Please see the Transcriber’s Notes at the end of this text.

Most illustrations may be enlarged by clicking them or opening them in a new tab or window.

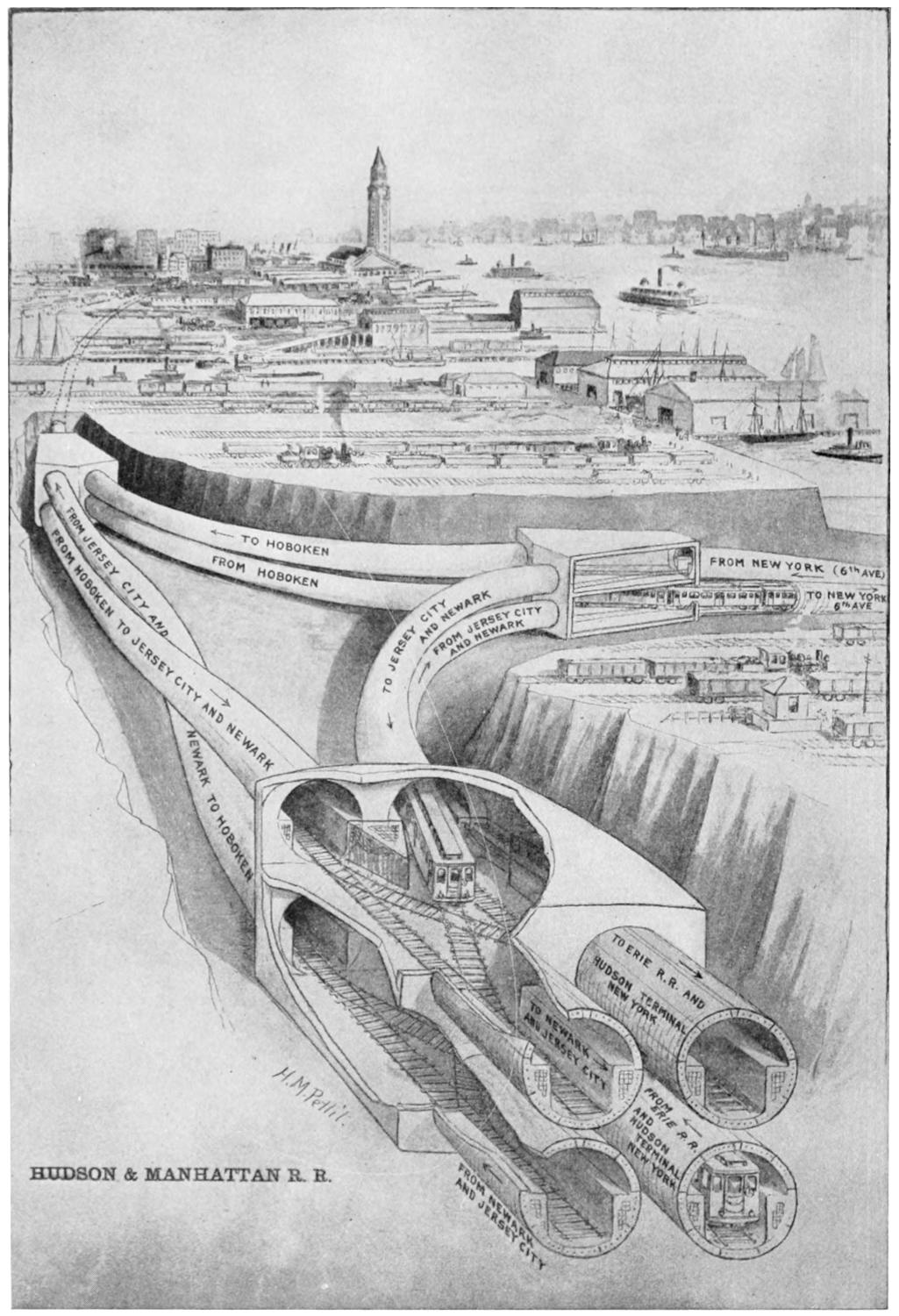

HOW MAN BURROWS UNDER THE WATER

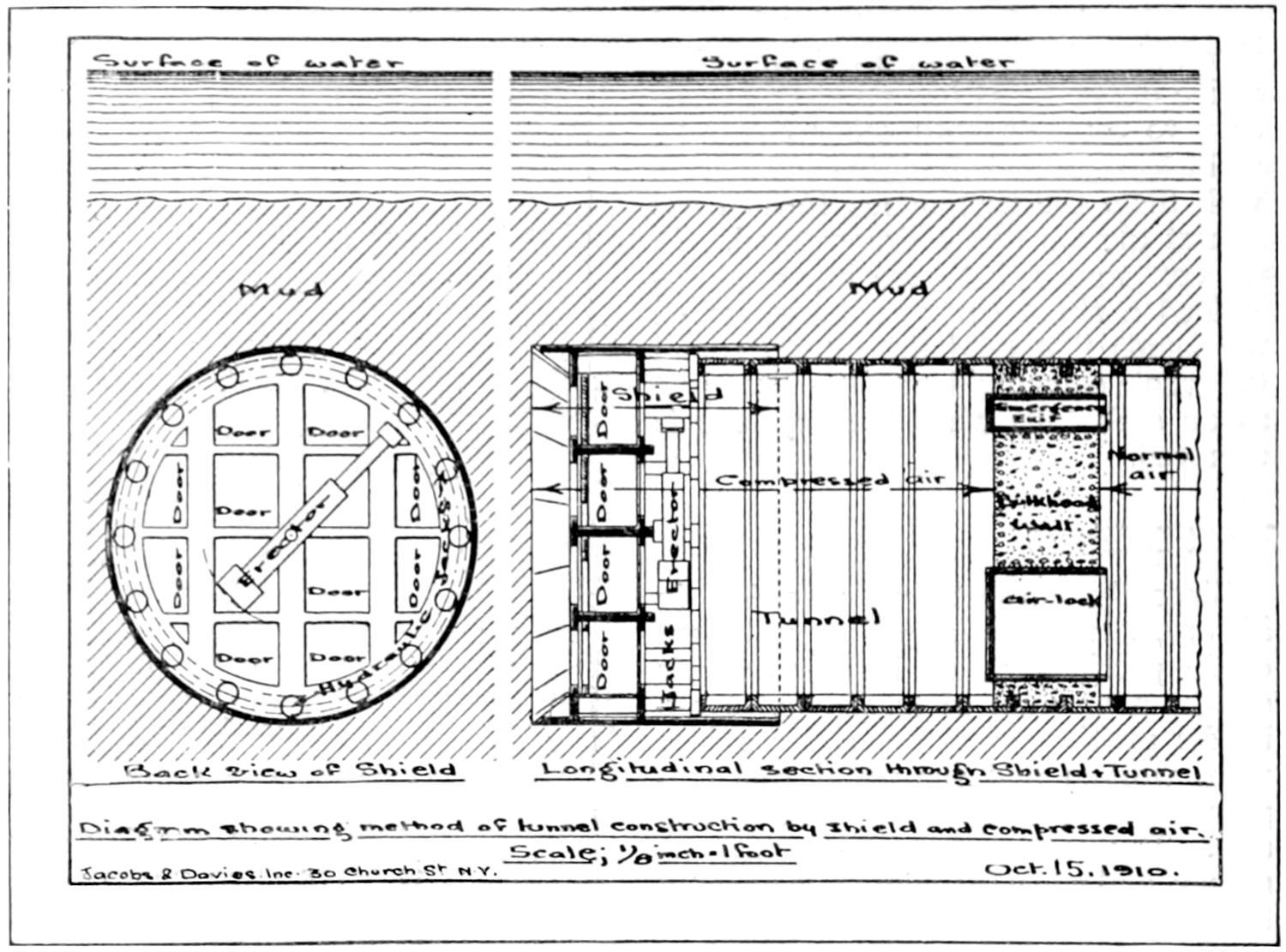

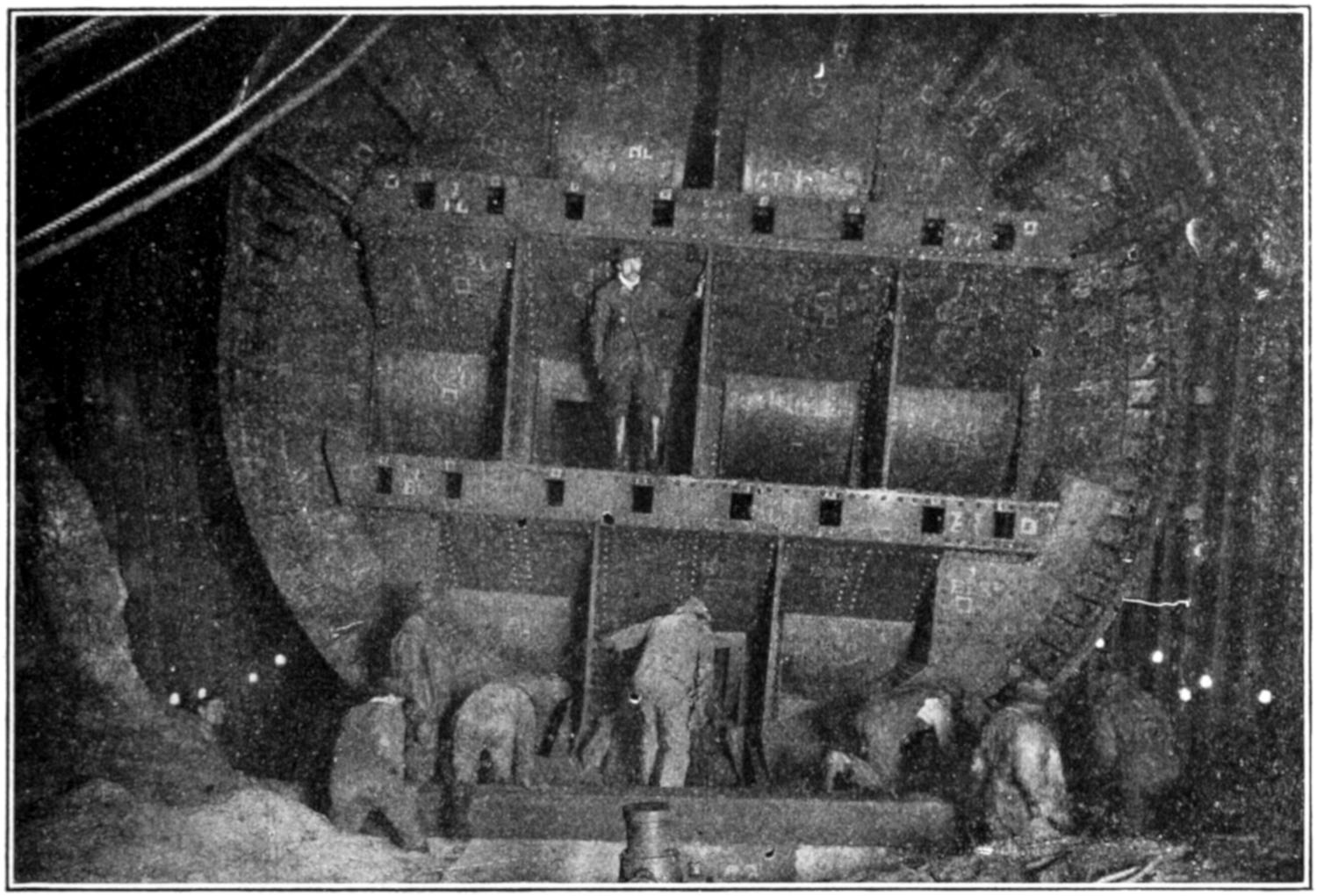

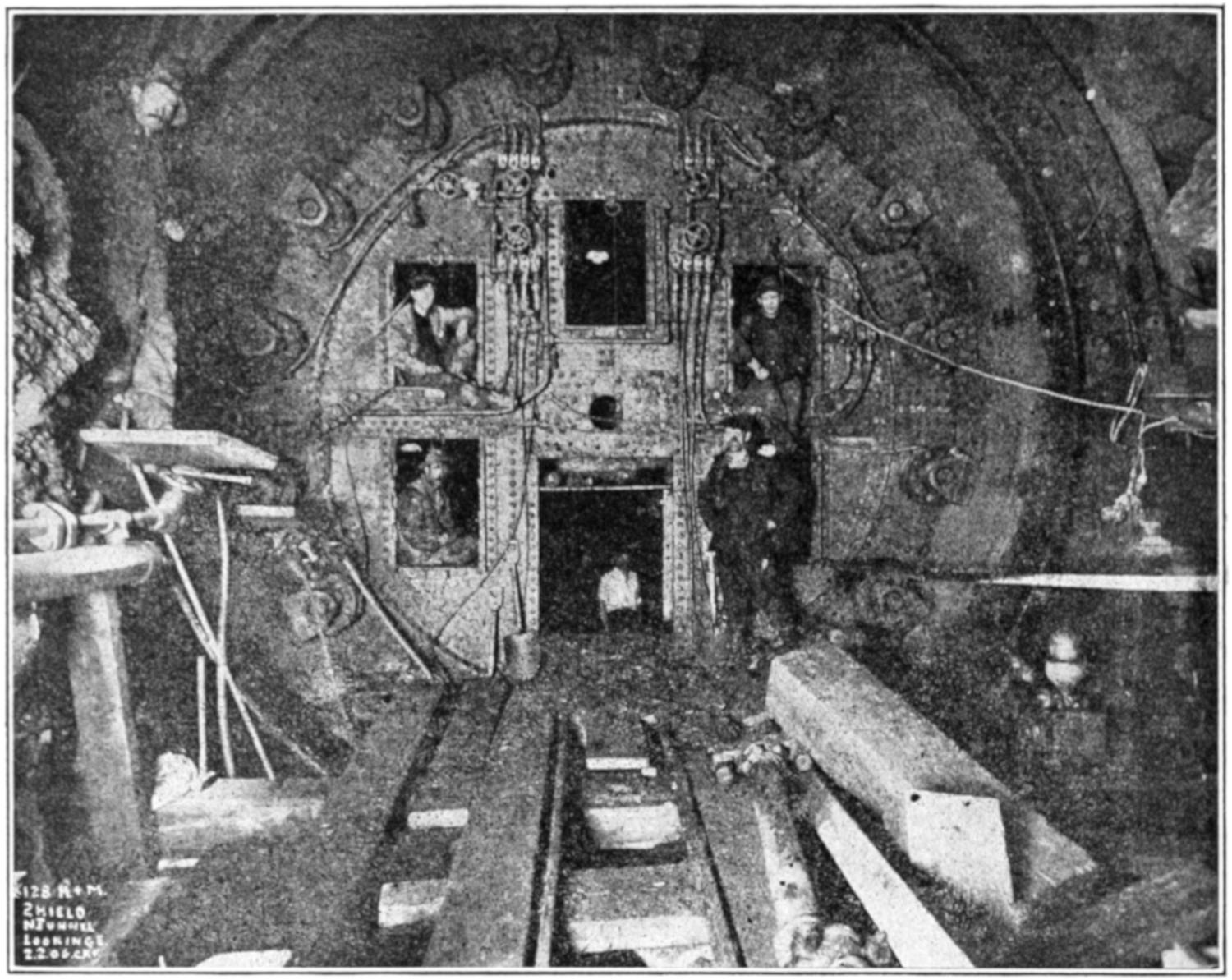

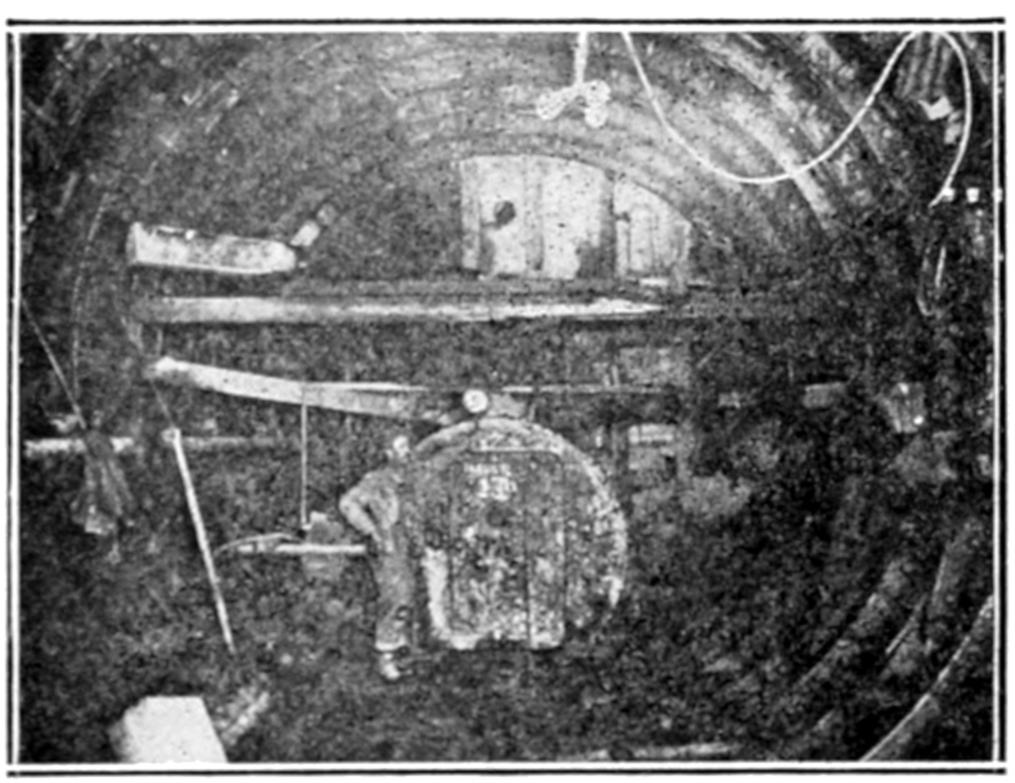

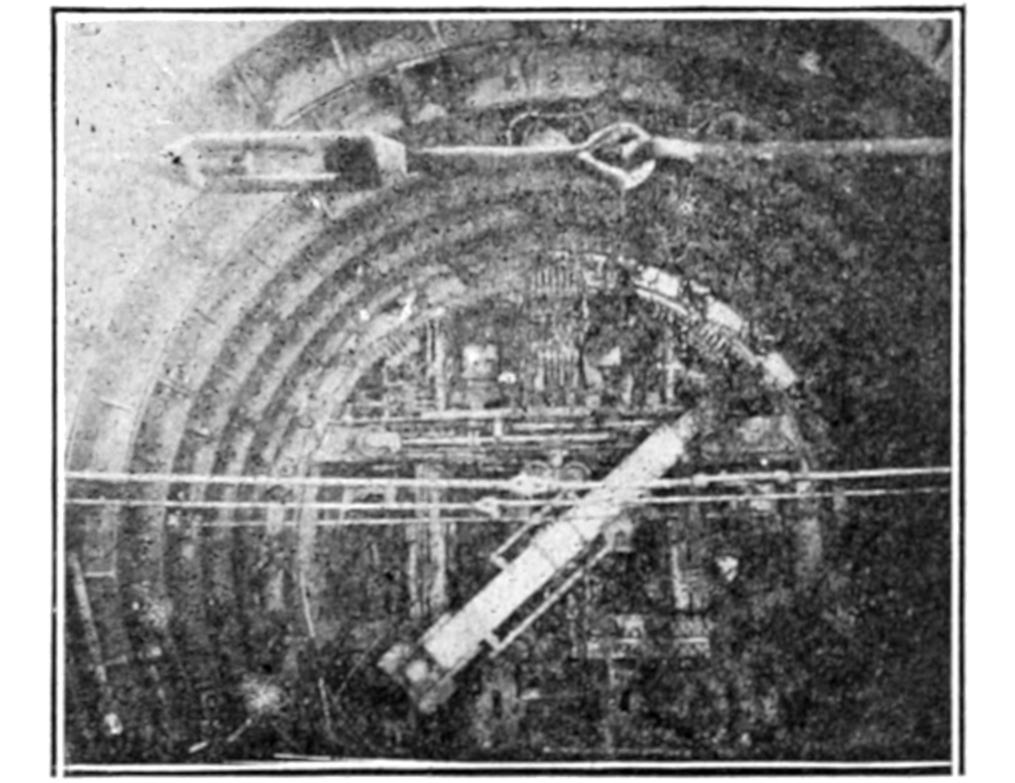

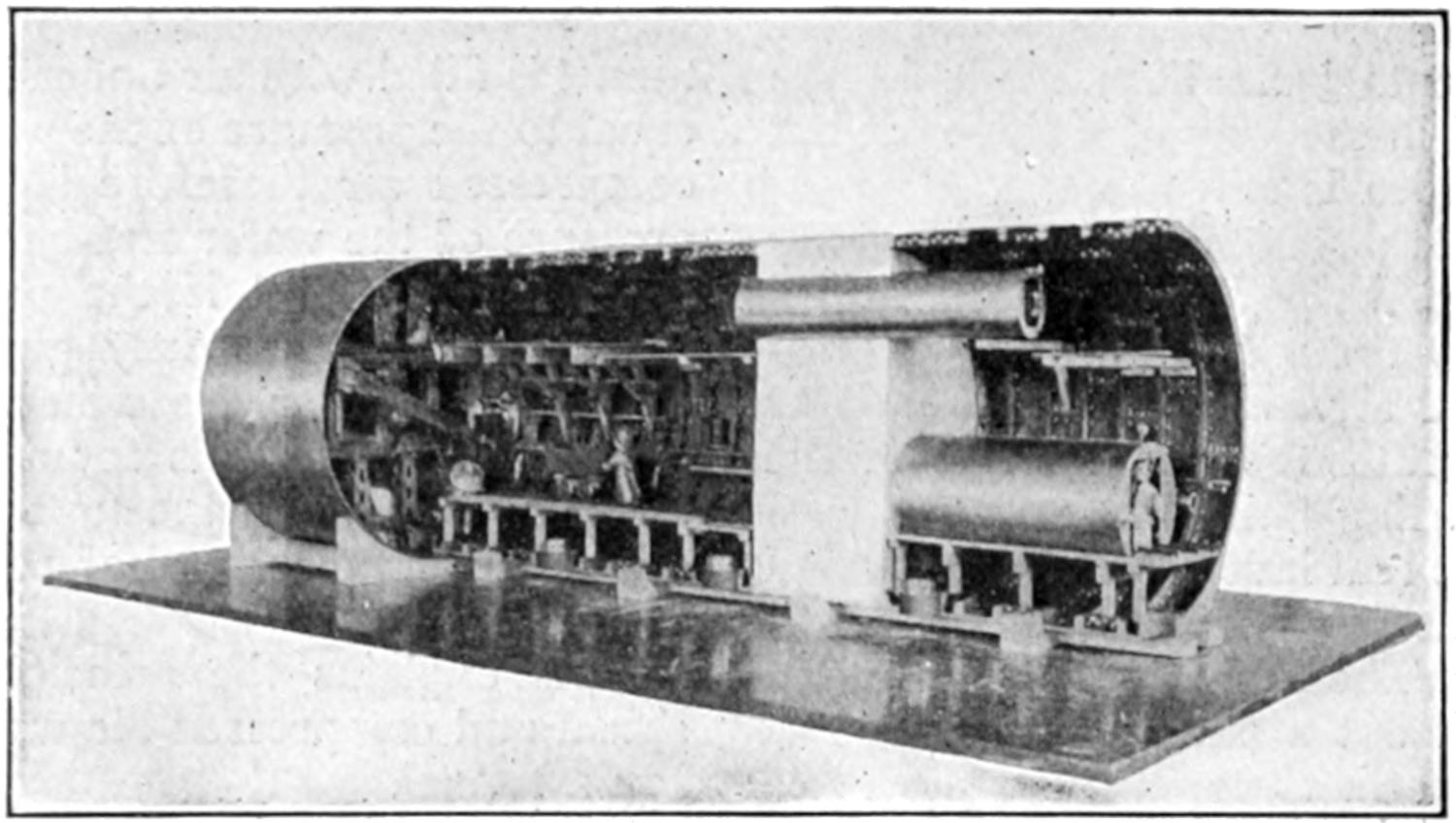

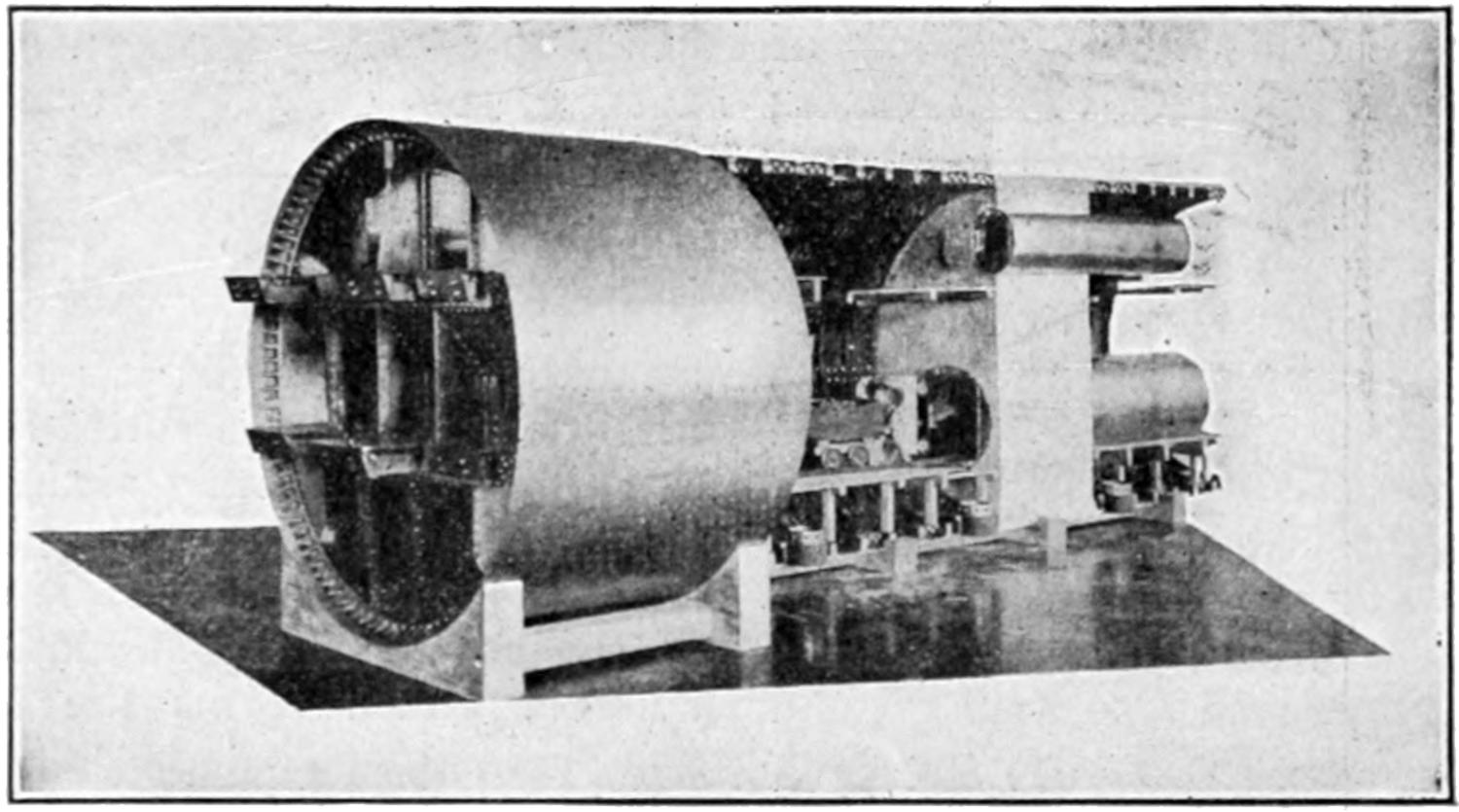

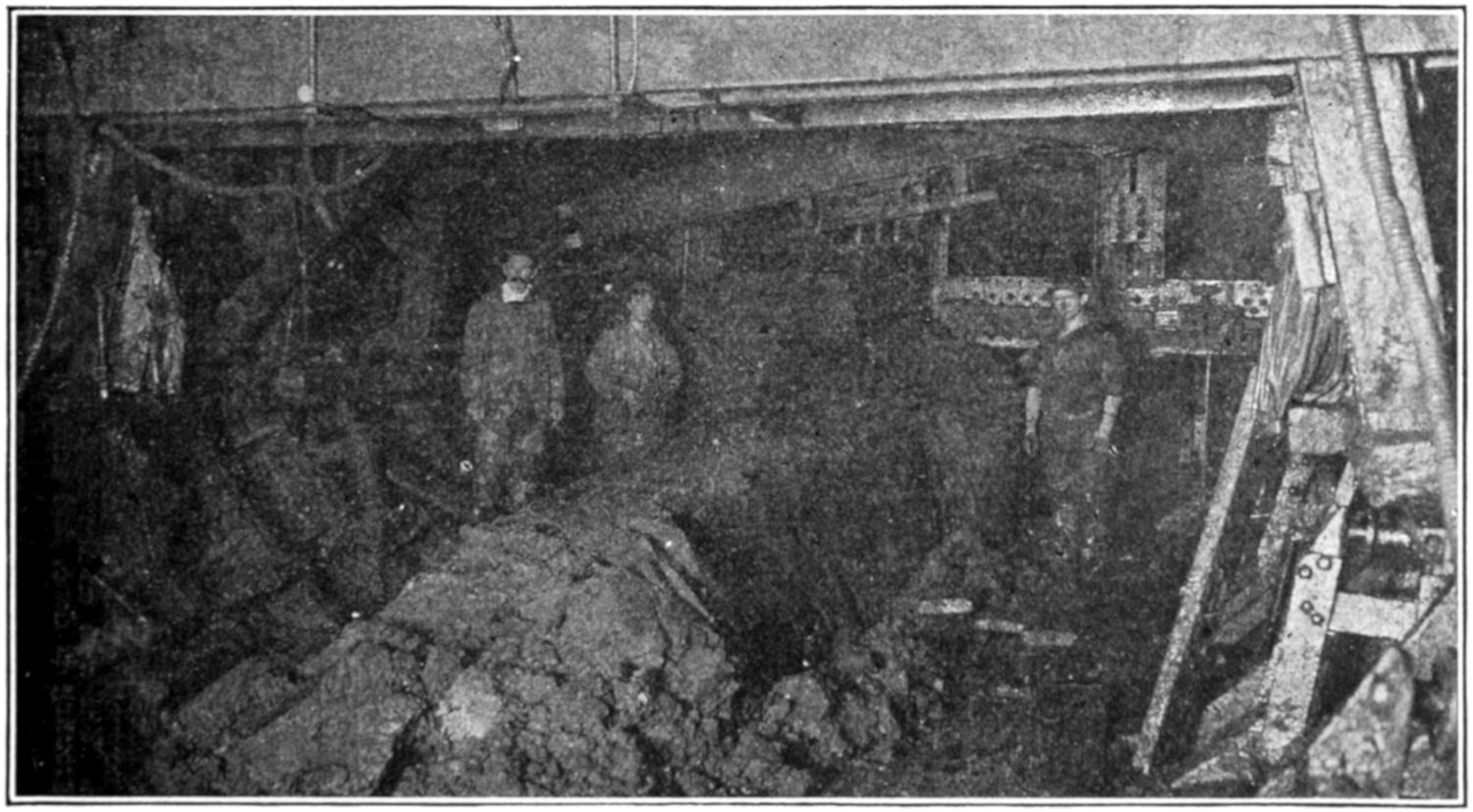

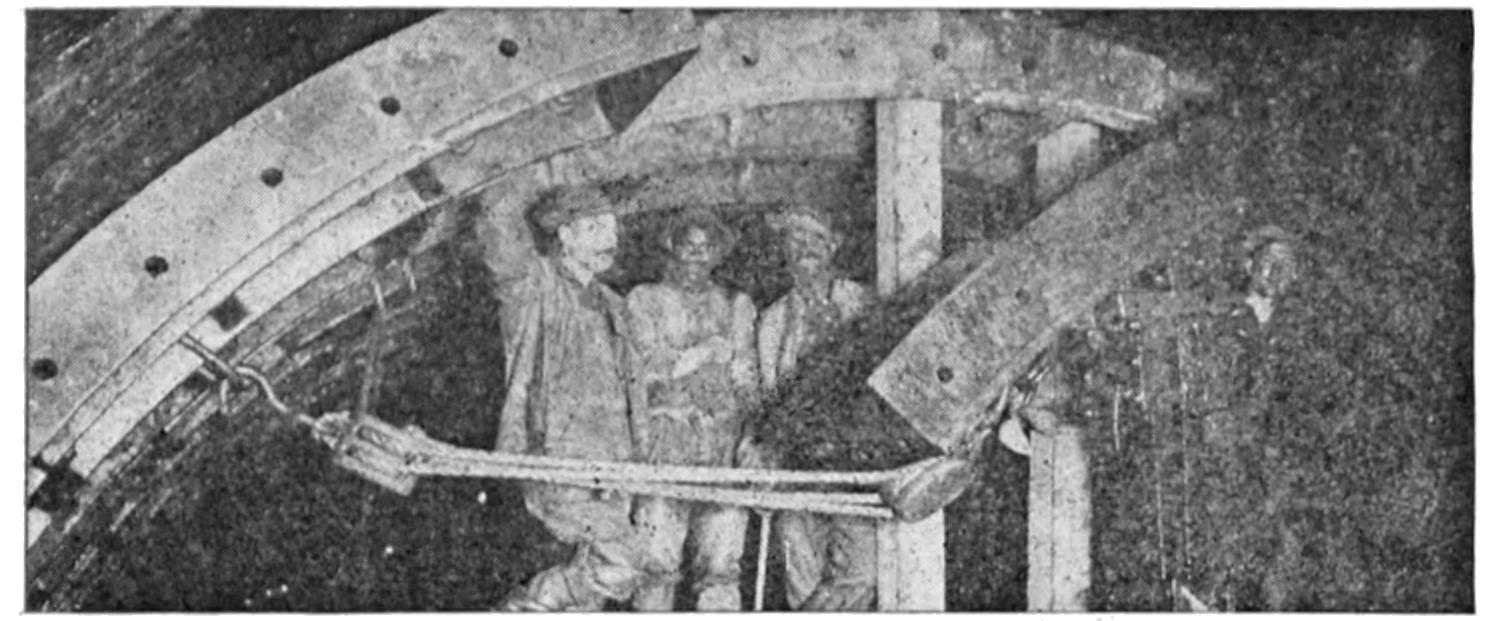

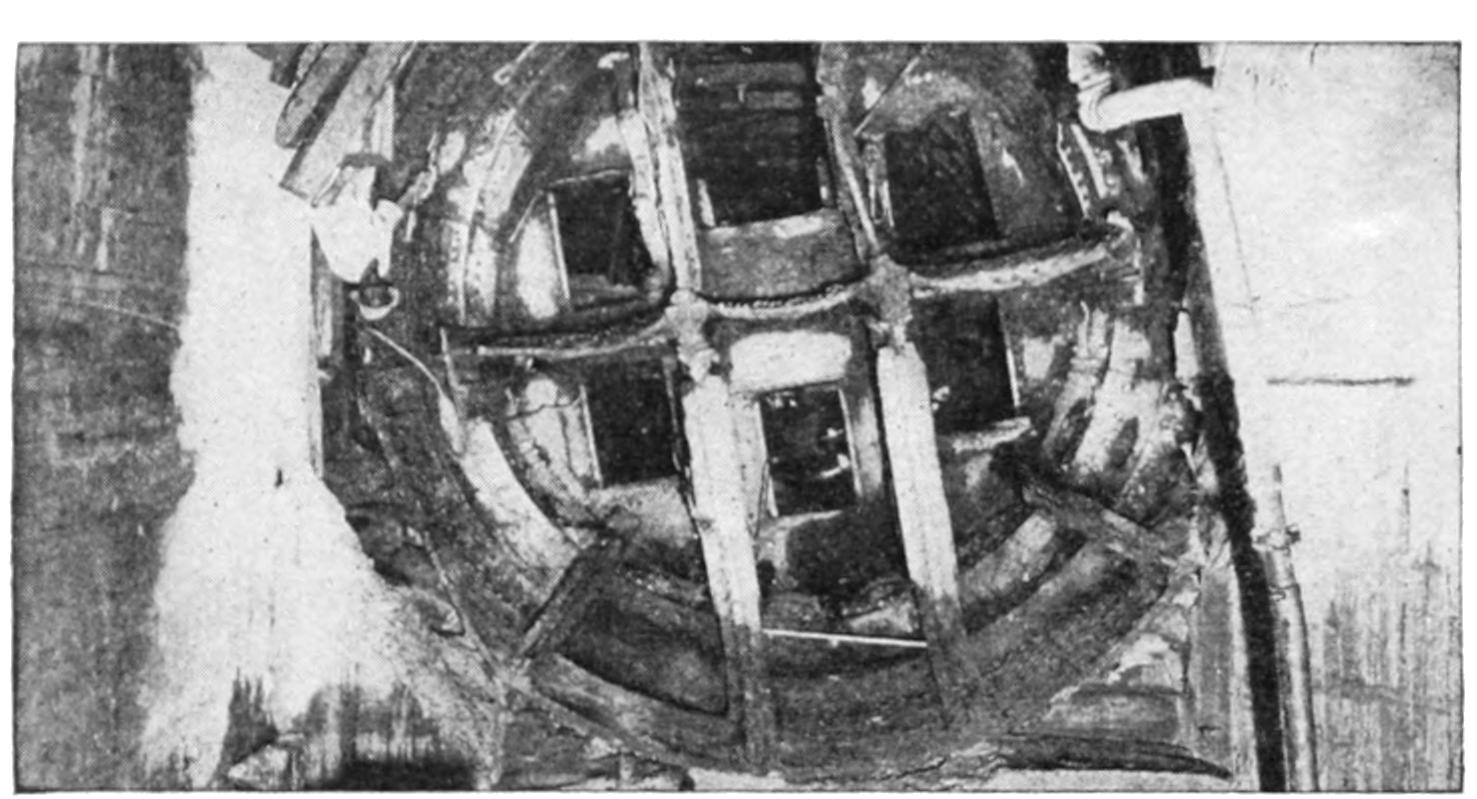

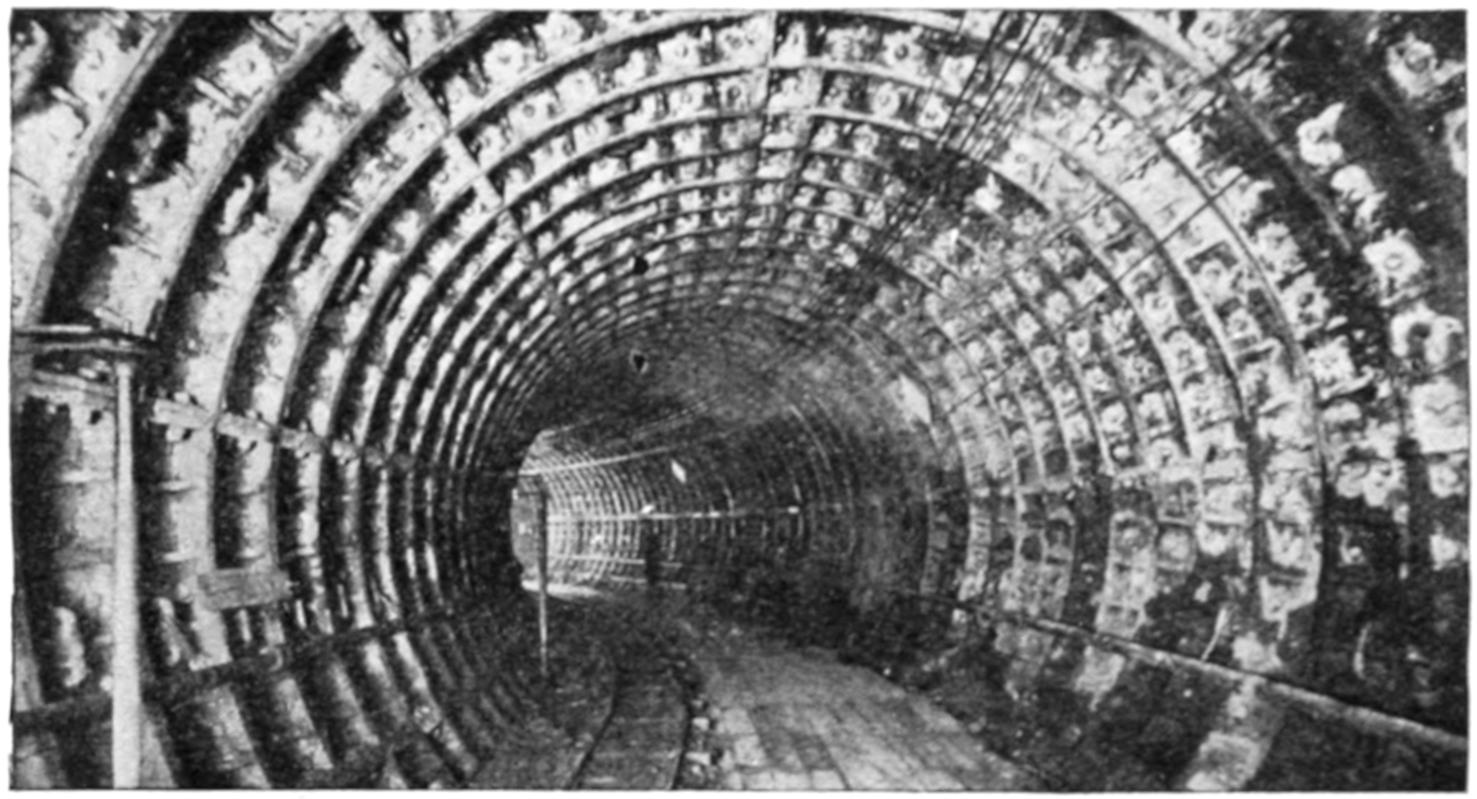

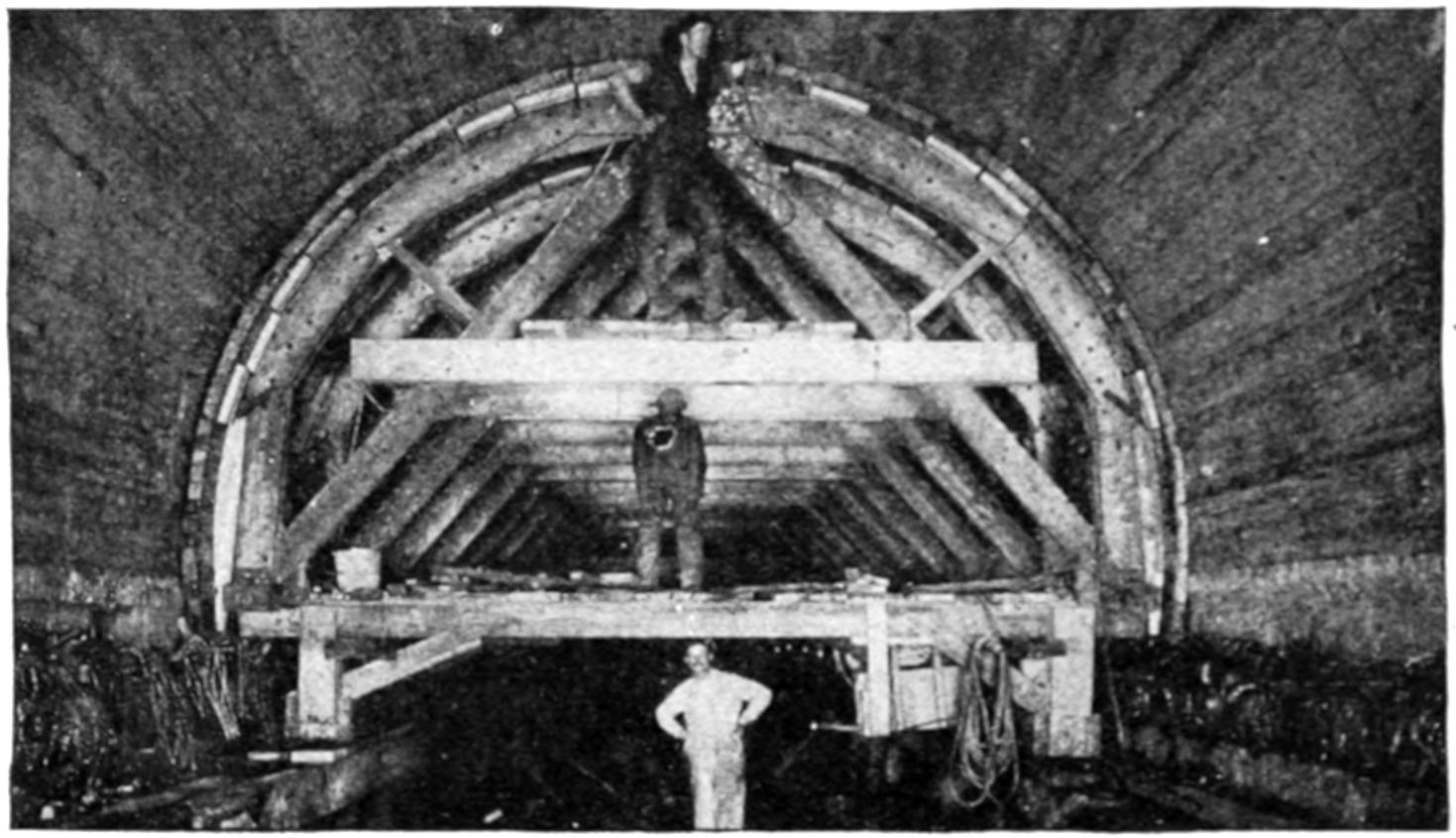

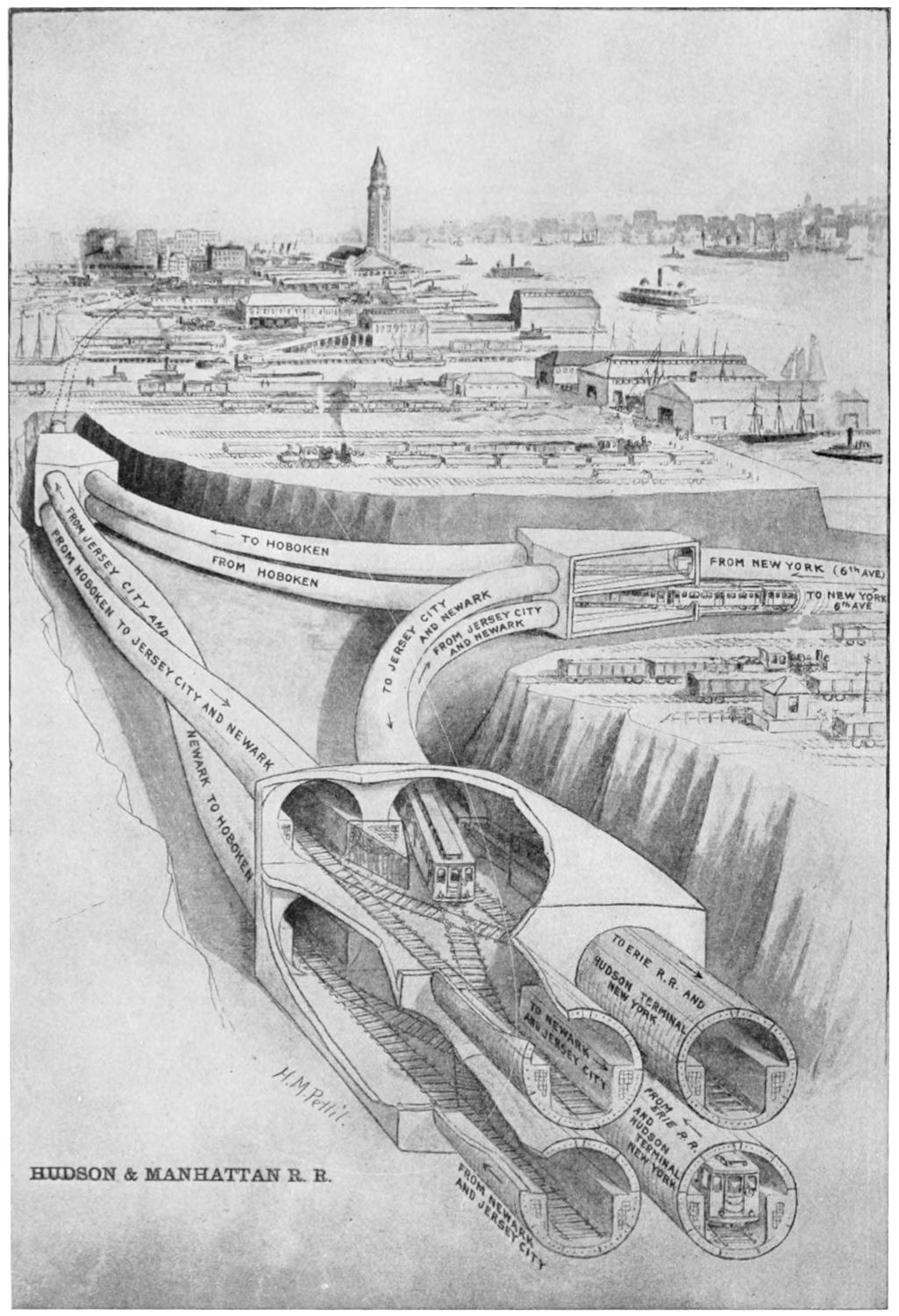

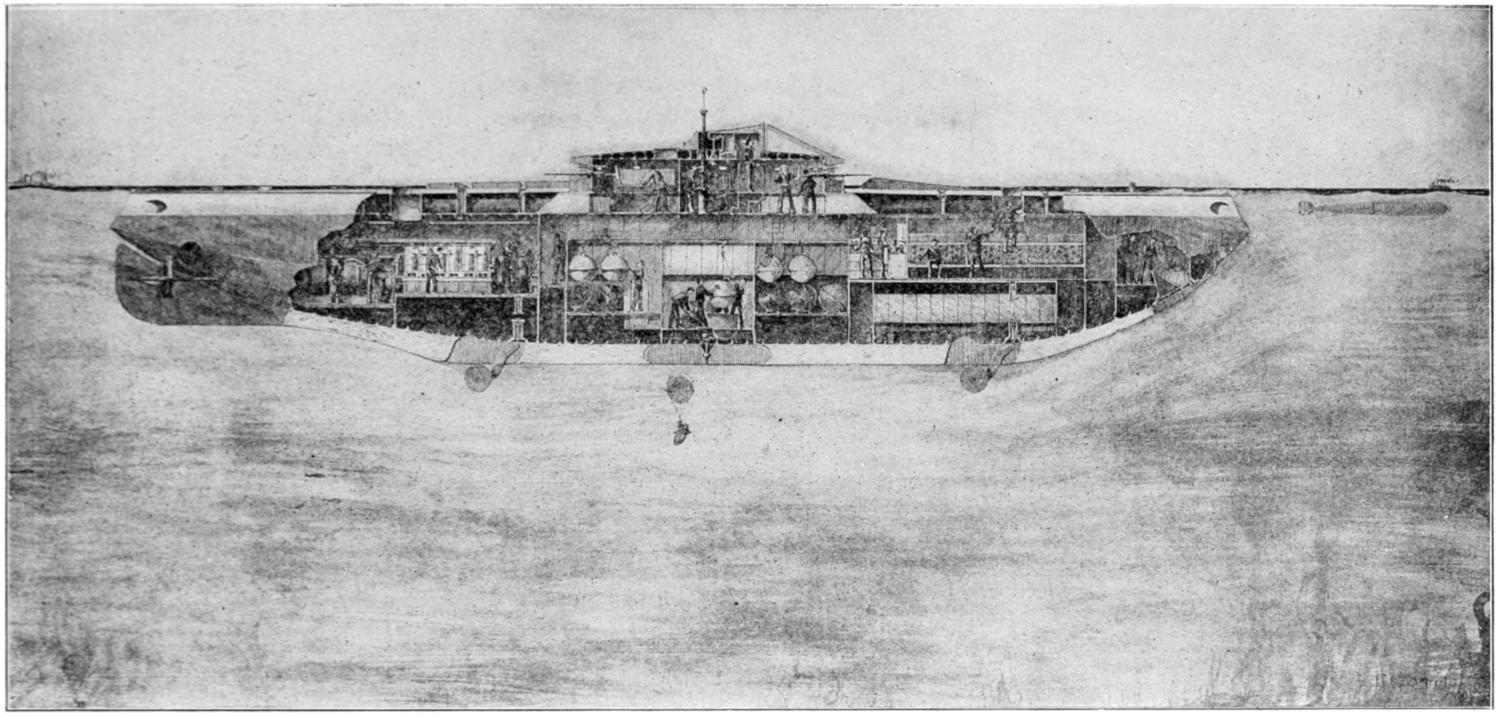

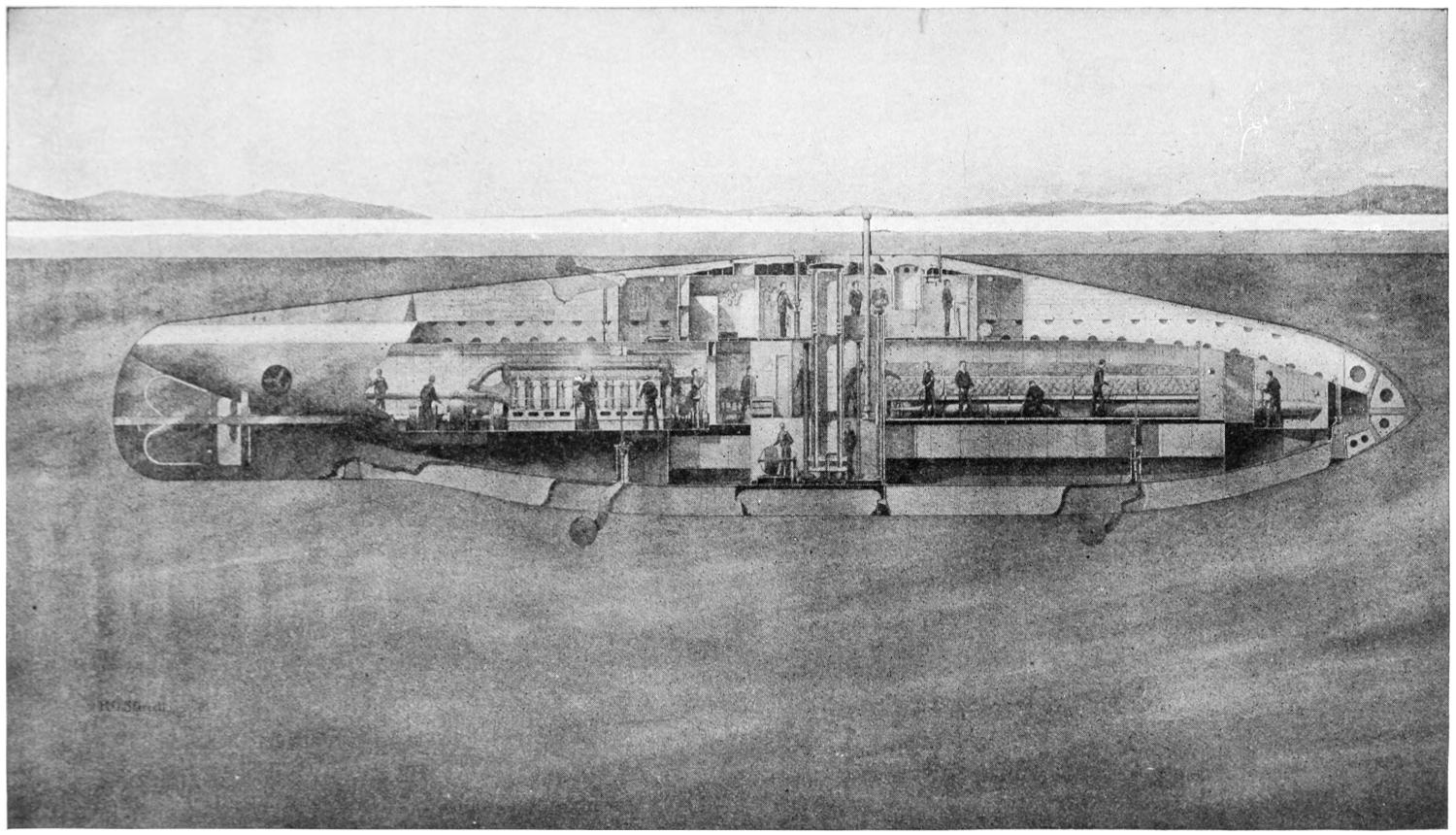

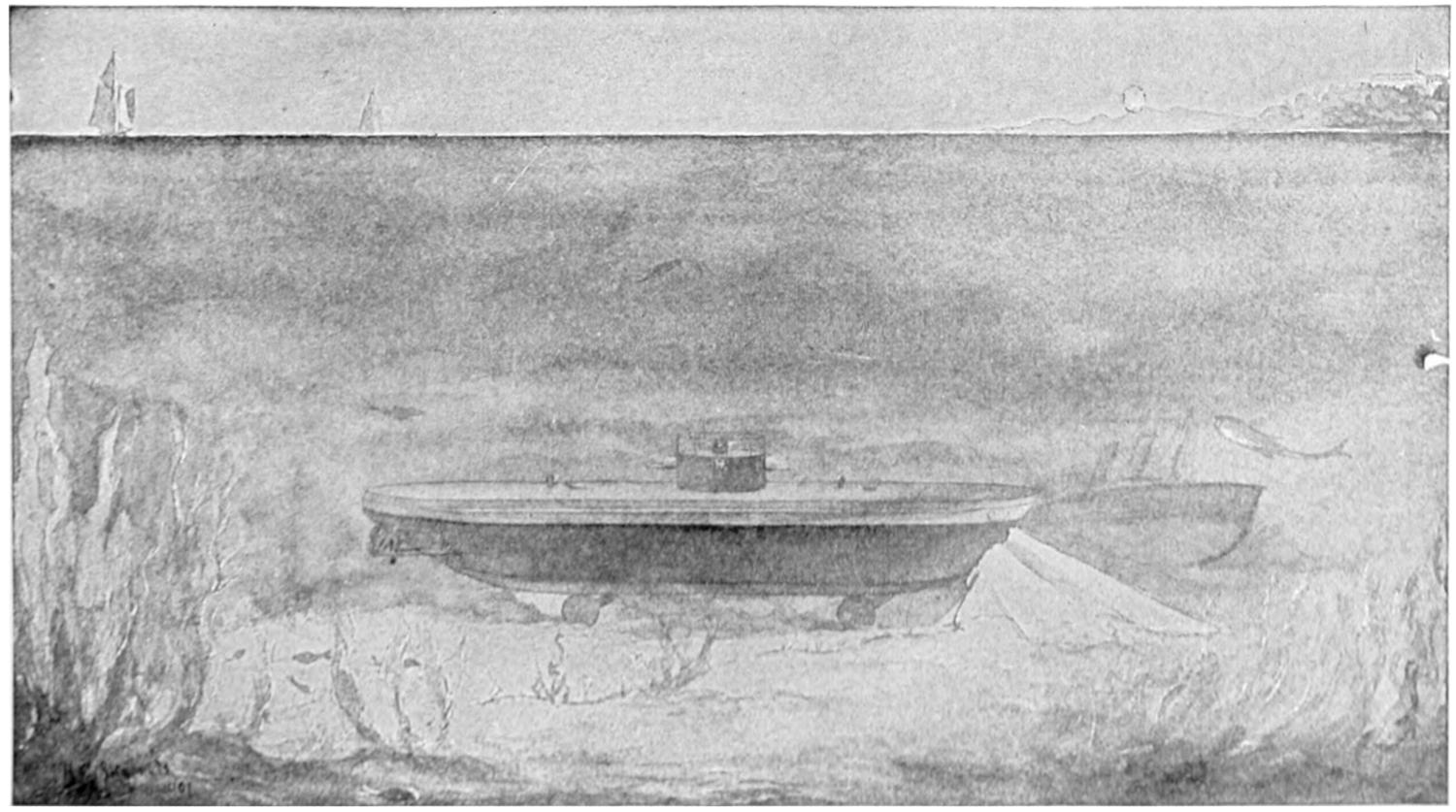

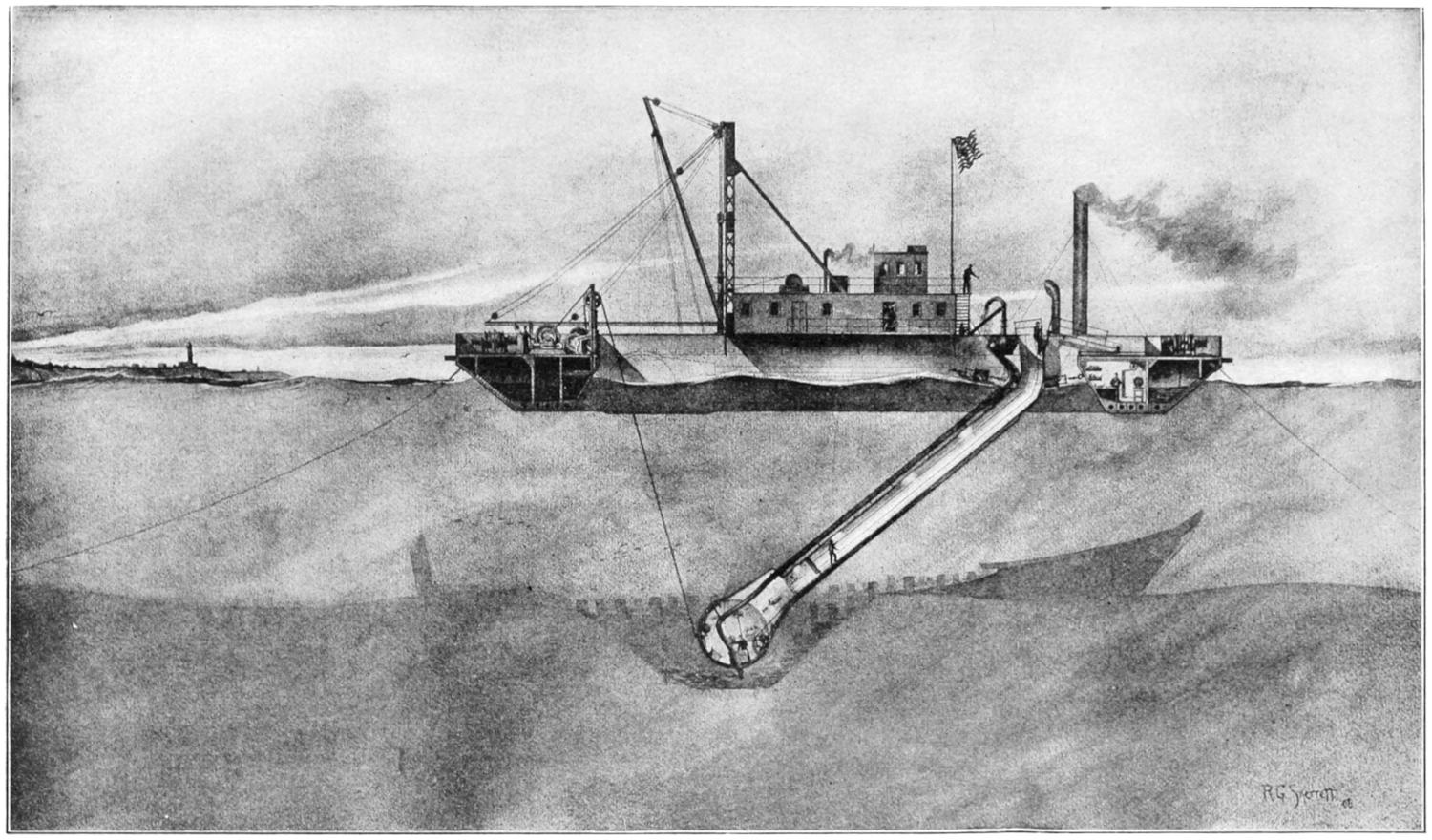

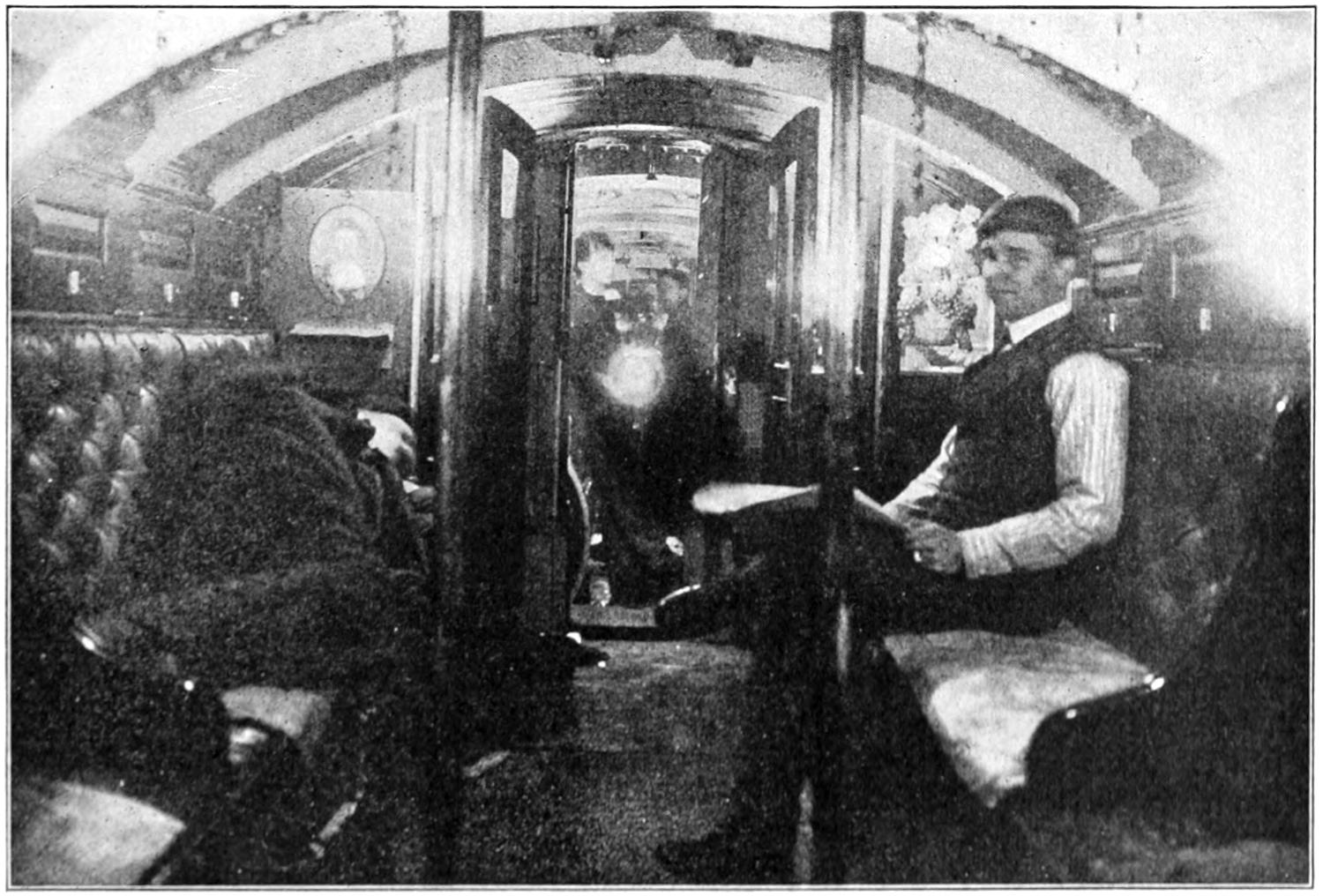

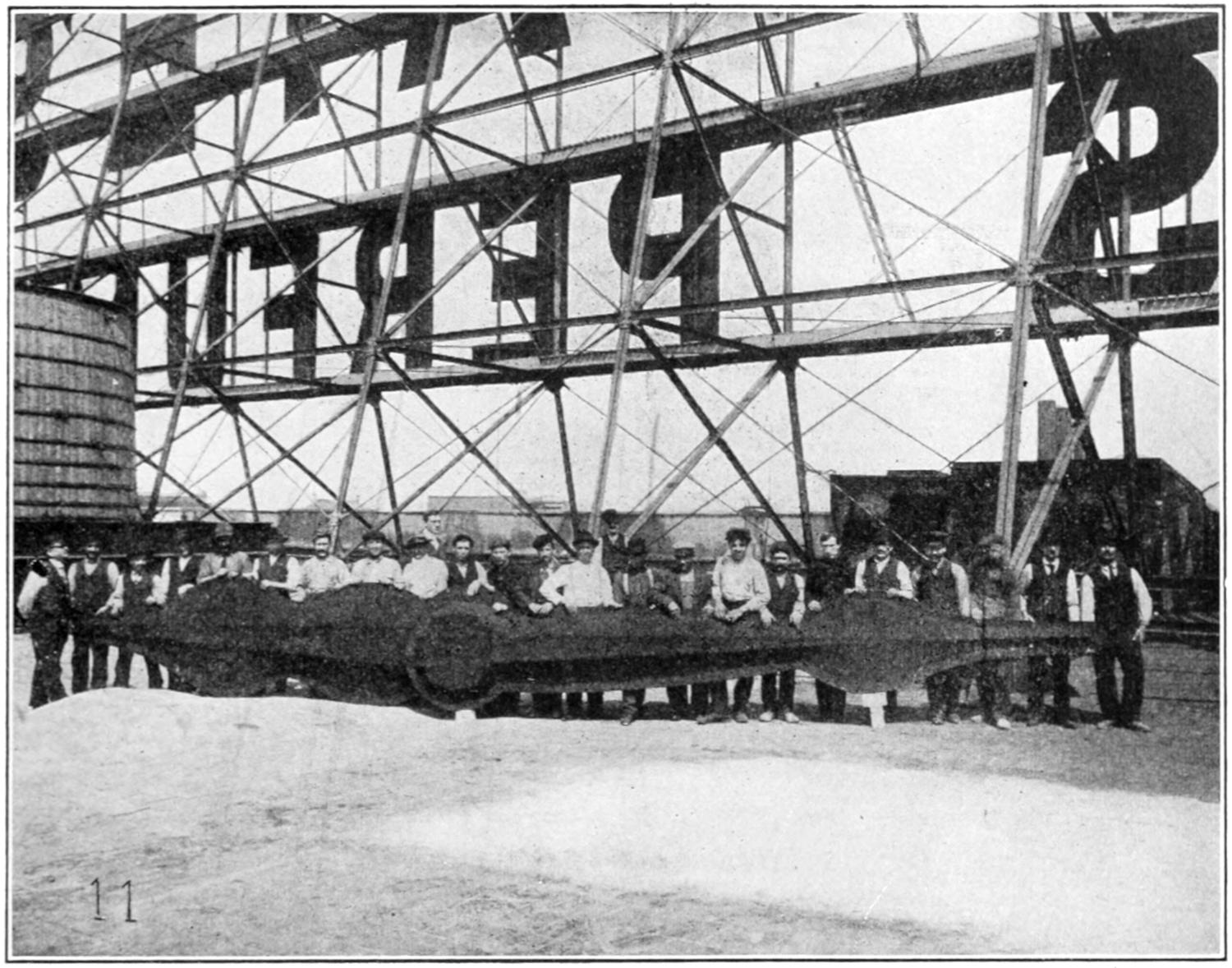

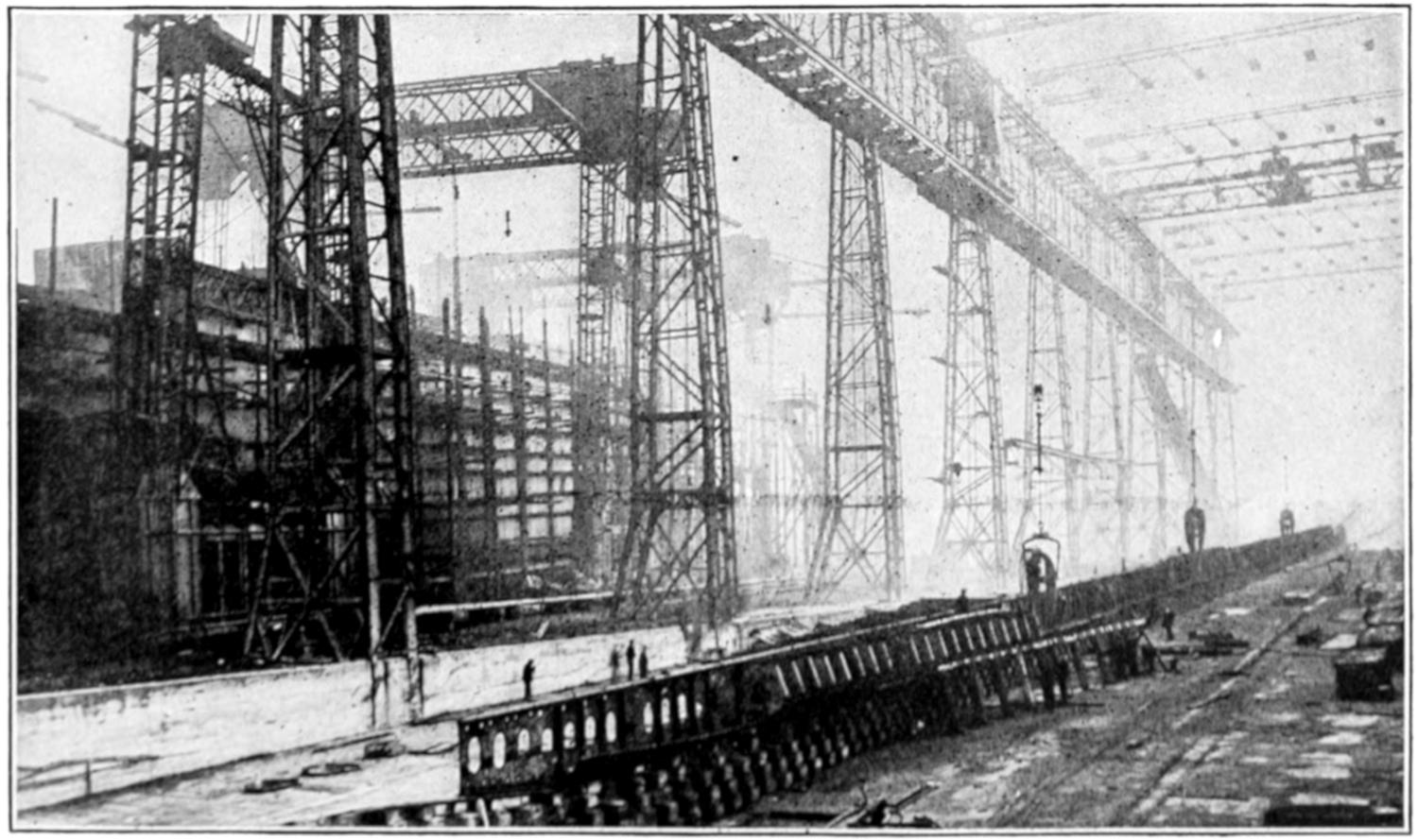

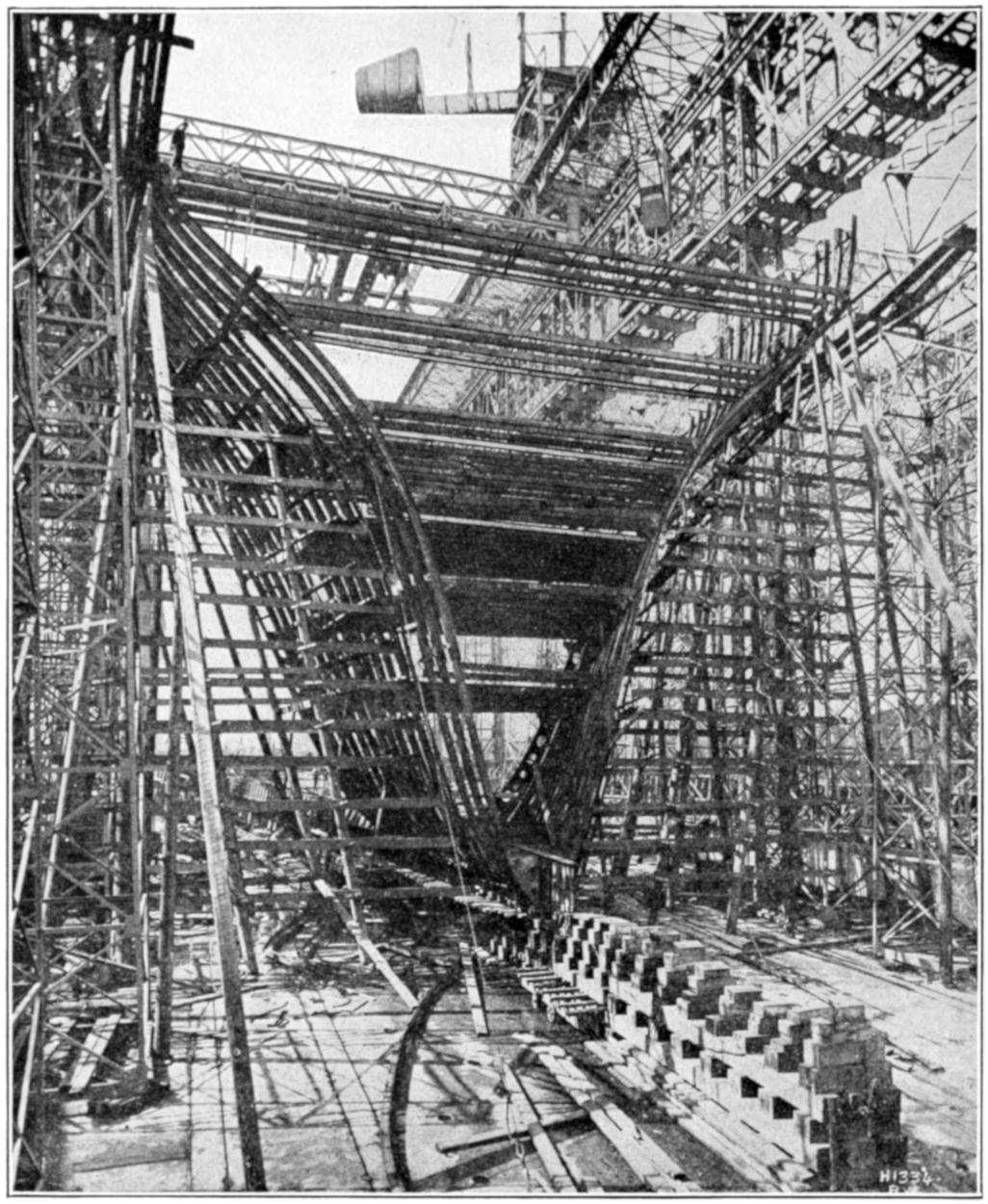

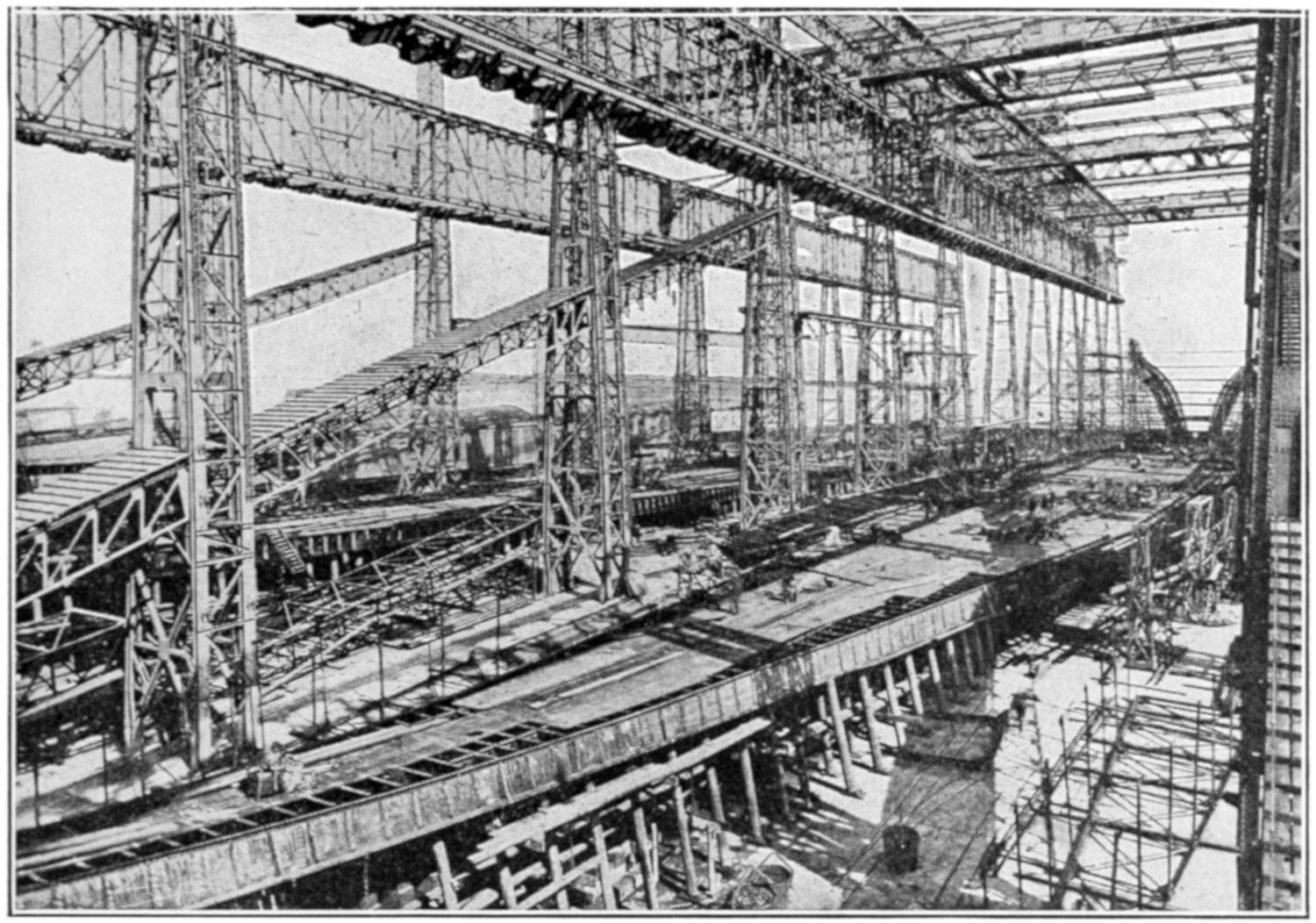

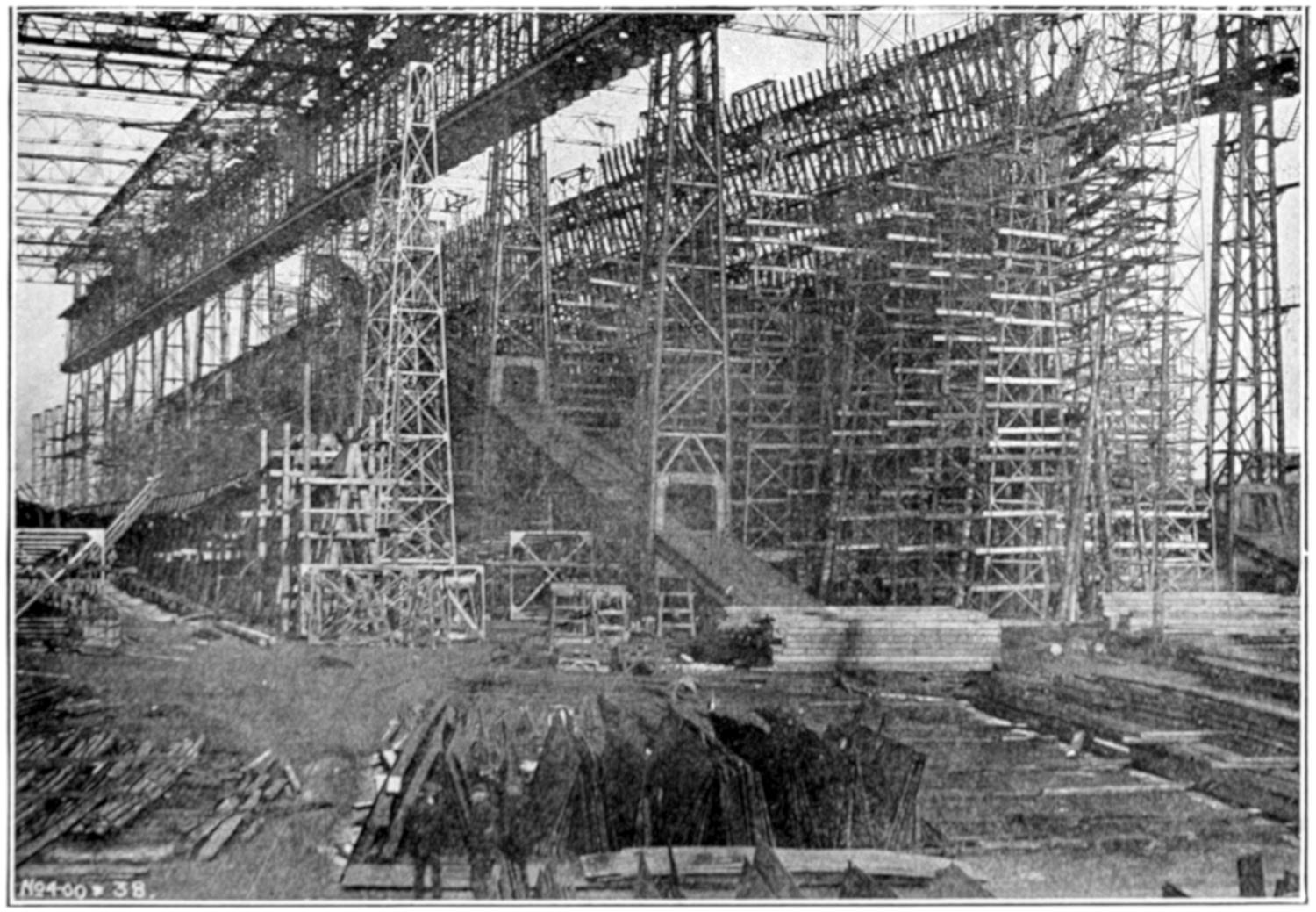

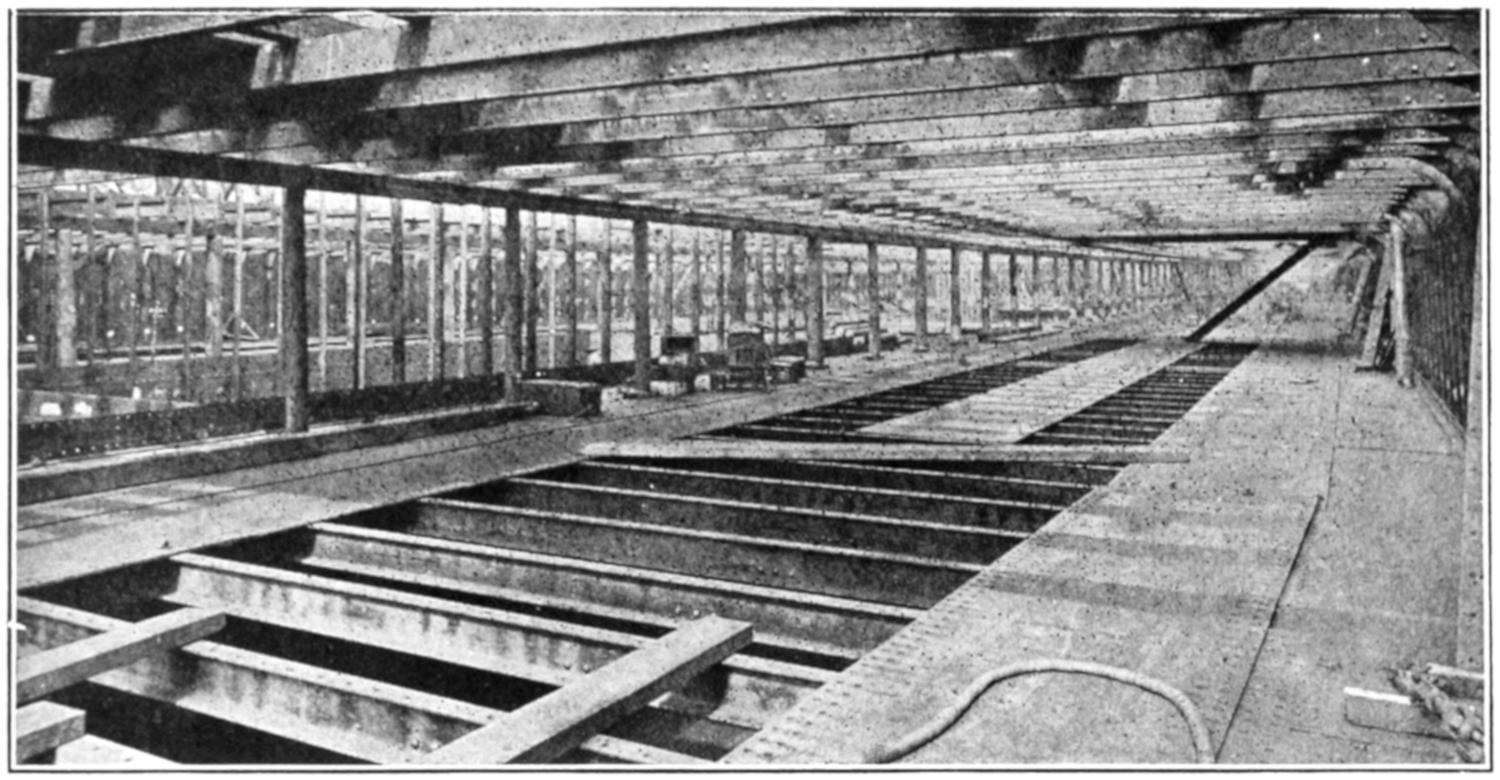

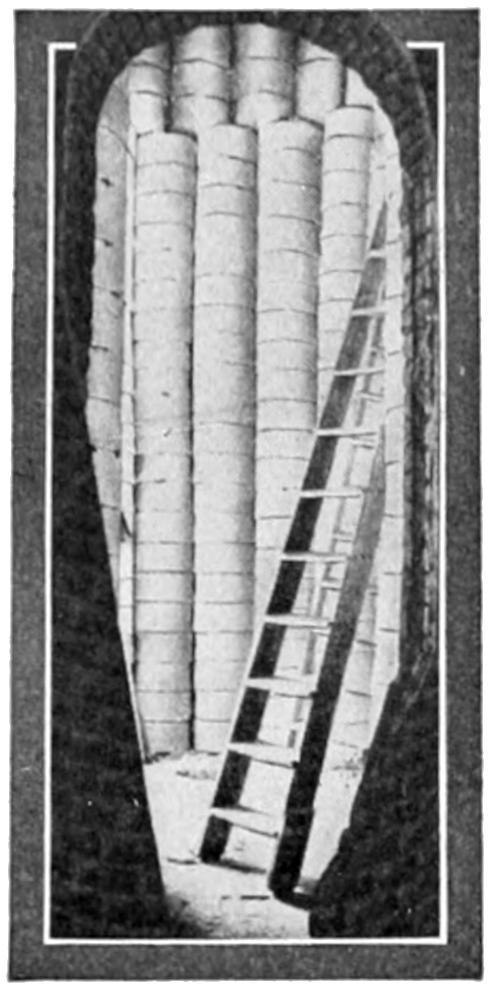

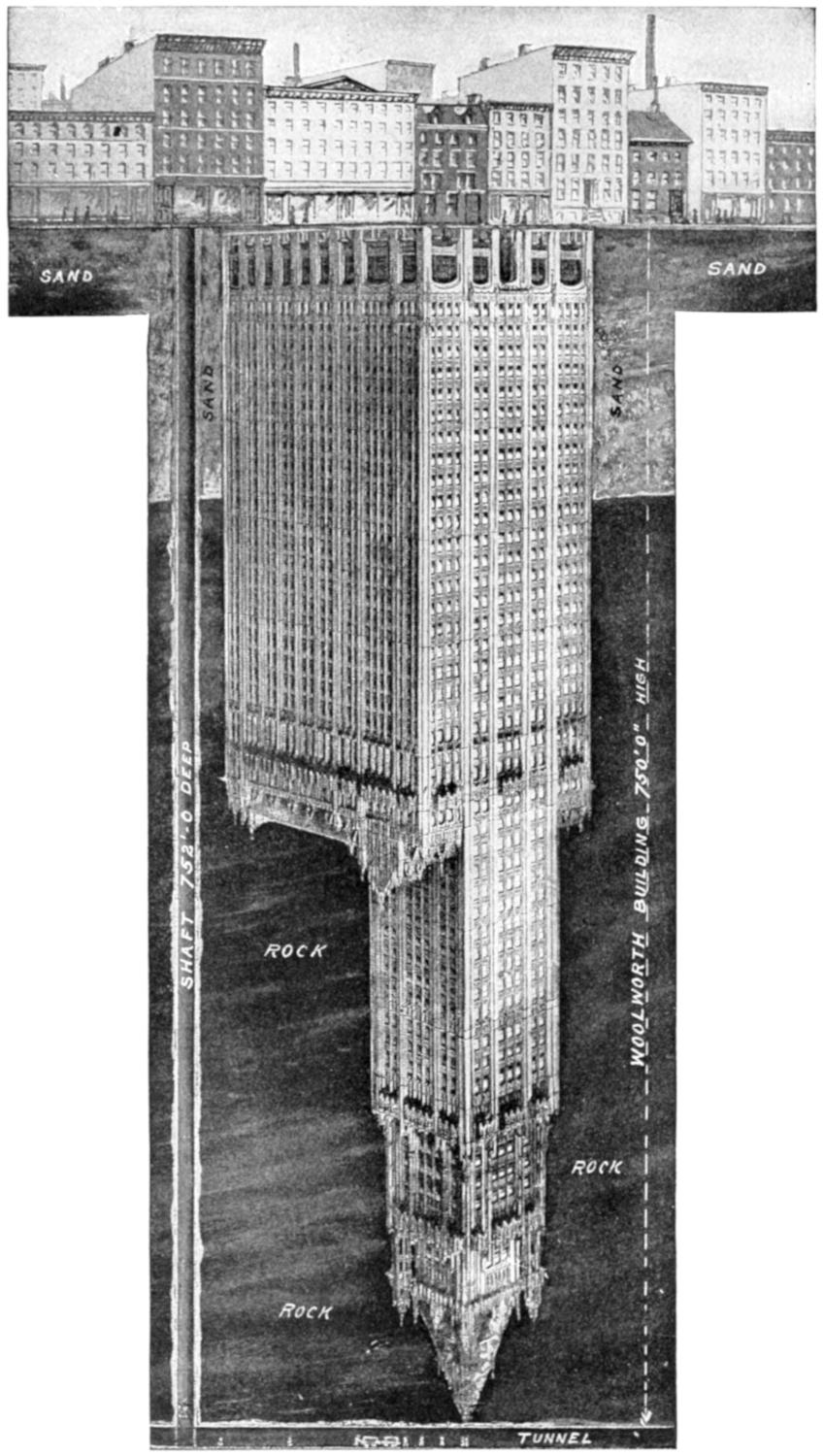

This is a picture of a section of one of the world’s greatest tunnels, showing how man has learned to construct great tubes of steel beneath the surface of the water and land, in which to run the swiftly moving trains which carry him rapidly from place to place.

