cordage.

Name the important knots used in mine work and explain how to make four of them. The mooring rope of a heavy weight cannot pass over the winch, but lifting must be done with the fall; explain the method of proceeding.

(e) U. S. Magazine Rifle.—Nomenclature of the piece, kind and weight of powder used, description and weight of projectile, muzzle velocity. Setting of sight for range and deflection.

(a) Care and Preservation of Mine Material.

Name the supplies necessary for cleaning mine material. Name those used in preserving it, stating for what each is used, and how certain ones (to be selected by the examiner) are applied.

(b) Handling High Explosives.

What high explosives are used in mines? What are the important precautions to be taken in loading mines? How is frozen dynamite thawed? Where is the main supply of explosive kept, and how much is taken out at one time to the explosive house near the loading-room?

(c) Knowledge and Use of Azimuth Instrument and Plotting Board.

Names of important parts. Set up the instrument with given data. Read angles from instrument. Act as observer. Act as reader.

Describe a plotting board. Explain the method of computing the time from any plotted point to a mine. Act as plotter.

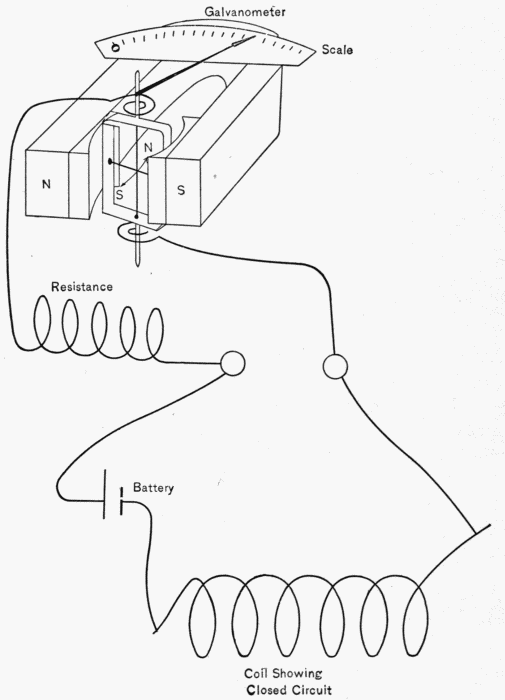

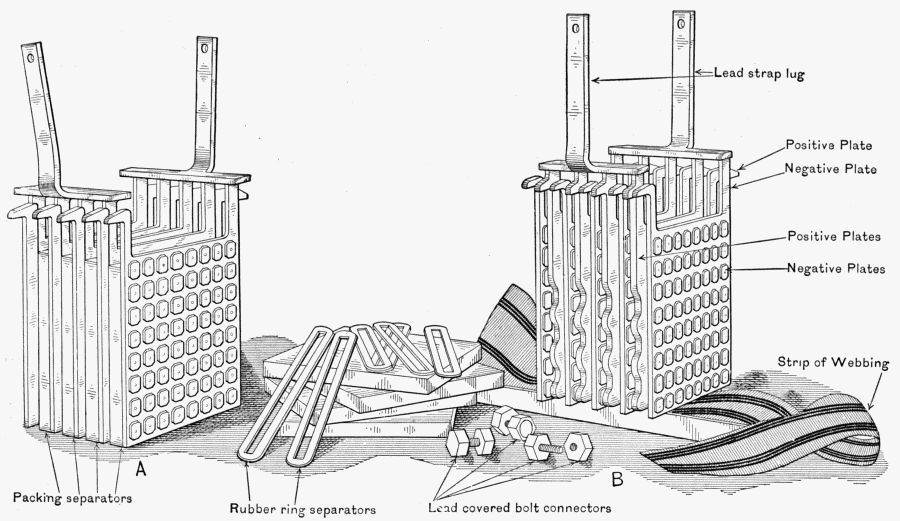

(d) Batteries, Generators, and Searchlights assigned to the Company of which the Candidate is a Member.

Name the batteries used in mine work. Describe the casemate battery. What precautions are necessary in keeping it in order? What is used as the signal battery in mine work? Describe a searchlight. Describe parts of generators and important points to be observed in caring for them.

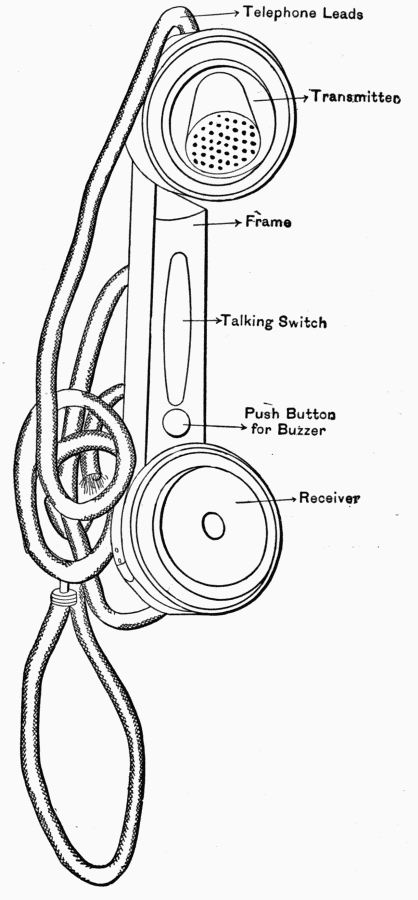

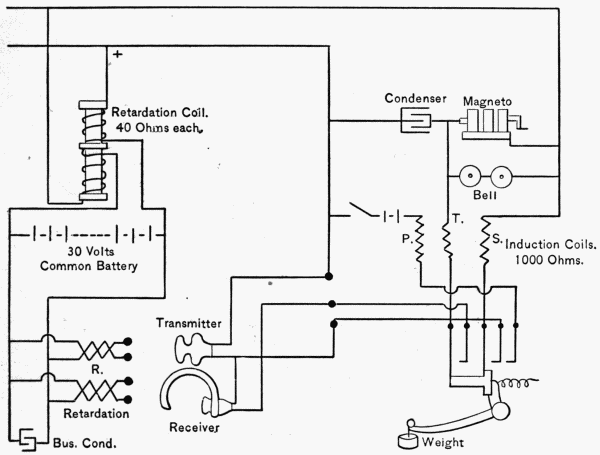

(e) Apparatus and Operation of Casemate Switchboard and Care and Use of Telephone.

Name the apparatus of the switchboard. Explain how to fire a mine by judgment, and how to start the motor generator. Explain how to test mine and cable ends. How are boat telephones[13] operated? Name the parts of fire-control telephones used in mine-commander stations, and give the principal points to be observed in operating them.

1. Gunnery is the science and art of operating and firing guns.

2. A gun is a machine which throws projectiles with great force in a certain direction under the expanding force of powder gas.

3. The army is composed of the following divisions: The line and the staff. The line is composed of Infantry, Cavalry, Artillery, Engineers, etc. The staff of Quartermaster Dept., Commissary Dept., Ordnance Dept., Signal Corps, Pay Dept., etc.

4. The artillery in our army is organized as a corps of Coast Artillery composed of 169 companies and 6 regiments in the Field Artillery.

5. A battery of coast artillery consists of two or more guns or two or more pits of mortars.

6. A fire command is composed of two batteries or more whose fire sweeps the same area or adjoining areas; this fire is controlled by one man, called the fire commander.

7. A battle command is two or more fire or mine commands sweeping the same or adjacent areas; this commanded by one man—the battle commander.

8. A mine command is a portion of submarine defenses and rapid-fire guns, all commanded by one man—the mine commander.

9. The number of men required for a fire, battle, or mine command depends on the number and caliber of the guns or mortars or the size of the mine command.

10. The number of men in a coast artillery company is 109; in a troop of cavalry 65, in a company of infantry 60.

| Entries of the first column: | |||||||

| A = 15 pdr. R. F. (all models) | |||||||

| B = 4-inch and 4·72-inch R. F. | |||||||

| C = 5-inch R. F., models of 1897 and 1900 | |||||||

| D = 6-inch Ordnance Department R. F., models of 1897, 1900, 1903, and 1905 | |||||||

| E = 8-inch rifle | |||||||

| F = 10-inch rifle, models of 1888, 1895, and 1900 | |||||||

| G = 12-inch rifle, models of 1888, 1895, and 1900 | |||||||

| H = 12-inch mortar, models of 1886 and 1890: | |||||||

| H1 = At batteries to which only one company is assigned | |||||||

| H2 = At batteries to which two companies are assigned | |||||||

| Full Service Charges. | Additional | ||||||

| Primers for Drill. | |||||||

| Guns, Caliber | Trial Shots. | Record Shots. | Sub- | Service | Drill | ||

| and Model. | caliber. | Primers. | Primers. | ||||

| 1st | 2d | 1st | 2d | ||||

| Pract. | Pract. | Pract. | Pract. | ||||

| A | 3 | 3 | 10 | 10 | 3000 | 160 | 800 |

| B | 3 | — | 10 | — | 900 | 225 | 225 |

| C | 3 | — | 10 | — | 900 | 60 | 400 |

| D | 3 | 3 | 10 | 10 | 900 | 60 | 400 |

| E | 3 | 3 | 6 | 4 | 600 | 60 | 400 |

| F | 3 | 3 | 6 | 4 | 600 | 60 | 400 |

| G | 3 | 3 | 6 | 4 | 600 | 60 | 400 |

| H | |||||||

| H1 | 3 | 3 | 16 | 16 | 150 | 100 | 400 |

| H2 | 3 | 3 | 16 | 16 | 300 | 200 | 800 |

Note.—All projectiles will be service weight and form, cast iron only, or such projectiles as are specially designated for target practice. Companies which cannot have subcaliber practice at home station have only one-half the annual subcaliber allowance.

12-inch Mortars.—The number of zones, muzzle velocities corresponding thereto, zone limits, width of zones and overlaps for the 12-inch mortar, cast-iron, steel-hooped, and the 12-inch mortar, steel, have been rearranged and are now as shown by the following table:

| Column headings: | ||||||||||

| A = Number of Zone. | ||||||||||

| B = Muzzle Velocity. | ||||||||||

| C = Weight of Projectile. | ||||||||||

| D = Zone Limits. | ||||||||||

| E = Width of Zone. | ||||||||||

| F = Overlaps. | ||||||||||

| 12-inch Mortar, Cast-iron, Steel-hooped. | 12-inch Mortar, Steel. | |||||||||

| A | B | C | D | E | F | B | C | D | E | F |

| F. S. | Lbs. | Yds. | Yds. | Yds. | F. S. | Lbs. | Yds. | Yds. | Yds. | |

| 1 | 560 | 1046 | 2225-3000 | 775 | 400 | 550 | 1046 | 2210-2970 | 760 | 370 |

| 2 | 610 | 1046 | 2600-3480 | 880 | 480 | 600 | 1046 | 2600-3431 | 831 | 361 |

| 3 | 670 | 1046 | 3080-4110 | 1030 | 400 | 660 | 1046 | 3070-4030 | 960 | 399 |

| 4 | 743 | 1046 | 3710-5000 | 1290 | 400 | 725 | 1046 | 3631-4800 | 1169 | 371 |

| 5 | 837 | 1046 | 4600-6240 | 1640 | 400 | 810 | 1046 | 4429-5940 | 1511 | 420 |

| 6 | 910 | 1046 | 5840-7319 | 1479 | 594 | 915 | 1046 | 5520-7476 | 1956 | 449 |

| 7 | 1050 | 824 | —— | —— | —— | 1050 | 1046 | 7027-9250 | 2223 | 492 |

| 8 | —— | —— | —— | —— | —— | 1300 | 824 | |||

Note.—Each smokeless powder cartridge to have 10-ounce igniter (black rifle powder) at each end in addition to above charges.

All smokeless-powder charges for mortars will be issued made up, ready for use, as the charges vary with each lot of powder. They will be distinctly marked to indicate the zone number.

Q. Give the general duties of a gun commander.

A. The gun commander repeats the commands "Commence firing" and "Cease firing," announces the kind of projectile to be used, the order to fire, the method of pointing, and in restricted fire the number of shots and the firing interval, all in accordance with the orders of a battery commander. The gun commander is responsible to the battery commander for the condition of the material and the efficiency of the personnel of his command.