THE

BOOK OF WONDERS

GIVES PLAIN AND SIMPLE ANSWERS TO THE

THOUSANDS OF EVERYDAY QUESTIONS

THAT ARE ASKED AND WHICH ALL SHOULD

BE ABLE TO, BUT CANNOT ANSWER

FULLY ILLUSTRATED WITH HUNDREDS OF EDUCATIONAL PICTURES

WHICH STIMULATE THE MIND AND GIVE A

BIRD’S EYE VIEW OF THE

WONDERS OF NATURE

and the

WONDERS PRODUCED BY MAN

Edited and Arranged by

RUDOLPH J. BODMER

Fully Indexed

1915

PRESBREY SYNDICATE, Inc.

456 Fourth Avenue

NEW YORK

Copyright, 1914

BY

PRESBREY SYNDICATE, Inc.

[9]

No truly great book needs an explanation of its aim and purpose. A great book just grows, as has this Book of Wonders.

It began with the attempt of a father to answer the natural questions of the active mind of a growing boy. It developed into a nightly search for plain, understandable answers to such questions as “What makes it night?” “Where does the wind begin?” “Why is the sky blue?” “Why does it hurt when I cut my finger?” “Why doesn’t it hurt when I cut my hair?” “Why does wood float?” “Why does iron sink?” “Why doesn’t an iron ship sink?” on through the maze of thousands of puzzling questions which occur to the child’s mind. It has grown until the answers to the mere questions cover practically the entire range of every-day knowledge, and has been arranged in such a form that any child may now find the answer to his own inquiries.