Q. Give the general duties of a chief of detachment.

A. Each chief commands his own subdivision whenever it acts separately; is responsible for its drill efficiency and for the condition of the material to which it is assigned. He will especially see that the gas-check seat is clean and kept free from injury; that the projectile is rammed fully home; that the chamber is sponged properly after each firing; that the vent is properly served; that the cylinders are properly filled and the throttling-valve properly set before firing; that the mushroom head and gas-check are properly adjusted; that the kind of projectile designated by the battery commander is used, and that the breech detail observe great care and caution in sponging out and wiping breech mechanism and recess free from powder residue, dirt, etc., after each round fired.

Q. Describe how to signal elevate or depress.

A. Elevate: Raise either hand to the height of the head, fingers pointing upward. Depress: Raise either hand to the height of the head, fingers pointing downward.

Q. Describe how you would signal traverse right or traverse left.

A. Motion with either hand, fingers pointing in the required direction.

Q. Give the signals for the following: Clamp or Halt; Ready.

A. Clamp or Halt: Raise either arm to a horizontal position, fingers closed. Ready: Raise either arm vertically to its full extent, fingers extended.

Q. How would you signal stand fast with the whistle at a rapid-fire gun?

A. One blast signifies stand fast, the pause being of sufficient duration to enable orders to be correctly given and received; to resume operations the command "Go on!" will be given. Other signals may also be used.

Q. What composes a gun section?

A. A gun commander, a gun detachment, an ammunition detachment, and a reserve.

Q. How many men in a gun detachment?

A. One chief, one gunner, one range-keeper, and eighteen privates.

Q. Name the details into which a detachment is divided, and give posts of each.

A.

| Details. | Posts. |

| Chief of detachment | Two yards in rear of the breech, facing it |

| (sergeant). | or wherever presence is necessary. |

| Gunner (duly qualified | Sighting-platform or wherever presence is |

| non-commissioned | necessary. |

| officer or private). | |

| Range-keeper (non- | Near the elevation-scale, on the right or |

| commissioned officer | left of the carriage. |

| or private). | |

| Breech detail (Nos. | Nos. 1 and 2 in line immediately in rear of |

| 1, 2, and 3). | the breech, facing it, No. 1 on the right; |

| No. 3 on the right of the piece, two feet | |

| from and facing it, opposite the elevating-band. | |

| Rammer detail | At the platform rail facing the carriage, No. |

| (Nos. 4, 13, and 14). | 4 opposite the rammer, four feet from its |

| head, Nos. 13 and 14 four paces to his | |

| right and left respectively. | |

| Elevating detail | At the elevating hand-wheels, facing them, |

| (Nos. 5 and 6). | No. 5 on the right of the carriage, No. 6 |

| on the left. | |

| Traversing detail | In front of the traversing-cranks, facing |

| (Nos. 7 and 8). | from the parapet, No. 7 on the right of |

| the carriage, No. 8 on the left. | |

| Tripping detail | At the tripping-levers, facing the carriage,[18] |

| (Nos. 9 and 10). | No. 9 on the right of the carriage, No. 10 |

| on the left. | |

| Truck detail | Near the hoist, in rear of a loaded truck, |

| (Nos. 11 and 12). | No. 11 on the right, No. 12 on the left, |

| both facing the truck. | |

| Telautograph detail | At the telautograph. |

| (No. 15). | |

| Hoist detail (Nos. | At the delivery-table and facing it. |

| 16, 17, and 18). |

Q. Name the equipments or implements which each member procures and places in proper position at the command "Posts!" on first arriving at the gun.

A. Gunner: Sight and difference-chart.

Range-keeper: Stop-watch and prediction-scale.

No. 1: Translating roller or crank, can with sponge and oil, and a silk wiper.

No. 2: Loading-tray and a silk wiper.

No. 3: Primer-pouch, bag for empty primers, scabbard containing punch, gimlet, and reamer, and a lanyard.

No. 4, assisted by No. 13: Rammer.

No. 9: Wrench, funnel, and measure with oil.

No. 10: Chamber-sponge and wrench.

No. 11: Dummy-cartridge extractor.

No. 12: Shot-trucks.

No. 13: Same as No. 4 (Rammer). No. 13 assists No. 4.

Q. State in brief what each member of the gun detachment inspects and tests at the command "Examine gun!"

A. Chief inspects gun and carriage throughout.

Gunner inspects and tests sight, sight-standard, azimuth subscale, traversing-gear, and firing-key.

Range-keeper inspects elevating gear.

No. 1 removes breech-cover and inspects breech mechanism, and assists in sponging bore when necessary.

No. 2 examines bore, chamber, gas-check seat, and breech-recess, cleans them when necessary, and oils breech-recess.

No. 3 cleans vent and primer-seat, hangs lanyard on elevating-arm.

No. 4 brings sponges and assists Nos. 1 and 2 when necessary and replaces sponges.

Nos. 5 and 6 test elevating-gear with range-keeper.

Nos. 7 and 8 test traversing-gear with gunner.

Nos. 9 and 10 examine recoil-cylinders to see that they are properly filled. No. 9 does the filling with oil when necessary. Wrenches, funnel, and measure are passed back and replaced, filling-plugs replaced, and Nos. 9 and 10 take posts two paces on right and left, respectively, of No. 4.

No. 11 receives and disposes of muzzle-cover, passes up and replaces funnel and oil-measure when necessary, then takes post near No. 12 at the trucks.

No. 12 removes muzzle-cover, examines trucks.

No. 13 inspects and tests telautograph. If a telephone is used, he puts on head receiver and wears it until dismissed.

Q. Explain briefly how to open a breech mechanism, Model 1888.

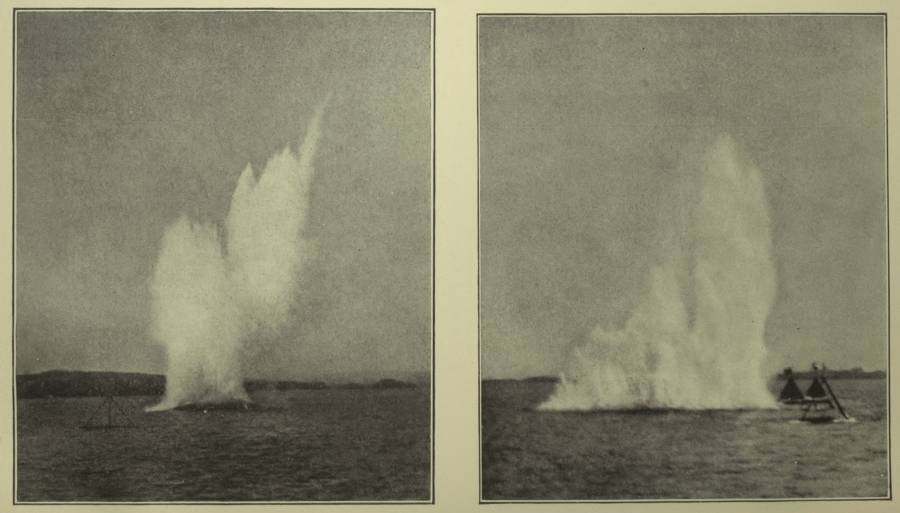

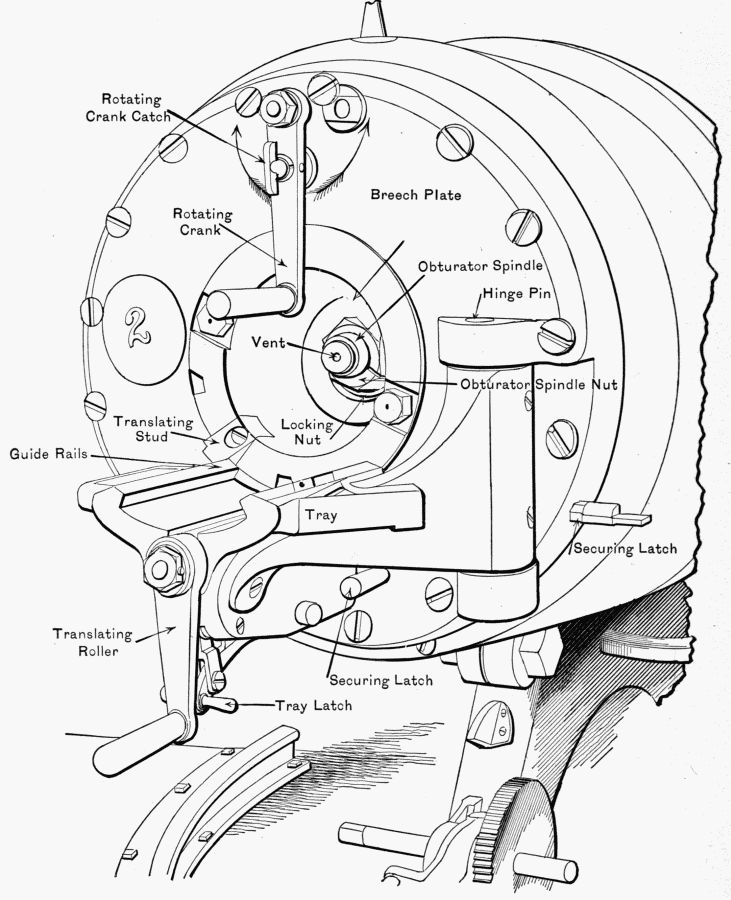

A. Figure 1 shows breech in normal position—closed. No. 2 turns rotating crank-catch 90° to left and turns rotating-crank in the direction of the arrow till it stops (Fig. 2).

No. 1 turns translating-roller to left till, at the end, the shock releases the block (Fig. 3), then swings block free to right of gun till it engages securing-latch (Fig. 4). Mechanism 1895 is opened by No. 3 turning crank continuously till motion stops, being careful that crank does not catch safety-lanyard.

Q. Give duties of each member of the detachment at the command "Load!"

A. Chief commands: (1) "With shot!" (shell or dummy projectile); (2) "Load!"

Gunner gives direction to piece according to the system[20] used, and either fires electrically or signals to No. 3 to fire. (Except in Case 3.)

Fig. 1.

Range-keeper calls off range, using predicting-scale, and corrects same for gun difference; signals or calls out "Elevation-set!"

No. 1 assists in opening and closing breech. Examines for dirt, etc., the breech-block and gas-check. Oils same. When necessary, assists in ramming. Places third section of cartridge on shot-tray.

Fig. 2.

No. 2 assists in opening and closing breech, examines for dirt,[22] etc., and oils gas-check seat and threads of breech-recess. He commands: (1) "Home!"; (2) "Ram!" Observes scale on rammer, places second section of cartridge on front part of shot-tray, pushes fourth section into chamber, such that its base will almost clear the gas-check seat. If necessary, inserts loading-tray and sponges, assisted by No. 10.

Fig. 3.

No. 3 inserts a primer. At command "Trip!" steps to rear and slightly to right of piece. Fires at gunner's signal. Coils lanyard. Removes old primer and places it in a bag.

No. 4 brings up rammer and places it against base of projectile, assisted by Nos. 9 and 13. Assists in ramming projectile and sections of cartridge. Replaces rammer on its support.

Nos. 5 and 6 set the elevation-scale for given range.

Nos. 7 and 8 traverse, at the command of the gunner.

Nos. 9 and 10 assist in ramming. Trip the piece. After firing No. 10 brings up chamber-sponge.

Fig. 4.

Nos. 11 and 12 bring loaded truck and place it in position, adjusting height of shot-tray to that of the breech. No. 11 steps to right, and No. 12 to left, of truck. If there be a brake, No. 12 sets it; if not, No. 11 chocks the front wheels. No. 12 places first section of cartridge on tray, No. 11 the fourth. Both remove truck to delivery-table and take posts at a loaded truck.

Nos. 13 and 14 assist in ramming projectile and sections of cartridge. Assist 9 and 10 at pinch-bars when piece will not trip.

No. 13 assists No. 4 in bringing up and replacing rammer.

No. 15 calls out and posts ranges and deflections or azimuths received.

No. 16 notifies chief of ammunition detachment kind of projectile required, also when to start and stop the hoist.

Nos. 16, 17, and 18 load the trucks.