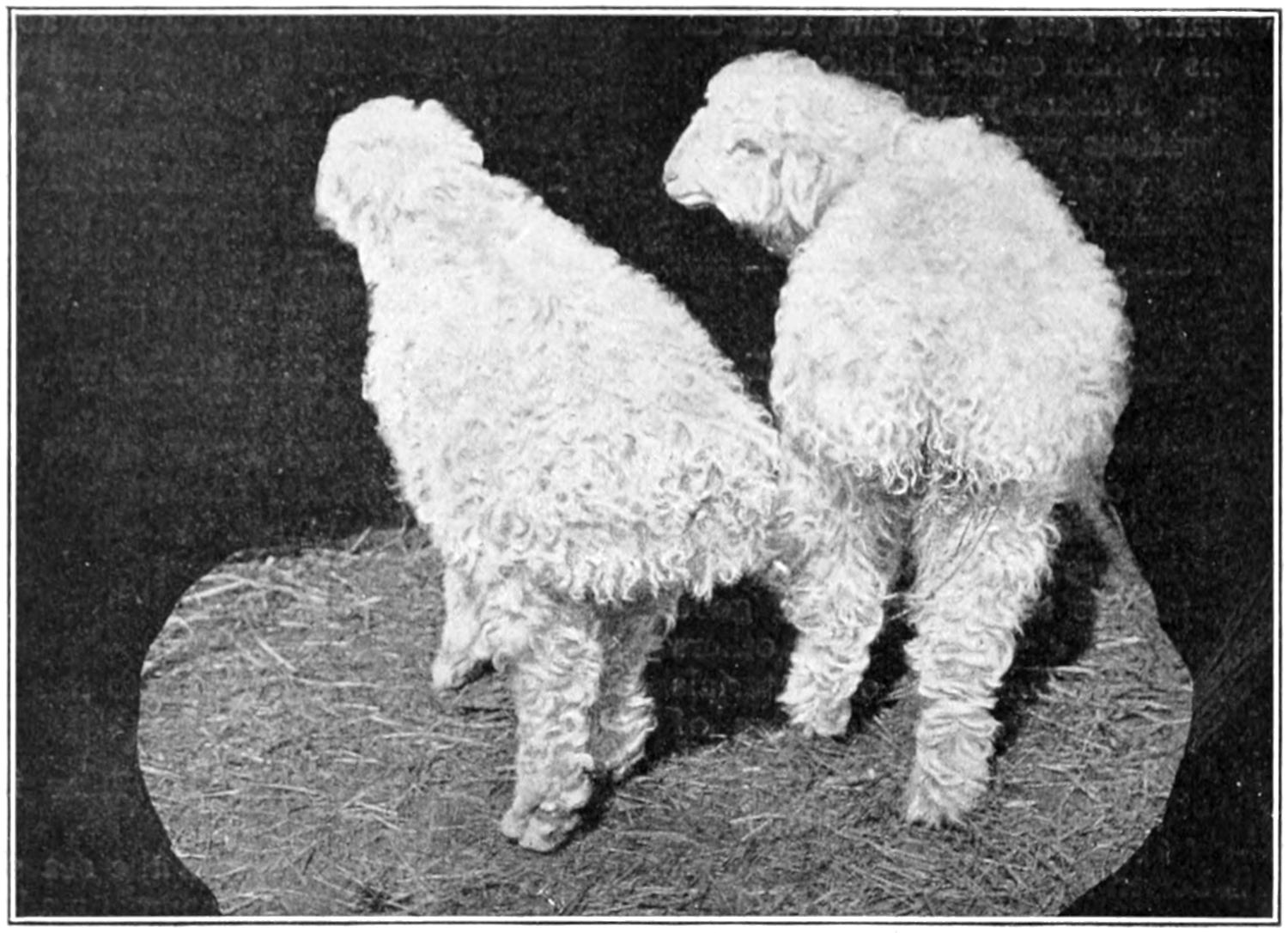

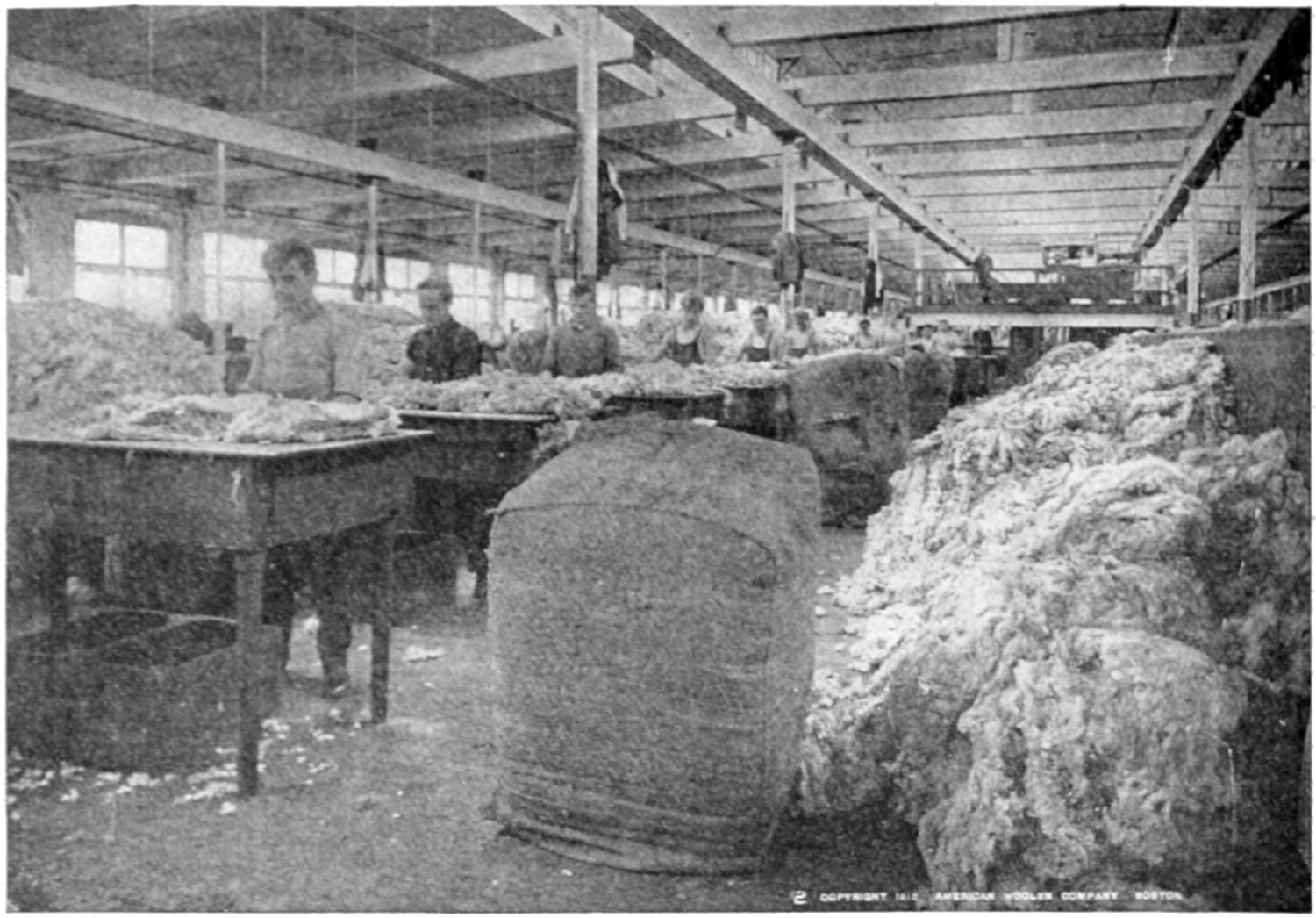

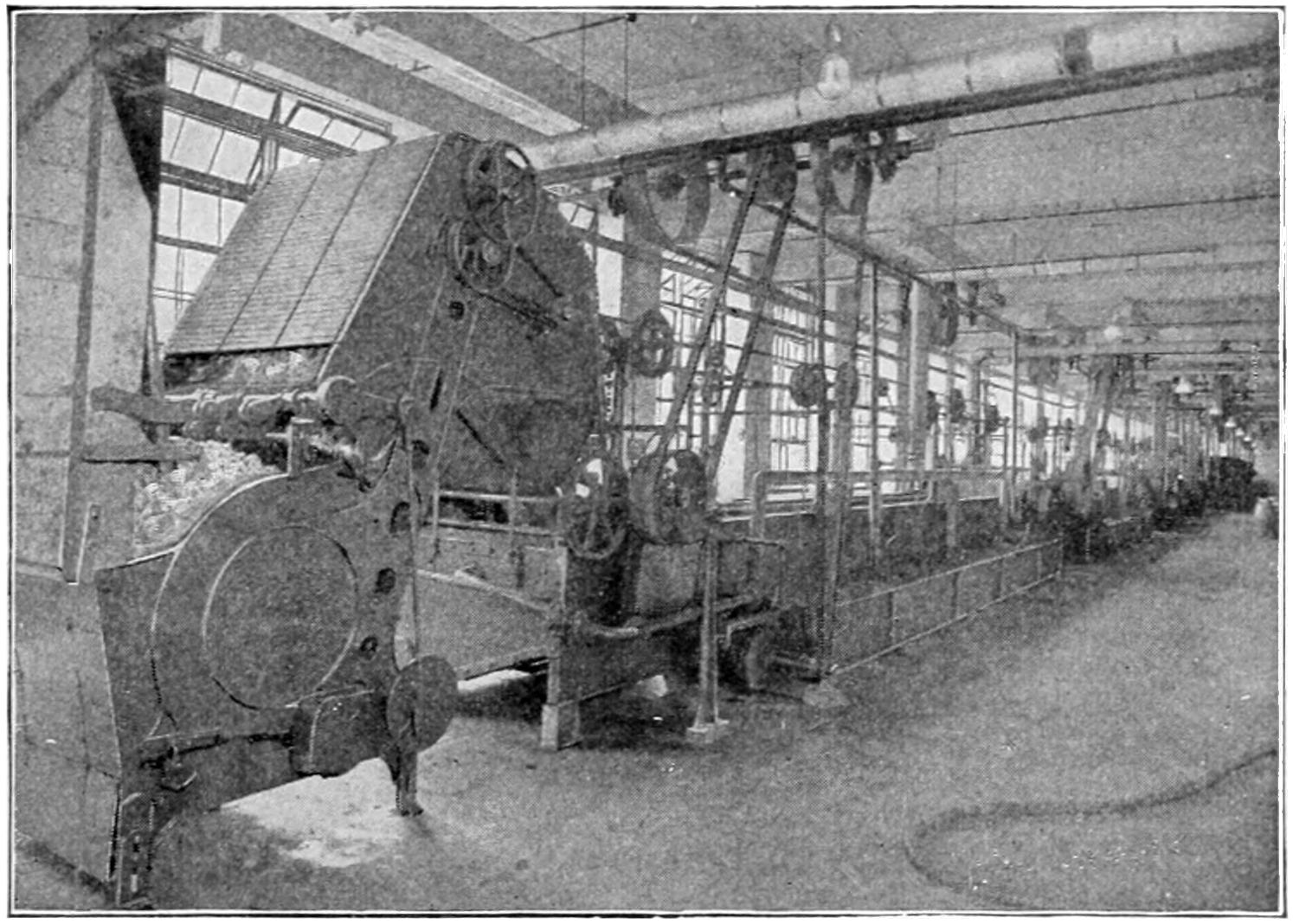

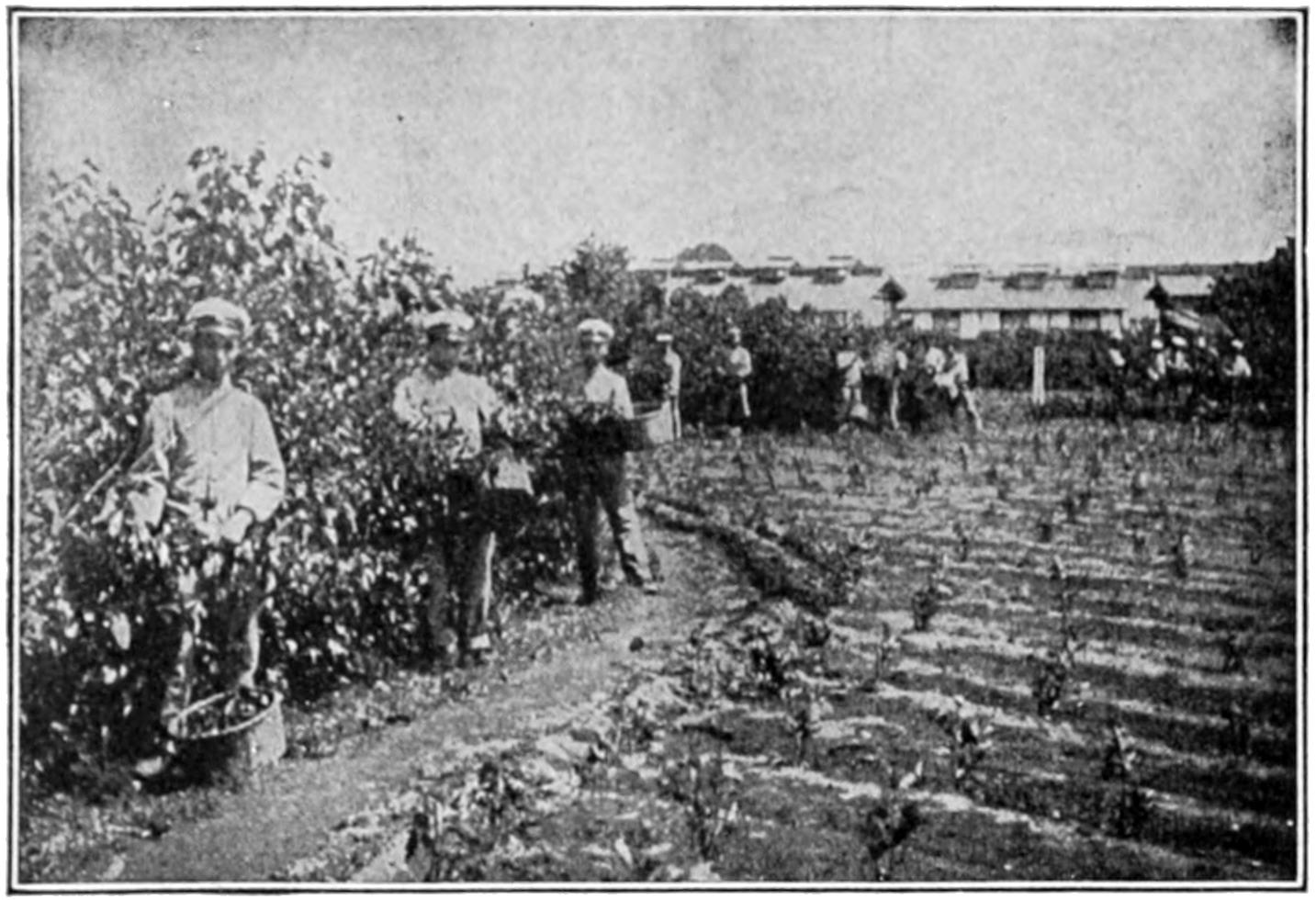

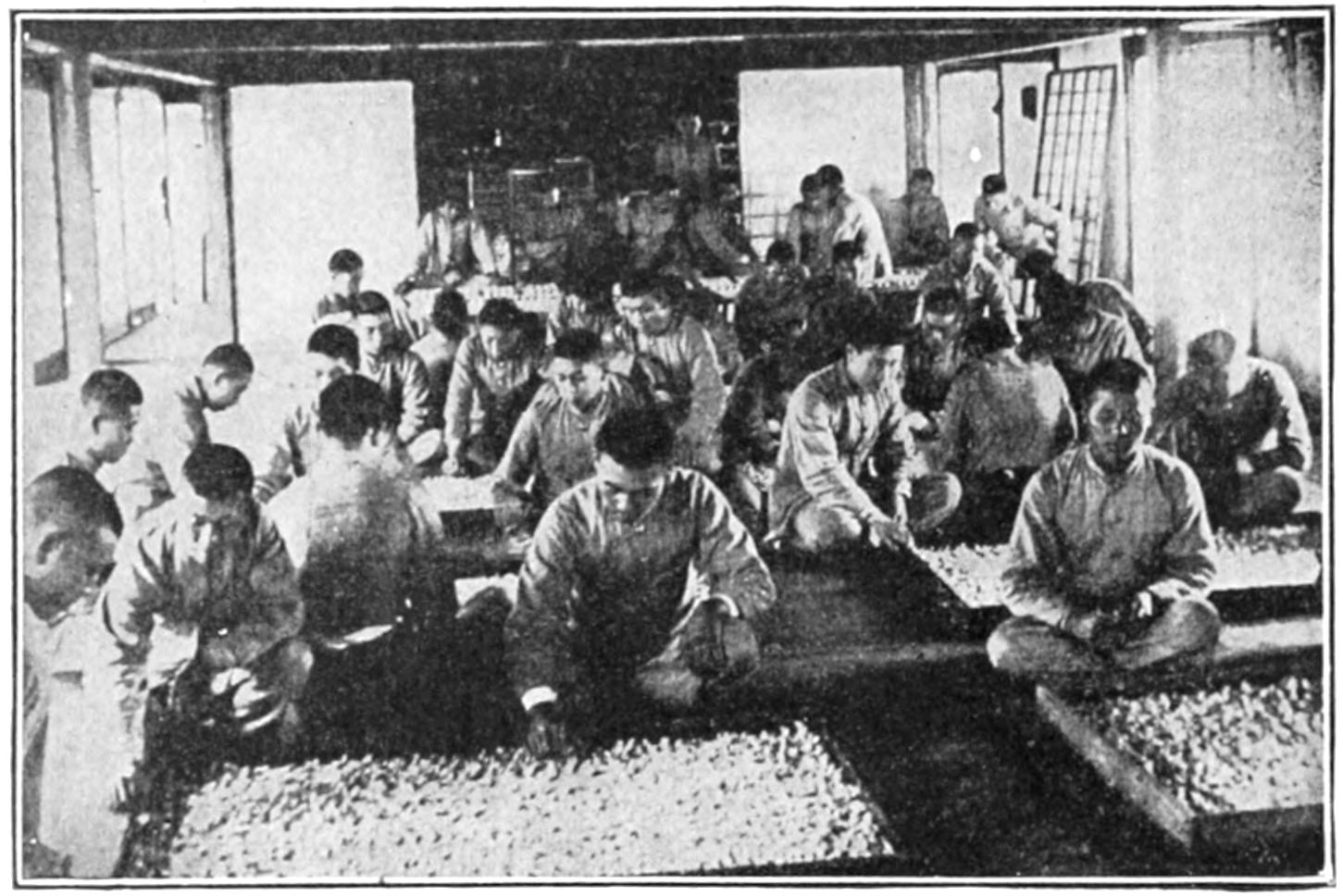

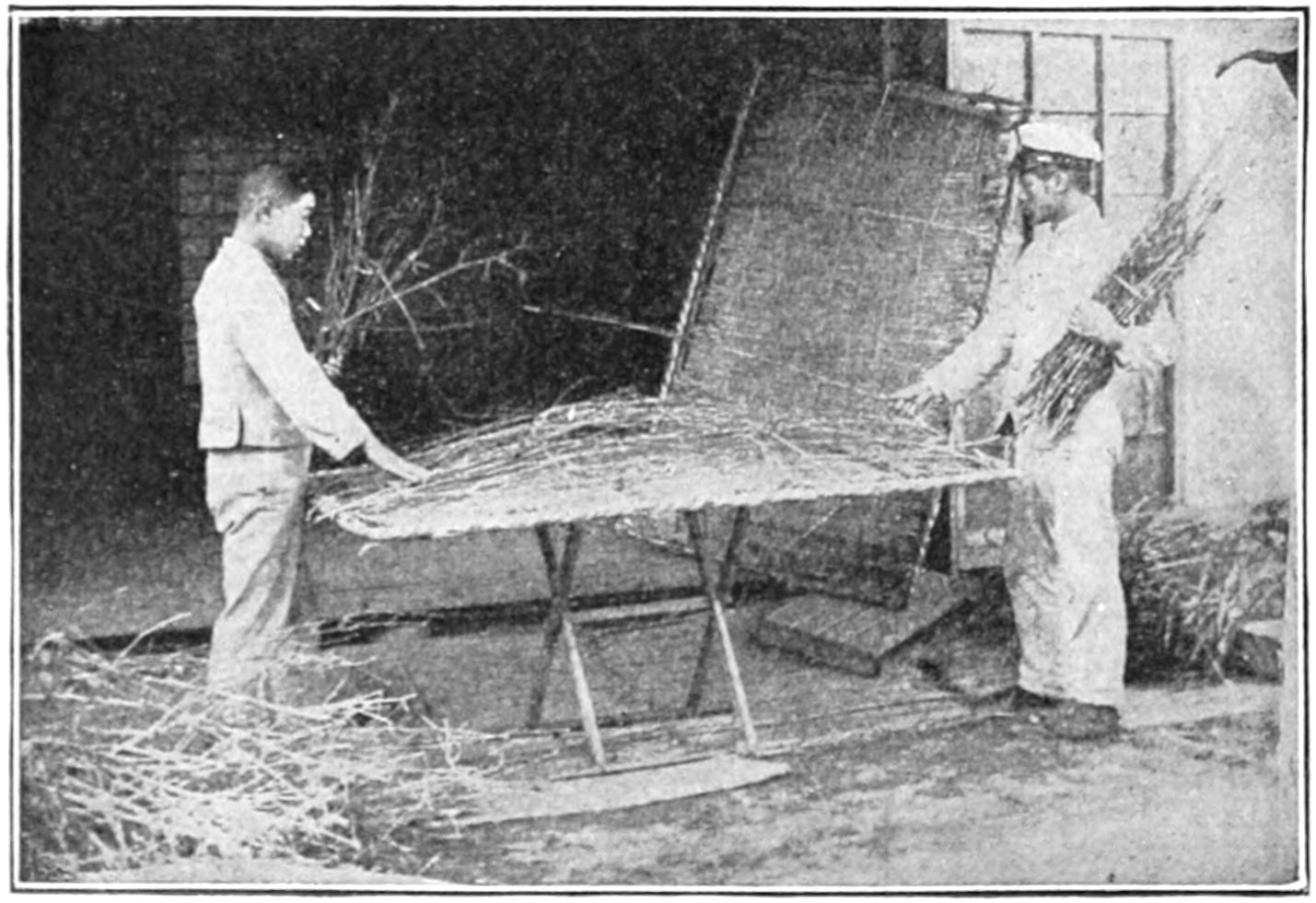

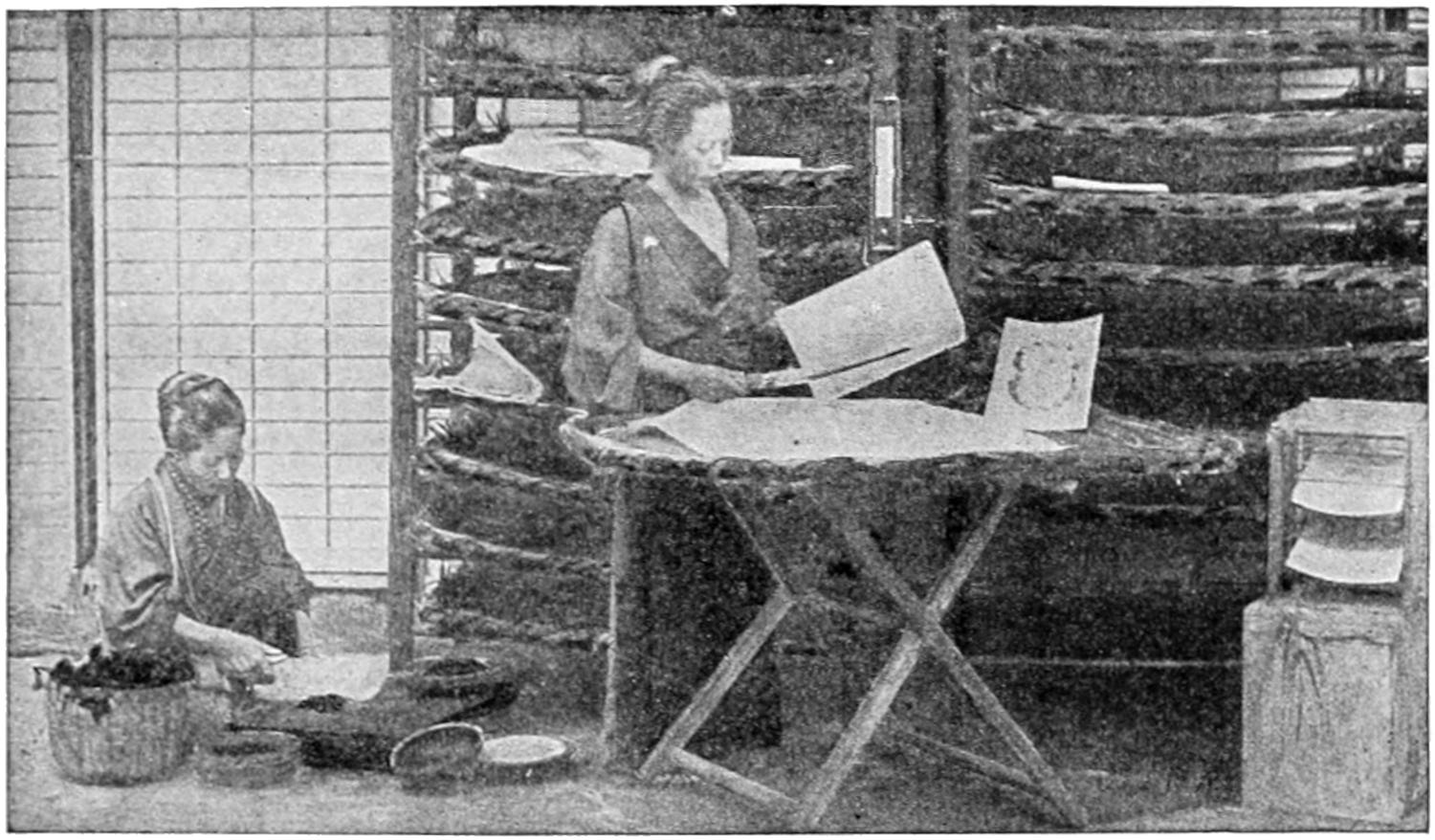

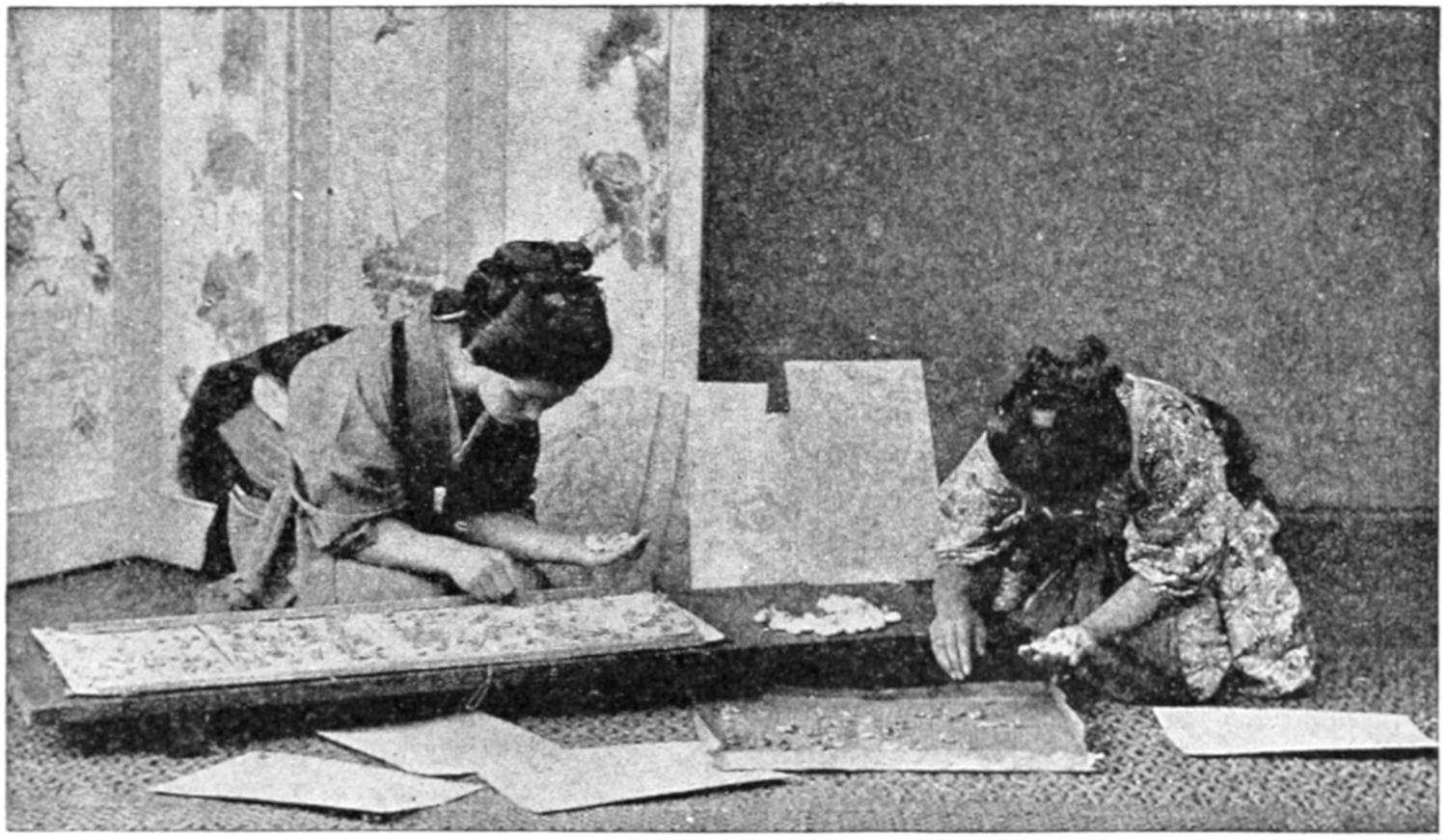

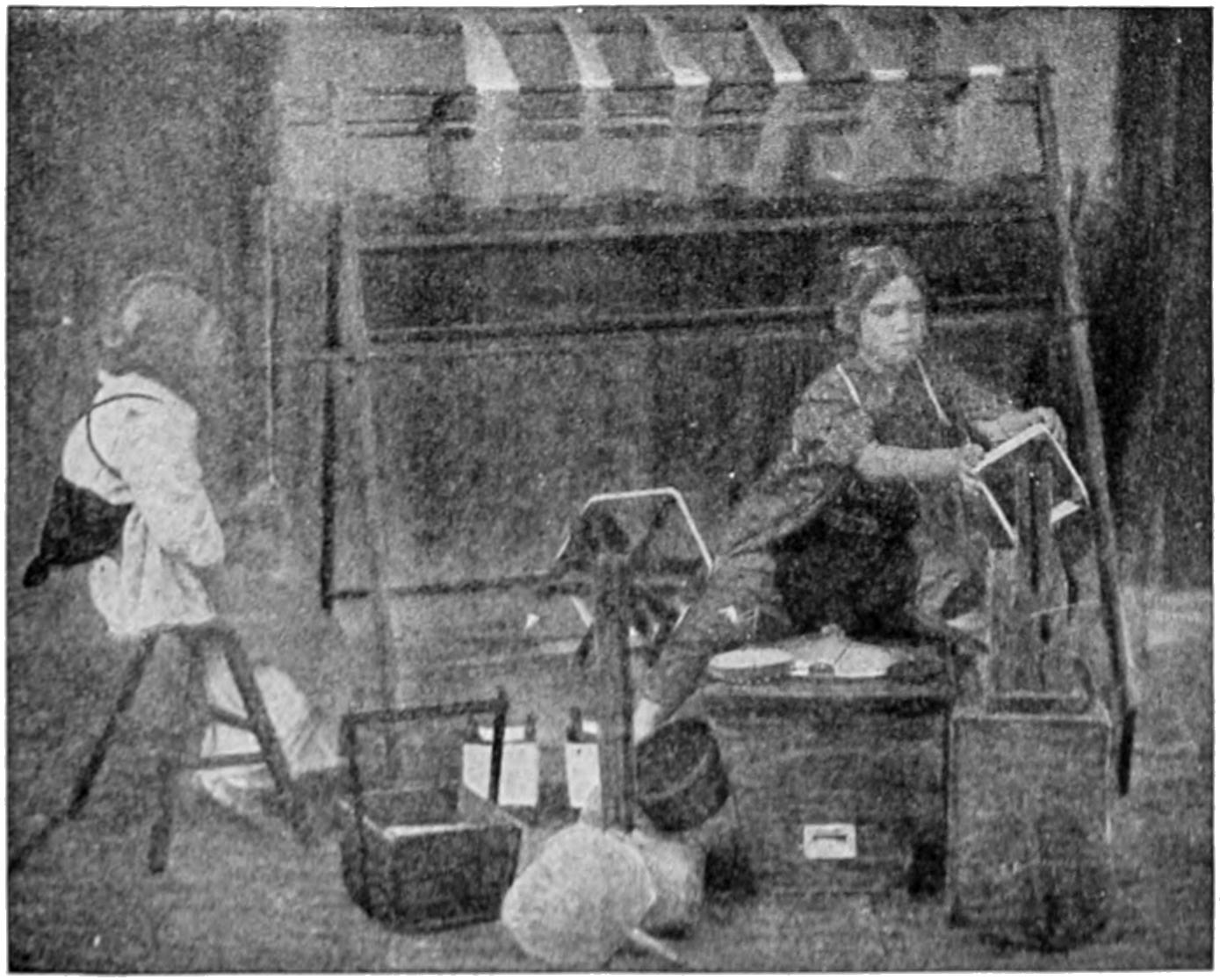

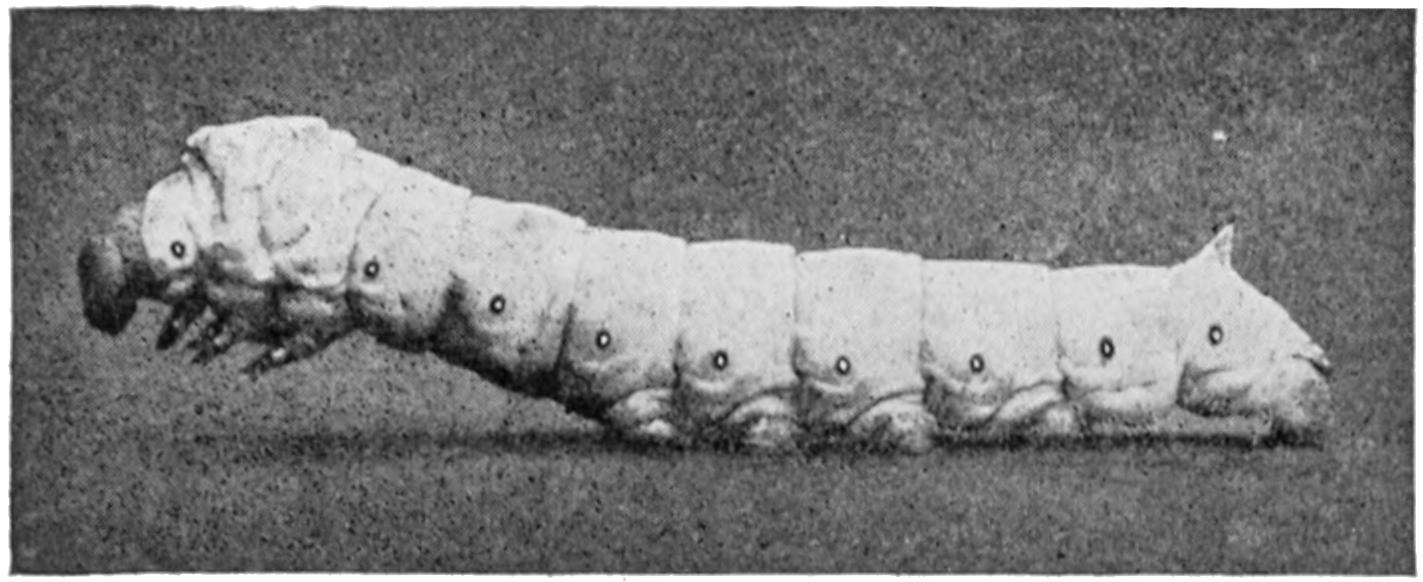

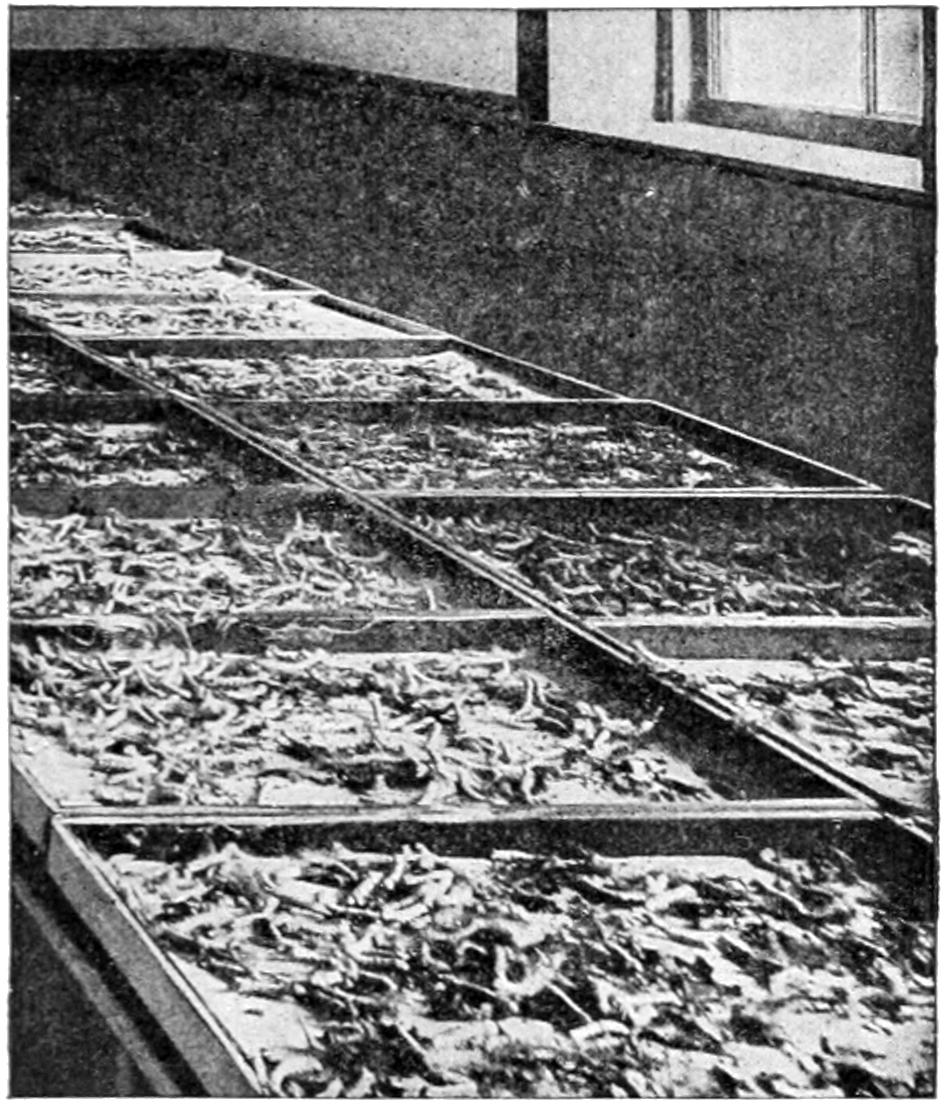

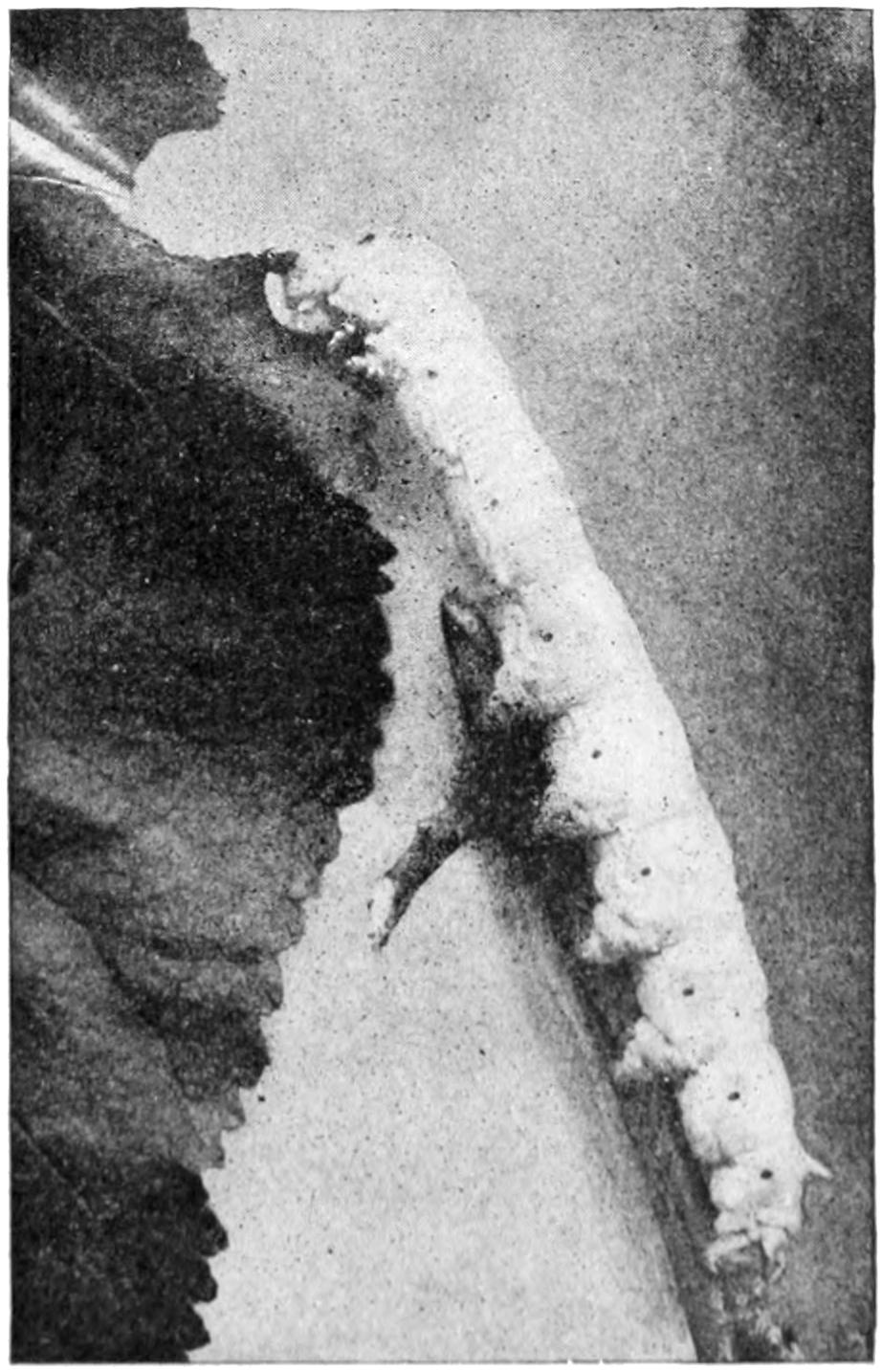

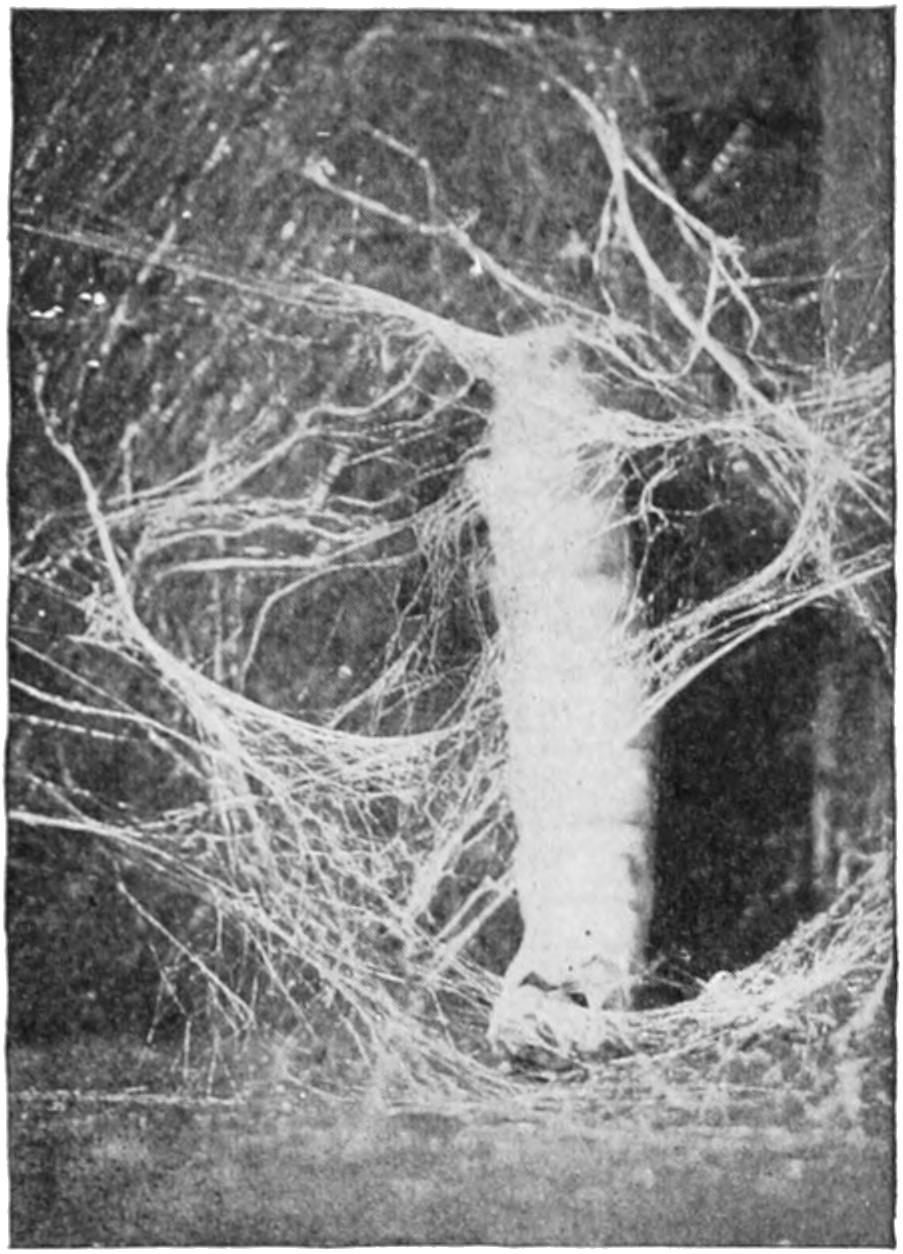

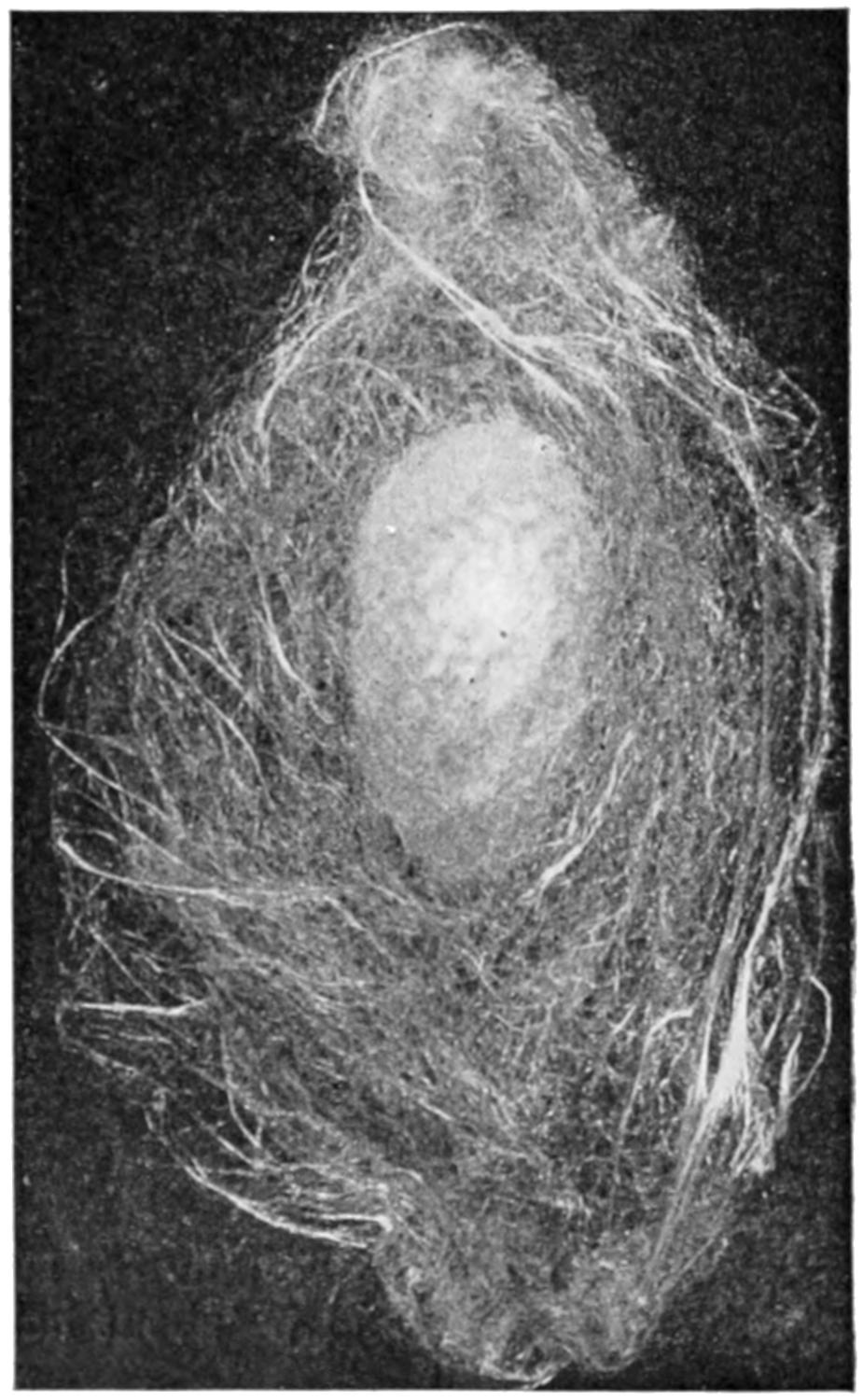

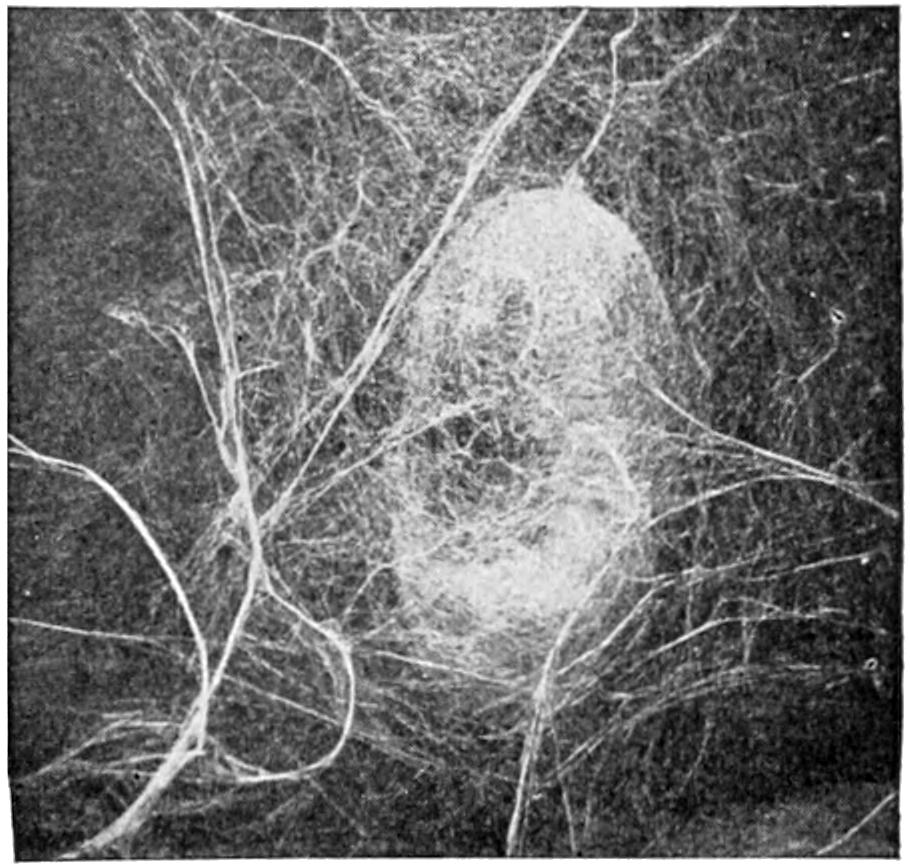

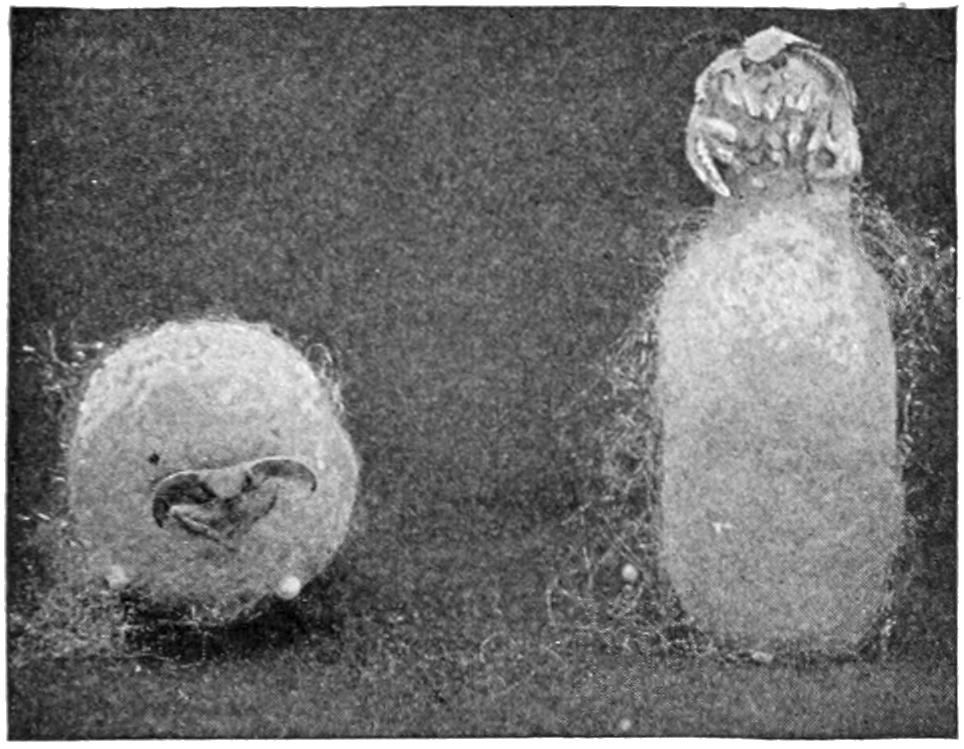

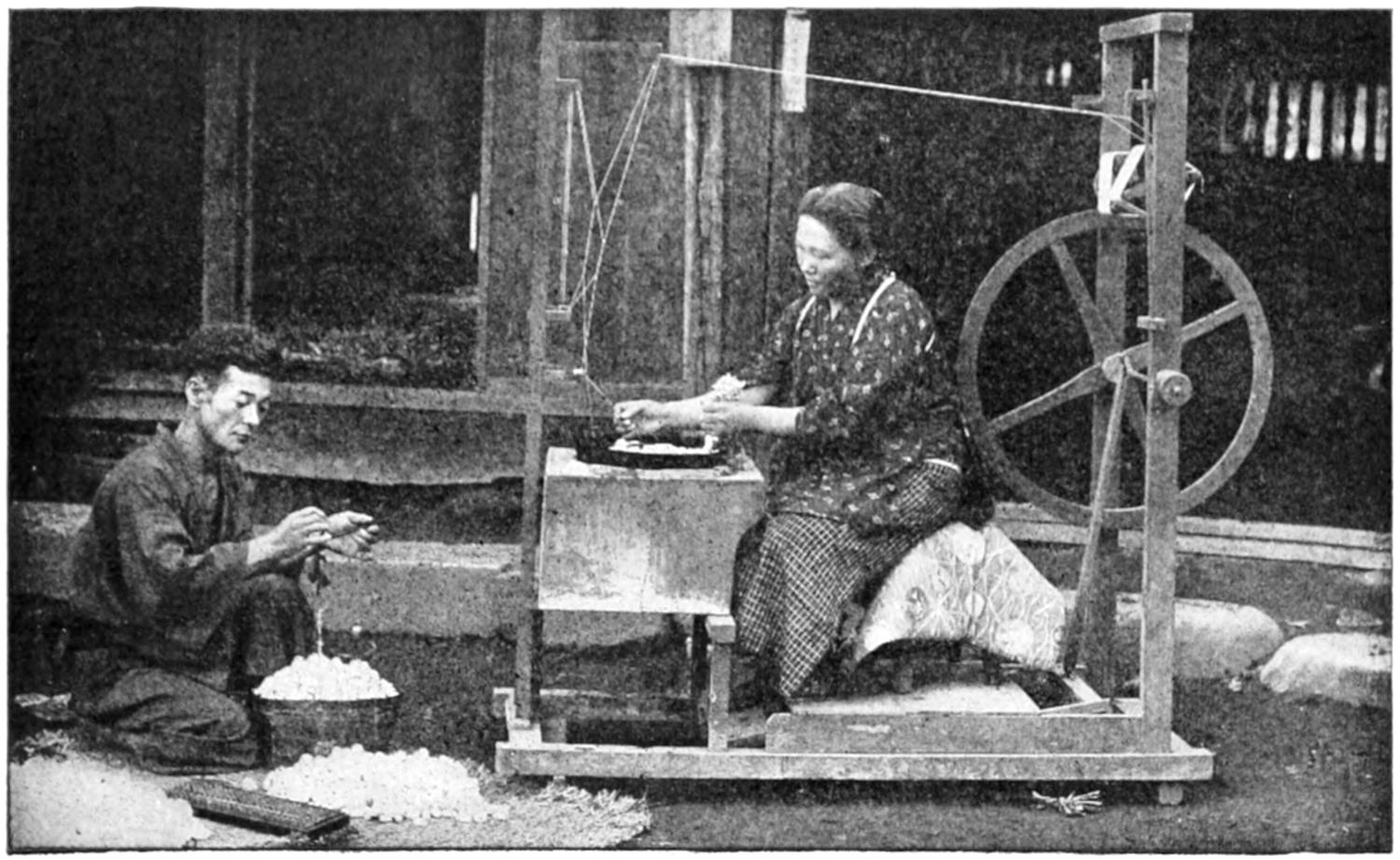

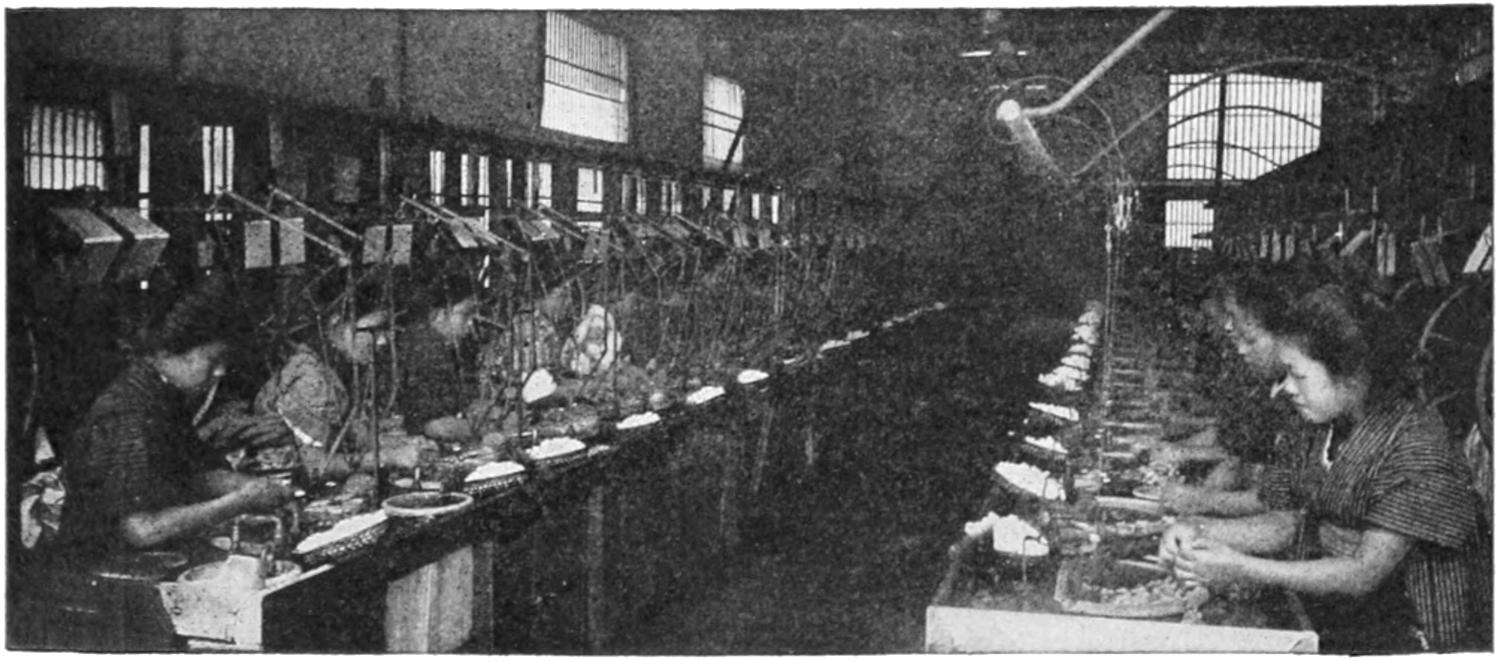

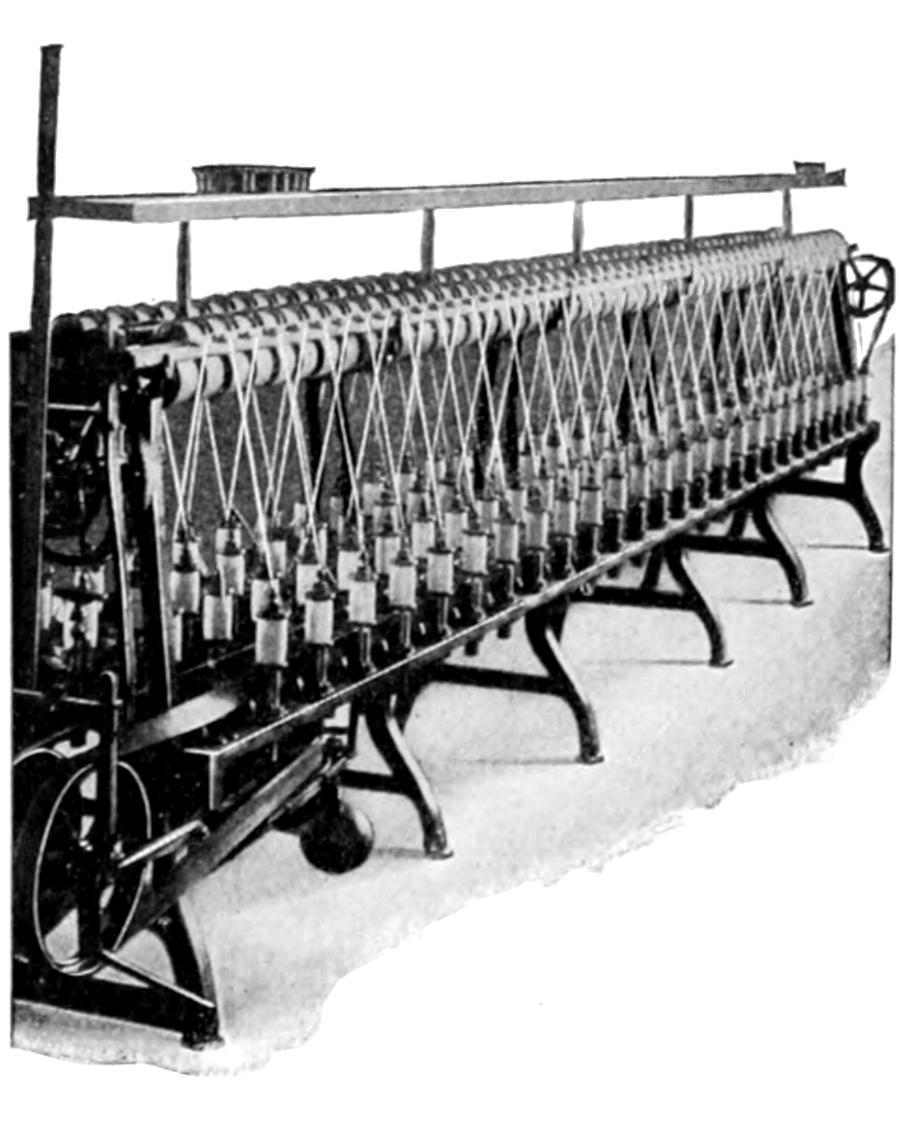

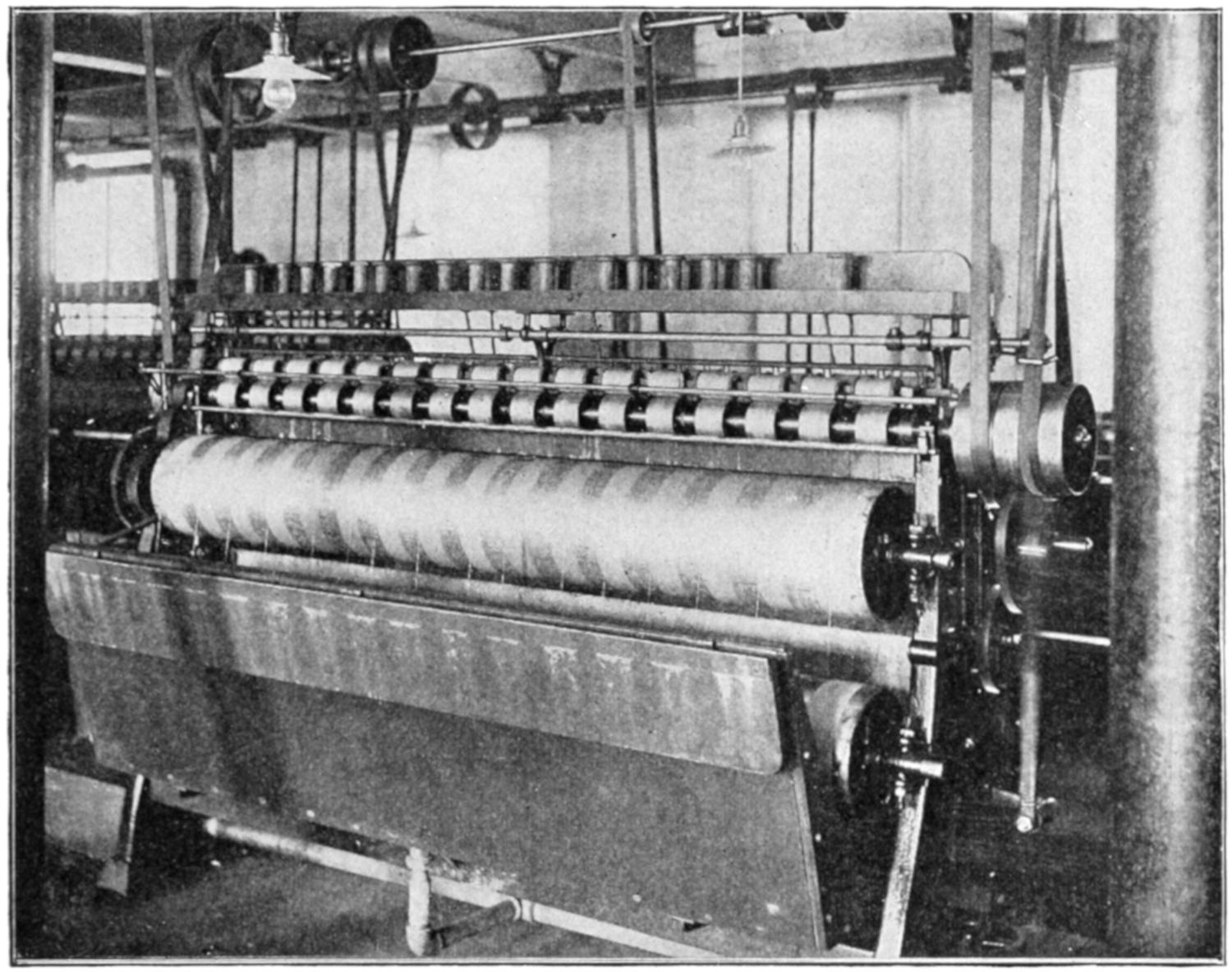

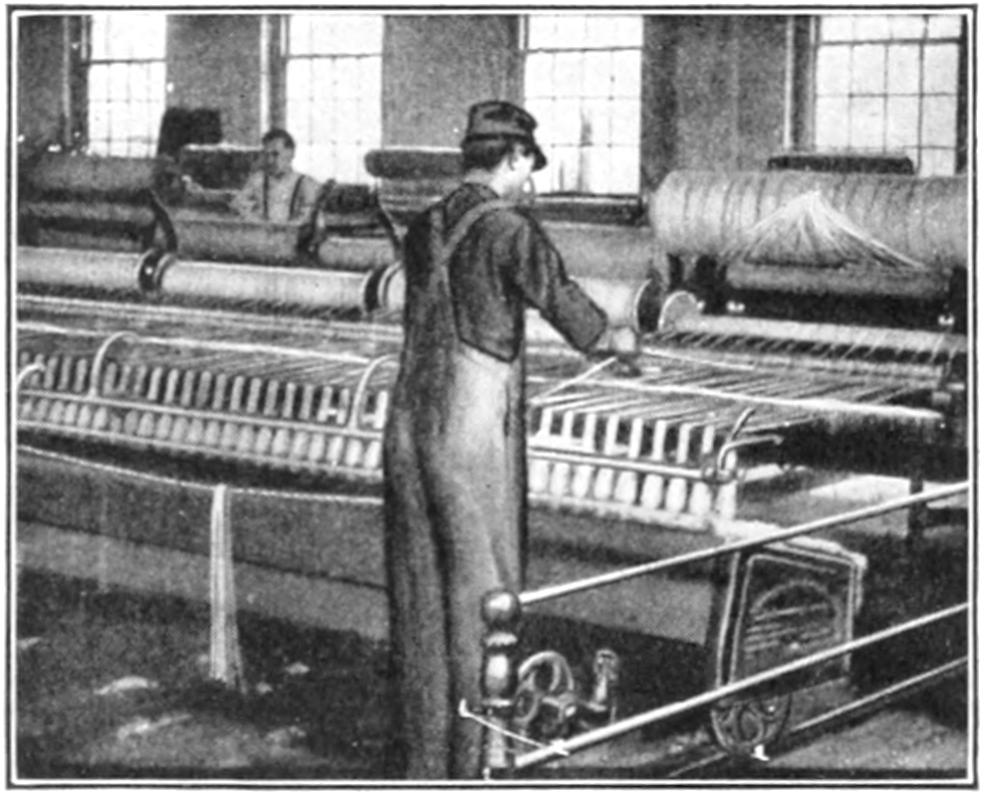

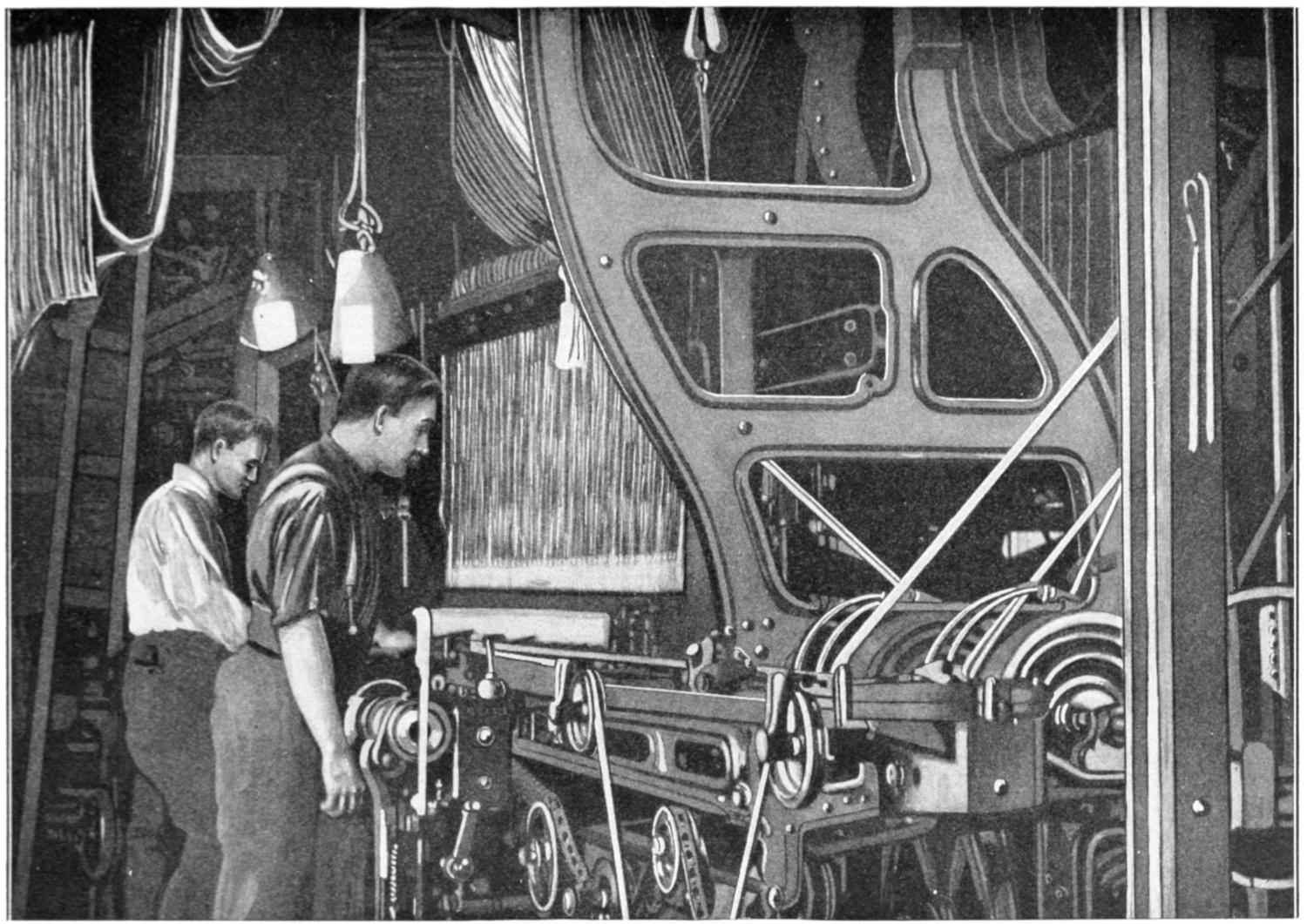

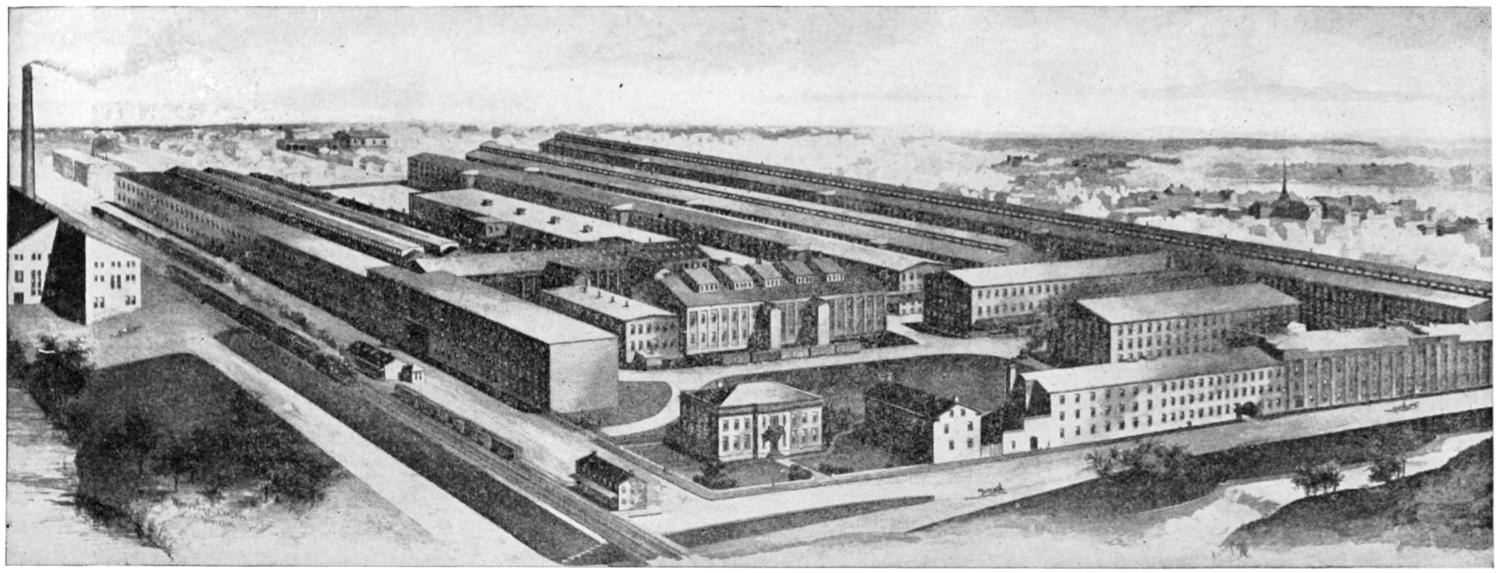

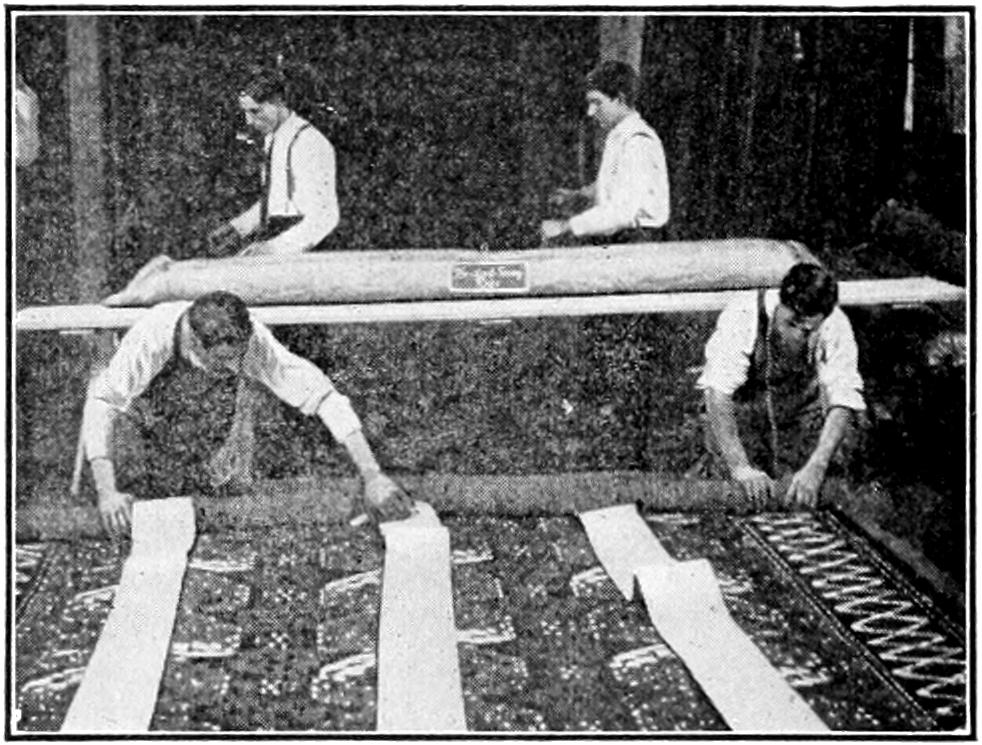

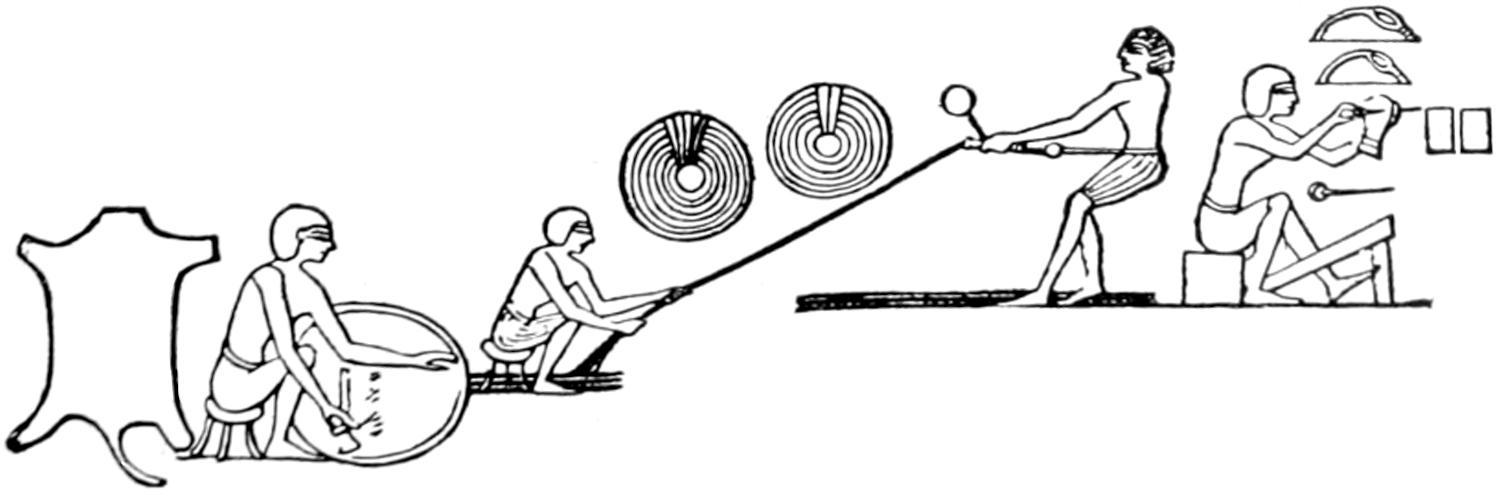

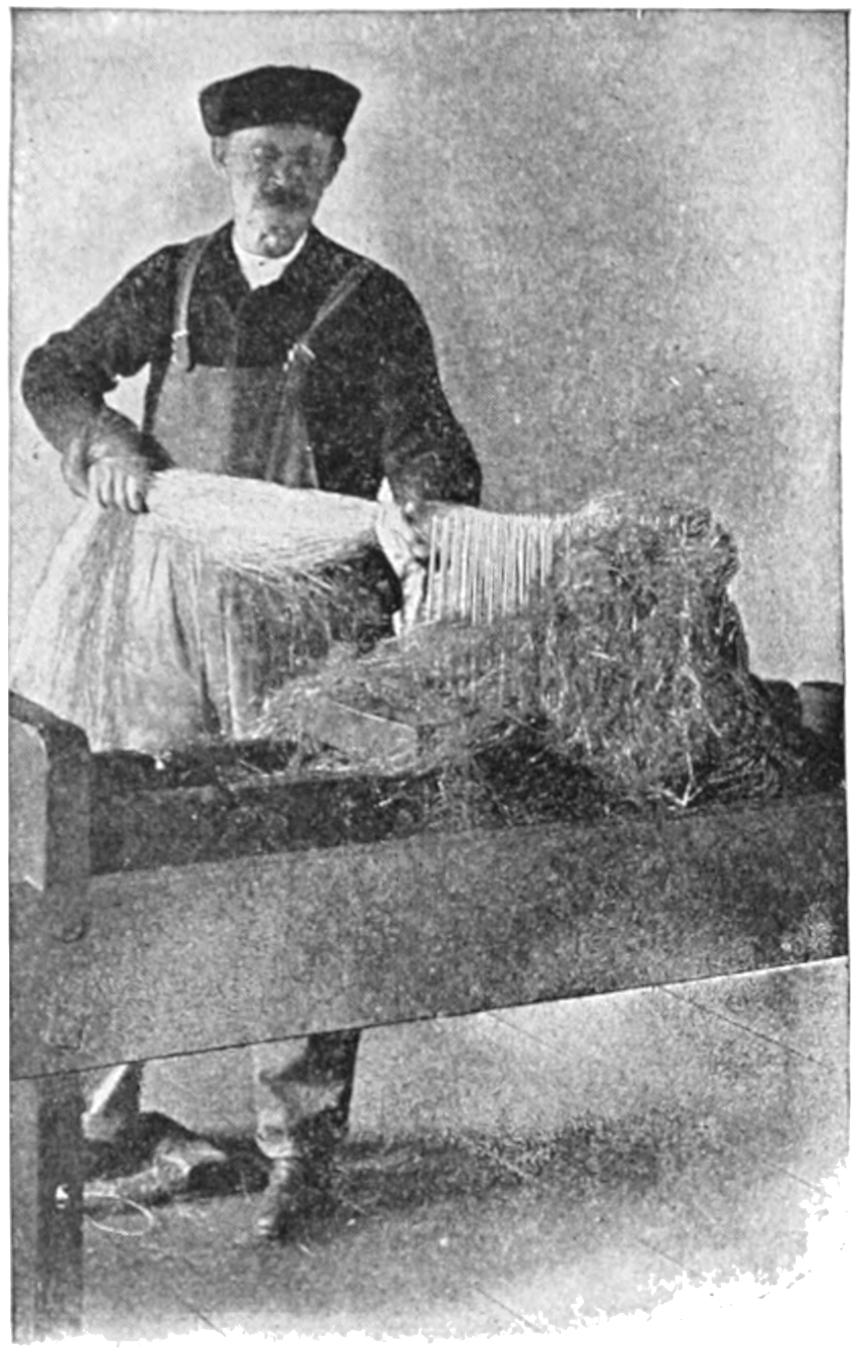

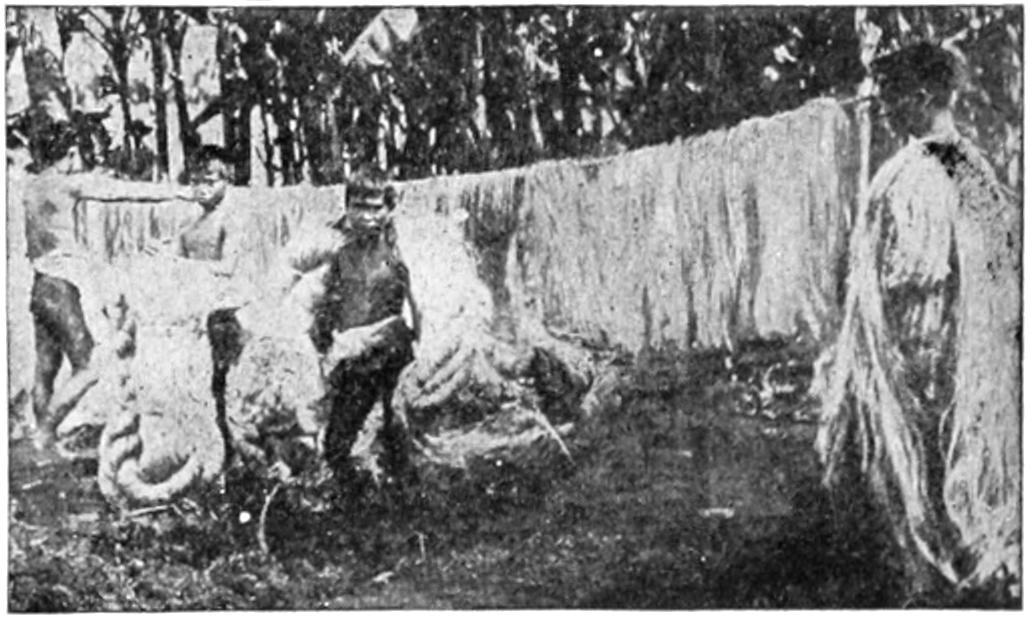

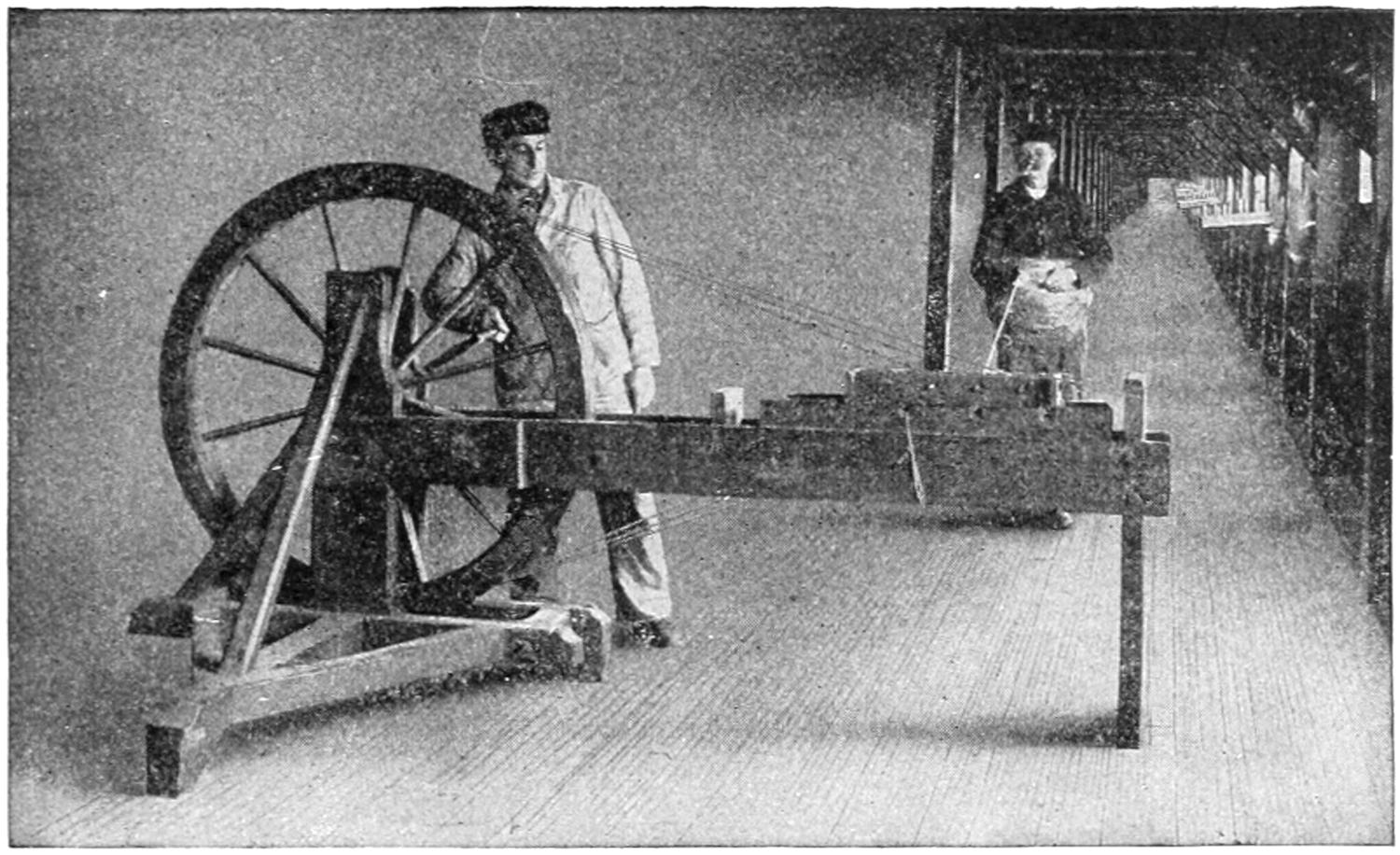

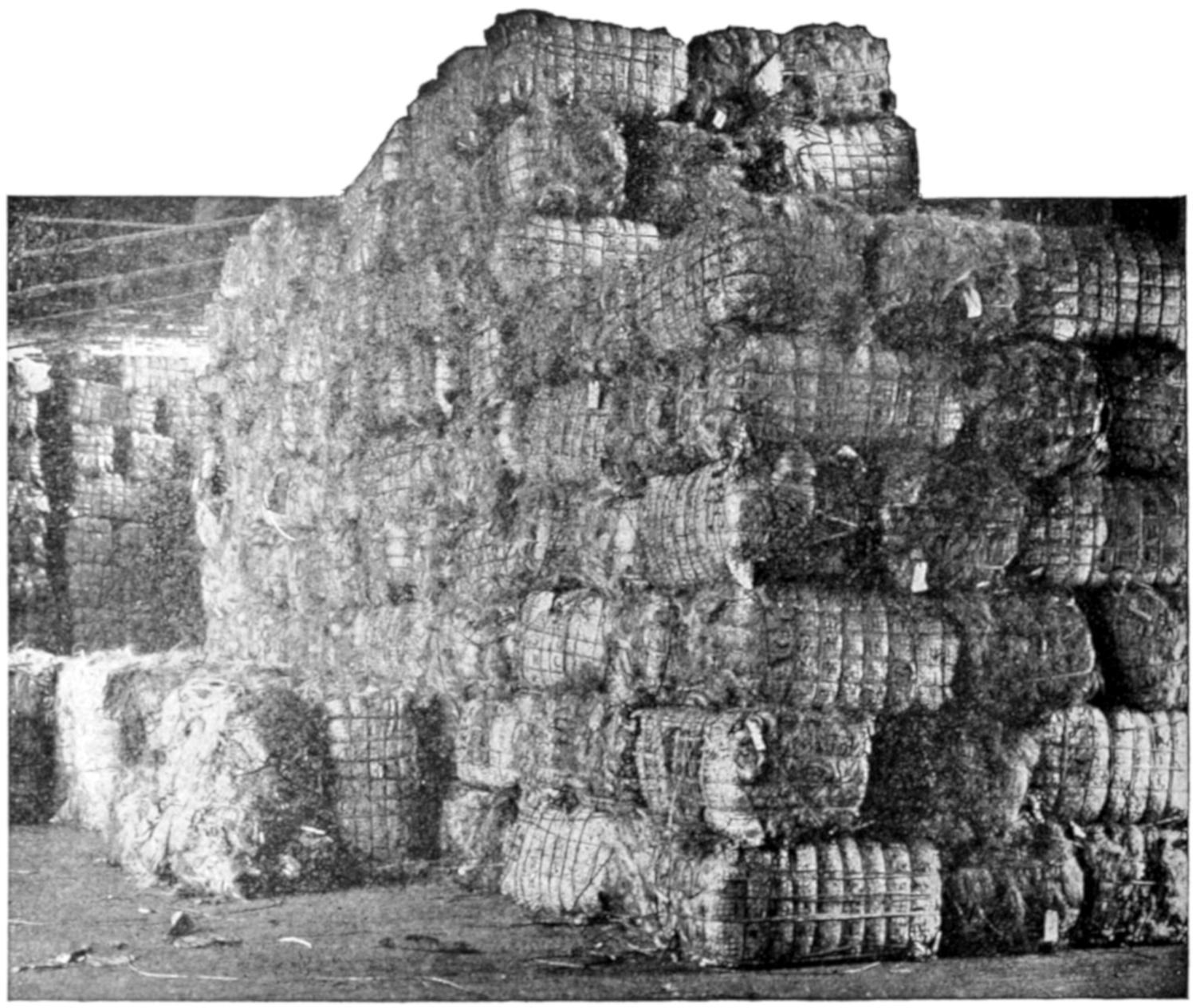

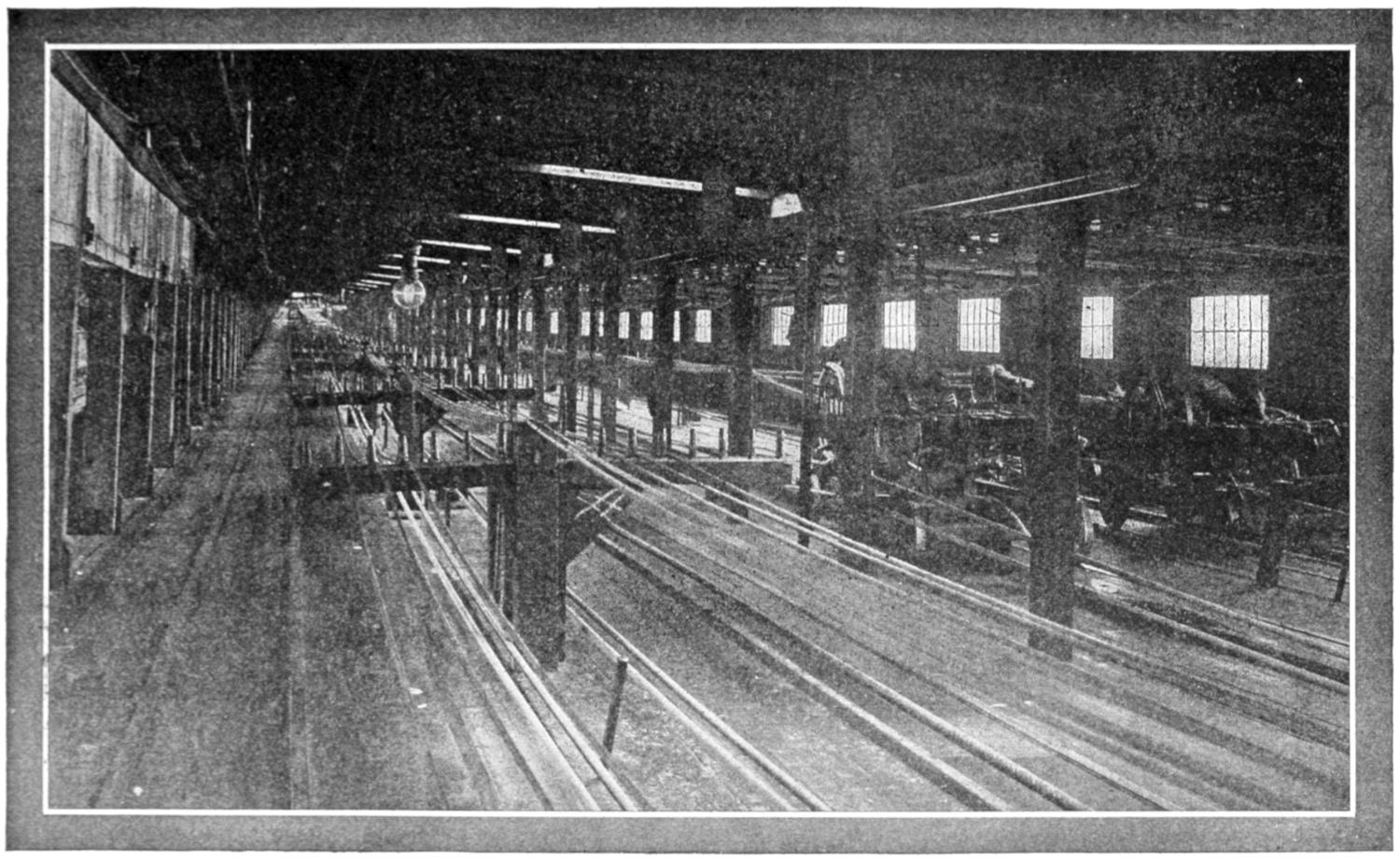

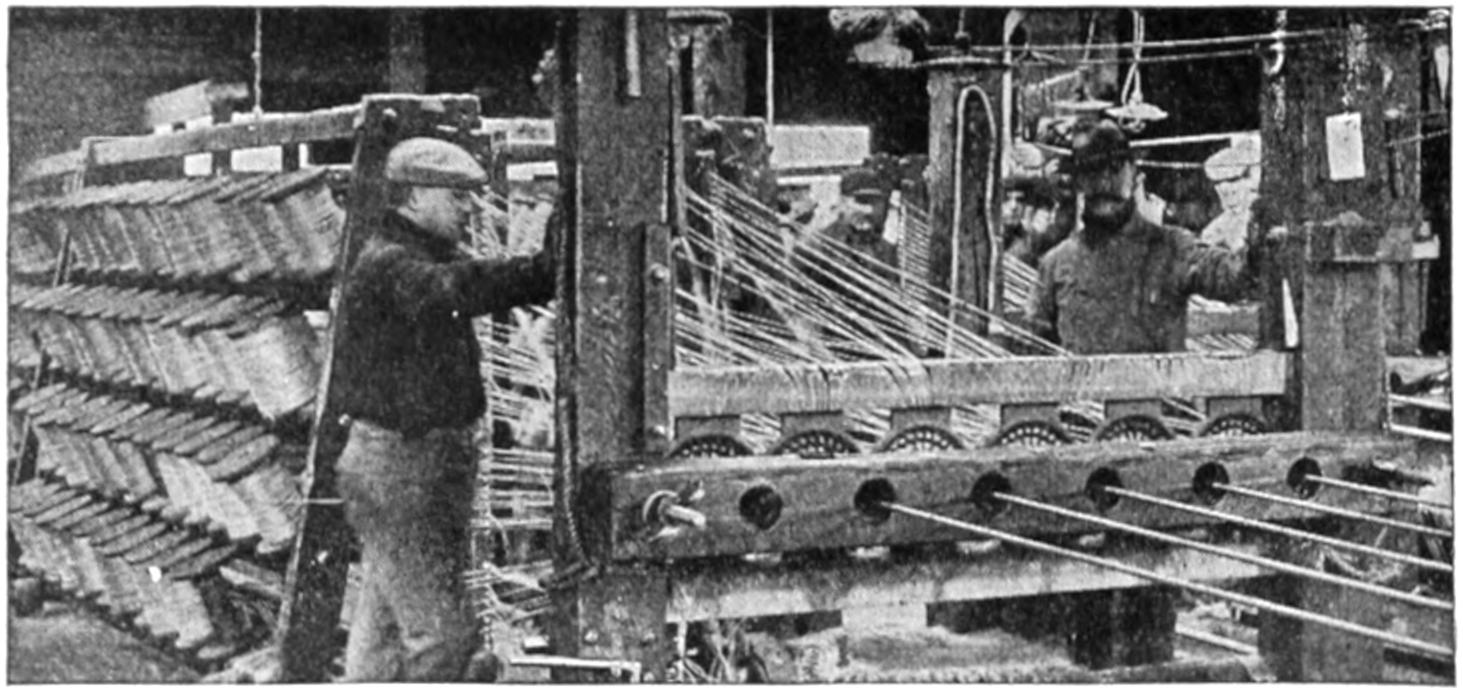

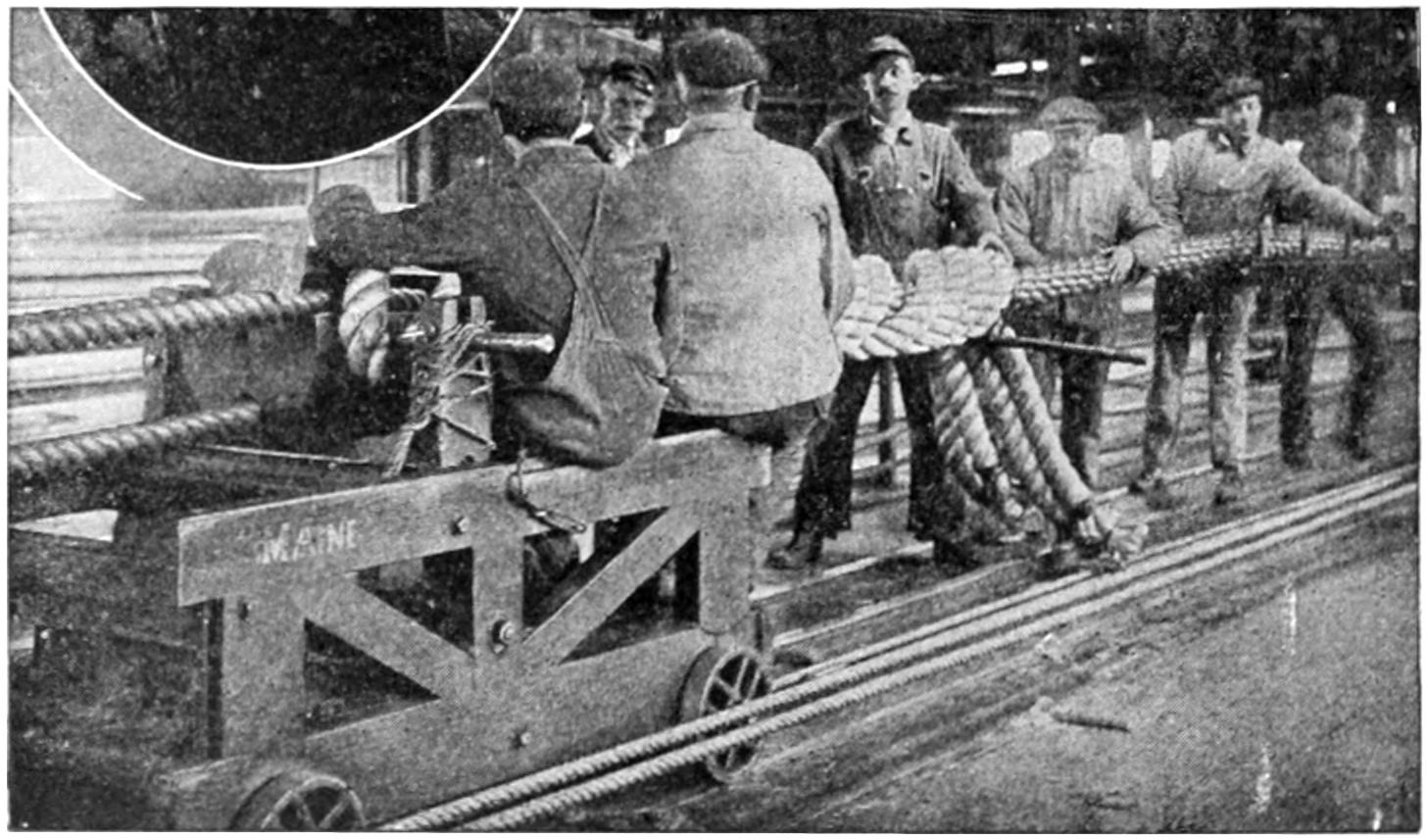

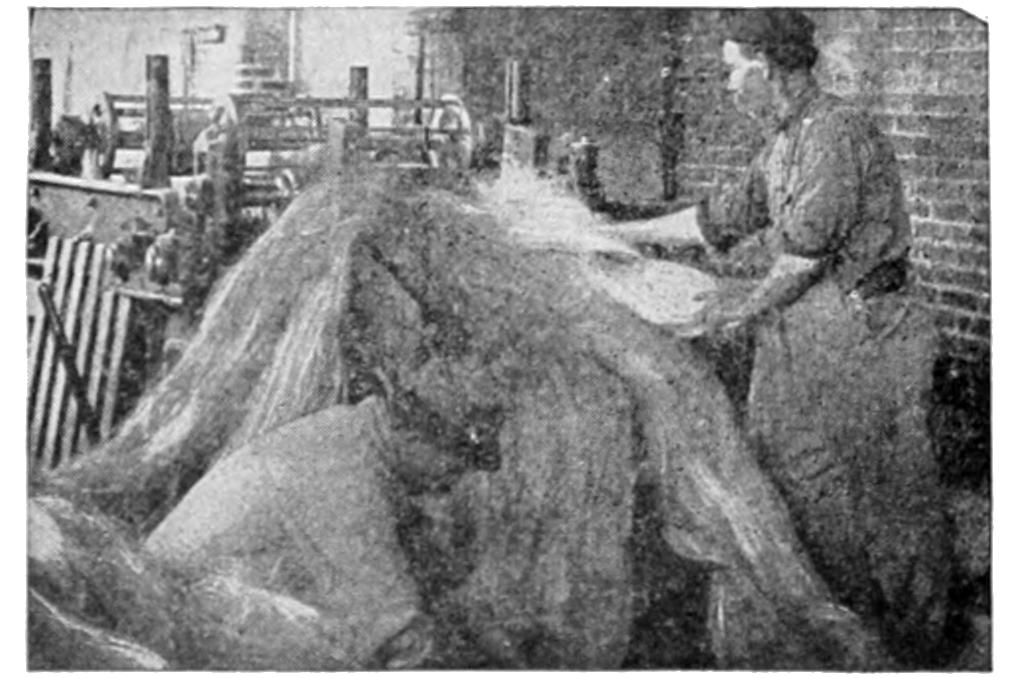

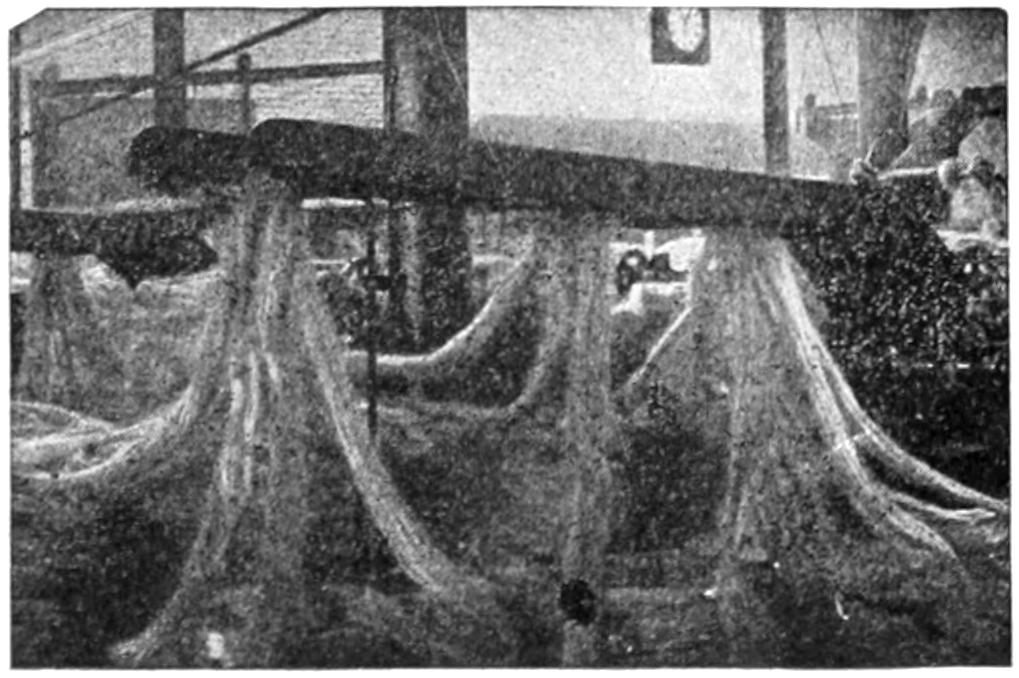

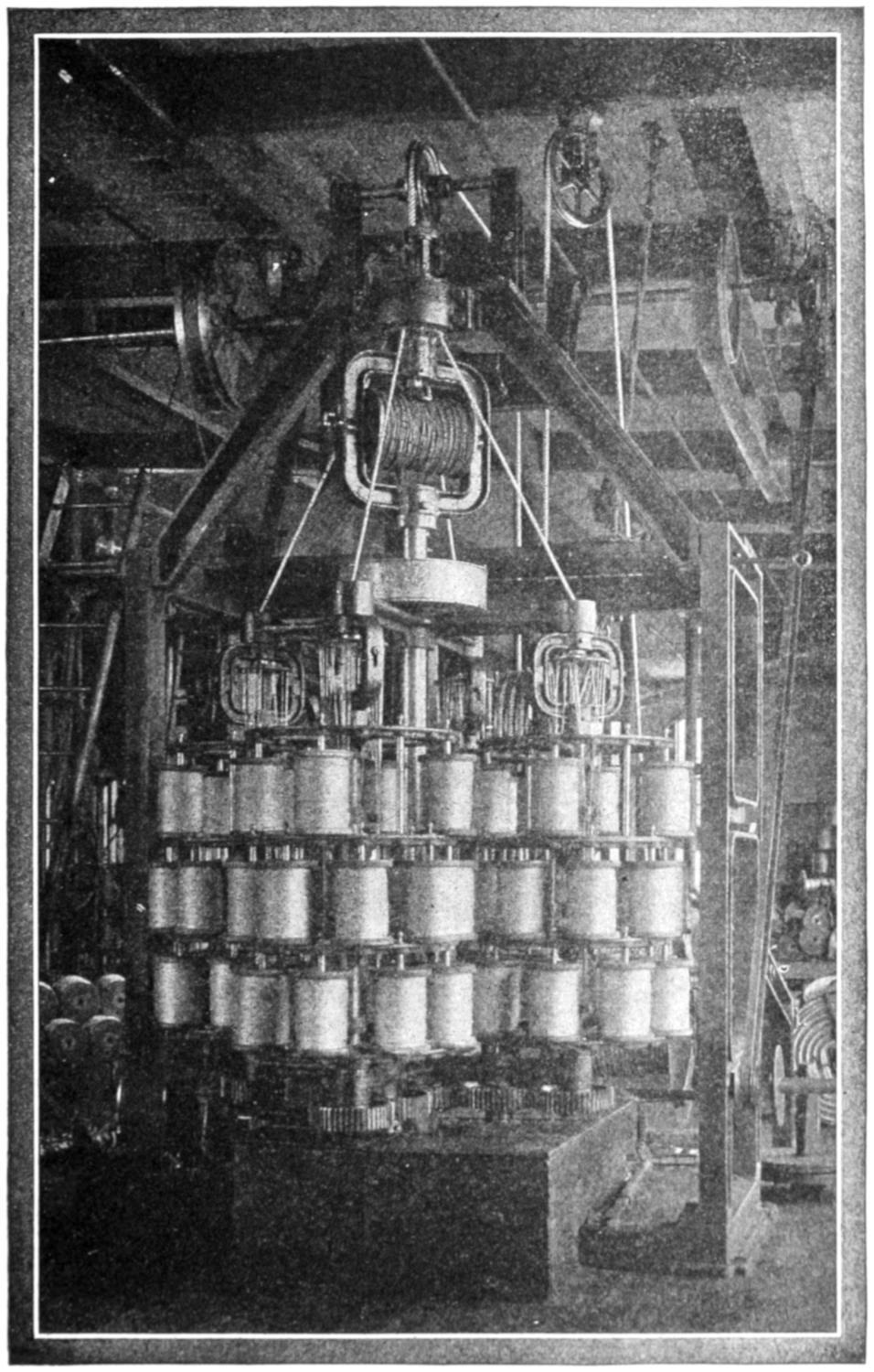

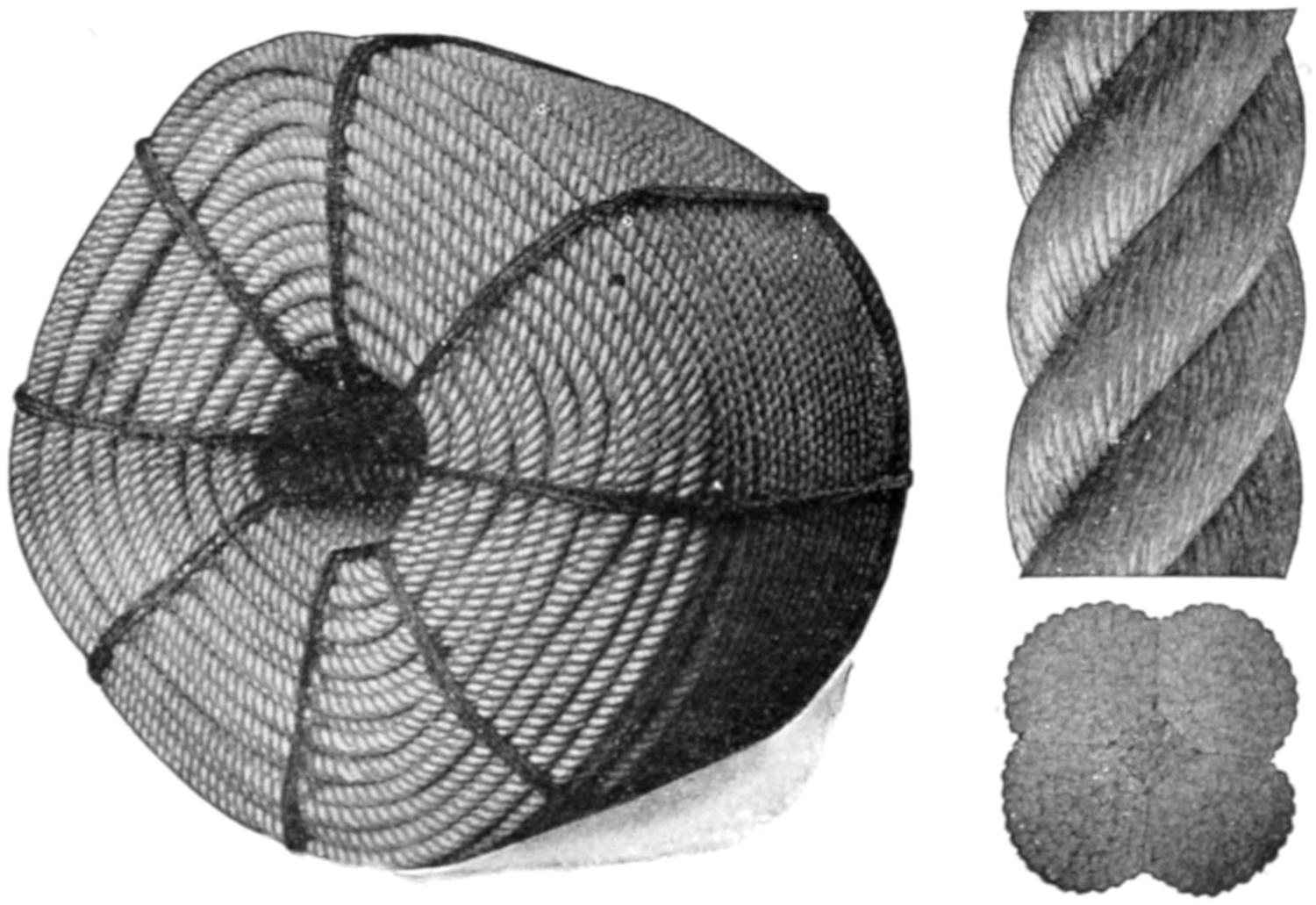

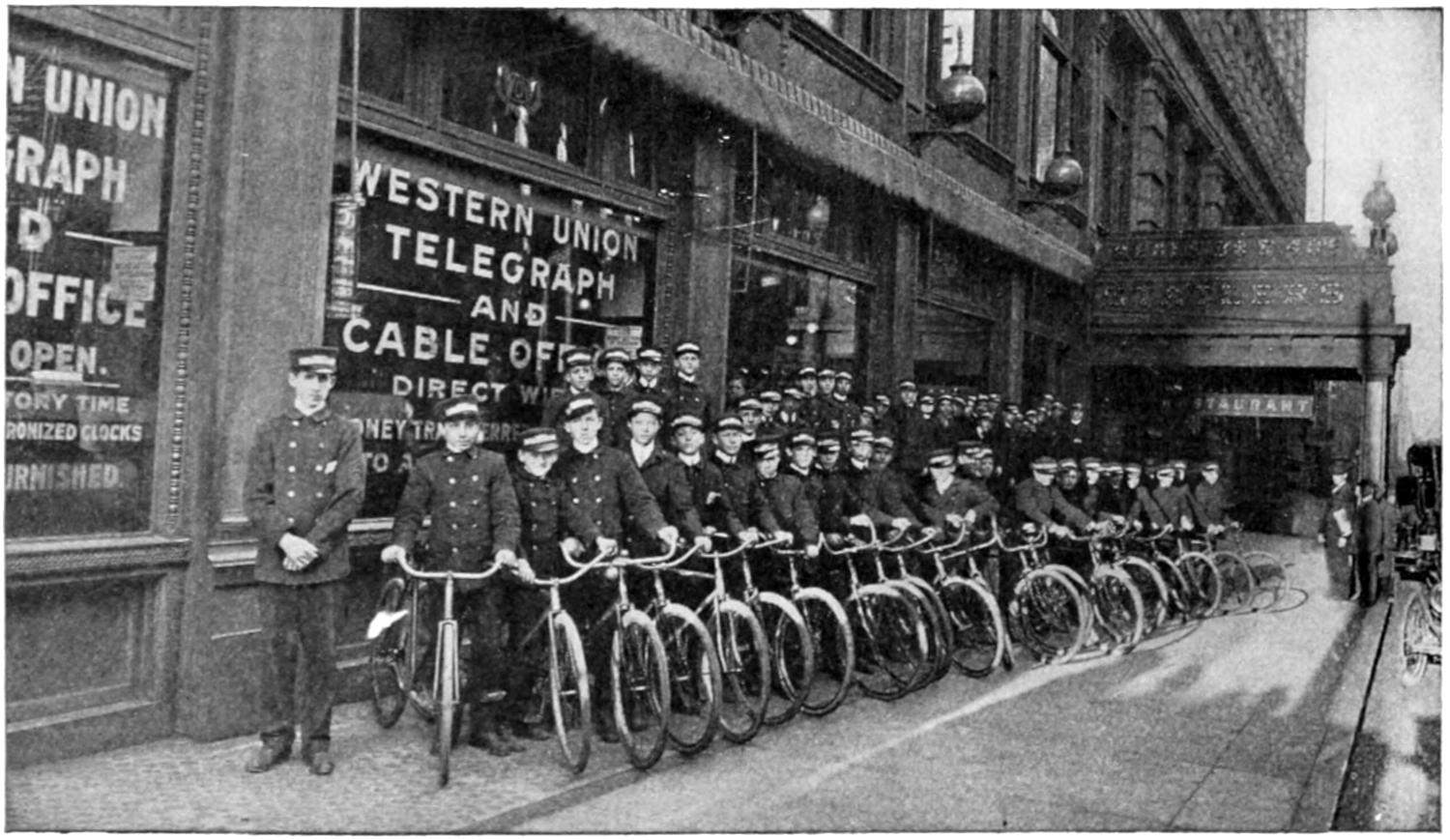

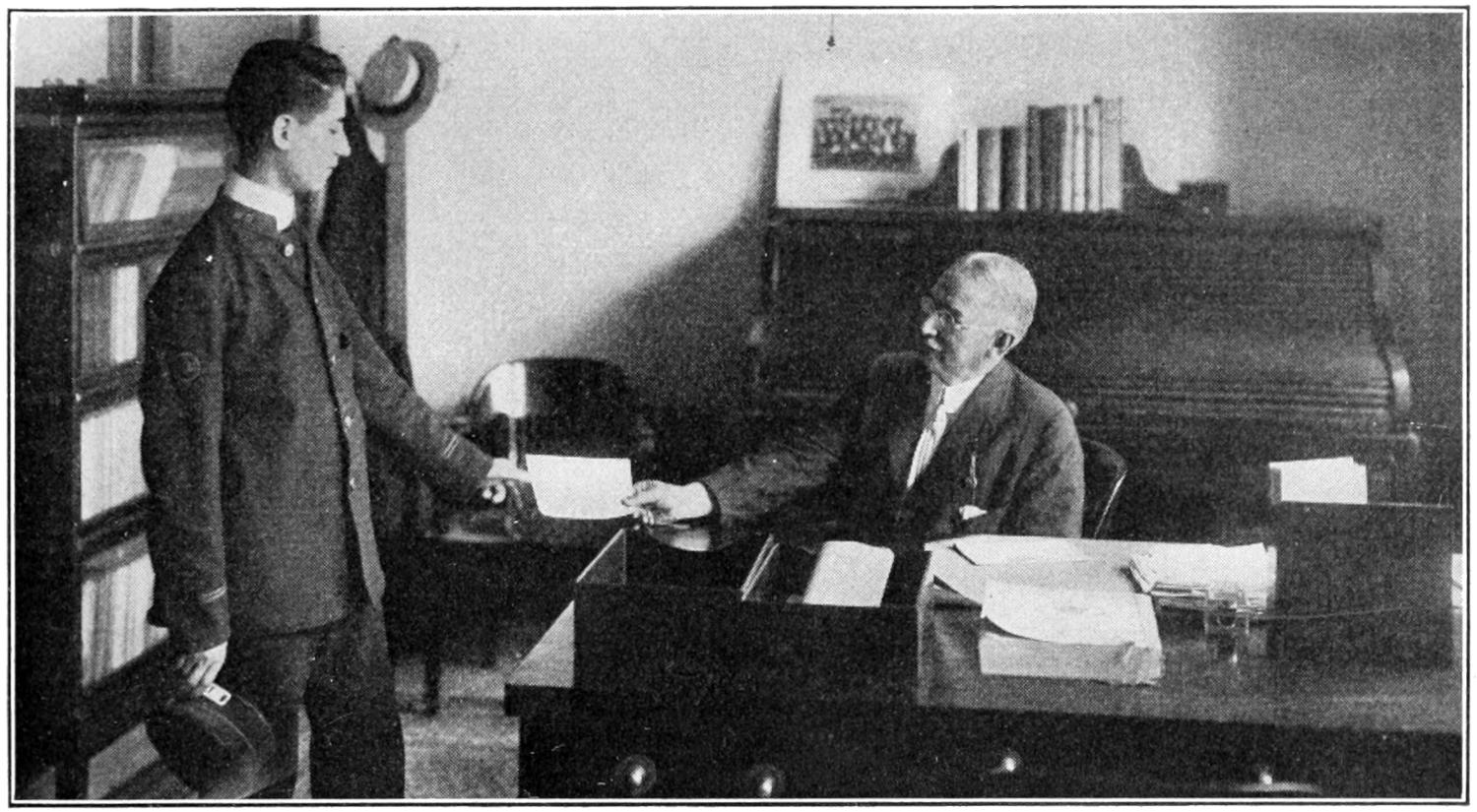

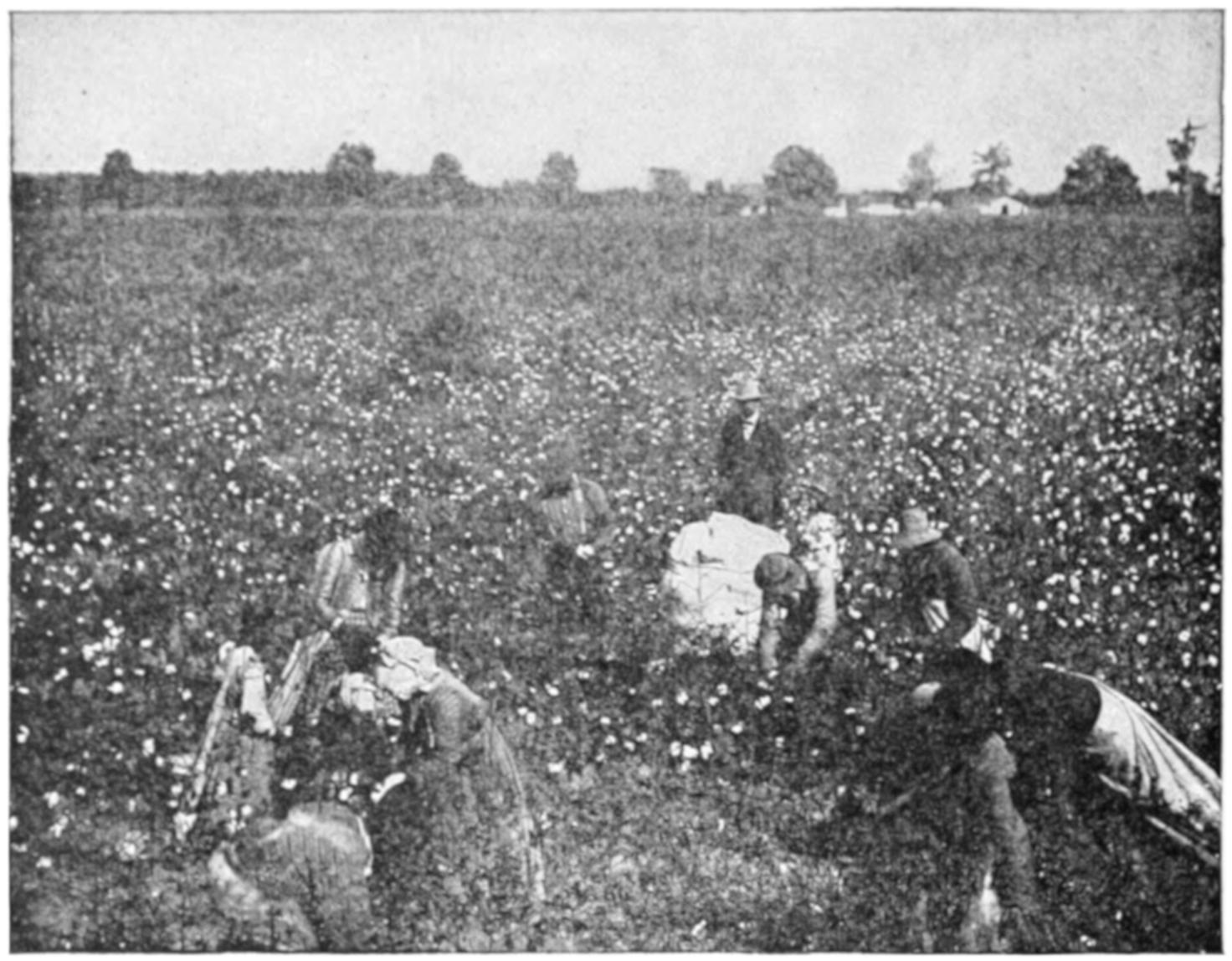

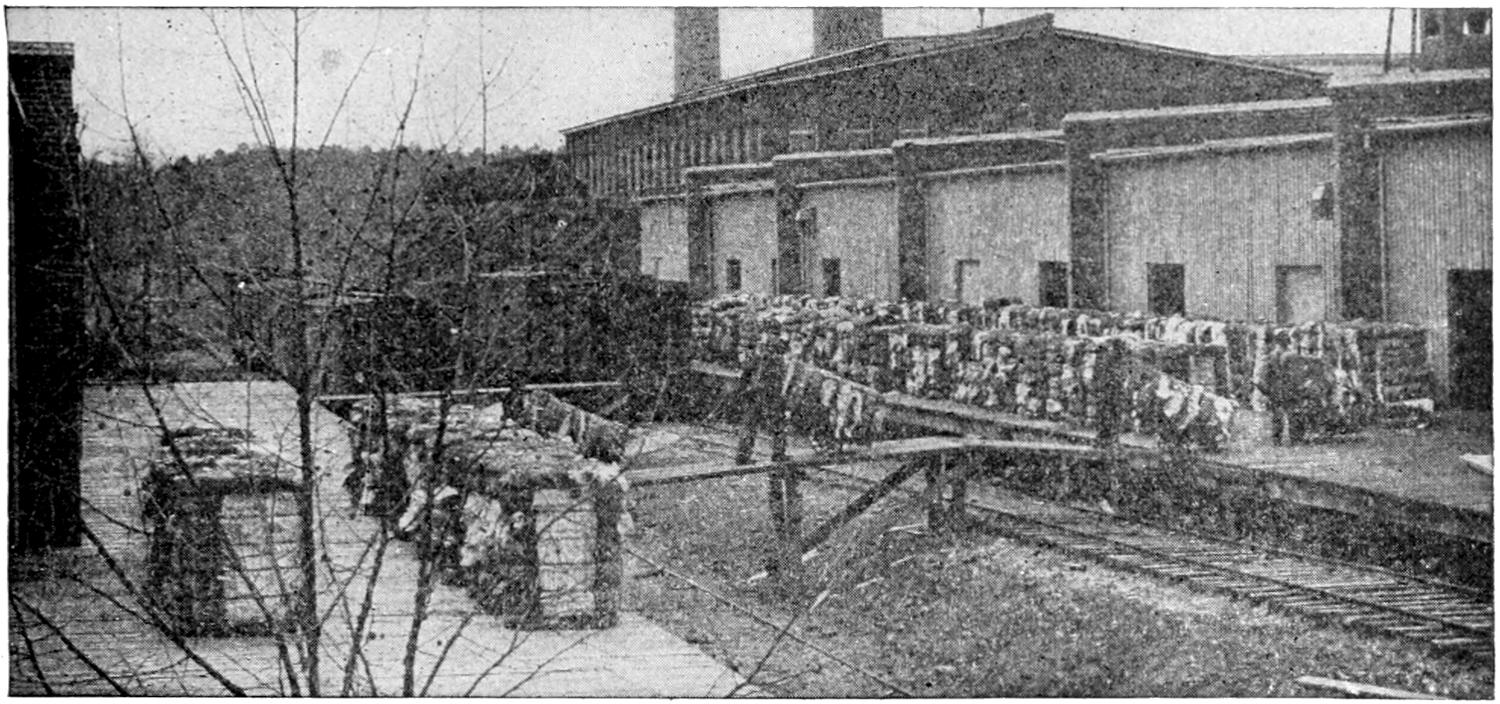

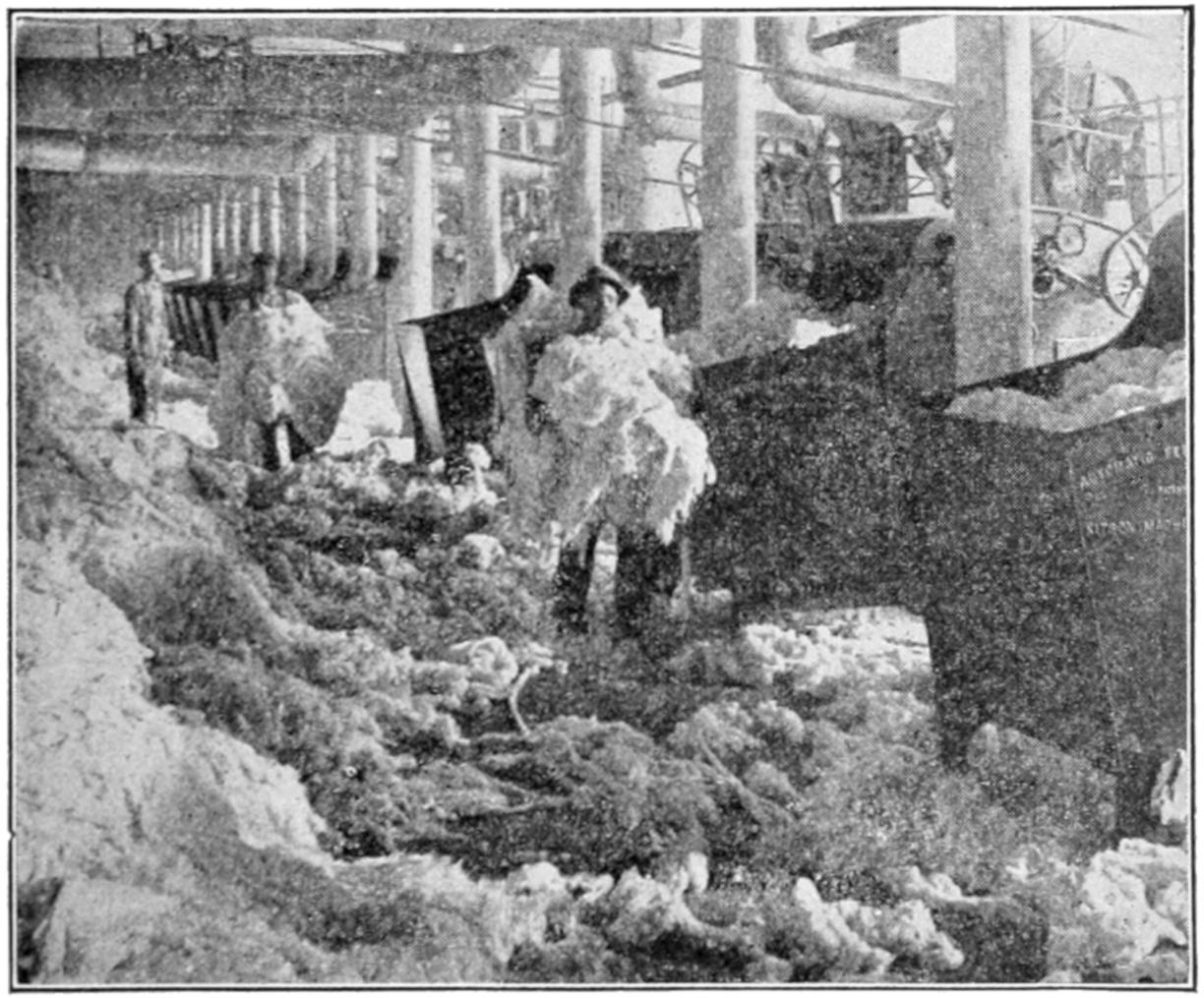

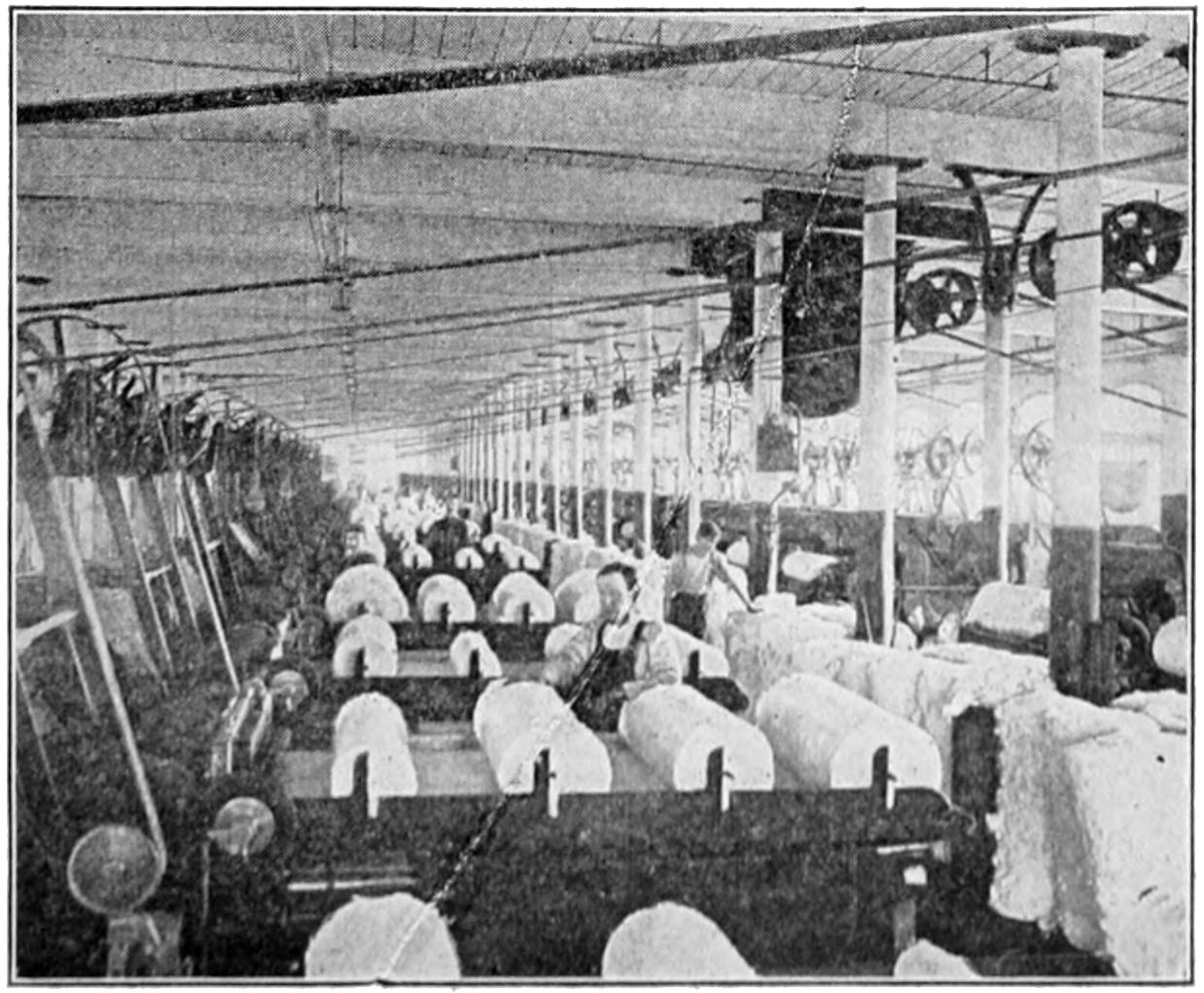