Q. Give the positions of the ramming detail.

A. Nos. 1, 4, 9, and 13 on right. Nos. 2, 10, and 14 on left. All face rammer and grasp it with both hands.

Q. Explain the method of ramming.

A. Nos. 13 and 14 take hold near the end of the rammer, rammer-head being on base of projectile. At the command "Ram!", all rush forward, carrying projectile to its seat with force. Nos. 1 and 2 quit the rammer when near the truck. First three sections of cartridge are rammed without command.

Q. Explain how to unload a dummy charge.

A. The chief commands "Unload!" Breech is opened and truck brought up as for loading. No. 4 brings up extractor and pulls out sections. No. 1 puts two sections on right of truck, No. 2 puts others on left.

Nos. 1, 2, 3, and 4 withdraw projectile to truck. Truck is removed and extractor replaced.

Q. Explain how to retract a gun.

A. Chief commands (1) "From battery!", (2) "Heave!", (3) "Halt!"

At the first command Nos. 7 and 8 go to the retraction-cranks. No. 7 operates the retaining-pawl and speed-crank to permit the pulling out of the ropes. Nos. 9 and 10 mount on the gun-levers and place the ends of the ropes on the hooks, receiving them from Nos. 3 and 4, who mount on the chassis to assist. Nos. 1 and 2 pull out the ropes and pass the ends to Nos. 3 and 4. No. 7 takes in the slack. Nos. 7, 8, 9, and 10 take positions at the retraction-cranks, and at the second command turn the cranks.

Nos. 3, 4, 5, and 6 relieve Nos. 7, 8, 9, and 10 when directed by the chief of the detachment. Odd numbers work on the right side of the carriage, even numbers on the left side. When the gun has reached the loading position the command "Halt!" is given. As the command "Cast off!" is given No. 7 lets out enough slack to enable Nos. 1 and 2 to take the rope-ends off the hooks.

Q. Where electric motors are provided, who operates them?

A. The gunner the traversing-controllers, No. 5 the elevating and retracting controllers; No. 6 watches the circuit-breakers, and when broken by an overload he closes the breaker.

Q. When the shot-hoist is on the right, what changes in the service of the piece are made?

A. No. 4 in ramming takes position between Nos. 2 and 10 on the left side. Nos. 10 and 14 assist No. 4 in bringing up and replacing the rammer, instead of Nos. 9 and 13. No. 9 brings up and replaces sponge and assists in sponging, instead of No. 10.

Q. How many men in the ammunition detail?

A. One chief and twelve privates.

Q. Name the details into which it is divided, and the numbers composing each.

A. Hoist detail, Nos. 1 and 2.

Projectile detail, Nos. 3, 4, 5, and 6.

Cartridge detail, Nos. 7, 8, 9, 10, 11, and 12.

Q. Give the duties of each in brief.

A. No. 1 operates the controller and starts the hoist supplying the delivery-table with ammunition.

No. 2 repeats name of projectile announced, rolls same with cartridge to hoist-carrier.

Nos. 3 and 4 operate a trolley and differential pulley.

Nos. 5 and 6 operate another trolley and pulley.

Nos. 7 and 8 uncase cartridges.

Nos. 9, 10, 11, and 12 place sections on receiving-table in proper order. If electrical power fails, Nos. 1 and 2 operate hoist by hand-cranks.

Note.—Since the drills for the 10-inch and 8-inch disappearing guns differ from the drill for the 12-inch in so few minor details, no separate questions and answers in these cases are given. In the 10-inch piece the following differences were noted: Nos. 13 and 14 are omitted in the rammer detail; No. 4 in procuring implements attends to the rammer alone; in loading, No. 2 pushes the second section of cartridge into the chamber instead of the fourth; in ramming, the positions from front to rear are Nos. 1 and 9 on right, Nos. 2, 4, and 10 on left, facing rammer, etc. When hoist is on right side No. 10 assists No. 4 (No. 13 being left out).

In the 8-inch piece the rammer detail consists of No. 4 (13 and 14 omitted), the truck detail of No. 11 (12 omitted), and the hoist detail of Nos. 16 and 17 (No. 18 omitted). The duties of the numbers omitted in these details are performed by the remaining numbers in that detail, otherwise the drill is precisely the same as for the 12-inch piece. In extracting a dummy Nos. 2 and 3 do not assist in withdrawing; Nos. 1 and 4 do this.

Q. How many men in a detachment?

A. One chief, one gunner, one range-keeper, and nineteen privates.

Q. Name the details into which a gun detachment is divided, and give posts of each.

A.

| Name of Detail. | Posts. |

| Chief of detachment (sergeant). | Two yards in rear of the |

| carriage-platform, facing it. | |

| Gunner (duly qualified | Sighting-platform. |

| non-commissioned officer | |

| or private). | |

| Range-keeper (non-commissioned | On the left of the carriage, opposite |

| officer or private). | the elevation-scale. |

| Breech detail (four privates, | Nos. 1 and 2 immediately in[27] |

| Nos. 1, 2, 3, and 4). | rear of the breech, Nos. 3 |

| and 4 one yard in rear of | |

| Nos. 1 and 2, all facing the | |

| breech, odd numbers on the right. | |

| Elevating detail (two privates, | At the elevating hand-wheels, |

| Nos. 5 and 6). | facing them, No. 5 on the |

| right of the carriage, No. 6 | |

| on the left. | |

| Traversing detail (two privates, | At the traversing-cranks, facing |

| Nos. 7 and 8). | the carriage, No. 7 on the |

| right of the carriage, No. 8 | |

| on the left. | |

| Sponge and rammer detail (two | One yard in rear of the carriage |

| privates, Nos. 9 and 10). | platform, facing it, No. |

| 9 on the right. | |

| Shot-hoist detail (four privates, | No. 11 opposite the shot-hoist |

| Nos. 11, 12, 13, and 14). | tackle, facing the carriage, |

| Nos. 12 and 13 in rear of the | |

| windlass crank-handle, facing | |

| it, No. 13 on the right, No. 14 | |

| in front of the windlass | |

| crank-handle, facing it. | |

| Truck detail (two privates, | Near the hoist, in rear of a |

| Nos. 15 and 16). | loaded truck, No. 15 on the right. |

| Telautograph detail (one private, | At the telautograph. |

| No. 17). | |

| Telautograph detail (two privates, | At the delivery-table and facing it. |

| Nos. 18 and 19). |

The posts of the gun detachment as given above are for inspection, and preparatory to the service of the gun.

The chief of detachment and gunner go wherever their presence is necessary.

Q. Name the equipments or implements which each member procures and places in proper position at the command "Posts!"

A. Gunner: Sight and difference-chart.

Range-keeper: Stop-watch and prediction-scale.

No. 1: Translating-roller (or crank), can of oil with sponge, lanyard, and silk wiper.

No. 2: Loading-tray, primer-pouch, etc.

No. 5: Wrench, funnel, and measure of oil.

No. 6: Wrench.

No. 9: Rammer and prop.

No. 10: Chamber-sponge.

No. 11: Dummy-extractor.

Nos. 15 and 16: The trucks.

Q. State in brief what each member inspects and tests at the command "Examine gun!"

A. Chief: Gun and carriage generally.

Gunner: Sights and sight-standard, azimuth subscale, traversing-gear, and firing-key.

Range-keeper: Elevating-gear.

No. 1: Removes breech-cover and inspects breech mechanism.

No. 2: Bore, chamber, gas-check seat, breech-recess, vent, primer-seat.

Nos. 3 and 4 assist in sponging bore if on No. 2's inspection it is found to need it.

Nos. 5 and 6: Recoil-cylinders.

No. 9 passes up funnel, measure, etc., to No. 5.

Nos. 7 and 8: Traversing-gear with gunner.

No. 10 passes up and replaces sponge when necessary.

Nos. 11 and 12: Shot-hoist tackle; remove muzzle-cover.

Nos. 13 and 14: Shot-hoist gearing.

Nos. 15 and 16: Trucks.

No. 17: Telautograph or telephone.

Q. Give duties of each member of the detachment at the command "Load!"

A. Chief gives commands for loading.

Gunner and range-keeper same as for 12-inch disappearing.

No. 1 assists in opening and closing breech. Examines for[29] residue, dirt, etc., the breech-block and gas-check, and oils same if necessary. Inserts first and third sections of cartridge. Adjusts lanyard. Fires at command of gunner.

No. 2 assists in opening and closing breech. Examines gas-check seat and breech-recess; oils and cleans the same if necessary. Inserts loading-tray. Swings projectile into position and gives commands for ramming. Observes scale on rammer. Inserts second and fourth sections of cartridge, seeing that the last section is properly seated. Removes loading-tray. Breech being closed, inserts a primer. After firing removes primer and places it in bag. Assisted by No. 4, sponges chamber.

No. 3 receives rammer and places it on base of projectile. Assists in ramming projectile and first three sections of cartridge. Passes rammer back to No. 9.

No. 4 assists in ramming. Receives chamber-sponge and assists in sponging. Passes sponge back to No. 10.

Nos. 5 and 6 elevate and depress the piece.

Nos. 7 and 8 traverse the piece at the gunner's command, and assist in depressing the piece if necessary.

No. 8 closes safety-switch at command "Ready!"

No. 9 passes up rammer to No. 3, and assists in ramming. Replaces rammer.

No. 10 passes up and replaces chamber-sponge. Mounts carriage-platform and assists in ramming.

No. 11 hooks tackle to shot-tray and commands "Hoist!", mounting the steps and steadying the projectile in time to command "Halt!" When the projectile is at height of breech commands "Lower!", and guides tray to truck-platform and unhooks it.

Nos. 12 and 13 hoist the projectile. Pass sections of cartridge to Nos. 1 and 2.

No. 14 assists in hoisting, and, while Nos. 12 and 13 pass up sections, lowers shot-tray.

Nos. 15 and 16 bring up and return trucks.

No. 17 calls out data received and posts it.

No. 18 notifies chief of ammunition detachment when to start and stop hoist. Repeats to him kind of projectile designated.

Nos. 18 and 19 load the trucks.

Q. Give positions of rammer detail.

A. Nos. 1, 3, and 9 on right; Nos. 2, 4, and 10 on left, facing rammer.

Note.—No. 2 commands "Ram!", and by about three separate rushes the projectile is rammed home; No. 2 giving "Home!", "Ram!", when the brass scale on rammer is about two feet from face of breech. Nos. 3 and 4 withdraw rammer.

Q. Explain how to unload a dummy.

A. Chief commands "Unload!" (gun being depressed to 0° elevation).

No. 10 passes extractor to No. 4, who withdraws cartridge.

Shot-tray being in position at the breech as in loading, Nos. 1, 2, 3, and 4 withdraw projectile to shot-tray. It is lowered and replaced by the shot-hoist detail. Where no chain ammunition-hoist is provided the drill will be modified to meet the conditions by the battery commander.

The ammunition detachment and duties of members operating electric motors are the same as in the 12-inch disappearing-gun drill.

Q. In what particulars does the drill for the 10-inch non-disappearing gun differ from the 12-inch non-disappearing?

A. First. Nos. 1, 2, 3, and 4 man the rammer.

Second. Sponge and rammer detail is composed of No. 9 only.

Third. Truck detail consists of No. 10 only.

Fourth. The cartridge detail consists of four men only.

Q. How many privates in a detachment?

A. Fifteen.

Q. Name the details into which a detachment is divided, and give posts of each.

A.

| Name of Detail. | Posts. |

| Chief of detachment (sergeant). | Two yards in rear of the carriage, |

| facing it. | |

| Gunner (duly qualified | Sighting-platform. |

| non-commissioned officer | |

| or private). | |

| Range-keeper (non-commissioned | On the left of the carriage, |

| officer or private). | opposite the elevation-scale. |

| Breech detail (two privates, | In line, immediately in rear of |

| Nos. 1 and 2). | the breech, facing it, No. 1 |

| on the right. | |

| Elevating detail (two privates, | At the elevating hand-wheels, |

| Nos. 3 and 4). | facing them, No. 3 on the |

| right of the carriage, No. 4 | |

| on the left. | |

| Traversing detail (two privates, | In front of the traversing cranks, |

| Nos. 5 and 6). | facing from the parapet, No. |

| 5 on the right of the carriage, | |

| No. 6 on the left. | |

| Shot-hoist detail (four privates, | Nos. 7 and 8 at the |

| Nos. 7, 8, 9, and 10). | windlass-cranks, |

| facing to the rear, No. | |

| 7 on the right of the carriage, | |

| No. 8 on the left, No. 9 | |

| opposite the shot-hoist tackle, | |

| facing the carriage, No. 10 | |

| at the foot of the steps to the | |

| carriage-platform, on the left | |

| of the carriage, facing it. | |

| Sponge and rammer detail (one | One yard in rear of the |

| private, No. 11). | carriage-platform, facing it. |

| Truck detail (one private, No. 12). | Near the hoist, in rear of a |

| loaded truck. | |

| Telautograph detail (one private, | At the telautograph. |

| No. 13). | |

| Hoist detail (two privates, Nos. | At the delivery-table, facing it. |

| 14 and 15). |

The posts of the gun detachment as given above are for inspection, and preparatory to the service of the gun.