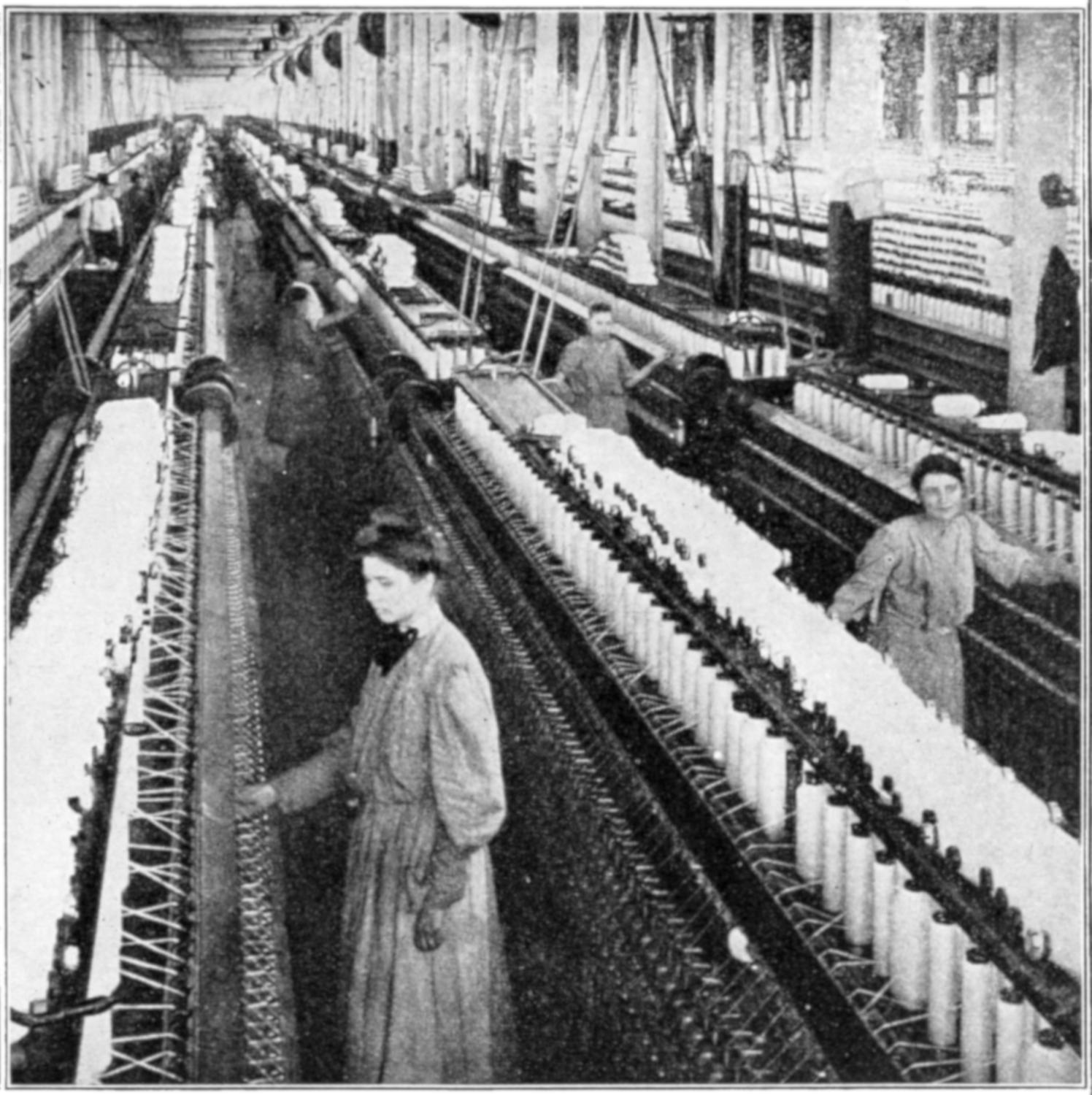

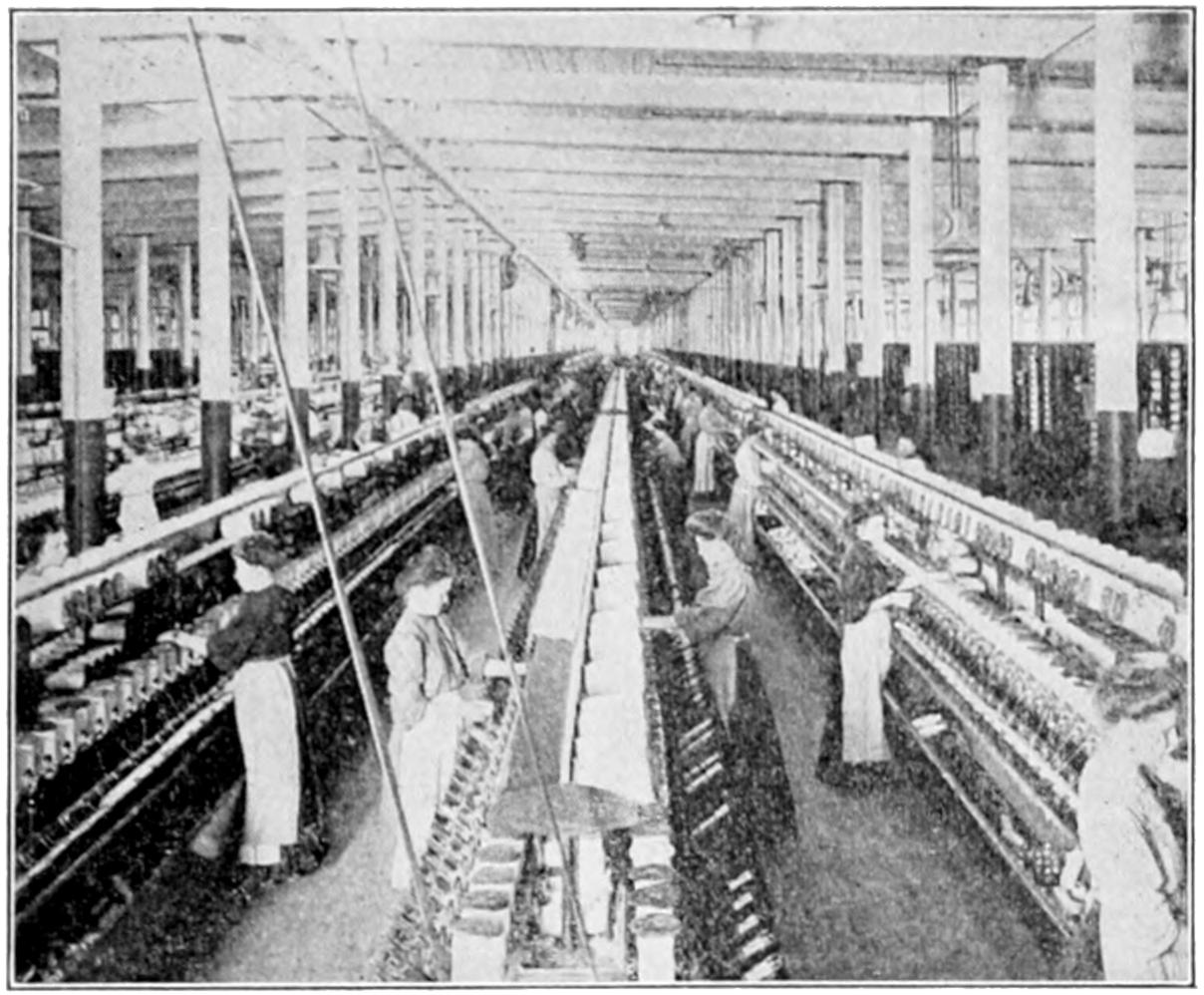

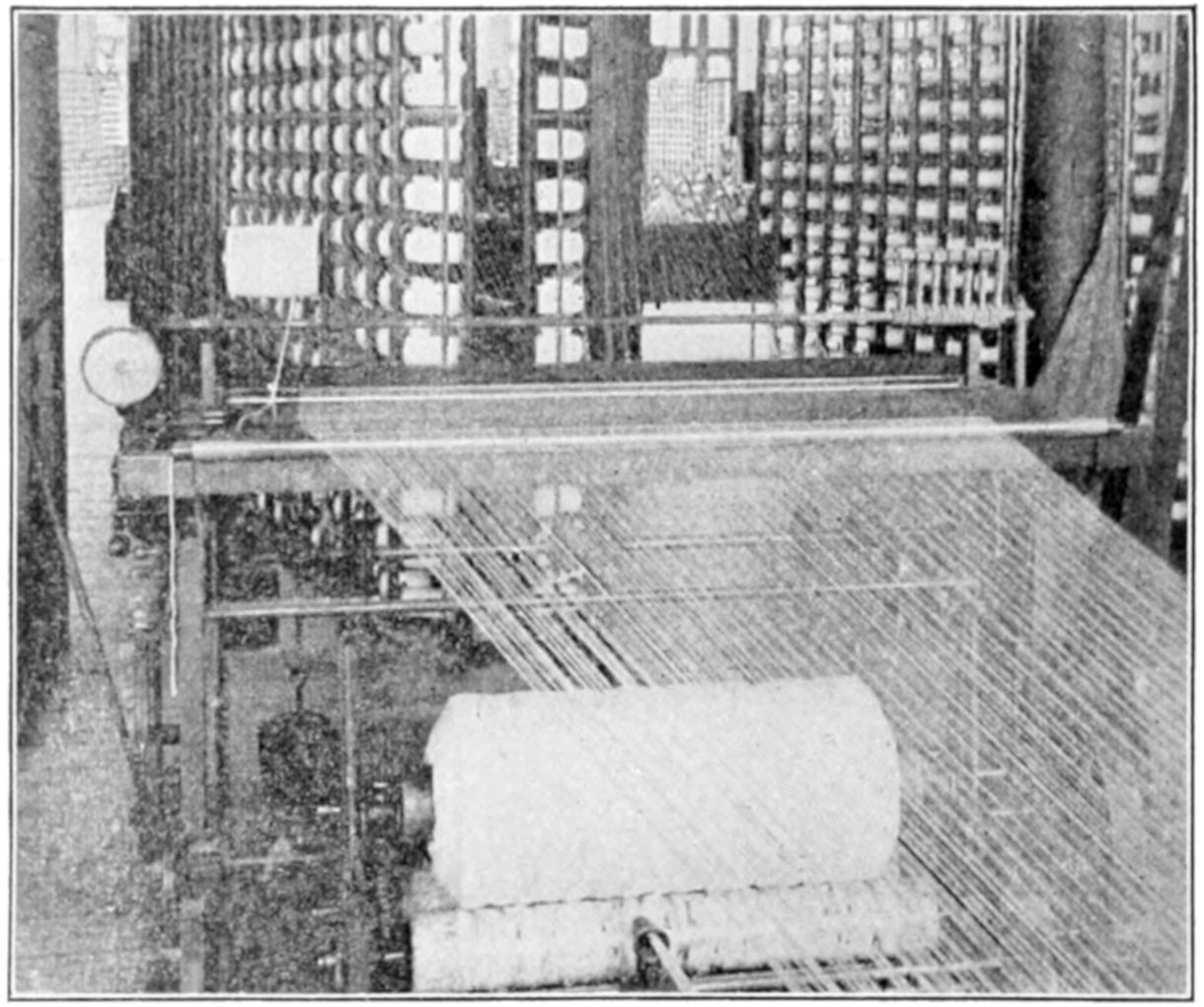

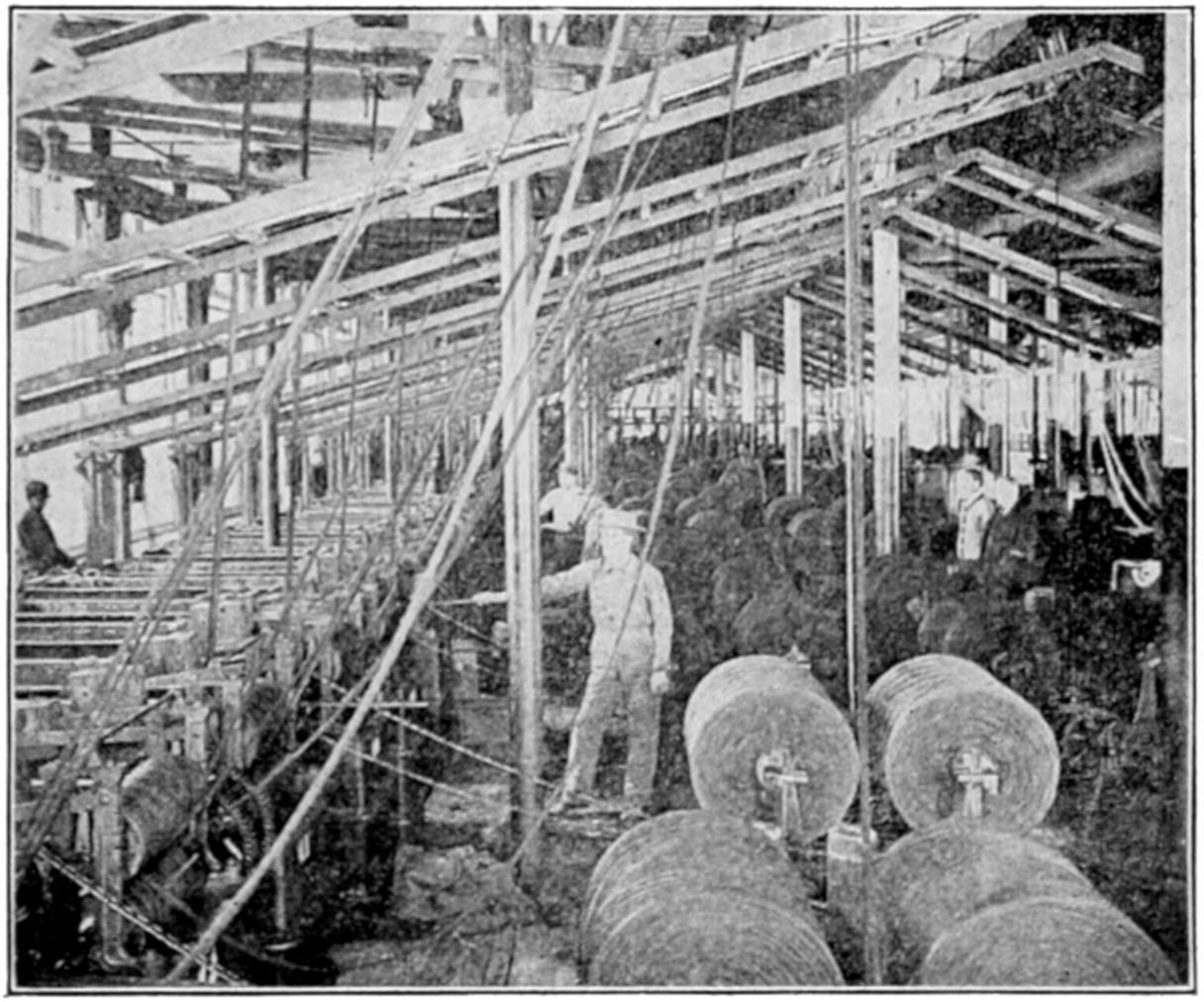

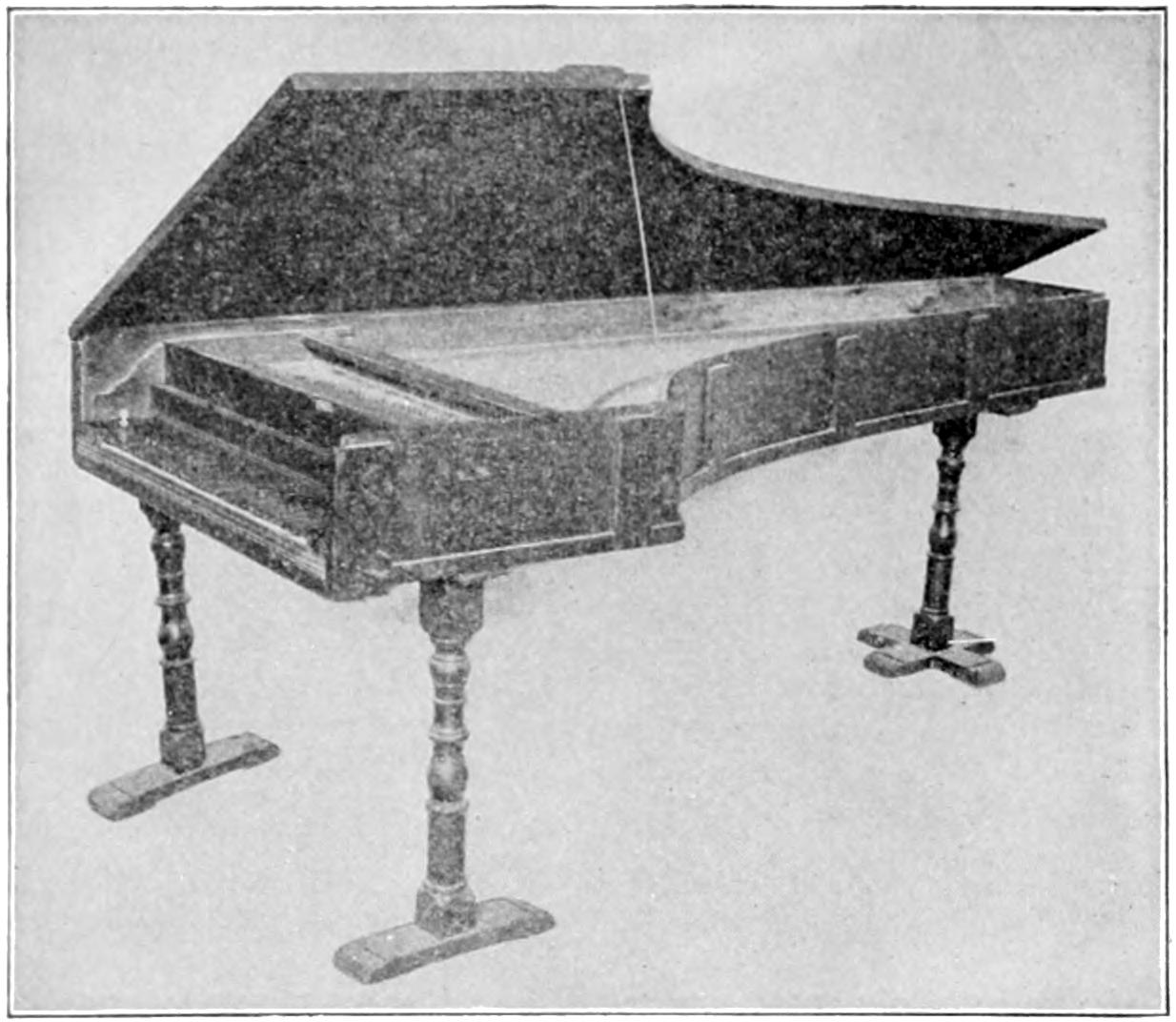

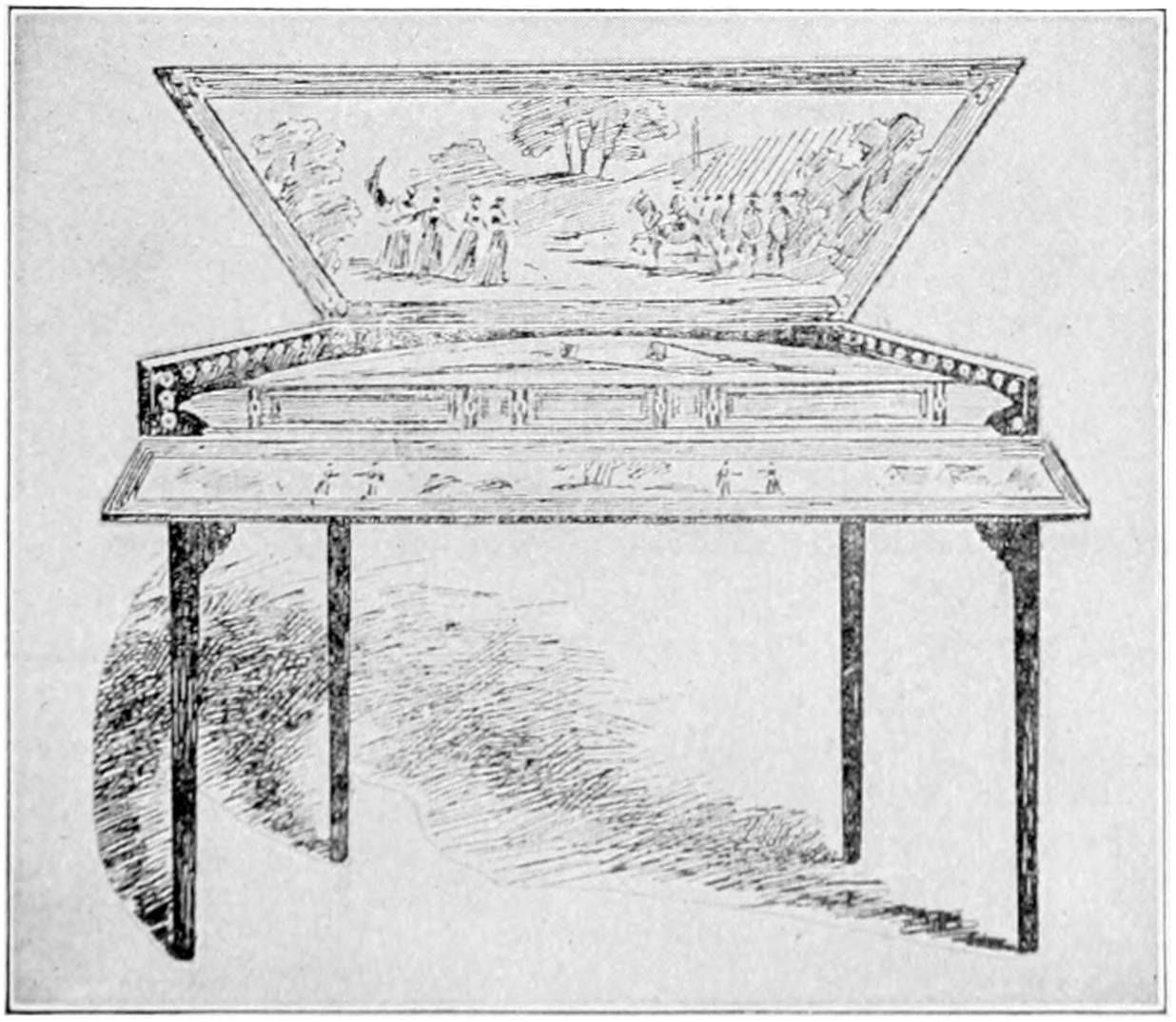

As the mind of the child matures, the questions naturally drift toward the things which the genius of man has provided for his comfort and pleasure. We have become so accustomed to the use and benefits of these wonders produced by man that we generally leave out of our books the stories of our great industries, and yet the mind of the child wonders and inquires about them. We have so long worn clothes made of wool or cotton, that we have forgotten the wonder there is in making a bolt of cloth. Every industry has a fascinating story equal to that of the silkworm, which moves its head sixty-five times a minute while spinning his thousand yards of silk.