The chief of detachment and gunner go wherever their presence is necessary.

Q. Name the equipments or implements which each member procures and places in proper position at the command "Posts!"

A. Gunner, range-keeper, Nos. 1, 2, 5, and 6 procure the same as for the 12-inch piece.

No. 9: Chamber-sponge.

No. 10: Extractor for dummy.

No. 11: Rammer and prop.

No. 12: Trucks.

Q. State in brief what each member inspects and tests at the command "Examine gun!"

A. Chief, gunner, range-keeper, Nos. 1 and 2 the same as for the 12-inch piece, Nos. 3 and 4 the elevating-gear.

Nos. 5 and 6: Recoil-cylinders, traversing gear.

No. 7 passes up and replaces funnel and measure.

No. 8: Hoisting-gear, and removes muzzle-cover.

No. 9 and 10: Tackle of shot-hoist.

No. 11 passes up and replaces sponges.

No. 12: Trucks.

No. 13: Telautograph or telephone.

Q. Give the duties of each at the command "Load!"

A. Chief, gunner, and range-keeper are the same as for the 12-inch piece.

No. 1 assists in opening and closing breech. Examines gas-check and breech-block. Assists in launching projectile on the loading-tray. Assists in ramming projectile. Passes back to No. 11 the rammer. Hooks lanyard to firing-leaf. Fires at signal of gunner.

No. 2 assists in opening and closing breech. Examines gas-check seat and breech-recess. Inserts loading-tray. Commands "Home!", "Ram!", and assists in ramming. Observes scale on rammer. Inserts sections of cartridge and pushes them home by[33] hand. Removes loading-tray. Inserts a primer and lowers slide. Removes old primer and places it in a bag. Sponges chamber.

Nos. 3 and 4 elevate the piece.

Nos. 5 and 6 traverse the piece.

Nos. 7 and 8 hoist the projectile at the command "Hoist!" No. 8 lowers the shot-tray.

No. 9 hooks the tackle to the shot-tray and commands "Hoist!" Steadies the projectile. Places section of cartridge on rear of carriage-platform.

No. 10 mounts steps and commands "Halt!" when projectile is level with breech. Launches it on loading-tray, and swings shot-tray clear of carriage-platform and resumes post.

No. 11 passes rammer to No. 2.

As soon as projectile is rammed passes both sections of cartridge to No. 2 and returns rammer.

No. 12 brings up and returns trucks.

No. 13 calls out and posts data received.

No. 14 repeats to ammunition-sergeant kind of projectile to be used; also notifies when to start and stop the hoist.

Nos. 14 and 15 load the trucks.

Q. How is a dummy charge unloaded?

A. The gun is brought to 0° elevation. No. 11 passes up extractor. No. 2 withdraws sections of cartridge. No. 10 passes them to No. 11, who places them on truck. The shot-tray is held in position while No. 2 withdraws the projectile to the shot-tray, when it is lowered to the truck.

Note.—The ammunition detachment is the same as prescribed for the 12-inch disappearing gun.

Q. What comprises a gun detachment?

A. Chief of detachment, gunner, and ten privates.

Q. Name the details into which it is divided, and give the posts of each.

A.

| Name of Detail. | Posts. |

| Chief of detachment (sergeant). | Two yards in rear of the breech, |

| facing it. | |

| Gunner (duly qualified corporal | Near the azimuth subscale |

| or private). | facing the mortar. |

| Breech detail (two privates, | In line immediately in rear of |

| Nos. 1 and 2). | the breech, facing it, No. 1 |

| on the right. | |

| Sponge and rammer detail (two | At the sponge and rammer, |

| privates, Nos. 3 and 4). | facing the mortar. |

| Elevating detail (two privates, | At the elevating hand-wheels, |

| Nos. 5 and 6). | facing them, No. 5 on the |

| right of the carriage, No. 6 | |

| on the left. | |

| Traversing detail (two privates, | At the traversing-cranks, facing |

| Nos. 7 and 8). | the mortar, No. 7 at the right |

| crank, No. 8 at the left. | |

| Truck detail (two privates, | In the gallery, near the entrance, |

| Nos. 9 and 10). | in the rear of and facing a |

| loaded truck, No. 9 on the | |

| right, No. 10 on the left. |

The posts of the gun detachment as given above are for inspection and preparatory to the service of the mortar.

Q. State in brief what equipments or implements each procures and places in proper positions.

A. No. 1: Oil-can, hand-sponge, and silk wiper.

No. 2: Silk wiper.

No. 3: Long lanyard, bore and chamber sponge.

No. 4: Rammer.

No. 5: Wrench for filling plug.

No. 6: Wrench for filling plug, measure and funnel.

No. 8: Primer-pouch, bag, scabbard, etc.

Q. How is a breech-block opened and closed?

A. In the same manner as for the 8-, 10-, and 12-inch guns.

Q. What does each member of the detachment inspect or[35] test with a view of cleaning or oiling, if necessary, at the command "Examine gun!"?

A. Chief: Mortar in general.

Gunner: Azimuth subscale and traversing-gear.

No. 1: Breech-block and breech mechanism.

No. 2: Bore, chamber, gas-check seat, and breech-recess.

No. 3: Lanyard. (He coils it properly.)

No. 4: Muzzle-cover. (Removes it and places it aside.)

Nos. 5 and 6: Elevating-gear and recoil-cylinders.

Nos. 7 and 8: Traversing-gear. No. 8 clears vent and wipes primer-seat.

Nos. 9 and 10: Trucks.

Q. After examining gun, what changes in posts are made?

A. The chief of detachment and gunner go wherever their presence is necessary. No. 7 takes post at the door of the cartridge-room.

Q. Give the duties of each member of the detachment at the command "Load!"

A. Gun commander operates switches and firing-plug. Observes all detachments.

Chief generally supervises the proper loading of his piece, signals "Ready" or "Misfire," etc.

Gunner gives the piece the proper azimuth, signals "Azimuth set" to the chief.

No. 1 assists in opening and closing breech. Examines or oils, if necessary, the breech-block and gas-check. Assists in ramming.

No. 2 assists in opening and closing breech. Examines or oils, if necessary, the gas-check seat and breech-recess. Commands "Home!", "Ram!" Assists in ramming. Observes the scale on the rammer. Inserts loading-tray and withdraws same. Pushes cartridge properly into chamber. After firing, assisted by No. 5, sponges chamber and bore.

No. 3 assists in ramming. If firing by lanyard be used, he attaches the long lanyard to the short one and, after the piece is[36] elevated, hooks the short lanyard to eye of firing-leaf and fires at the command. After firing, brings bore and chamber-sponge and assists No. 2 in sponging. Replaces sponge.

No. 4 brings up rammer, and places its head on the base of the projectile. Assists in ramming. Replaces rammer.

Nos. 5 and 6 give elevation at command of chief. (No. 5 operates the clamp and lock.) Assists in ramming.

After piece is fired, brings piece to 0° elevation.

No. 7 brings up cartridge and takes post at traverse-crank. On taking cover he returns to cartridge-room.

No. 8 inserts and removes primers.

Nos. 7 and 8 traverse the mortar at the signal of the gunner.

Nos. 9 and 10 bring up loaded trucks.

Q. What are the positions for ramming?

A. Nos. 1, 3, and 5 on right, Nos. 2, 4, and 6 on left, all facing rammer. The projectile is rammed home in one motion.

Q. In taking cover, what is the order of formation in rear of pits?

A. They take cover as shown in the following diagram:

| Mortar No. 4 | Mortar No. 2 | ||

| " " 3 | " " 1 | ||

| {8, 6, 5, G.} | {8, 6, 5, G.} | ||

| 4th detachment | { } | 2d detachment | { } |

| {4, 3, 2, 1 } | {4, 3, 2, 1 } | ||

| {8, 6, 5, G.} | {8, 6, 5, G.} | ||

| 3d detachment | { } | 1st detachment | { } |

| {4, 3, 2, 1 } | {4, 3, 2, 1 } | ||

Q. What comprises an ammunition detachment?

A. One chief, two corporals, and sixteen privates.

Q. Name the details.

A. Projectile: One corporal and Nos. 1 to 12.

Cartridge: One corporal and Nos. 13 to 16.

Q. Give their duties in brief.

A. The chief has general supervision and is responsible for the proper supply of ammunition.

Nos. 1 and 2 operate a trolley and pulley, and load trucks with shell.

Nos. 3 and 4, 5 and 6, 7 and 8 operate other trolleys similarly.

Nos. 9, 10, 11, and 12 run up empty trucks, and when loaded return them to gallery entrance.

Nos. 13, 14, 15, and 16 pass designated cartridge to No. 7.

Note.—Where there are two magazines to an emplacement there is a separate detachment for each, composed of three non-commissioned officers and eight privates each. (Nos. 1 to 6 compose the projectile detail, and Nos. 7 and 8 the cartridge detail.)

Q. How does the drill for the 12-inch mortar carriage, model 1891, differ from that of model 1896?

A. Nos. 1 and 2 lift shell-tray from hoist-scoop to truck after ramming.

Nos. 5 and 6 man the shell-hoist and hand-wheel, in addition to assisting in ramming.

No. 6 returns to hoist hand-wheel after ramming, and lowers scoop when directed by No. 2.

Nos. 9 and 10 deliver shell on scoop, and return truck.

Q. What composes a gun detachment?

A. One chief, a gunner, and ten privates.

Q. What are their posts preparatory to inspection or service of the piece?

A. Chief of detachment, two yards in rear of the breech, facing it.

Gunner, sighting-platform.

No. 1, two feet to the right and rear of the breech, facing it.

No. 2, two feet to the left and rear of the breech, facing it.

No. 3, two yards in rear of the breech, facing it.

No. 4, at the elevating hand-wheel, facing it.

Nos. 5 and 6, at the serving-table at the rear side of the loading-platform, facing to the front, No. 5 on the right side, No. 6 on the left.

No. 7, on the gun-platform at the head of the steps leading to the cartridge-room.

No. 8, at the telautograph.

Nos. 9 and 10, on the banquette, facing the gun, No. 9 on the right.

Q. What implements or equipments do each procure?

A. Gunner: Sight and difference-chart.

No. 1: Silk wiper, lanyard, sponge and oil-can.

No. 2: Loading-tray and silk wiper.

No. 3: Rammer and prop.

No. 5: Plug-wrench, funnel and measure.

No. 6: Plug-wrench.

No. 7: Chamber-sponge and dummy-extractor.

Q. What does each inspect or test with a view to cleaning or oiling, if necessary, at the command "Examine gun!"?

A. Chief: Gun and carriage throughout.

Gunner: Sight-standard, sight, azimuth subscale, traversing- and elevating-gears.

No. 1: (Removes breech-cover) breech-block and breech mechanism, vent, lanyard (hangs lanyard on elevating-arm).

No. 2: Bore, chamber, gas-check seat, and breech recess, and cleans them if necessary.

No. 3: The sponges (hangs them up when necessary).

No. 4: (Removes muzzle-cover, etc.) elevating- and traversing-gears under gunner's direction.

Nos. 5 and 6: Recoil-cylinders.

No. 7 passes up funnel and oil-measure when used.

No. 8: Telautograph or telephone.

Q. Give in brief the duties of each at the command "Load!"

A. Those of chief and gunner are practically the same as for the 8-inch disappearing.

No. 1 opens breech (by one continuous motion). Inserts a[39] primer and takes lanyard. Closes breech. Fires at the signal. After piece is fired coils lanyard, and opens breech and removes primer.