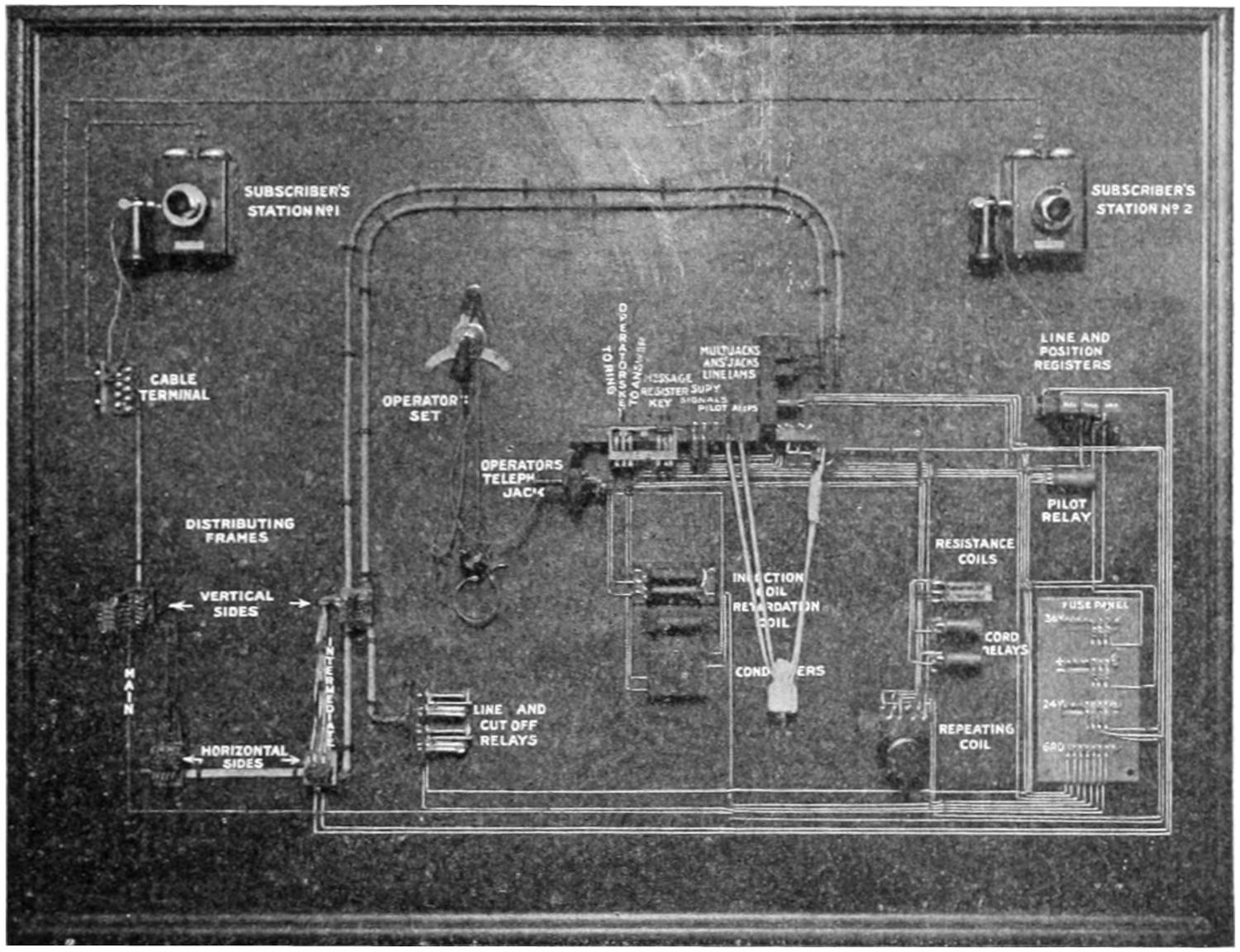

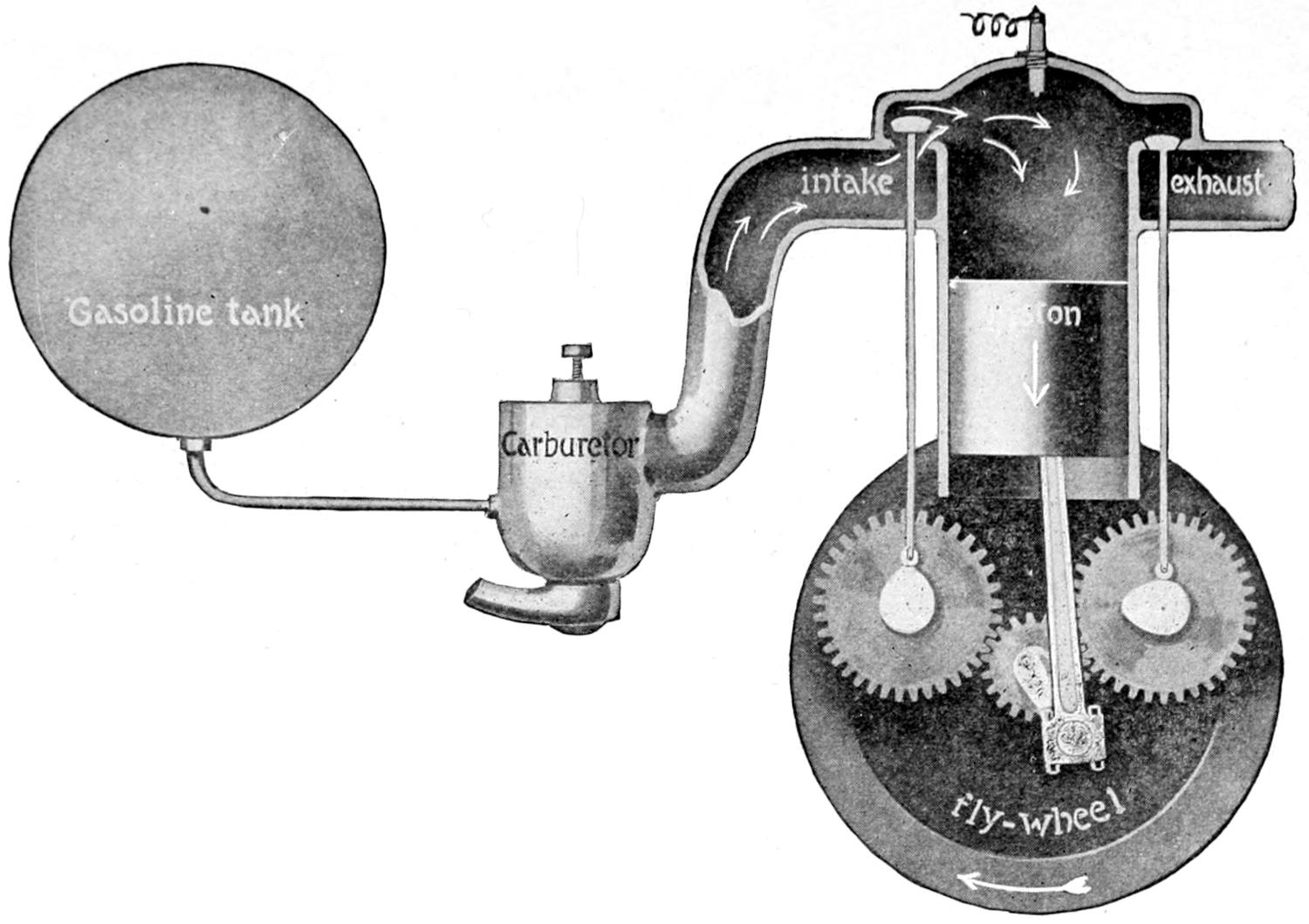

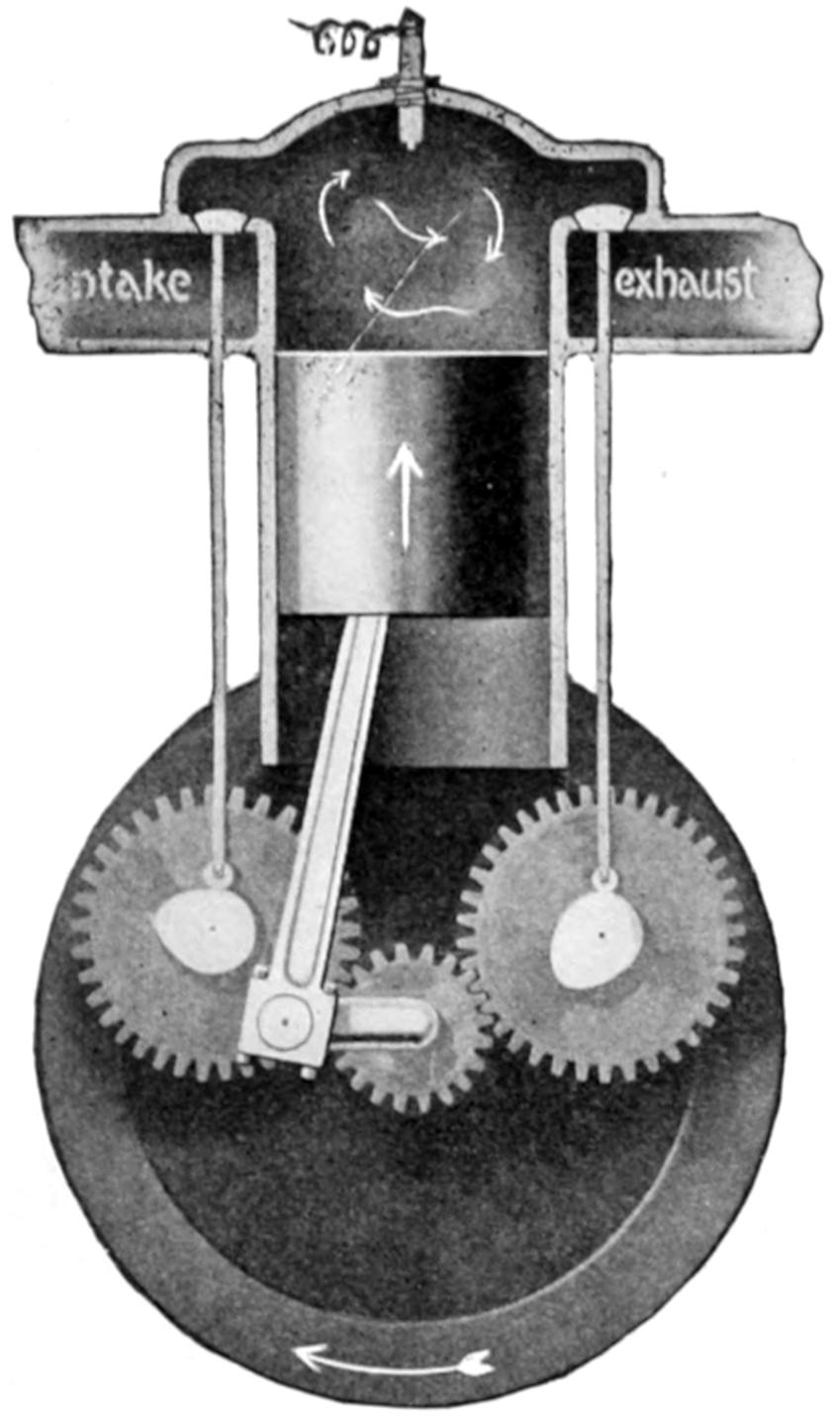

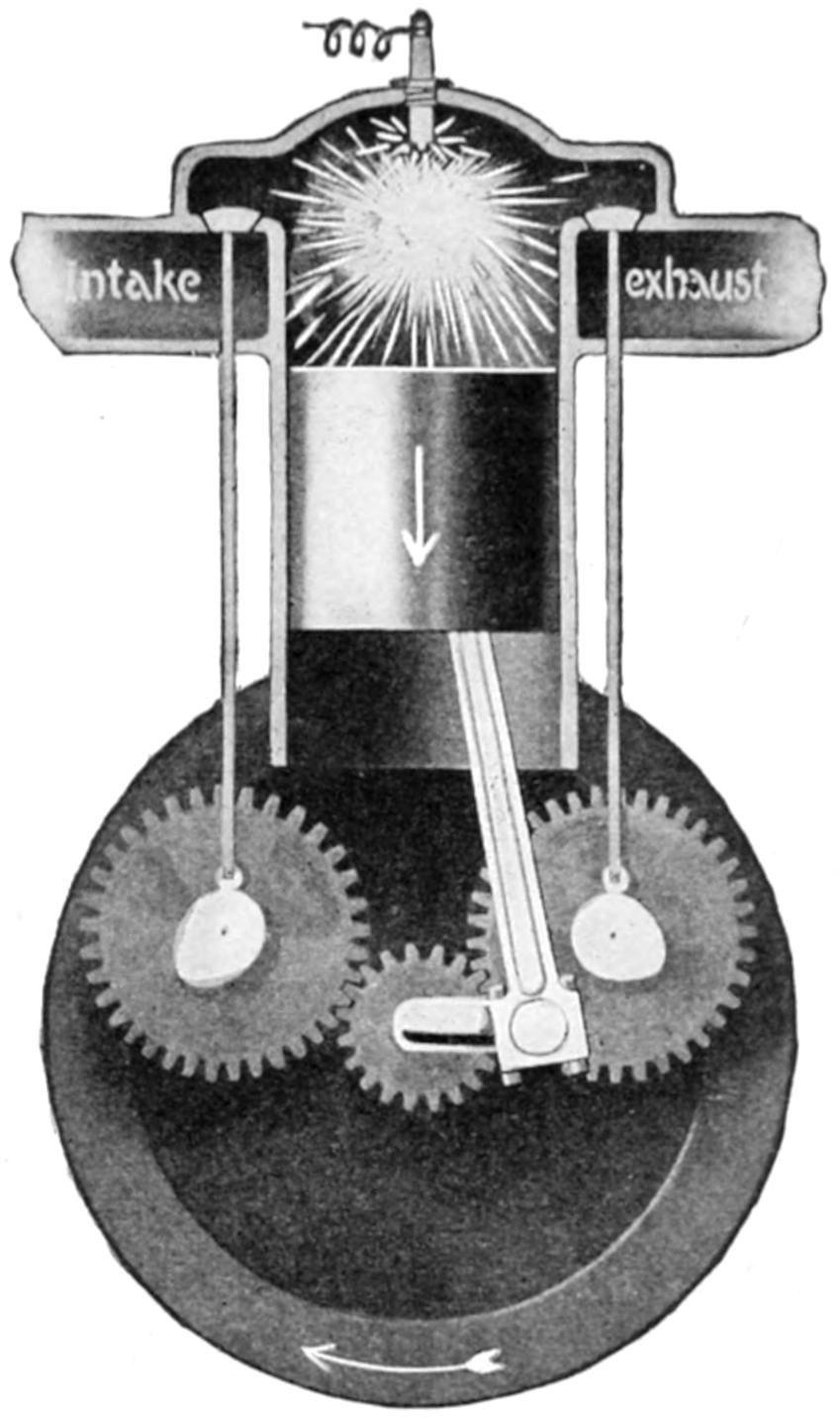

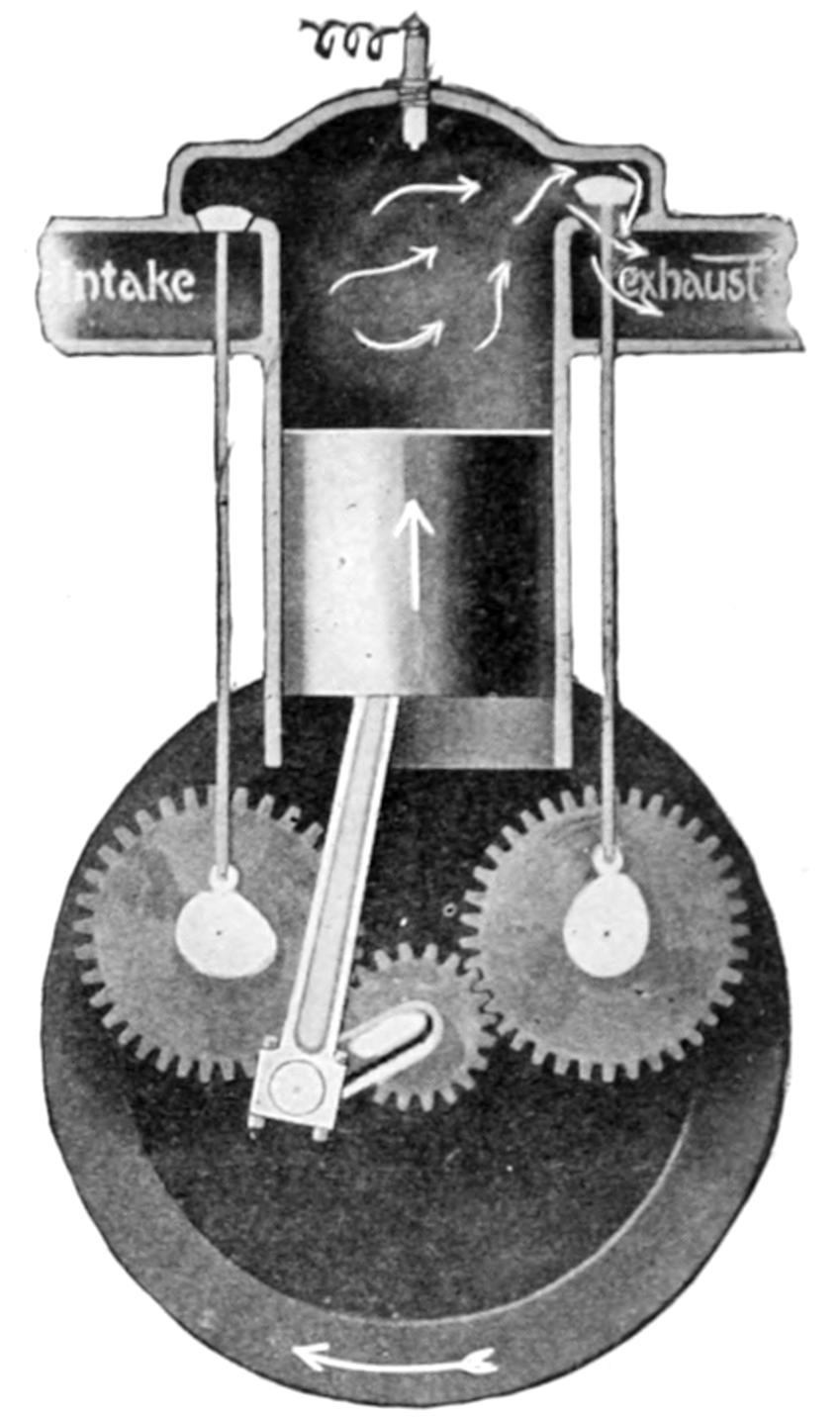

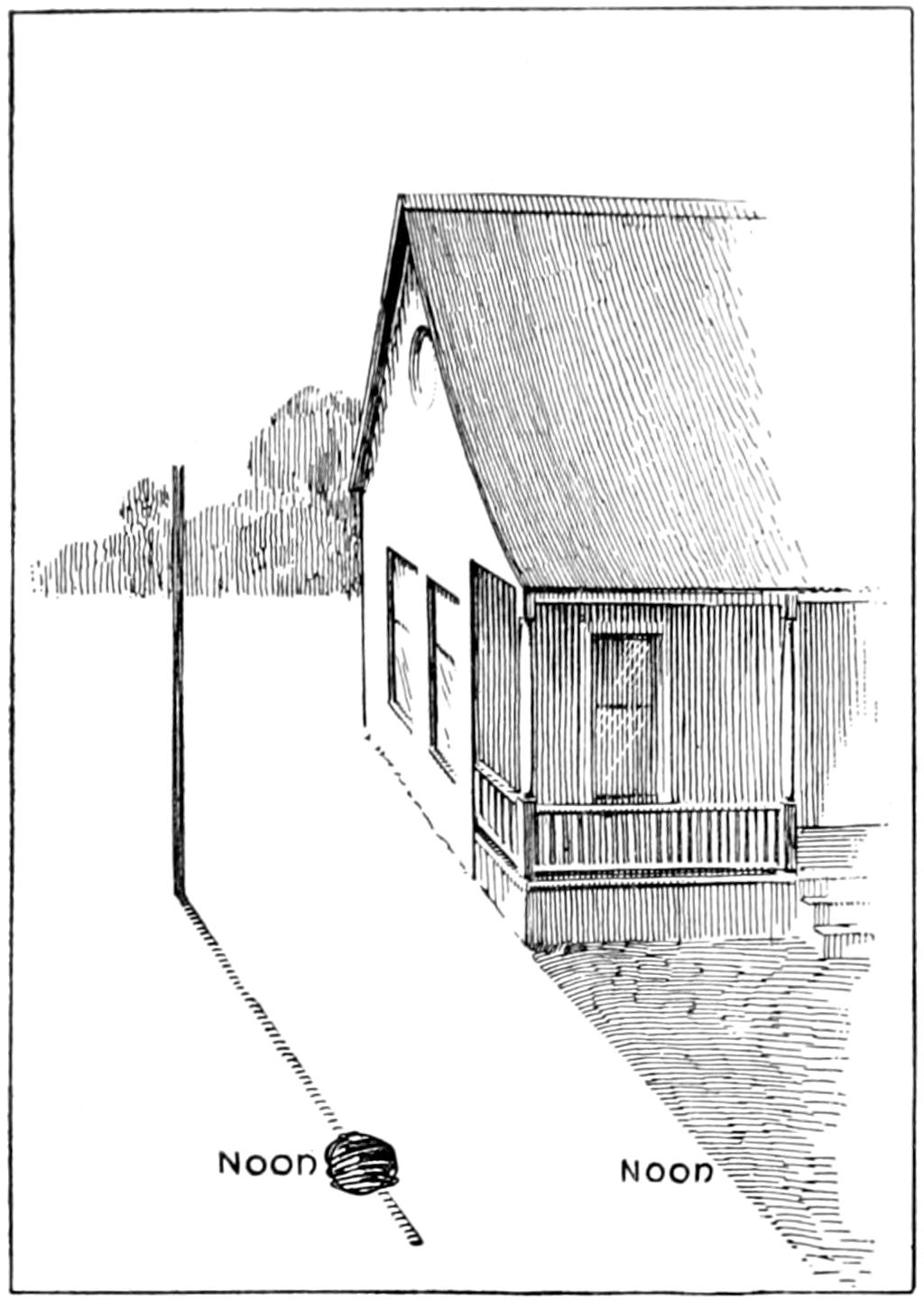

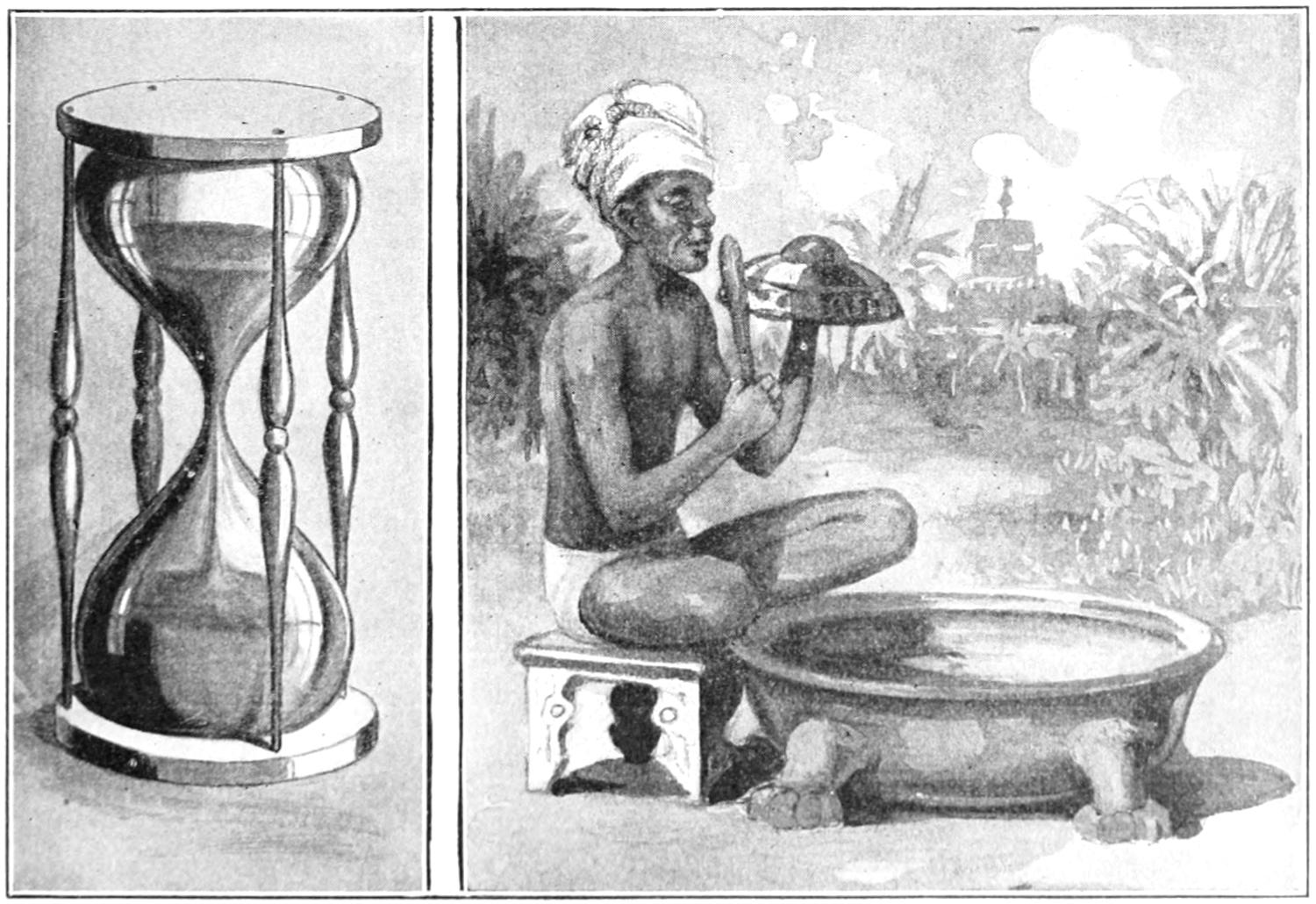

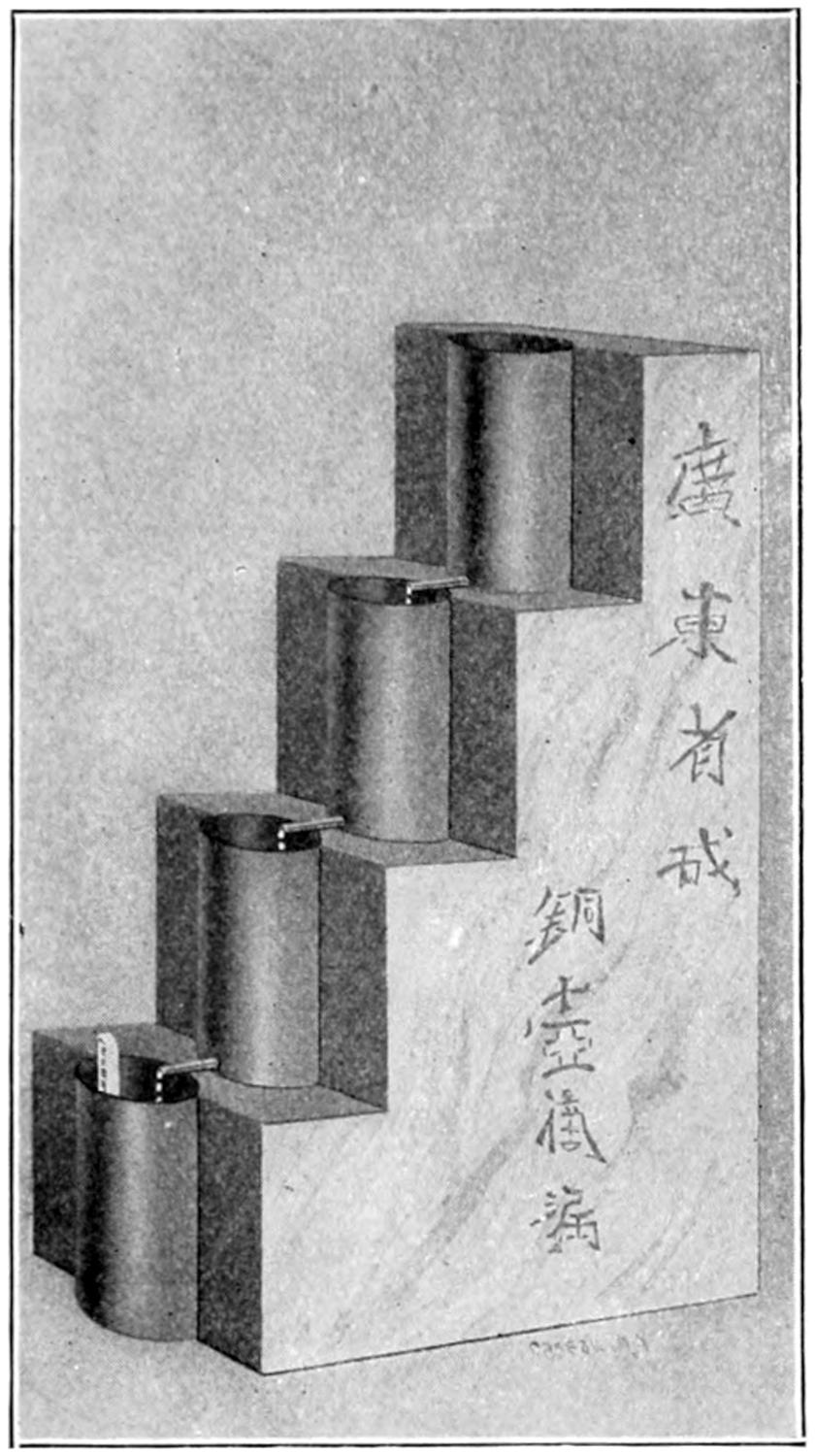

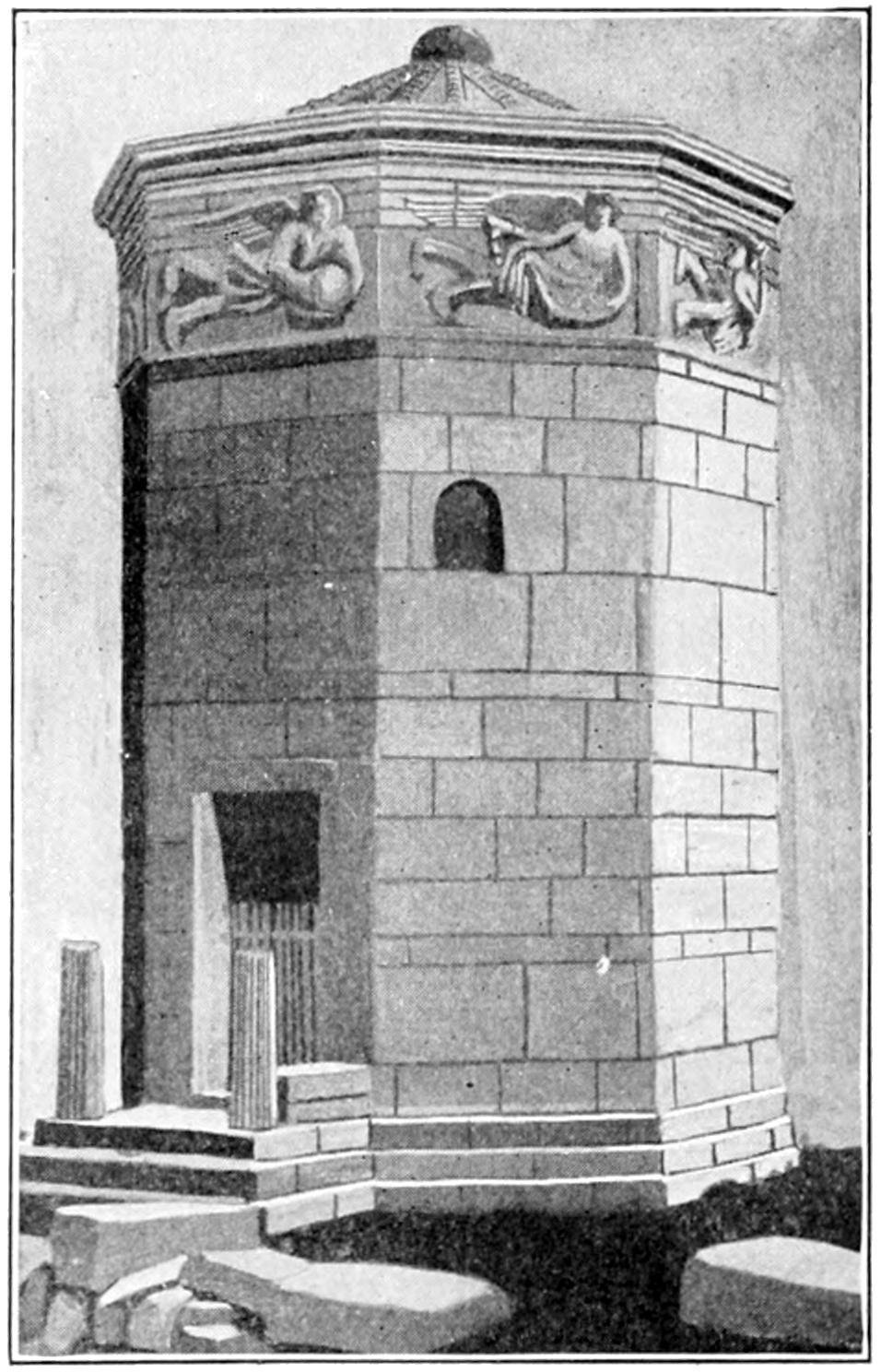

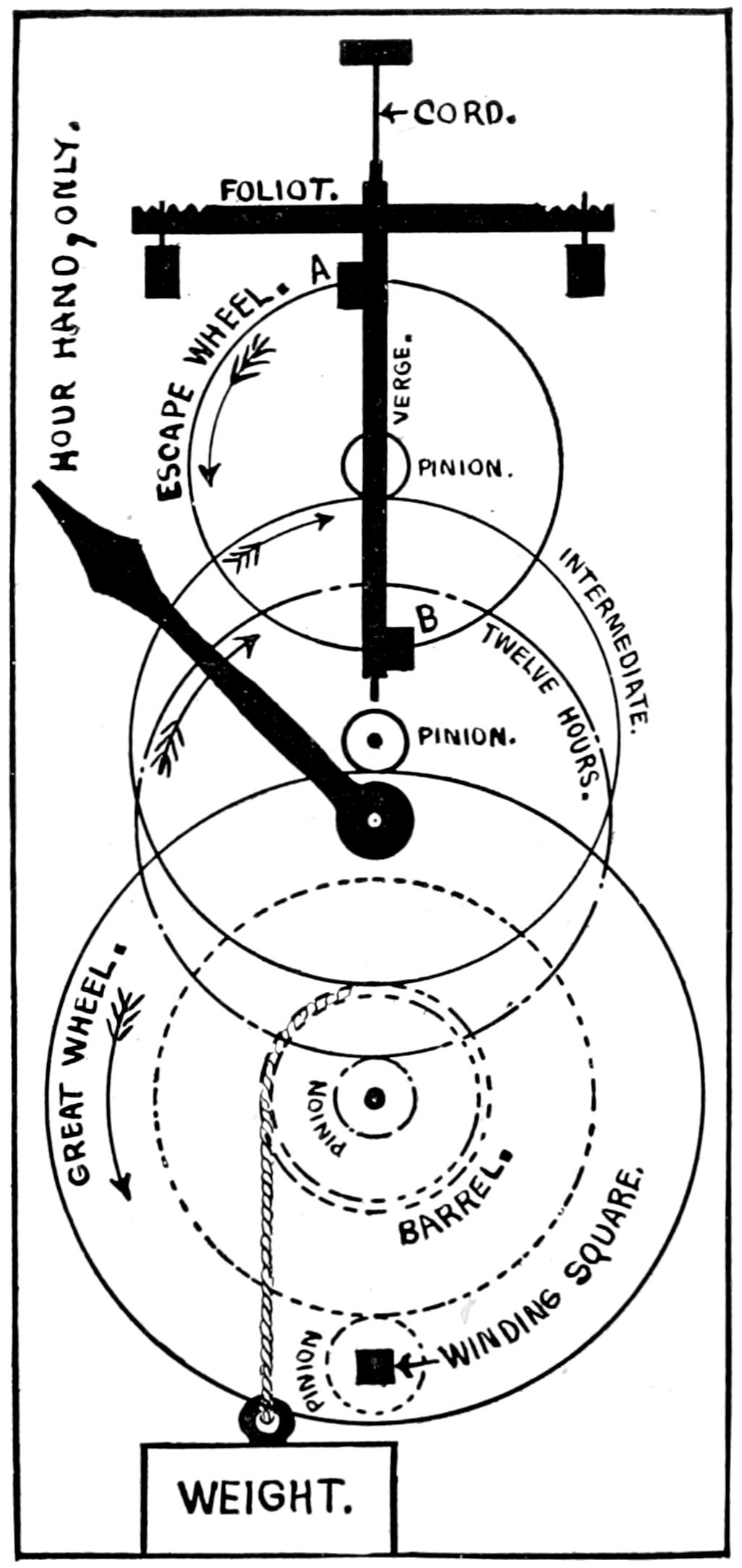

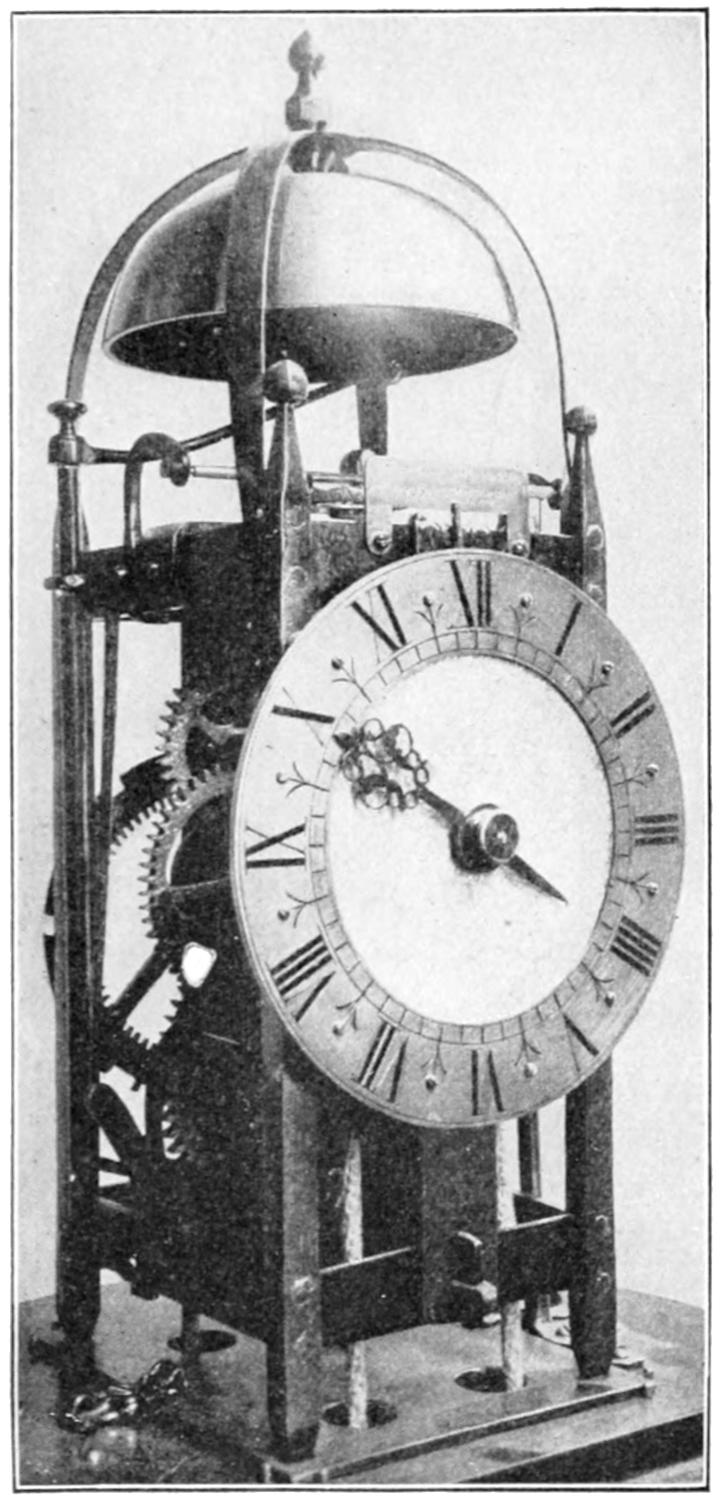

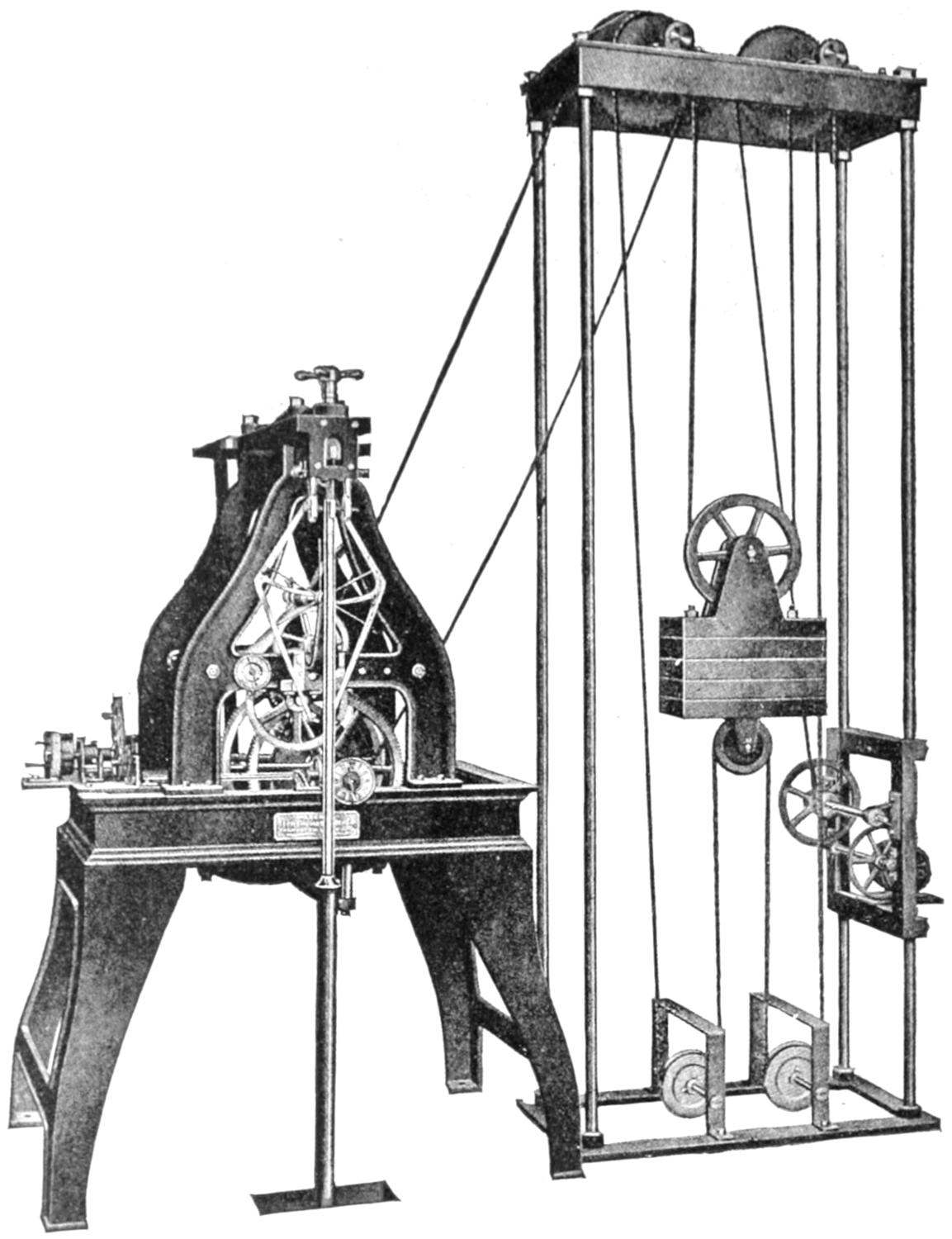

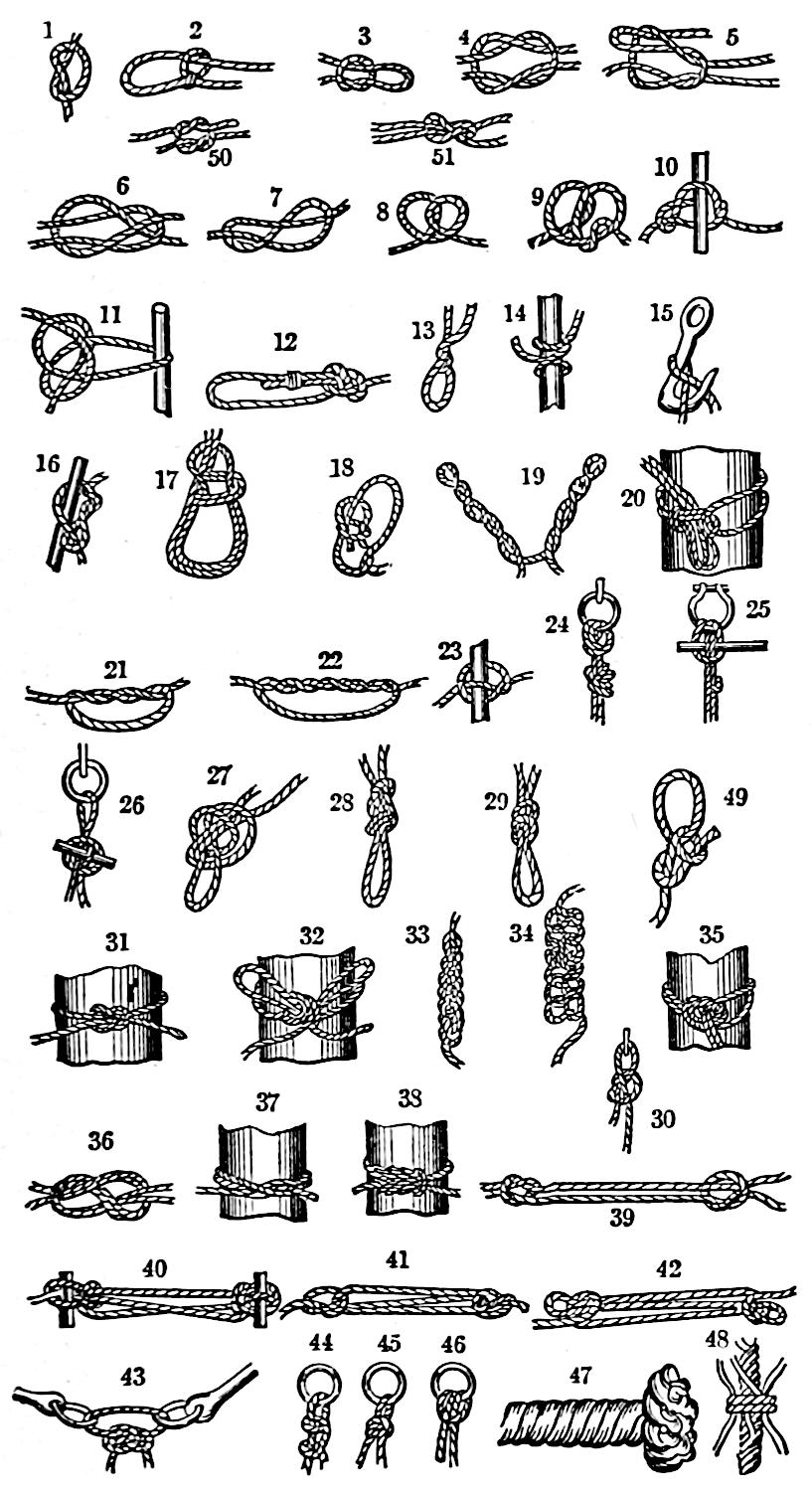

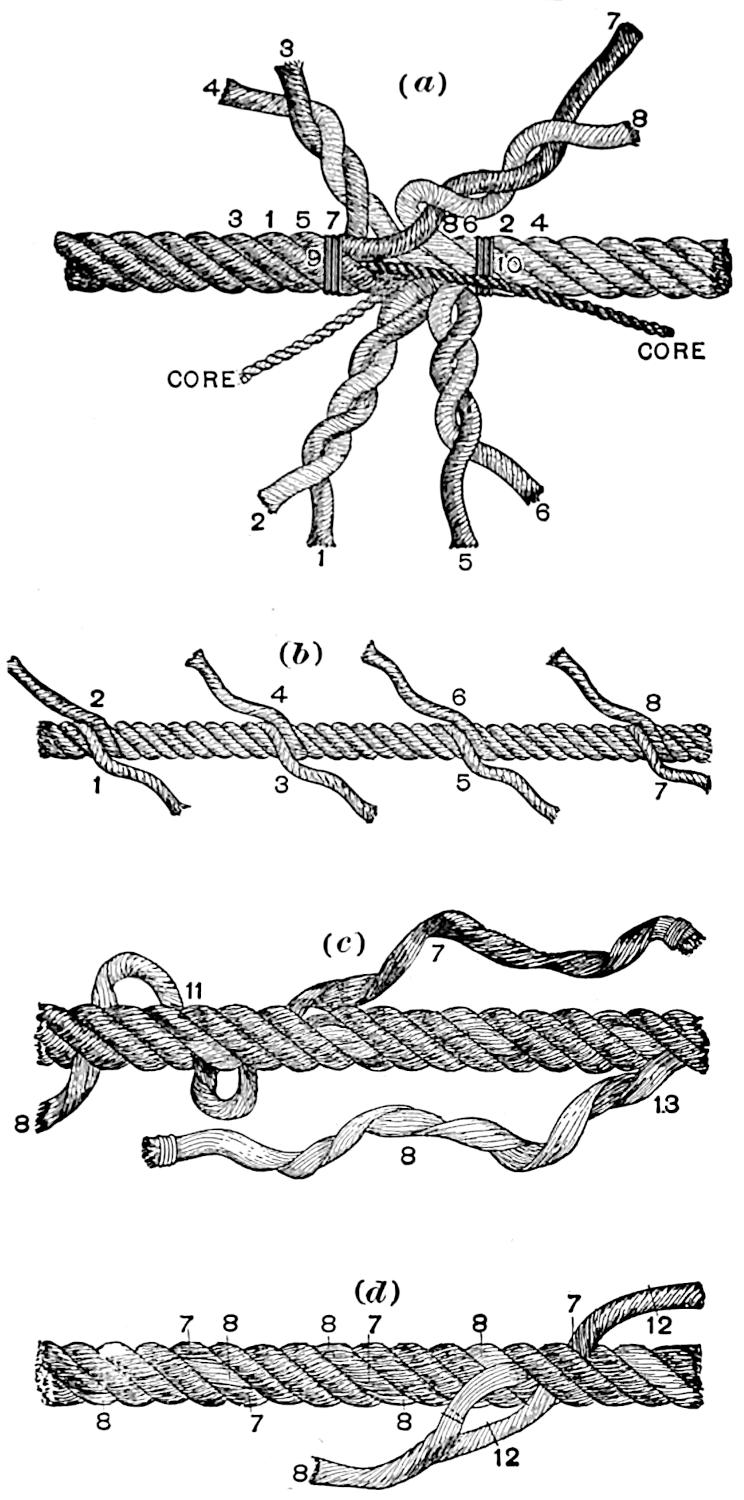

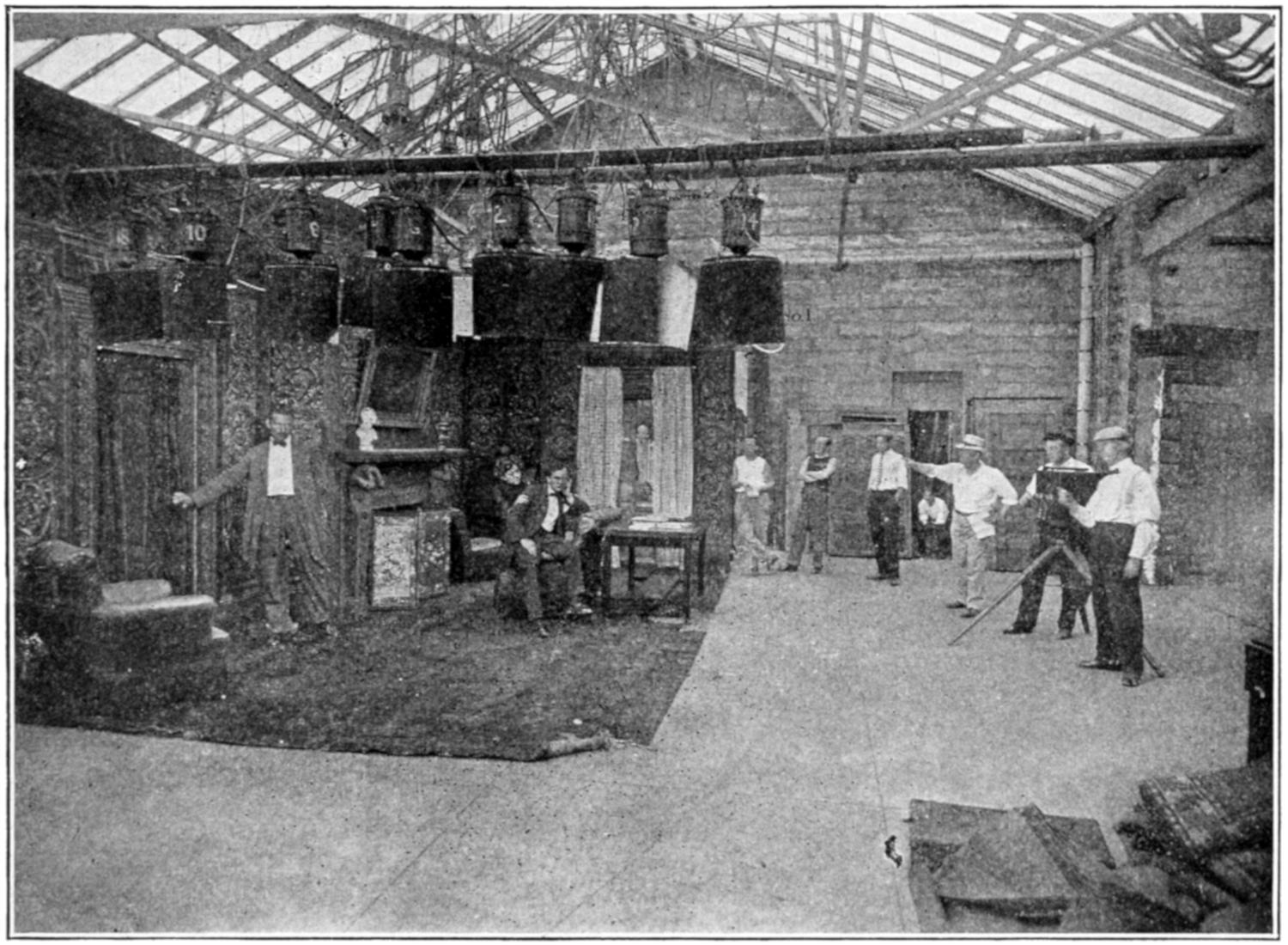

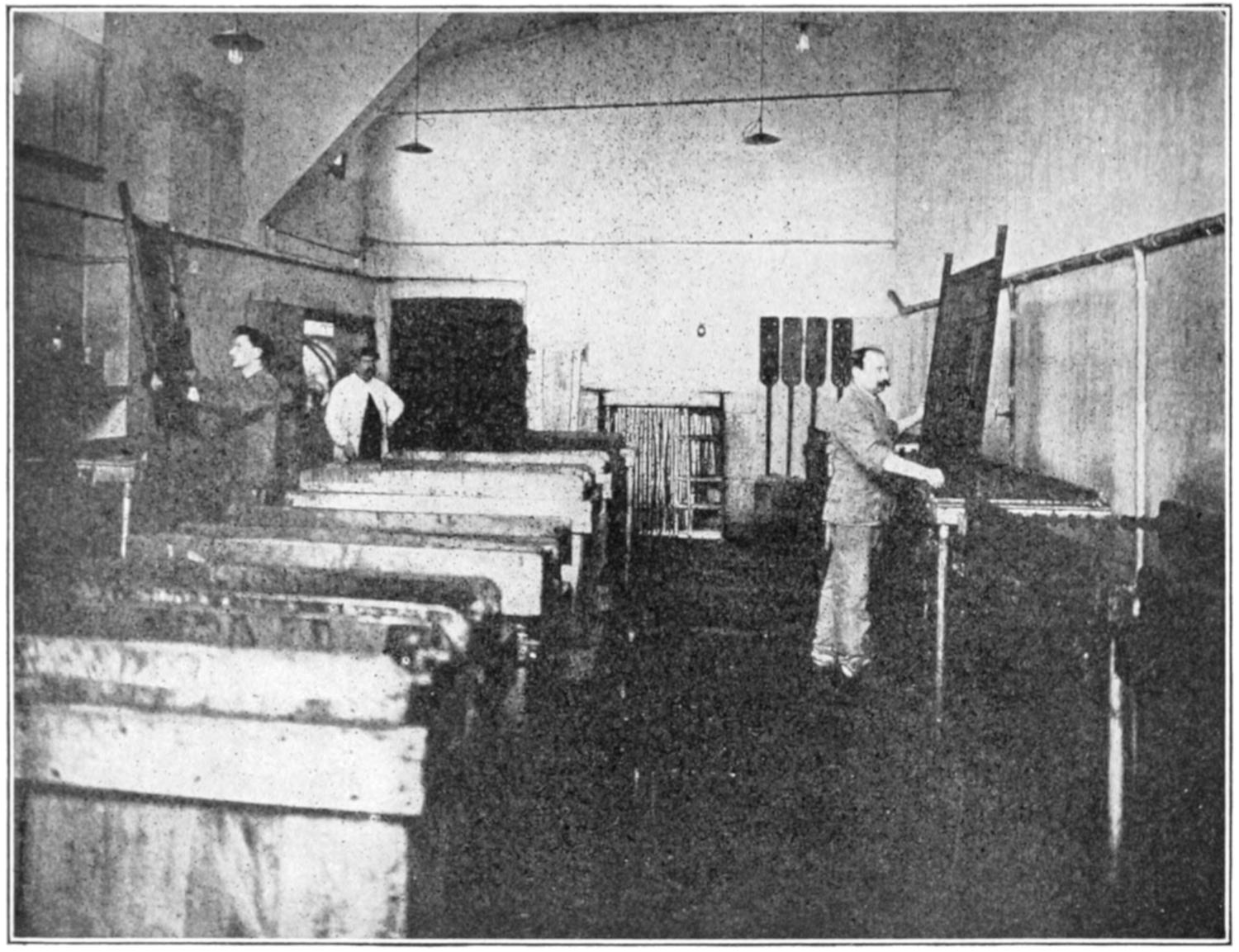

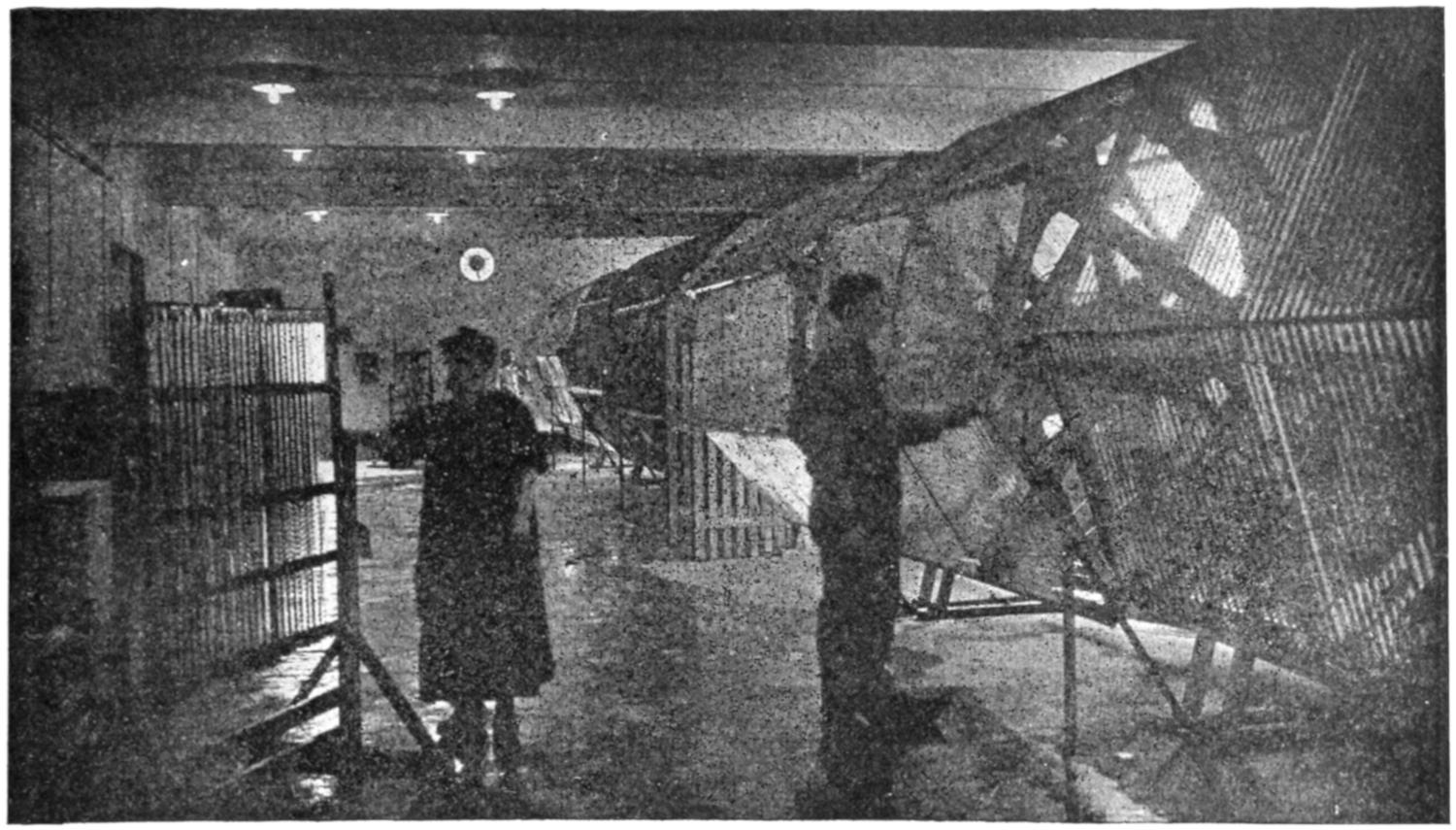

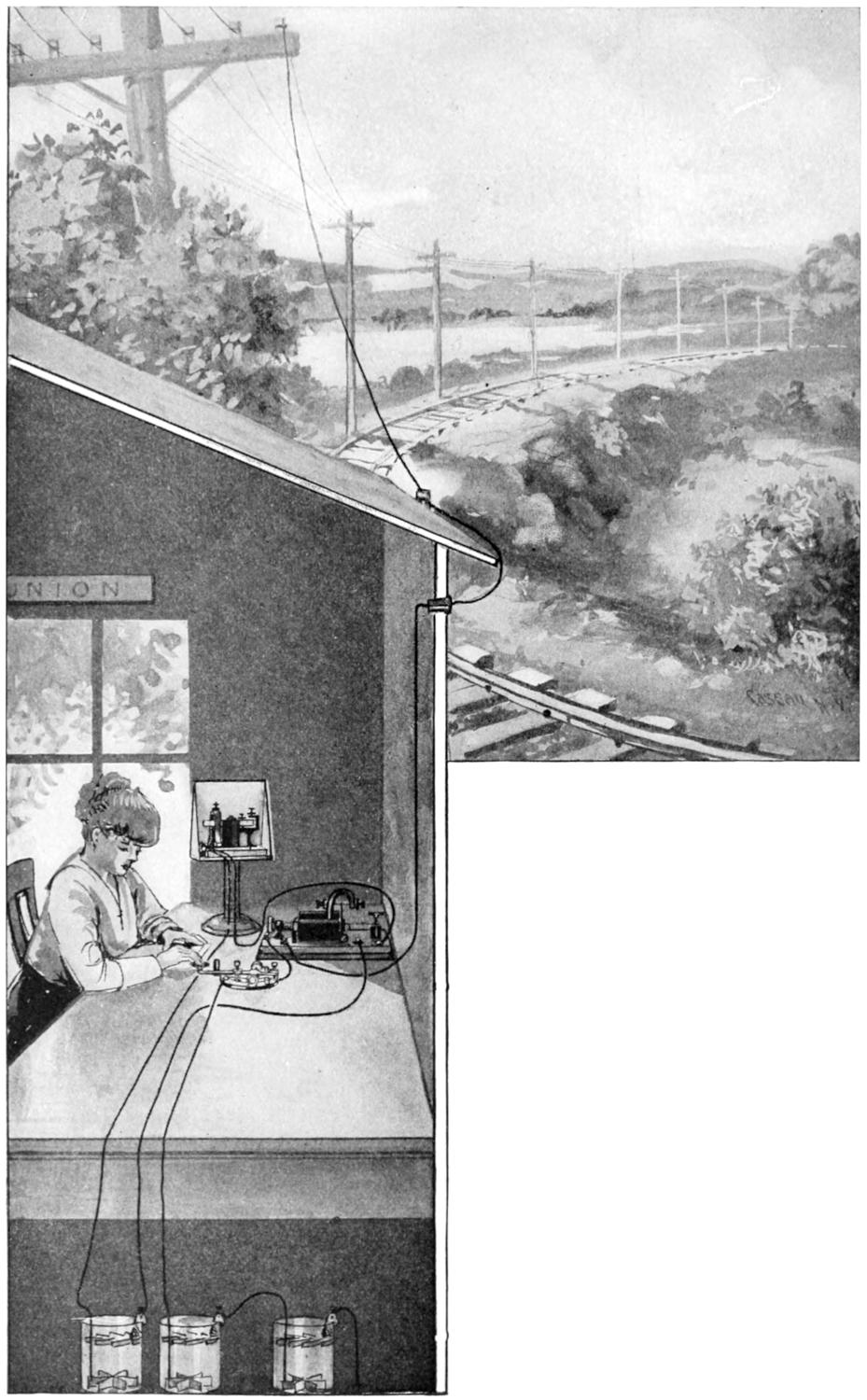

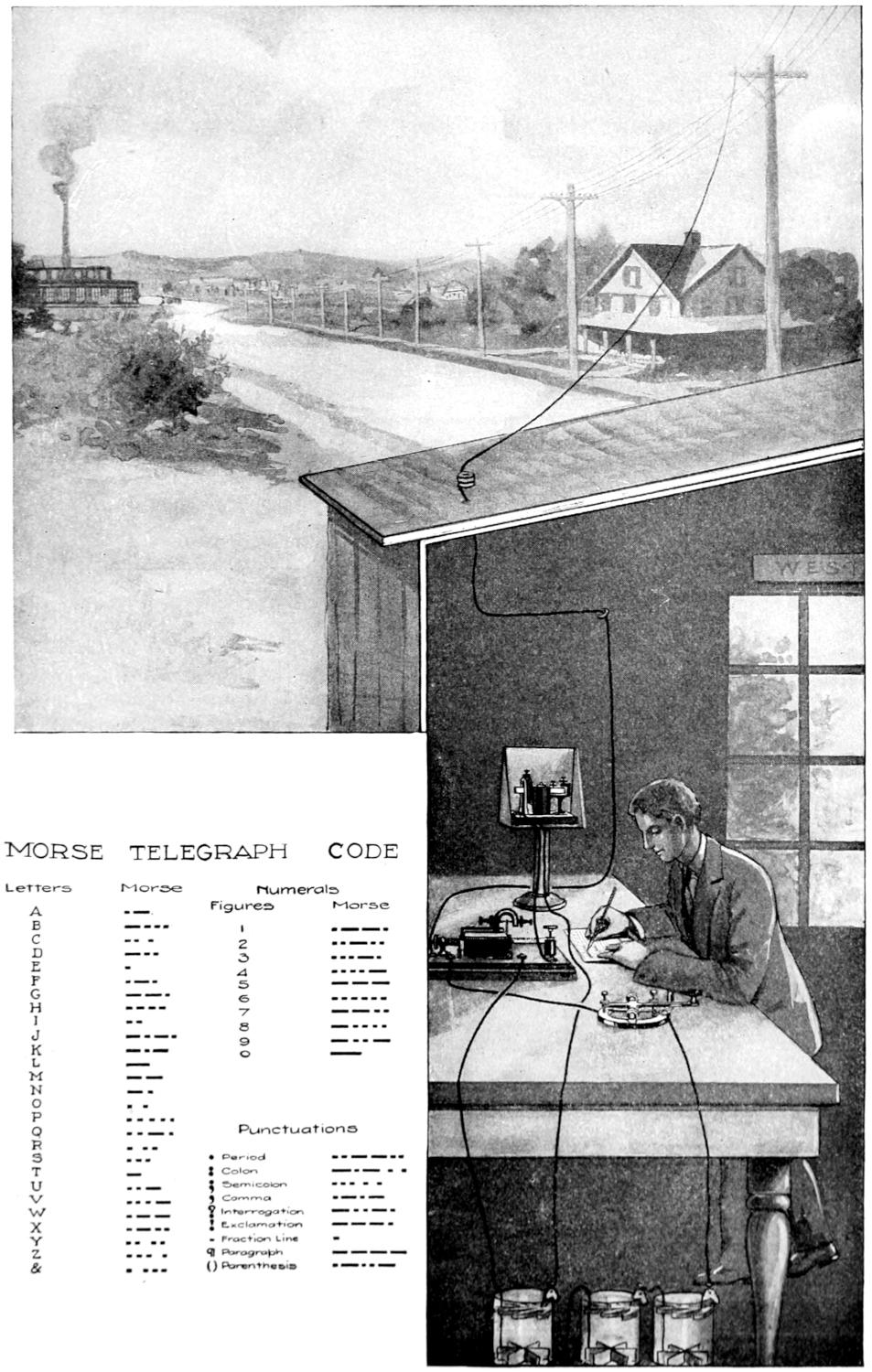

Can you tell What happens when we telephone? How a telegram gets there? What makes an automobile go? How man learned to tell time? How a moving-picture is made? How a camera takes a picture? How rope is made? How the light gets into the electric bulb? How glass is made? How the music gets into the piano? and hundreds of others that embrace the captivating tales of how man has made use of the wonders of nature and turned them to his advantage and comfort? The Book of Wonders does this with illuminating pictures which stimulate the mind and give a bird’s-eye view of each subject step by step.

Where shall such a book begin? Shall it begin with the Story of How[10] Man Learned to Light a Fire—he could not cook his food, see at night, or keep warm without a fire; or should it begin with How Man Learned to Shoot—he could not protect himself against the beasts of the forest, and, therefore, could not move about, till the soil or obtain food to cook until he knew how to shoot or destroy.

What was the vital thing for man to know before he could really become civilized? Some means, of course, by which the things he learned—the knowledge he had acquired—could be handed down to those who came after him so that they might go on with the intelligence handed down to them. This required some means of recording his knowledge. Man had to learn to write. Without writing there could be no Book of Wonders, and the book, then, begins naturally with the Story of Mow Man Learned to Write.