No. 2 inserts loading-tray. Inserts cartridge by hand.

No. 3 rams projectile home. Replaces rammer. Operates tripping-lever, and trips at the command. After piece is fired sponges chamber.

No. 4 sets the elevation, signalling "Elevation set" by holding one hand at height of head until signal "Ready" is made by chief.

Nos. 5 and 6 alternate in bringing up projectiles and placing them on the loading-tray.

No. 7 receives a cartridge from No. 4 or No. 5 of the ammunition detachment. Passes it to No. 2. Closes safety-switch when gun is in battery.

No. 8 calls out and posts data received.

Nos. 9 and 10 receive projectiles from a truck and place them on serving-table.

Q. How is a dummy charge unloaded?

A. The chief of detachment commands: "Unload!"

No. 1 opens the breech.

No. 2 inserts the loading-tray, withdraws the cartridge and passes it to No. 7, and, as soon as the projectile is withdrawn, removes the loading-tray.

No. 3 brings up the extractor, pulls the projectile on to the loading-tray, and replaces the extractor.

No. 5 withdraws the projectile and returns it to the serving-table.

No 7 carries the cartridge to the steps and passes it to No. 4 or No. 5 of the ammunition detachment.

Q. How is the piece retracted?

A. The chief of detachment commands: (1) "From battery!"; (2) "Heave!"; (3) "Halt!" At the first command No. 3 goes to the retraction-crank and operates the pawl and speed-crank to permit the pulling out of the ropes. Nos. 5 and 6 mount on the[40] carriage and place the loops of the ropes on the hooks. Nos. 1 and 2 pull out the ropes and pass the ends to Nos. 5 and 6. No. 3 takes in the slack. Nos. 3 and 4 take positions at the retraction-crank, and at the second command turn the crank. Nos. 5 and 6 relieve Nos. 3 and 4 when directed by the chief of detachment. When the gun has reached the loading position the command "Halt!" is given. At the command "Cast off!" No. 3 lets out enough slack to enable Nos. 1 and 2 to take the loops off the hooks.

Q. In an emplacement provided with an ammunition-hoist what changes in the above drill are made?

A. Nos. 5 and 6 serve projectiles from a loaded truck placed in rear of the gun.

Nos. 9 and 10 are posted at the delivery-table, and run loaded trucks to Nos. 5 and 6, returning empty ones.

Q. What composes an ammunition detachment?

A. One chief and five privates. Nos. 1, 2, and 3 in the shell-room, and Nos. 4 and 5 in the cartridge-room.

Q. Give their duties in brief.

A. The chief exercises general supervision.

Nos. 1 and 2 load trucks.

No. 3 runs up trucks convenient to the rear of gun, and returns them to shell-room.

Nos. 4 and 5 uncase cartridges and pass them to No. 7.

Note.—Owing to the comparative simplicity and the similarity of drill of almost all smaller-calibered pieces they are omitted in this work.

For definite details in the drill for 6-inch Pedestal, 5-inch Balanced Pillar, 4·7-inch Quick-firing, 15-pounder and 6-pounder Rapid-fire Guns, see Coast Artillery Drill Regulations.

Q. What are projectiles?

A. They correspond to the bullets in small-arm cartridges.

Q. Why are projectiles made oblong and guns rifled?

A. To prevent the projectile from tumbling, thereby securing greater penetration, and better results in accuracy of fire.

Q. What is the difference between guns and mortars?

A. Guns are long in comparison with their calibers, mortars are short in comparison with their calibers.

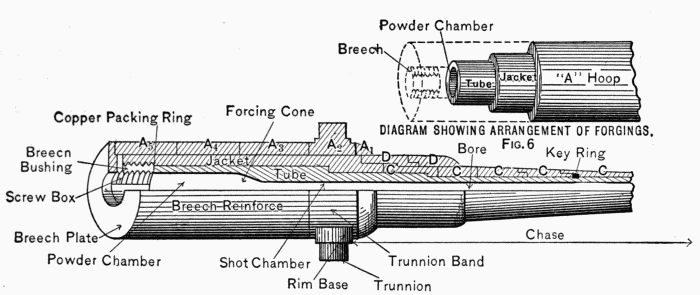

Q. What is meant by a built-up gun?

A. One that is composed of several cylindrical forgings separately shrunk one over the other.

Q. Why are these forgings shrunk on?

A. To give an initial compression to the steel toward the bore, such that the strength of the gun to resist the pressure of the powder-gas will be increased.

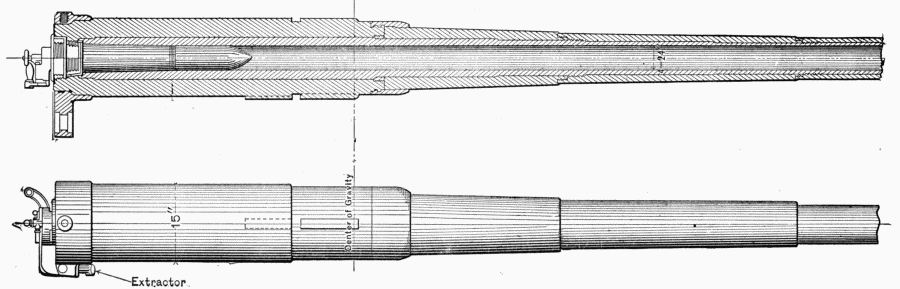

Q. Name the principal parts of a built-up gun.

A. The tube, jacket, hoops, and trunnion-band. (See Figs. 5, 6, and 23.)

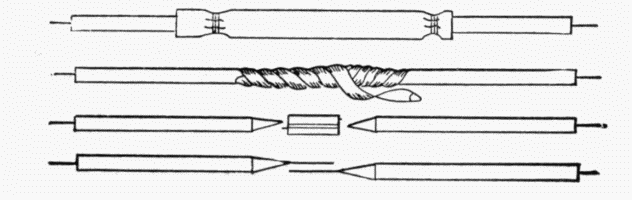

BUILT UP GUN. Fig. 5.

Q. What is a wire-wound gun?

A. One in which wire takes the place of the jacket and hoops and is wound over the tube. The wire is really in the form of a ribbon.

Q. Define the breech-reinforce.

A. That portion of the gun between the rear of the trunnion-band and the front of the breech. (Fig. 5.)

Q. Define the chase.

A. That portion of the gun between the front of the trunnion-band and the muzzle. (Fig. 5.)

Q. What is a barbette gun?

A. One that fires over a parapet.

Q. What two classes of barbette guns are there?

A. Barbette disappearing and barbette non-disappearing.

Q. What is the center of gravity?

A. That point where, if the gun were pivoted, it would balance. It is always near the trunnions.

Q. What is the difference between front-pintle and center-pintle carriages?

A. Front pintle is where the gun traverses about a point in the front part of the carriage; center pintle where it traverses about a point in the center of the carriage.

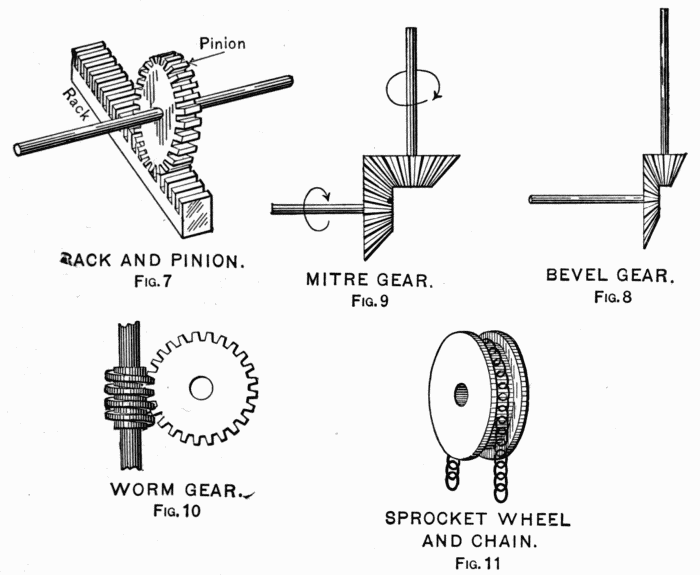

Q. What is a rack?

A. A bar or arc having teeth that engage in a gear-wheel or worm. (See Fig. 7.)

Q. What is a gear-wheel?

A. A wheel with teeth on the circumference.

Q. What is a bevel-gear?

A. Two wheels whose axles are at an angle to each other and whose teeth engage. (Fig. 8.)

Q. What is a miter-gear?

A. A bevel-gear with axles of equal-sized wheels at right angles. (Fig. 9.)

Q. What is a worm?

A. A gear-wheel in the form of a continuous screw. (Fig. 10.)

Q. What is a sprocket-wheel?

A. A toothed wheel that engages the links of a chain. (Fig. 11.)

Q. What is a spur-wheel?

A. A gear-wheel with teeth parallel with the axle of the[43] wheel. If in Fig. 7 the rack were in form of a wheel, it would be a spur-wheel. (The pinion is also a spur-wheel.)

RACK AND PINION.

Fig. 7.

MITRE GEAR.

Fig. 9.

BEVEL GEAR.

Fig. 8.

WORM GEAR.

Fig. 10.

SPROCKET WHEEL AND CHAIN.

Fig. 11.

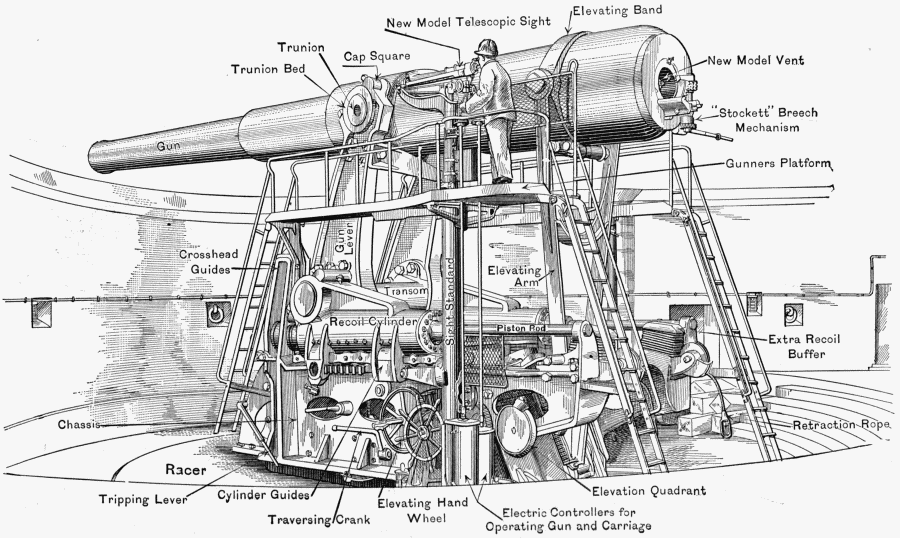

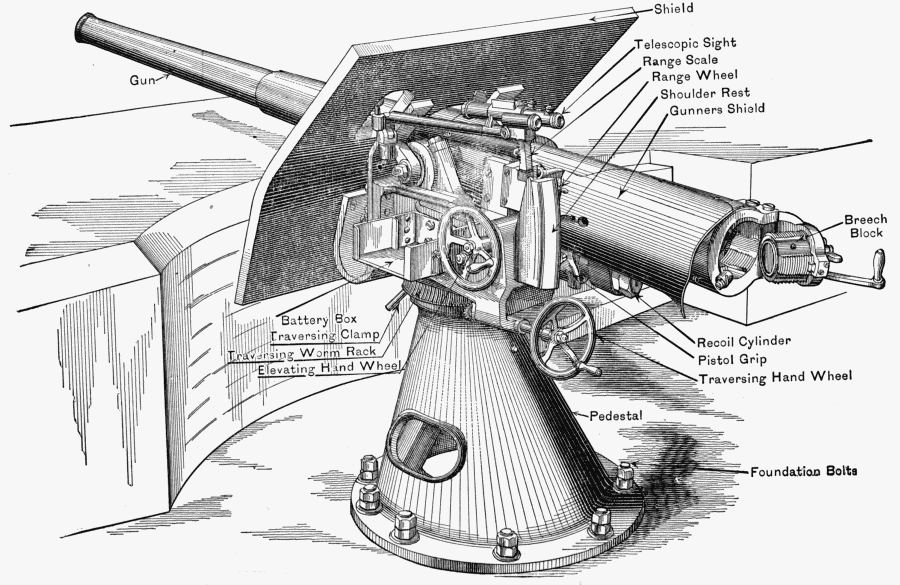

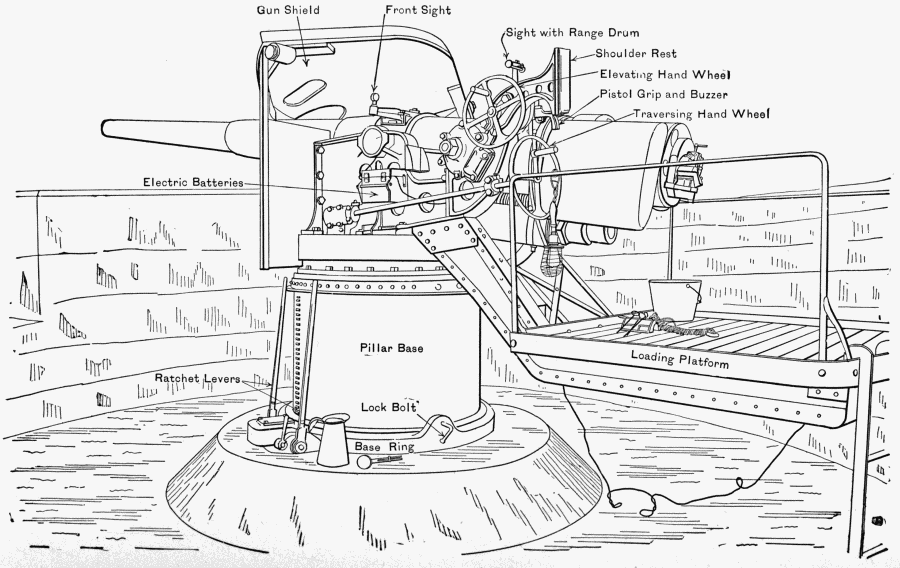

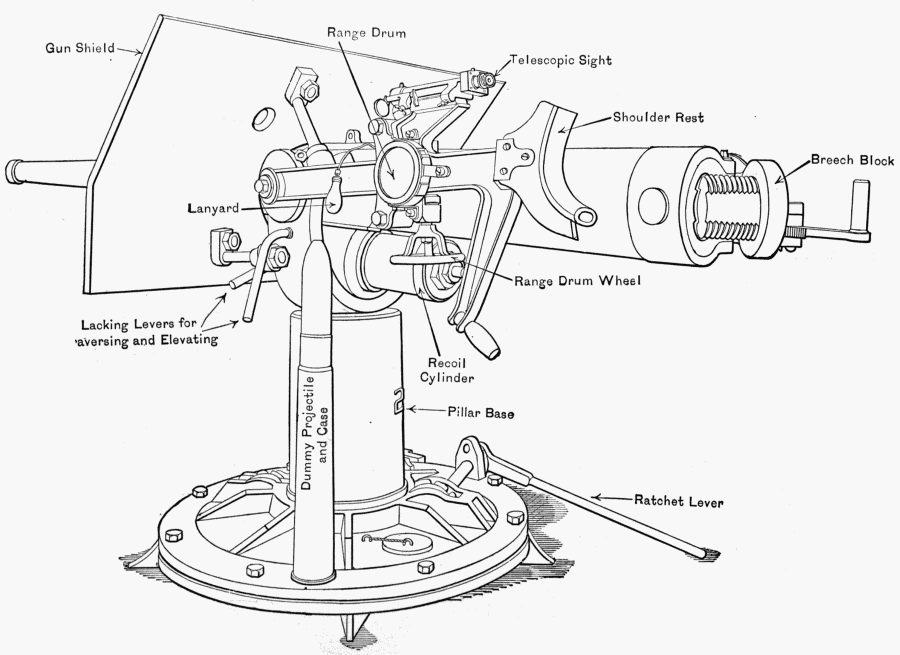

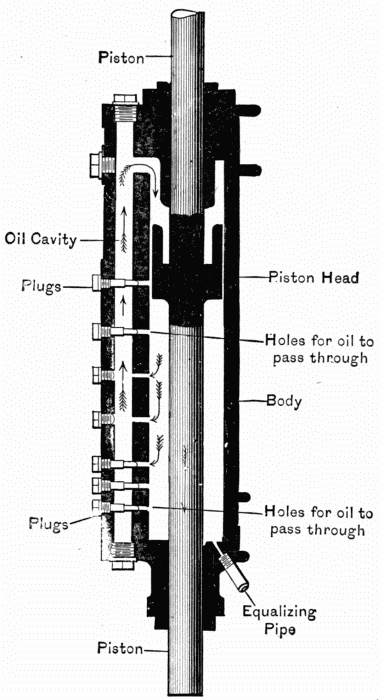

Q. Point out or describe the location of the following parts of a seacoast carriage:

Base-ring.

Foundation-bolts.

Leveling-bolts.

Upper-roller path.

Lower-roller path.

Traversing-rack.

Conical rollers.

Distance-ring.

Dust-guard.

Racer.

Chassis.

Top-carriage.

Recoil-cylinder.

Piston.

Piston-head.

Throttling-bars.

Followers.

Stuffing-box.

Packing.

Guide-hooks.

Trunnion-bed.

Trunnions.

Kim-base.

Cap-squares.

Cap-square bolts.

Elevating mechanism.

Traversing mechanism.

Azimuth circle.

Azimuth indicator.

Retraction-gear.

Sight standard.

Shot-hoist.

[44]Crane.

Shot-hoist drum.

Pawl.

Elevating-arc.

Recoil-rollers.

Chassis-rails.

Gun-shield support.

Loading-platform.

Elevating-shaft.

Extra for R. F. guns:

Pillar-base.

Shoulder-rest.

Electric batteries.

Pistol-grip.

Range-drum.

Extra for disappearing guns:

Gun-lever.

Lever-axle.

Counterweight-shaft.

Counterweight.

Cross-head.

Cross-head guides.

Cross-head rack.

Tripping-bars.

Counter-recoil-buffers.

Gunner's platform.

Retraction-ropes.

Extra recoil-buffers.

Electric traversing-controller.

Electric elevating-controller.

A. See Figs. 12 to 22 inclusive.

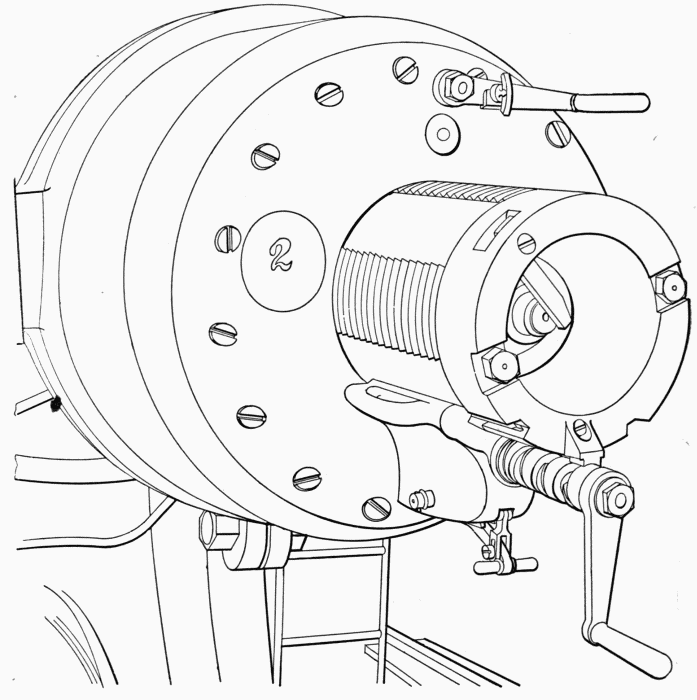

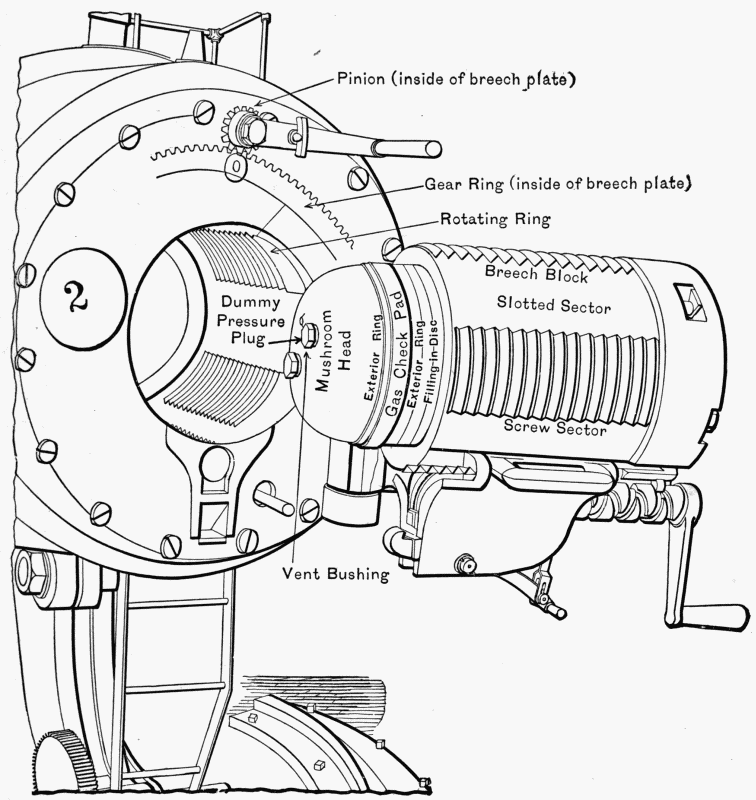

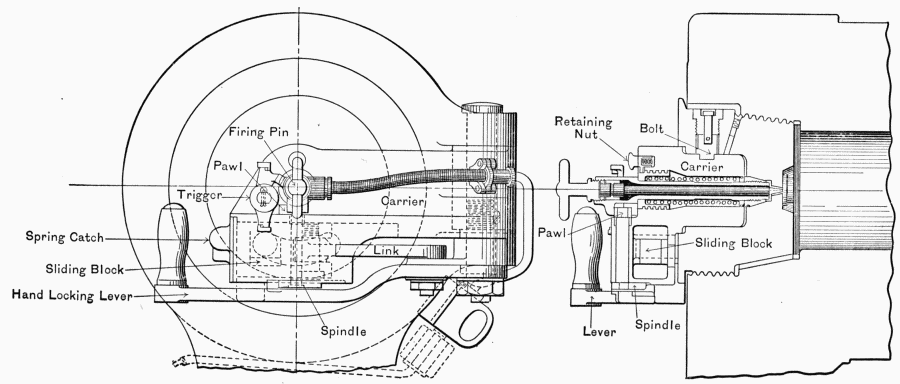

Q. Point out or describe the location of the following parts of the gun and breech mechanism of 8" and 12", Model 1888:

Bore.

Shot-chamber.

Muzzle.

Powder-chamber.

Forcing-cone.

Screw-box.

Breech-block.

Mushroom head.

Spindle.

Gas-check pad.

Vent.

Hinge-pin.

Rotating-crank.

Translating-roller.

Tray.

Breech-plate.

Slotted sectors.

Screw sectors.

Pinion- and gear-segment.

Vent-bushing.

Filling-in disc.

Exterior ring.

Interior ring.

Vent-cover.

Rotating-crank catch.

Obturator-spindle.

Obturator-spindle nut.

Locking-nut.

Translating-stud.

Guide-rails of tray.

Tray-latch.

Securing-latch.

Securing-latch catch.

Rotating-ring.

Rotating-pinion.