The Editor.

[11]

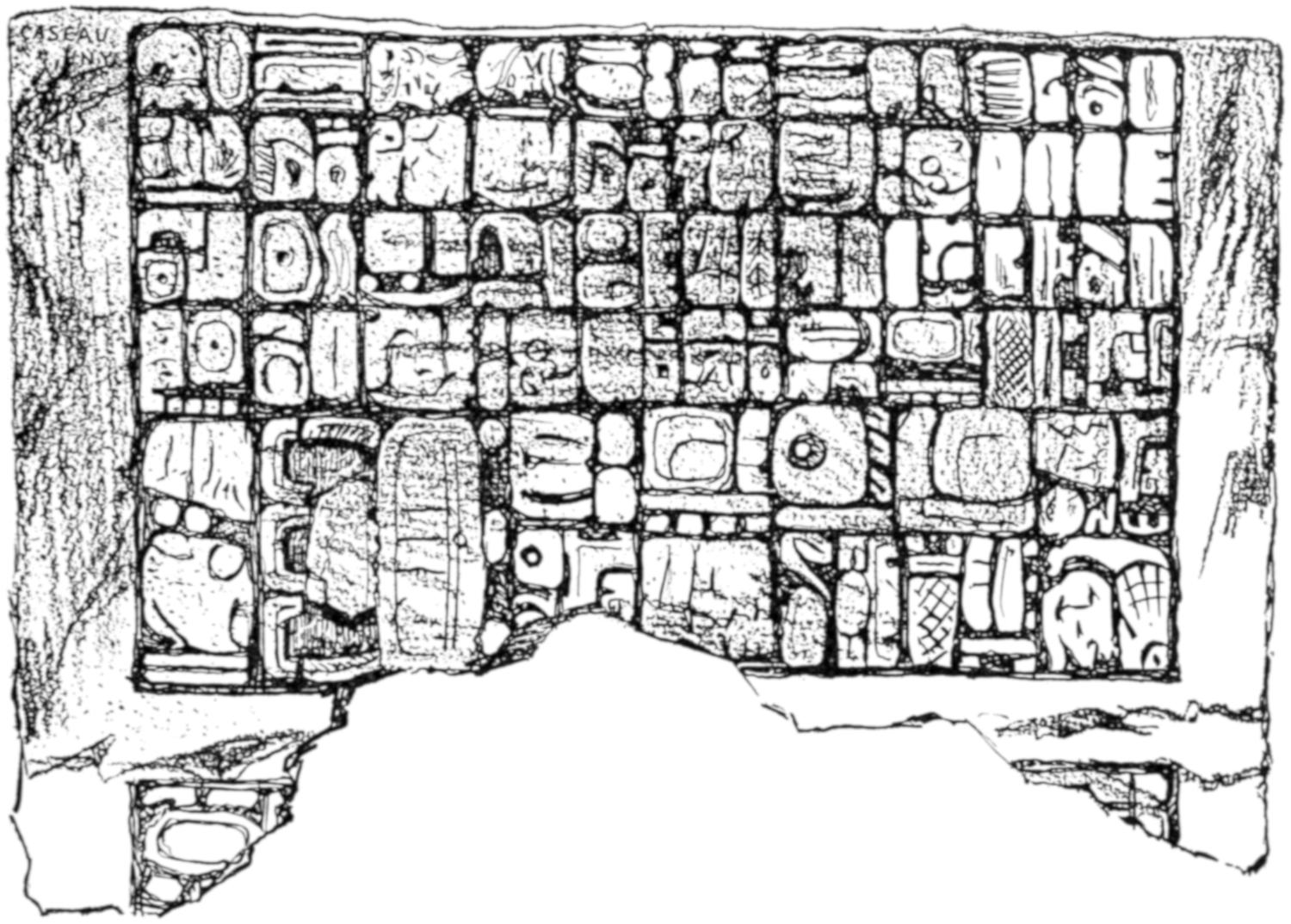

WRITING BY MEXICAN INDIANS THOUGHT TO BE MORE THAN TEN THOUSAND YEARS OLD.

It is a long time between the day of the cave-dwellers, with their instruments of chipped stone, and the present day of the pen. Yet wide apart as are these points of time, the trend of development can with but few obstacles be traced.

The story of the pen is a natural sequence of ideas between the first piece of rock scratched upon rock by prehistoric man, and the bit of metal which now so smoothly records our thoughts.

There was a time in the unwritten history of man when necessity prompted the invention of weapons, and the minds of these primitive men were concentrated upon this point. But the arts of war did not take up their entire time; some time must have been given to other pursuits. As the mind developed, and as an aid to memory, we find them carving, engraving, incising upon the rocks their hieroglyphics, which took the form of figures of men, habitations, weapons, and the animals of their period.

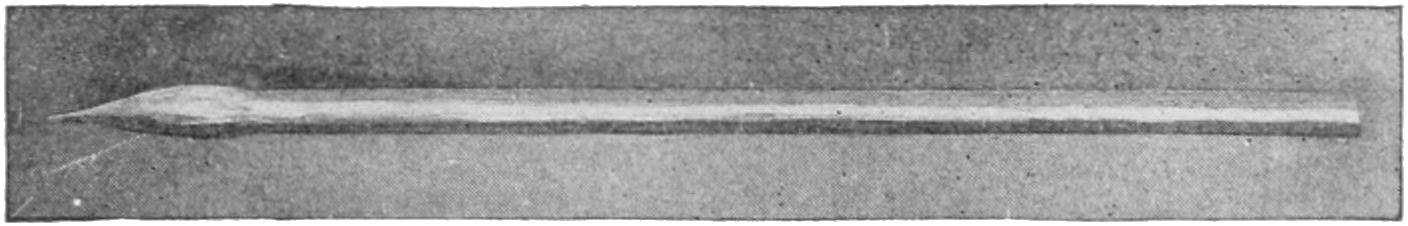

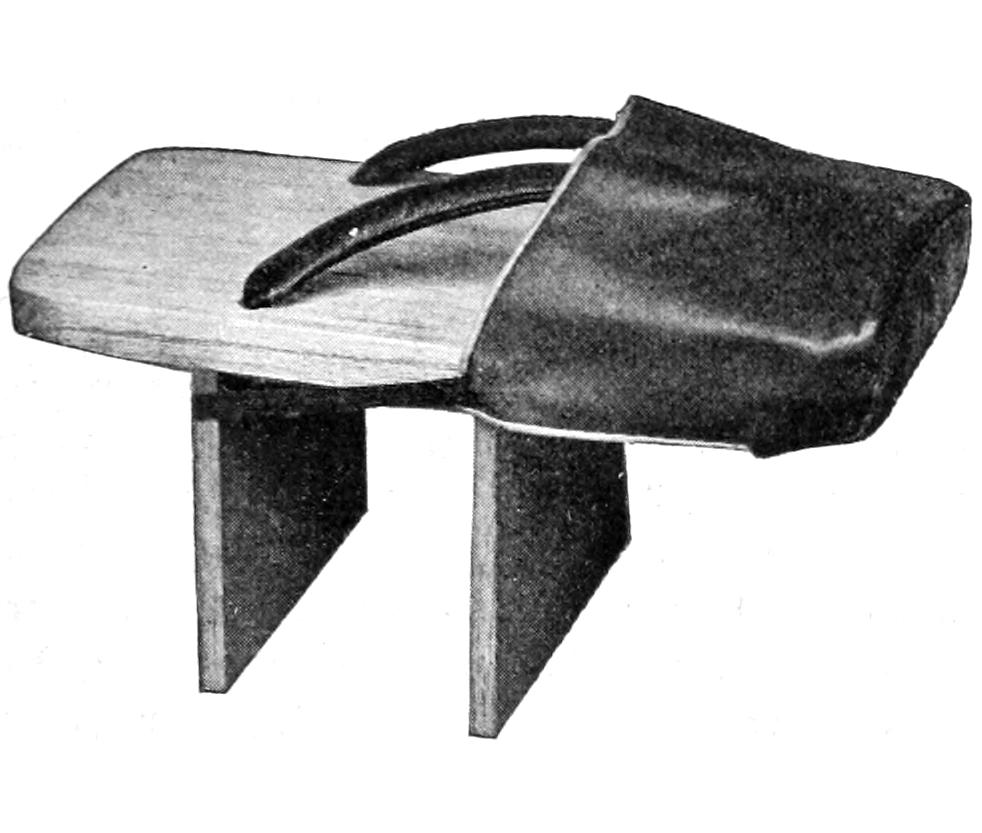

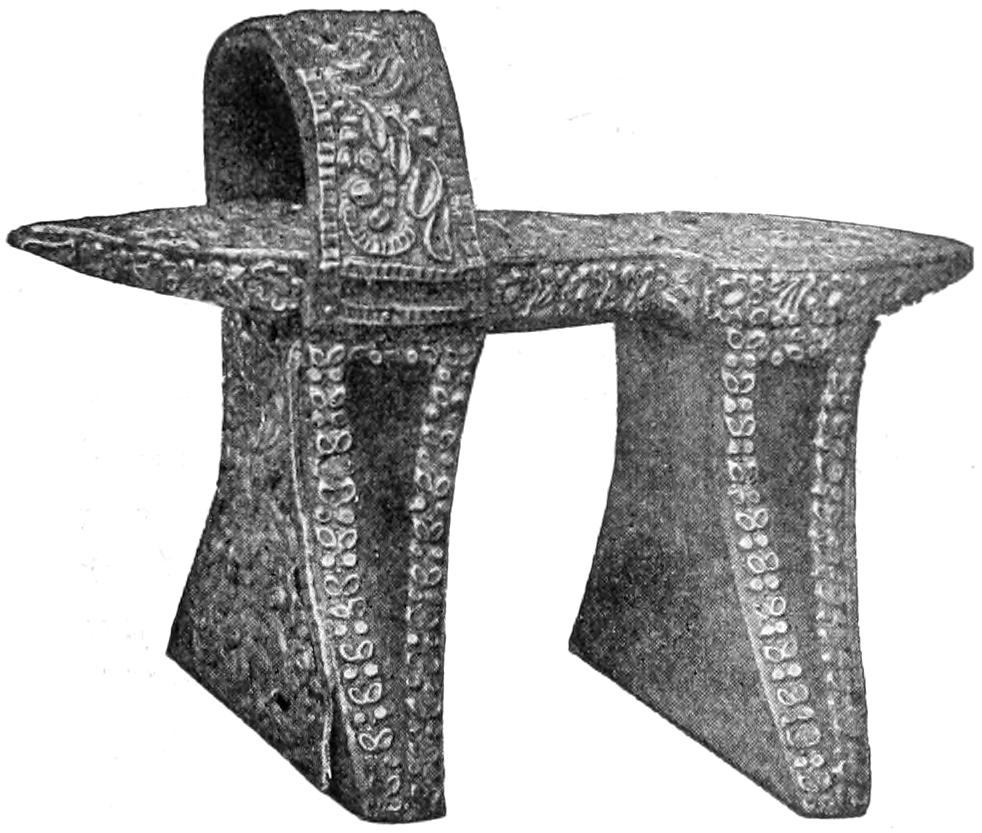

THE STYLUS

An apparently difficult question to answer, since without writing there can be no record of its origin, and without[12] records no facts; yet the deduction is so clear that the answer is simple. Somewhere far, far back in the dawn of the world, back in the beginning of human history, in the epoch which we have now named the Quaternary Period, man lived in a dense wilderness surrounded by the wildest and most ferocious beasts. His home was a cave, exposed to the dangers incidental to that time and his surroundings, and he was of necessity compelled to look about for means of defense. With this idea in mind, he found that by striking one stone against another he knocked off chips, which chips could be used as arrow-heads, spears and axes. Following along these lines he discovered that by rubbing one of these chips against another there was left a mark, which was the first imitation of writing; that the sharper the edge of the chip, the deeper was the scratch, and consequently the more distinct the mark.