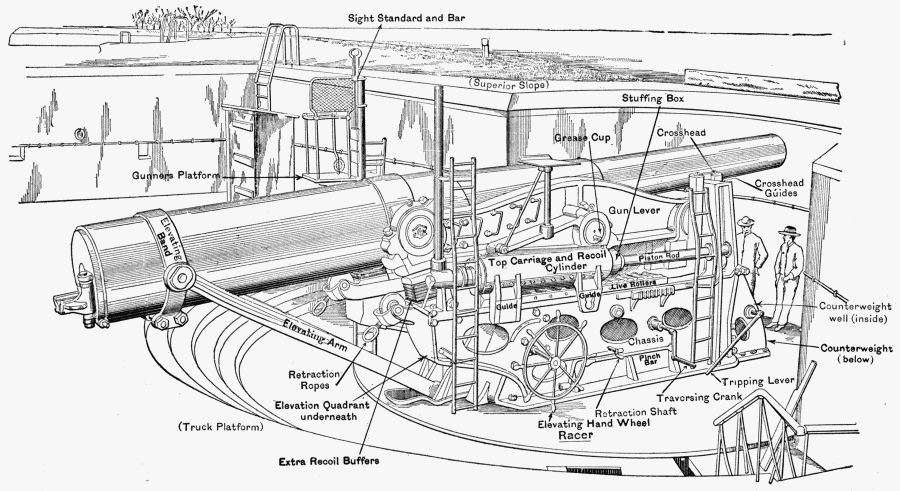

12" DISAPPEARING. (From Battery.)

Fig. 12.

12" DISAPPEARING. (in Battery.)

Fig. 13.

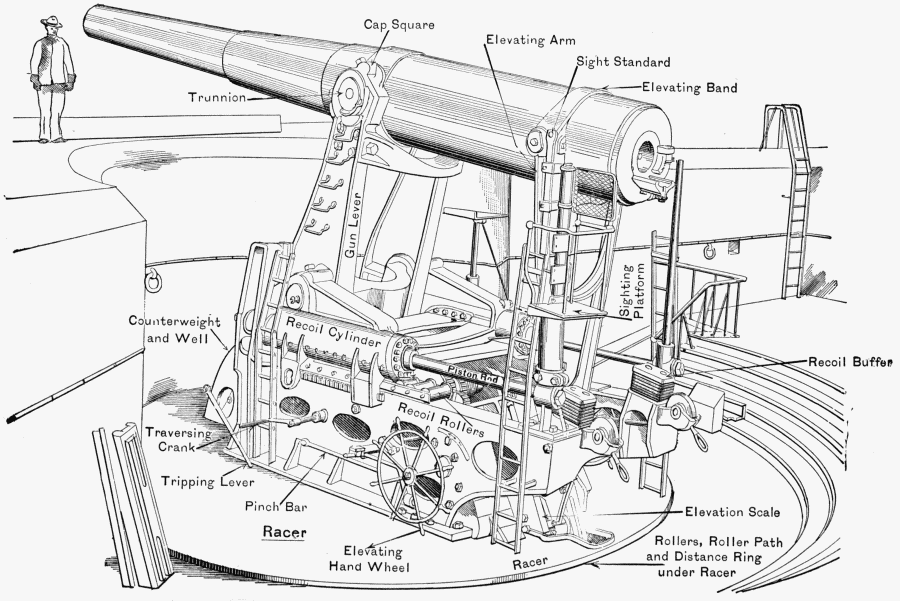

12" BARBETTE NON-DISAPPEARING.

Fig. 14.

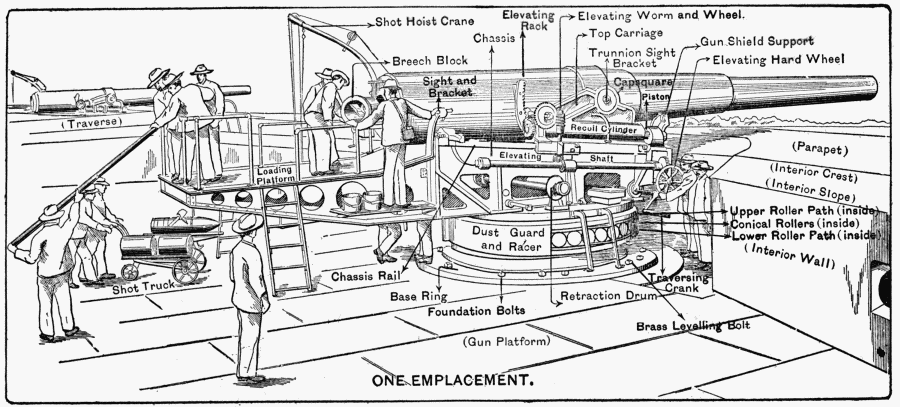

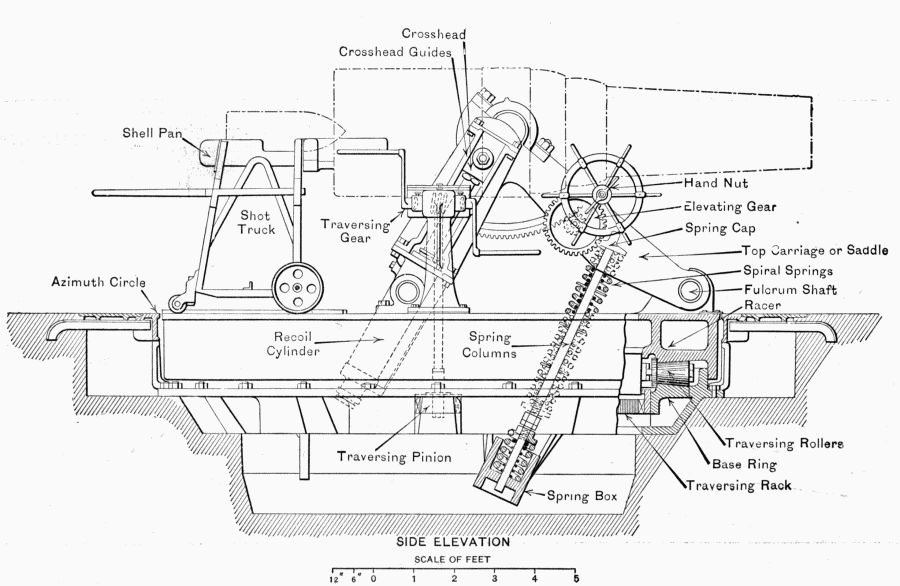

UNITED STATES CARRIAGE

MODEL OF 1896

FOR

12 INCH B.L. MORTAR.

(Steel)

Fig. 15.

LATEST MODEL 12" DISAPPEARING CARRIAGE AND GUN.

Fig. 16.

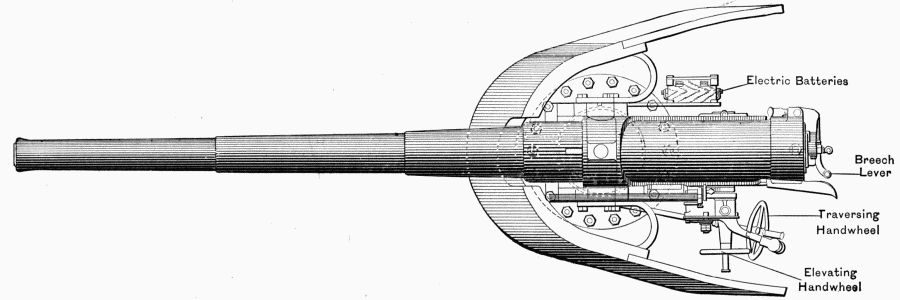

3" RAPID-FIRE GUN. (Pedestal Mount.)

Fig. 17.

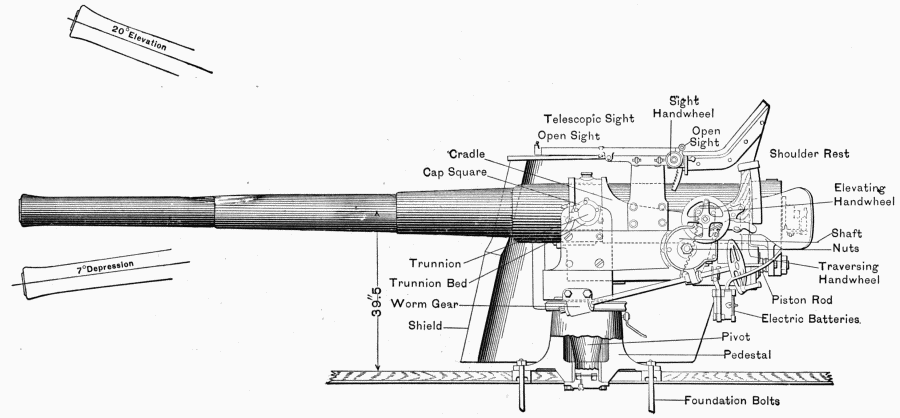

5" RAPID FIRE. (Balanced Pillar Mount.)

Fig. 18.

3-INCH R.F. GUN (Masking Parapet Mount).

Fig. 19.

4.7 INCH 120 m/m Q.F. GUN ON CENTRE PIVOT PEDESTAL MOUNTING.

Fig. 20.

4.7" Q.F. (Pedestal Mount.)

Fig. 21.

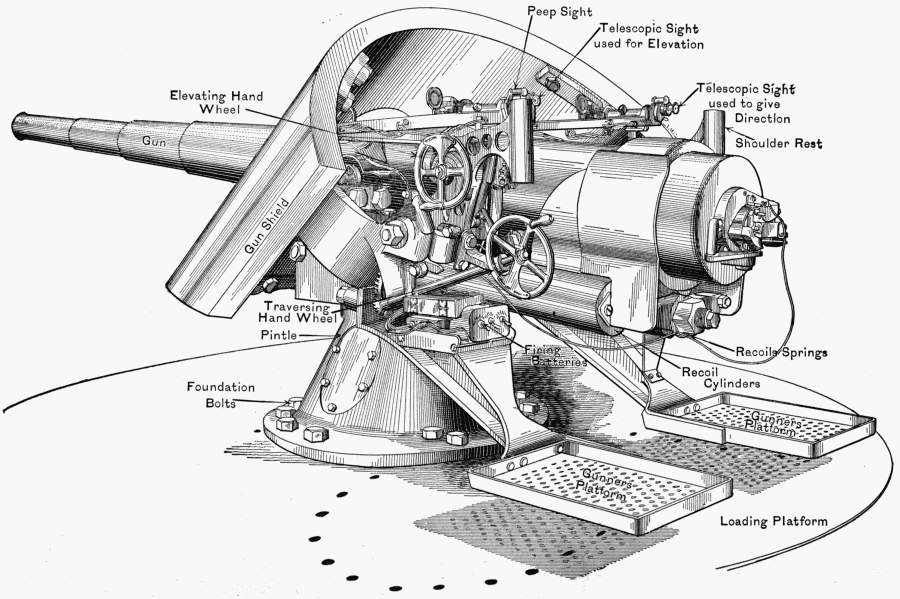

5" RAPID-FIRE GUN. (Pedestal Mount.)

Fig. 22.

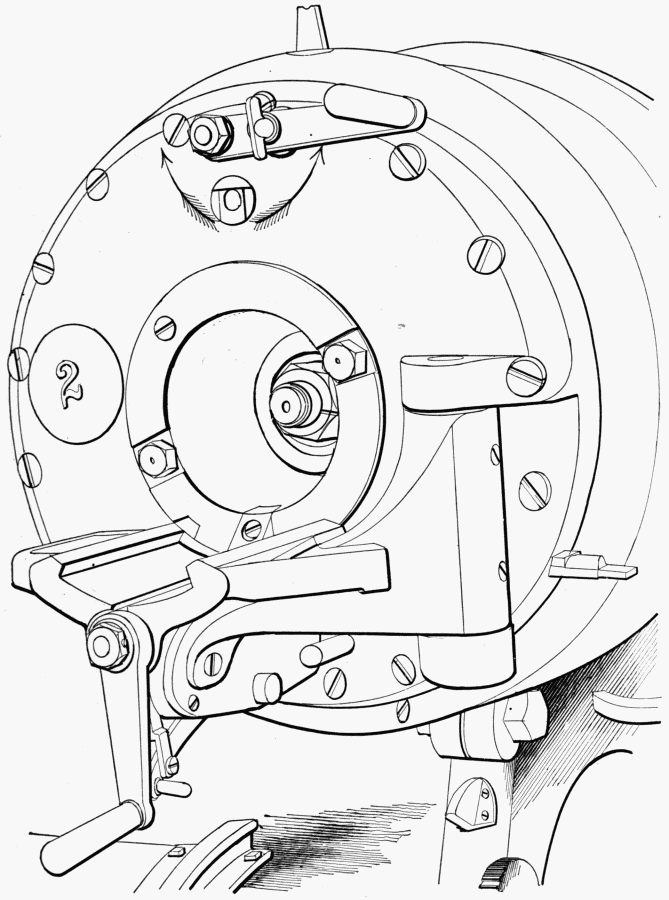

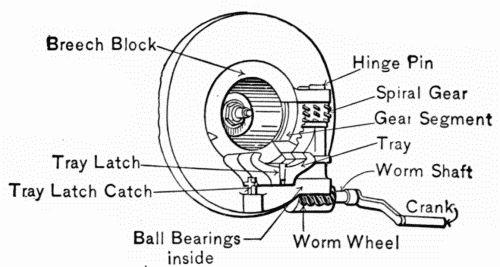

For continuous-motion or "Stockett" mechanism the following:

Spiral-gear.

Crank.

Worm-shaft.

Worm.

Worm-wheel.

Catch-bolt.

Spring-bolt.

Tray-latch catch.

Spindle-ball bearing.

A. See Figs, 1, 2, 3, 4, 23.

CONTINUOUS MOTION BREECH MECHANISM.

Fig. 23.

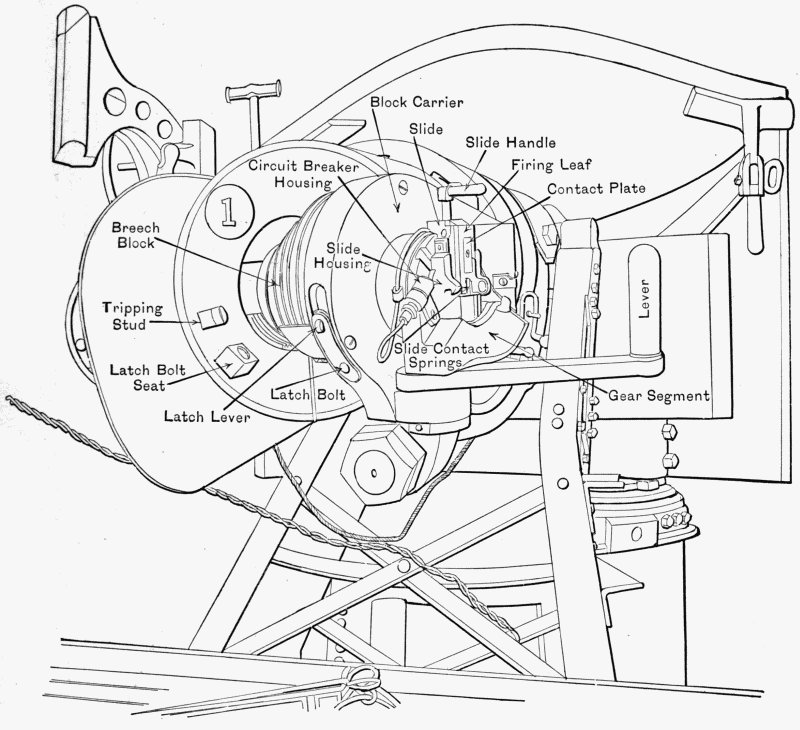

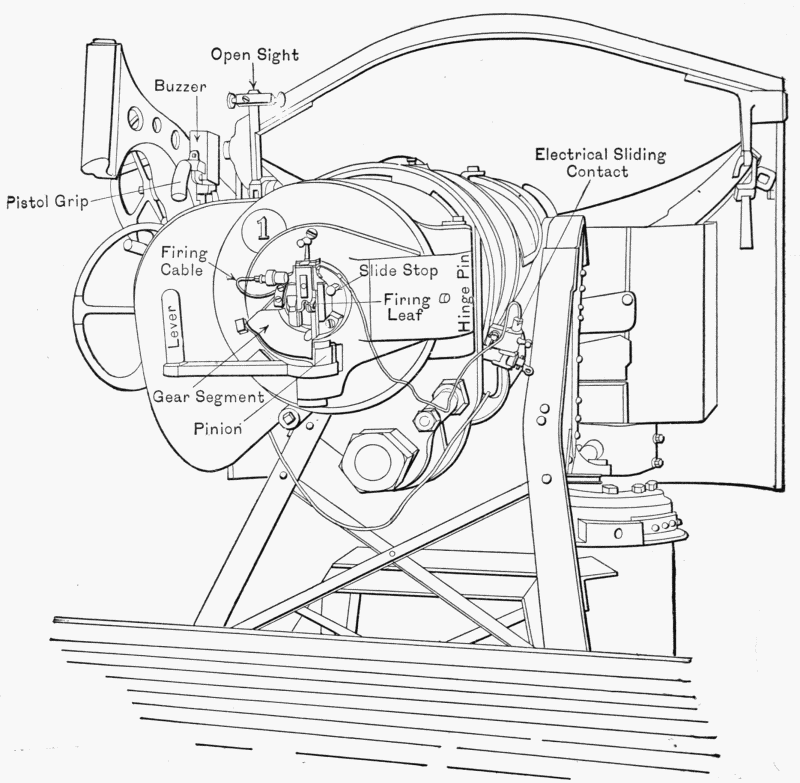

Q. Point out or describe the location of the following parts of the 5" R.F. breech mechanism:

Block-carrier.

Hinge-pin.

Spindle-key.

Latch-bolt.

Latch-lever.

Lever.

Pinion.

Breech-block.

Gear-segment.

Vent-bushing (copper).

Exterior split ring (front).

Exterior split ring (rear).

Interior split ring.

Gas-check pad.

Filling-in disc.

Tripping-stud.

Latch-bolt seat.

Slide-housing.

Slide-stop.

Slide.

Slide-handle.

Contact-plate.

Firing-leaf.

Circuit-breaker housing.

Circuit-breaker spring.

Circuit-breaker contact-pin.

Firing-cable.

A. See Figs. 24 and 25.

Q. Point out or describe the following parts of the 4·7-inch quick-firing breech mechanism: Carrier-link, spindle, hand-locking[57] lever, firing-pin, spring-catch, sliding-block, retaining-nut, bolt.

A. See Figs. 26 and 27.

5" R.F. GUN. SHOWING BREECH MECHANISM.

Fig. 24.

Q. Explain briefly how a breech-block of a heavy gun or mortar is dismantled.

A. The breech being open, remove the locking-nut and spindle-nut, place a block of wood against the spindle and gently hammer the mushroom head free from the gas-check pad, then[58] remove it by hand. Pry the exterior and interior split rings free from the gas-check pad and remove them, also the filling-in disc. The spindle-washers can be removed at any time. The parts are assembled as follows: Adjust in the following order: the gas-check pad, exterior and interior split rings, filling-in disc, and spindle-washers. The spindle-washers must be put on after the spindle is put in. Then gently insert the spindle and screw on the locking- and spindle-nuts as prescribed for adjusting the gas-check pad.

5" R.F. GUN AND BREECH MECHANISM.

Fig. 25.

4.7 INCH 120m/m QUICK FIRING GUN.

Fig. 26.

4.7 INCH.

BREECH CLOSING AND FIRING GEAR.

Fig. 27.

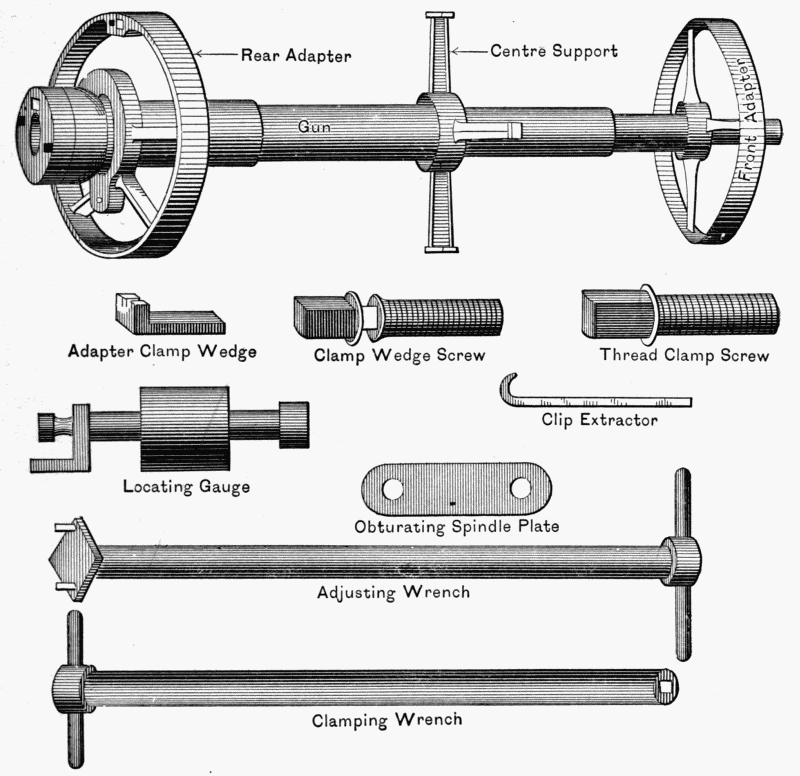

Q. Point out or describe the following parts of the one-pounder subcaliber tube for the 12" B. L. R., model 1895:

Gun.

Adapter clamp-wedge.

Clamp-wedge screw.

Thread clamp-screw.

Rear adapter.

Center support.

Front adapter.

Adjusting-wrench.

Clamping-wrench.

Locating-gauge.

Clip-extractor.

Obturator spindle-plate.

A. See Fig. 28.

ONE-POUNDER SUBCALIBER TUBE.

Fig. 28.

Q. How should gas-check pads be adjusted before firing?

A. First: Close the breech.

Second: Loosen spindle and locking-nuts.

Third: Rotate block half-way.

Fourth: Tighten spindle and locking-nuts in the usual manner, rotate the breech-block home, and pad is adjusted.

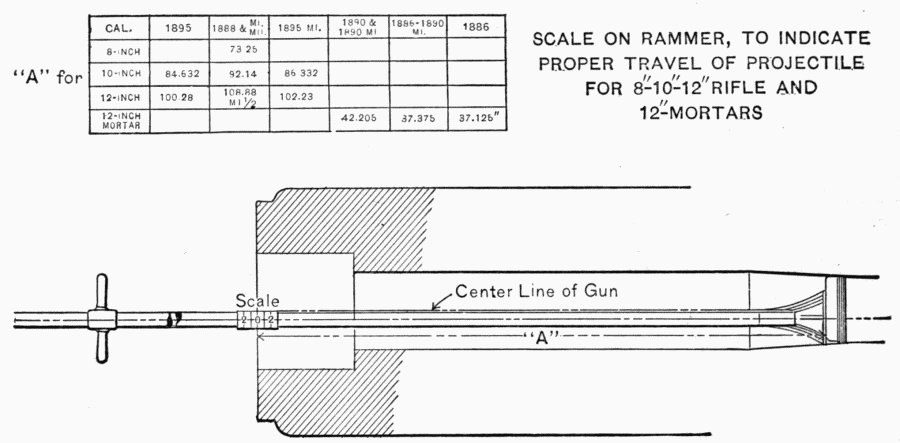

Q. How far should a projectile be rammed?

A. Until the zero of the brass ring on the rammer comes flush with the face of the breech-plate. (See Fig. 29.)

SCALE ON RAMMER, TO INDICATE

PROPER TRAVEL OF PROJECTILE

FOR 8"-10"-12" RIFLE AND

12"-MORTARS

Fig. 29.

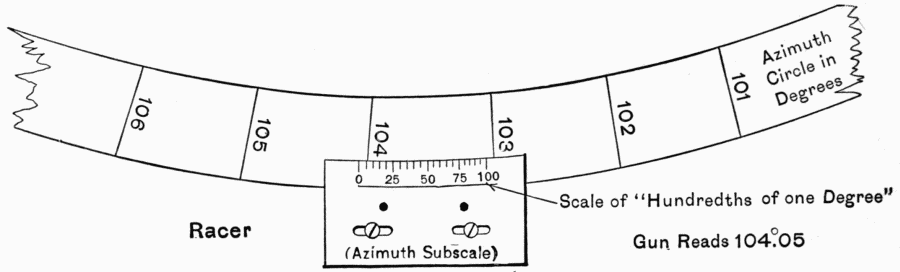

Q. Describe how to set the azimuth indicator-plate for a given azimuth.