EARLIEST WAYS OF WRITING

THE FIRST IMITATION OF WRITING

Next it was discovered that certain stones, such as flint, serpentine and chalcedony, marked more readily than others; that the elongated chip was handled with more facility; that by rubbing one stone against another the finest possible points and edges might be obtained. Thus in the Age of Stone was the long, tapering instrument of stone, the first pen, the Stylus, originated.

Then came the time, known as the Bronze Age, when men learned to hammer metal into shapes, and metal having many advantages over stone, the stylus of stone gave way to one of iron. So we find that in the time of the Egyptians, about fourteen or fifteen[13] centuries B.C., an iron stylus was in use for marking on soapstone, limestone and waxed surfaces. An improvement in this metal stylus was that the blunt end was convex and smooth, the purpose of which was to erase and smooth over irregularities. In some cases it was pointed with diamonds, which gave it greater cutting properties. The iron stylus was also used by the Egyptians of that period, as well as in later times, with a mallet, after the manner of the modern chisel (which indeed it resembled) for cutting out inscriptions on their monuments.

THE BRUSH

WRITING FLUIDS

HELPED DEVELOPMENT

In course of time a marking fluid was discovered, and this made necessary a writing instrument which could spread characters on parchment, tree-bark, etc. Thus it was found that by putting together a small bunch of hairs, arranging them in the shape of an acute cone, and fastening them together in some manner, an instrument could be made which would carry fluid in its path, and thus make a mark of the desired shape. The hair best adapted for the purpose was found to be camel’s hair, while that of the badger and sable was also used. A tube cut from a stalk of grass answered for a holder. The hairs were held together by a piece of thread which was then drawn through the tube, thus making the first writing instrument to be used in conjunction with ink, the Brush.

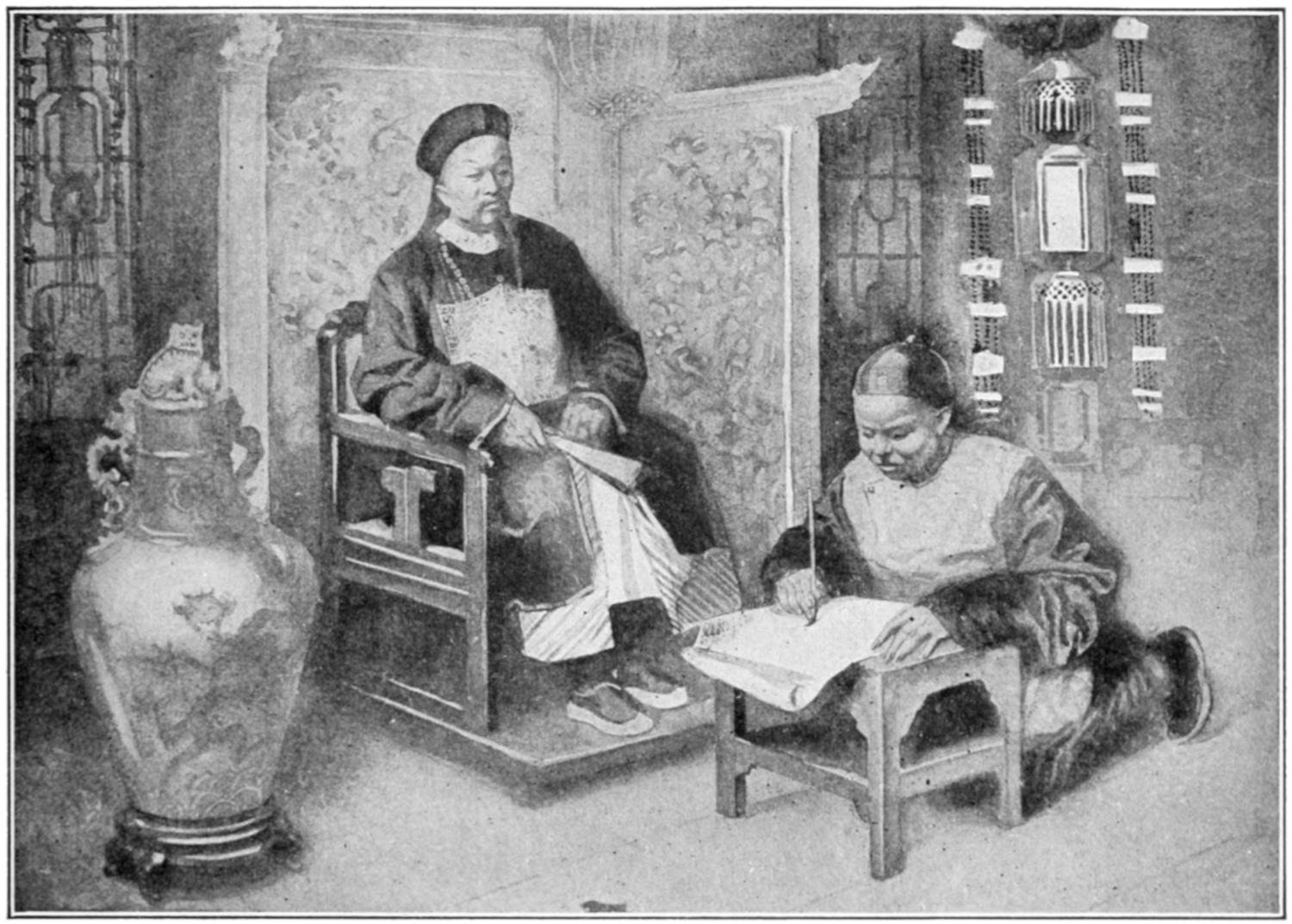

HOW THE CHINESE IMPROVED METHODS

Just when the Brush came into existence is not definitely known, but with this instrument the great Chinese philosopher Confucius wrote his marvelous philosophy. The Brush as a writing instrument is generally associated with[14] the Chinese, because the Chinese use this instrument even to the present day, it being especially adapted to their letters and mode of writing. We have now a pen (brush), as well as an ink, but the material upon which the people of that age wrote, in lieu of paper, was still very crude, parchment and tree-bark being most commonly used.

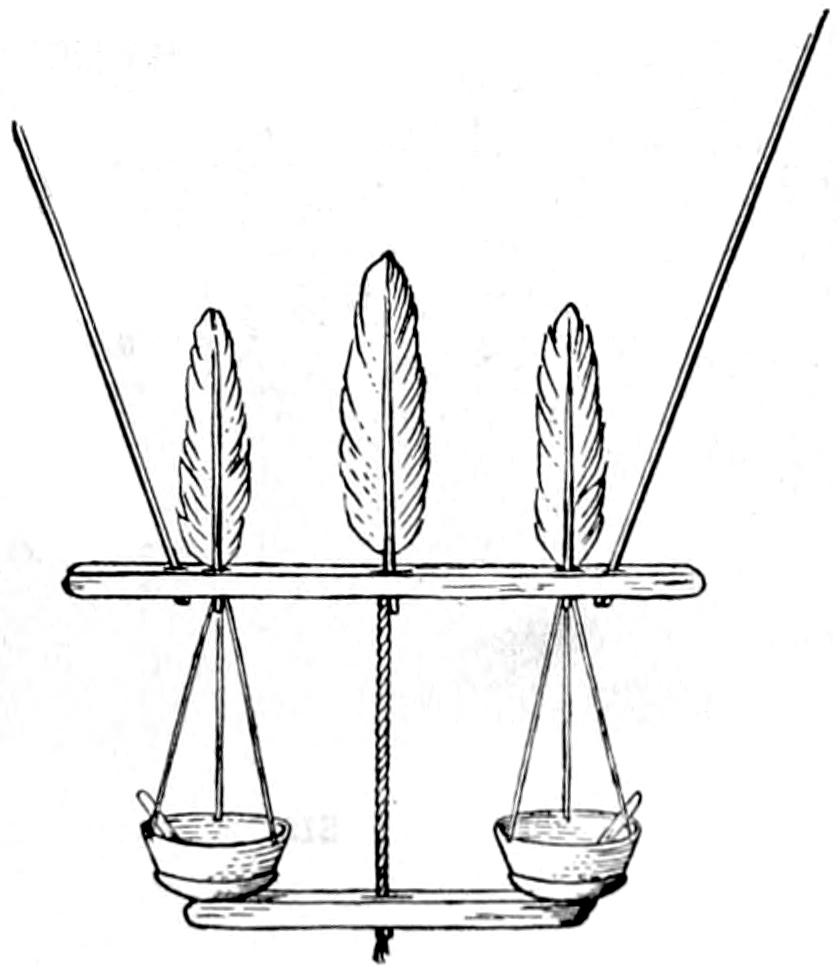

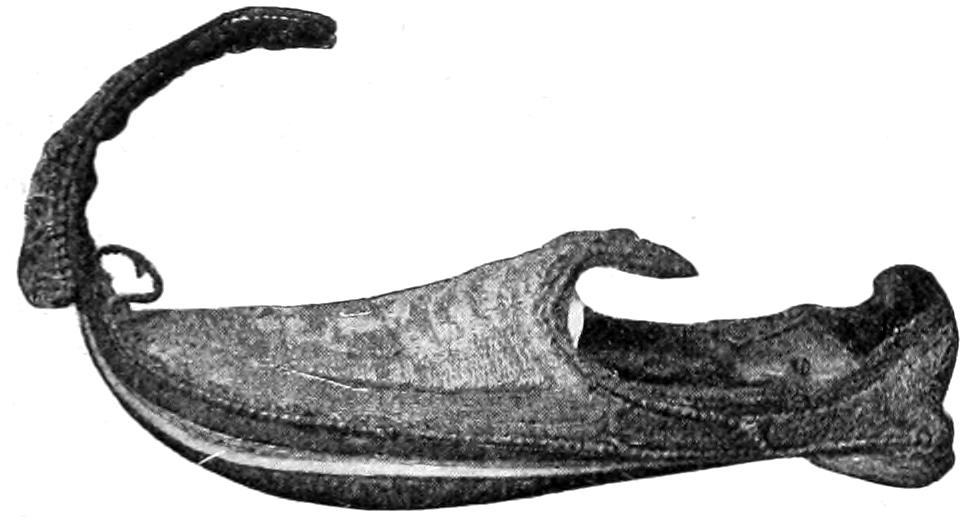

THE QUILL

THE EARLIEST

FORMS OF PAPER

Just as the discovery of an ink wrought a change from the Stylus to the Brush, so the advent of papyrus, a paper made from the papyrus plant, which was much finer and more economical than parchment, brought with it a pen better adapted for this material. It was found that the Reed, or Calamo, as it was called, which grew on the marshes on the shores of Egypt, Armenia and the Persian Gulf, if cut into short lengths and trimmed down to a point, made an admirable pen for this newly discovered paper. This was the true ancient representative and precursor of the modern pen. The use of the Reed can be traced to a remote antiquity among the civilized nations of the East, where Reeds are in use now as instruments for writing.

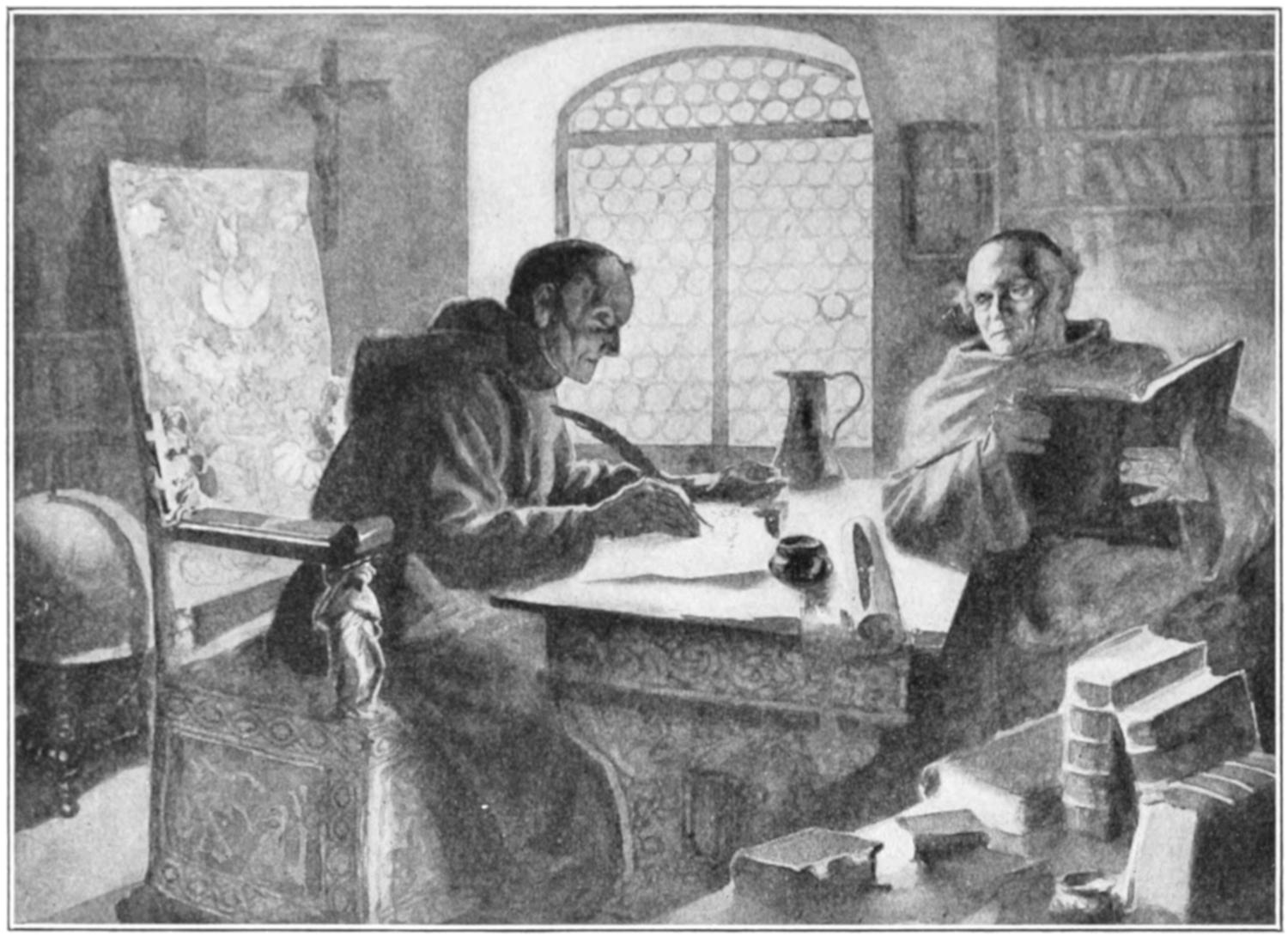

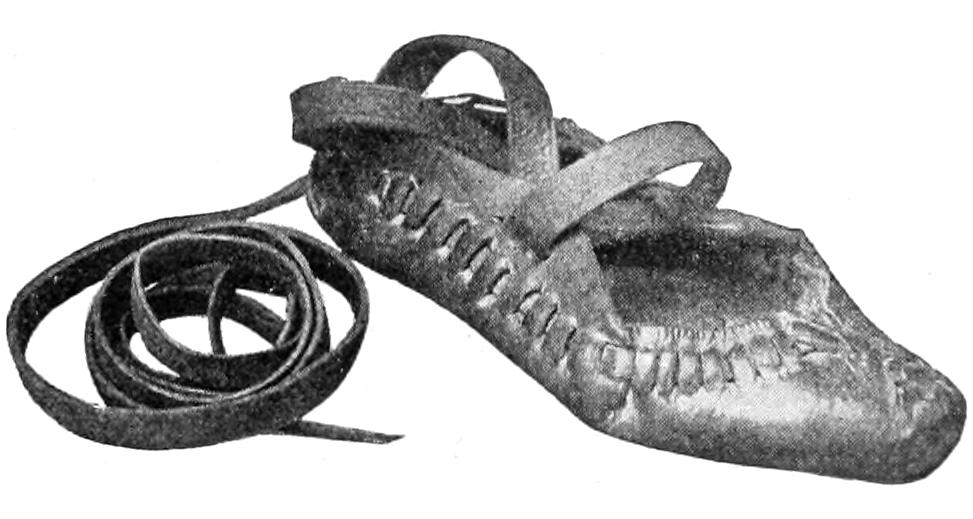

HOW THE MONKS DID THEIR WRITING

The introduction of a finer paper rendered necessary a finer instrument of writing, and the quill of the goose, swan, and, for very fine writing, of the crow, was found to be well adapted. Immense flocks of geese were raised, chiefly for their quills. The earliest specific allusion to the quill occurs in the writings of St. Isadore de Seville, seventh century, although it is believed to have been in use at an earlier period. The quill was used for many centuries. Most of the writing during its reign was done in the monasteries by the monks, and in the eighteenth century,[15] when quill-making became quite an art, every monk and every teacher was expected to be proficient in the art of making a pen from a quill. The preliminary process of preparing the quills was first to sort them according to their quality, dry in the hot sand, then clean them of the outer skin, and harden by dipping in a boiling solution of alum and diluted nitric acid. During the last century many efforts were made to improve the quill, its great defect being speedy injury from use. Ruby points were fitted to the nib, but this was found impracticable on account of the delicacy of the work. Joseph Bramah devised, in 1809, a machine for cutting the quill into separate nibs for use in holders, thus making several pens from one quill and anticipating the form of the modern pen.

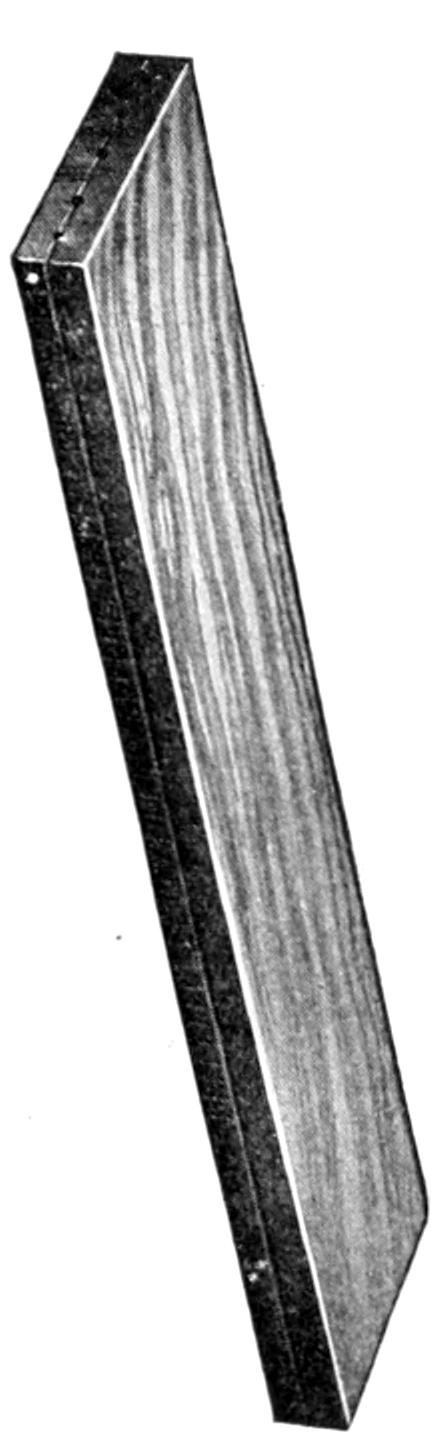

THE STEEL TUBE PEN

THE FIRST STEEL PEN

The quill held sway as writing instrument for many years, and with it the greatest masterpieces in literature have been written. Many attempts, however, had been made to supersede the quill by a pen not so easily injured by use, but it was not until about 1780 that, after much experimenting and numerous failures, Mr. Samuel Harrison introduced the first metallic pen.

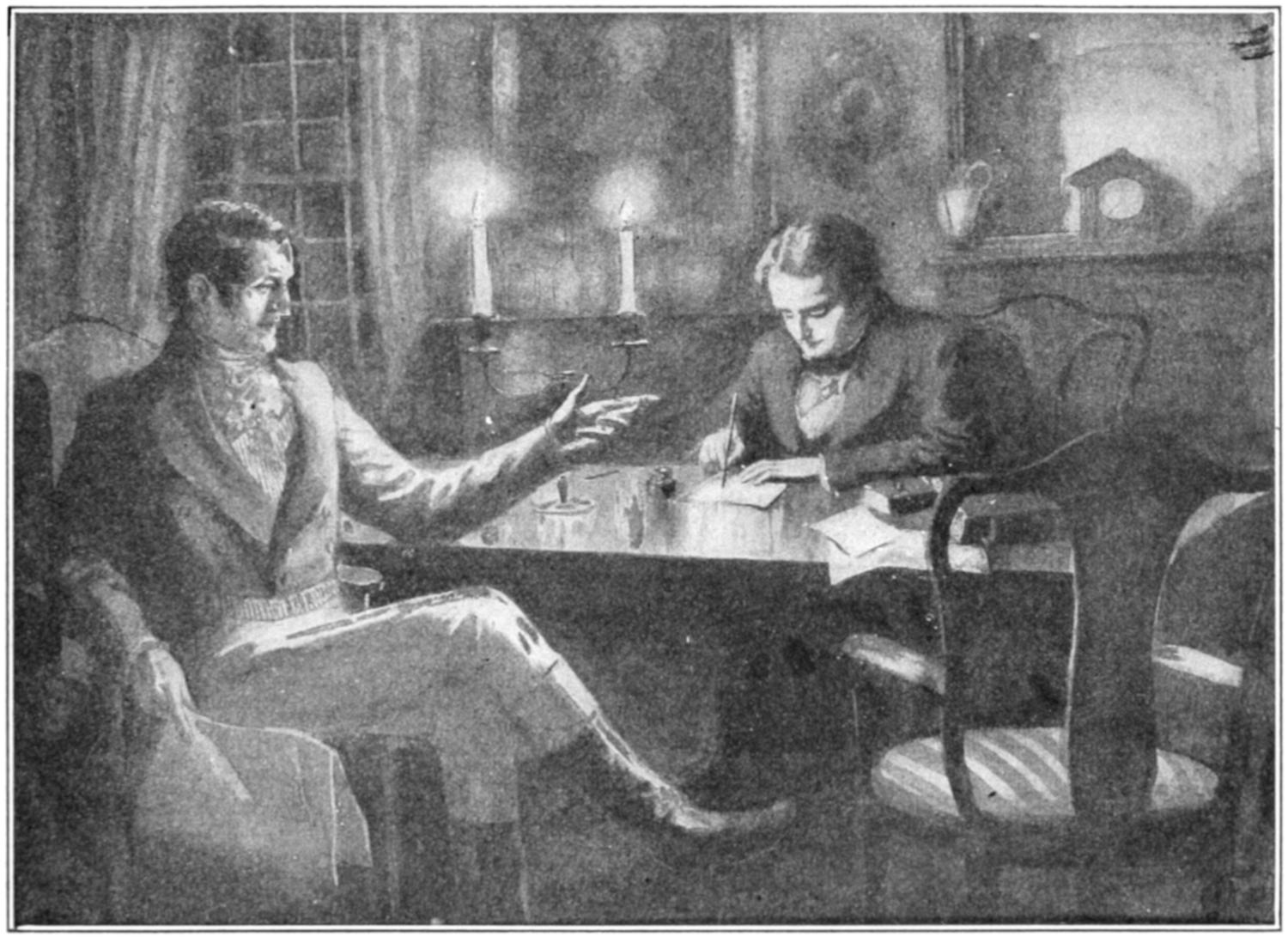

THE INVENTION

OF THE PEN

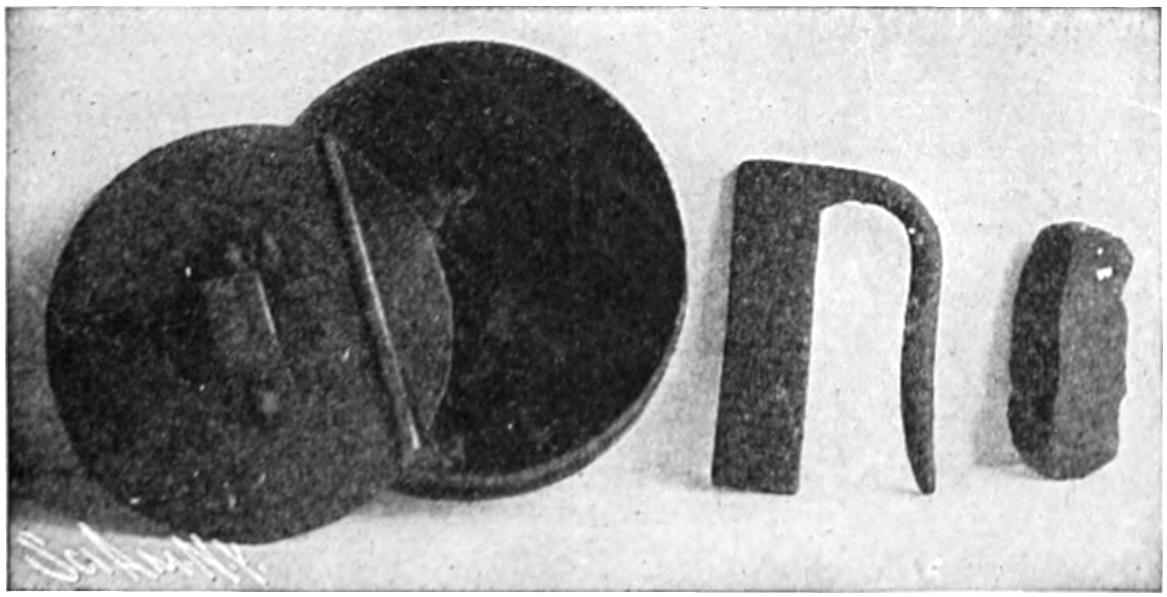

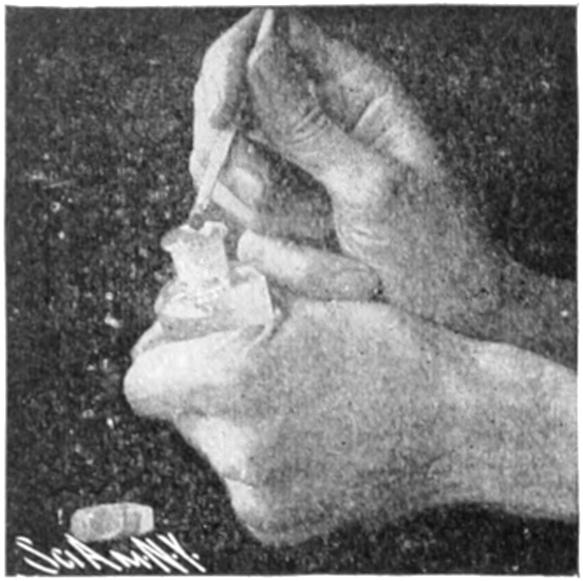

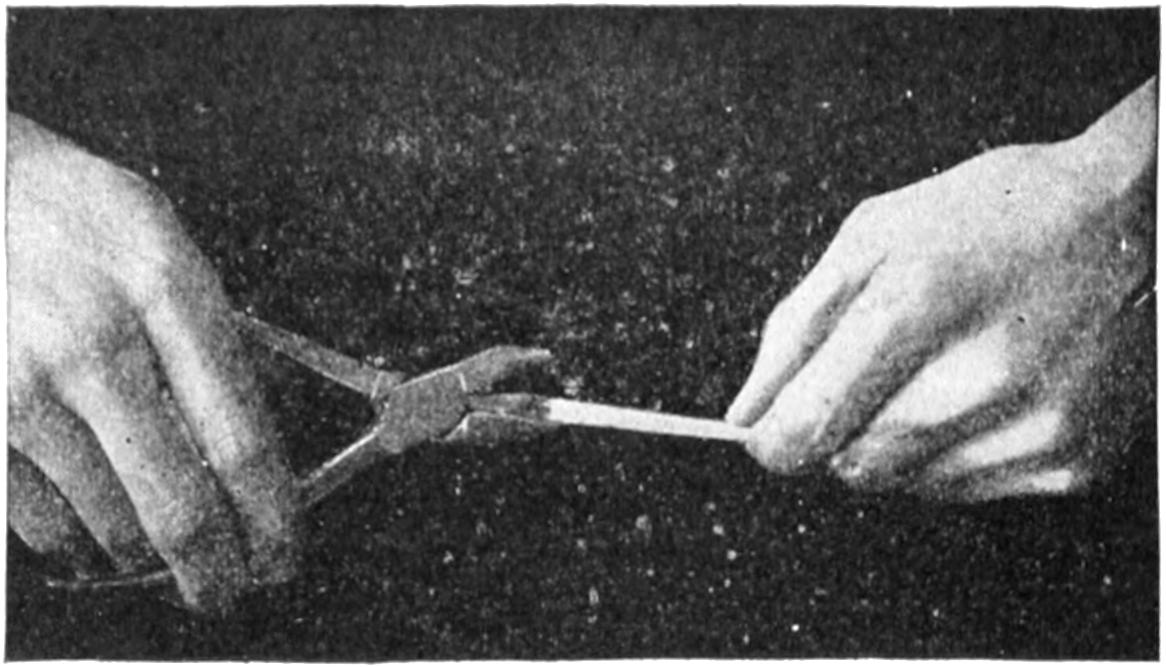

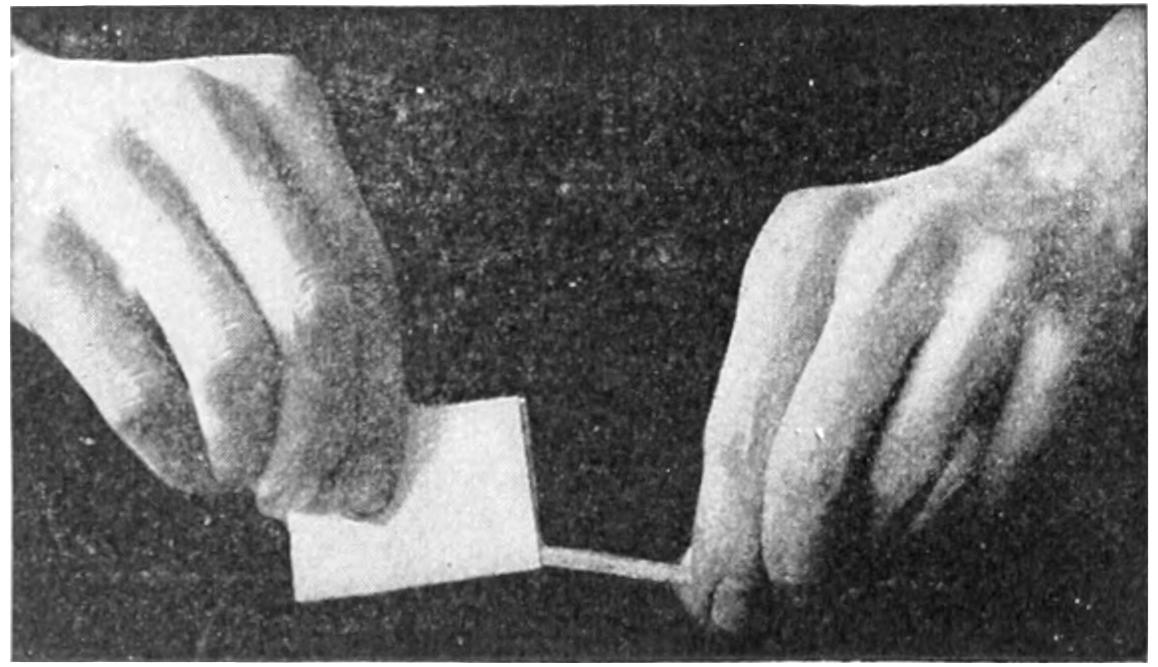

This pen was made as follows:

A sheet of steel was rolled in the form of a tube. One end was cut and trimmed to a point after the manner of the quill, the seam where both edges of the tube met forming the slit of the pen. This was soon after improved upon by cutting a rough blank out of a thin sheet of steel, which blank was filed into form about the nib, rounded, and with a sharp chisel marked inside where the slit was to be in the finished pen. After tempering, the nib was[16] ground and shaped to a point suitable for fine or broad writing, as required.

THE MODERN STEEL PEN

THE MODERN WRITING PEN

Once started, the steel pen made rapid strides in improvement. Mr. James Perry, in 1824, started in England the manufacture of pens on a large scale, and to him as well as Gillott is due the many improvements which followed.

Perry was the first to manufacture “slip” steel pens, up to this time the pen and holder being one piece.

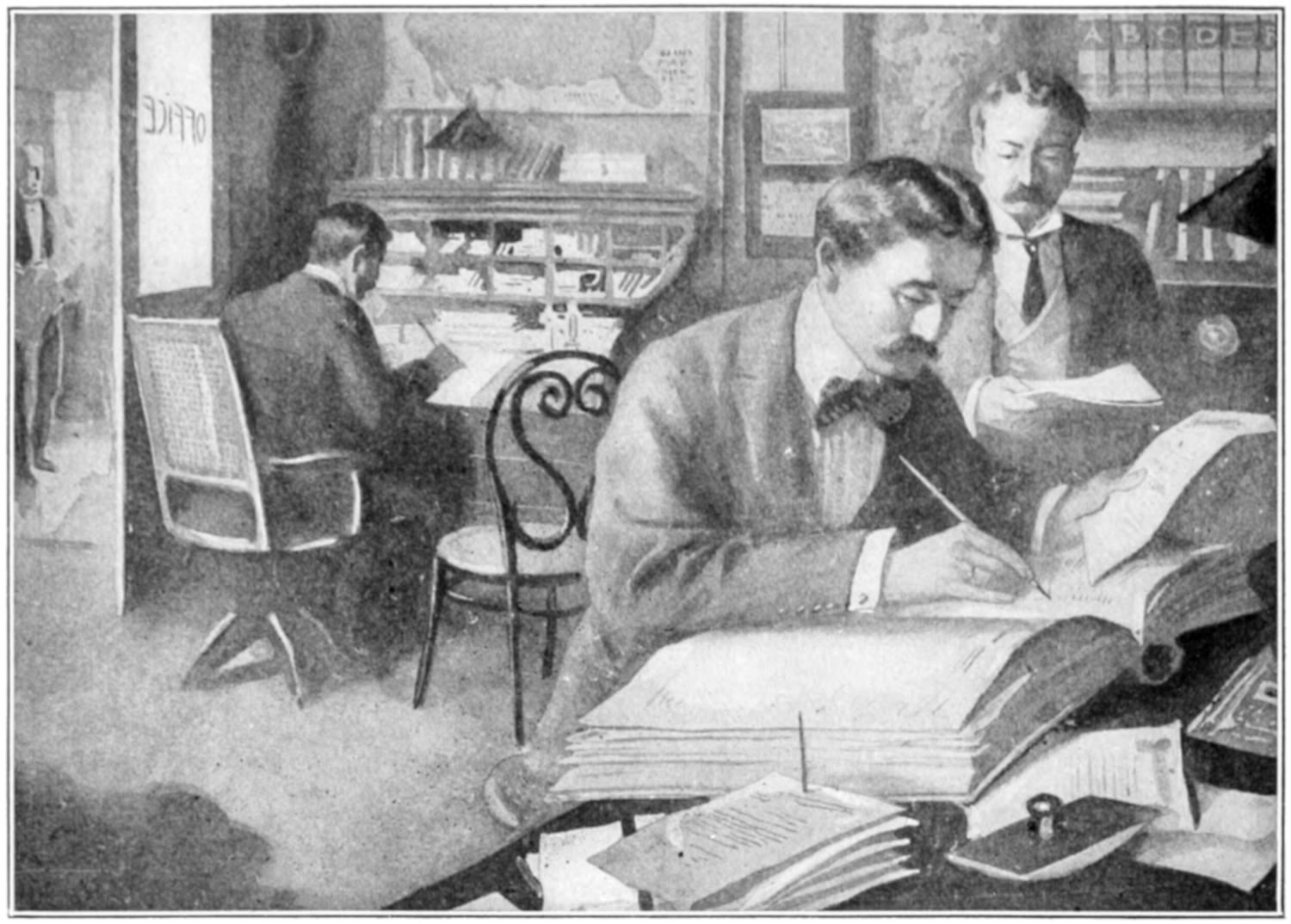

THE MODERN WAY

OF WRITING

The steel pen of the present day has reached the pinnacle of perfection, and the method of manufacture of this little but mighty instrument of writing, though of extreme interest, is practically unknown by the general public. To explain in detail the development from the rough steel to the finished pen would needs make a book in itself. And as it has been our intention to dwell, not upon the manufacture of the pen, but to trace its history and development from its most crude form, the Stylus, to the perfect and smooth-writing steel pen of to-day, we will close our story with the well-worn epigram of old, grim Cardinal Richelieu:

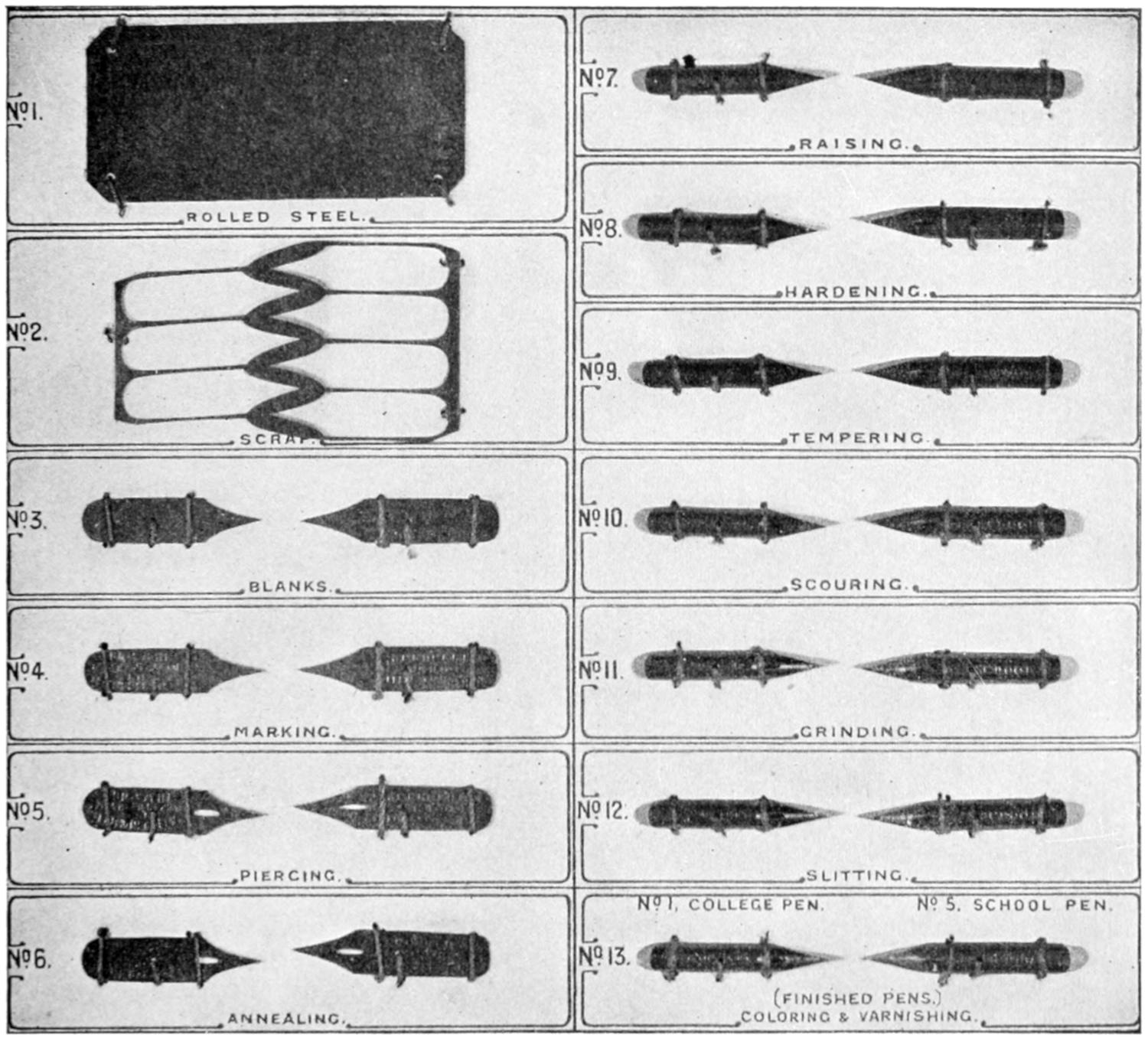

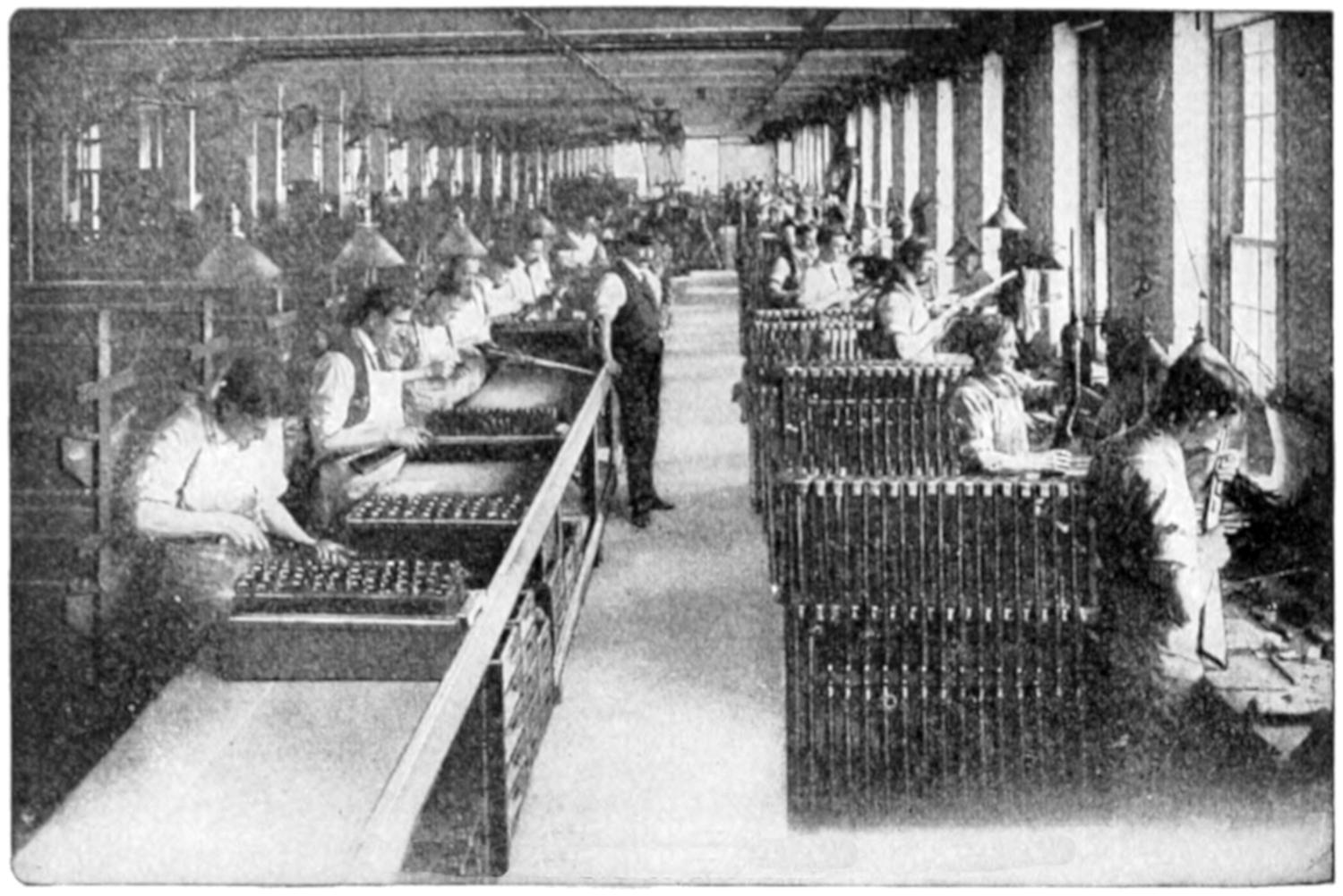

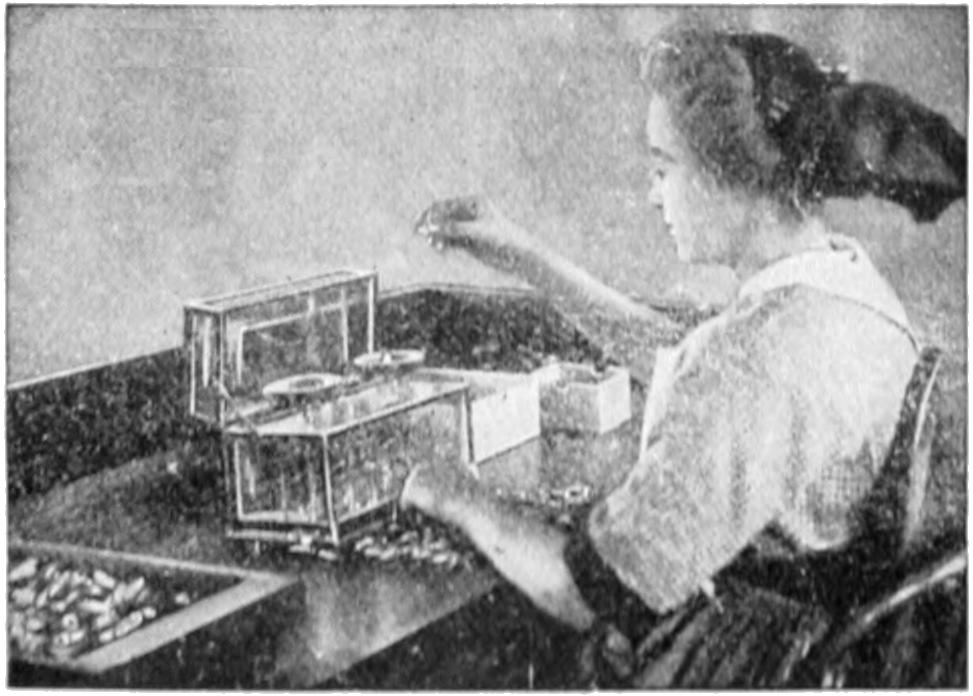

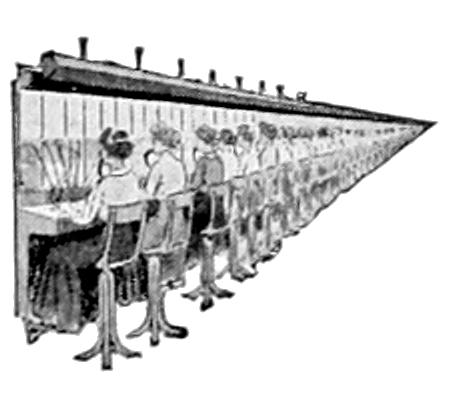

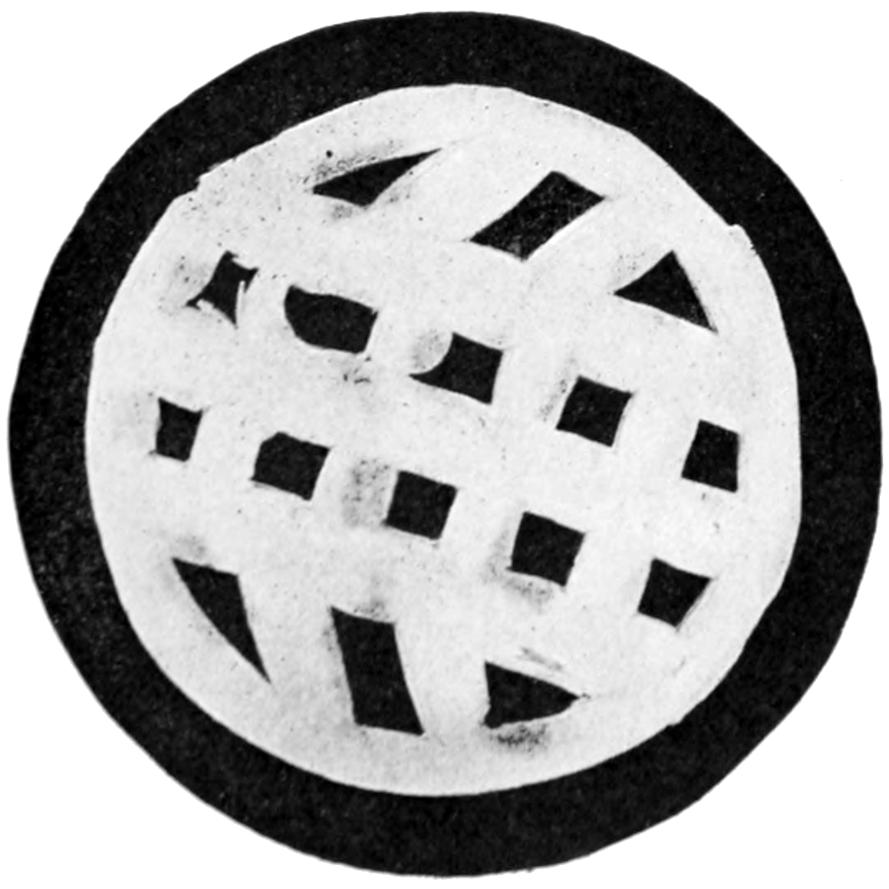

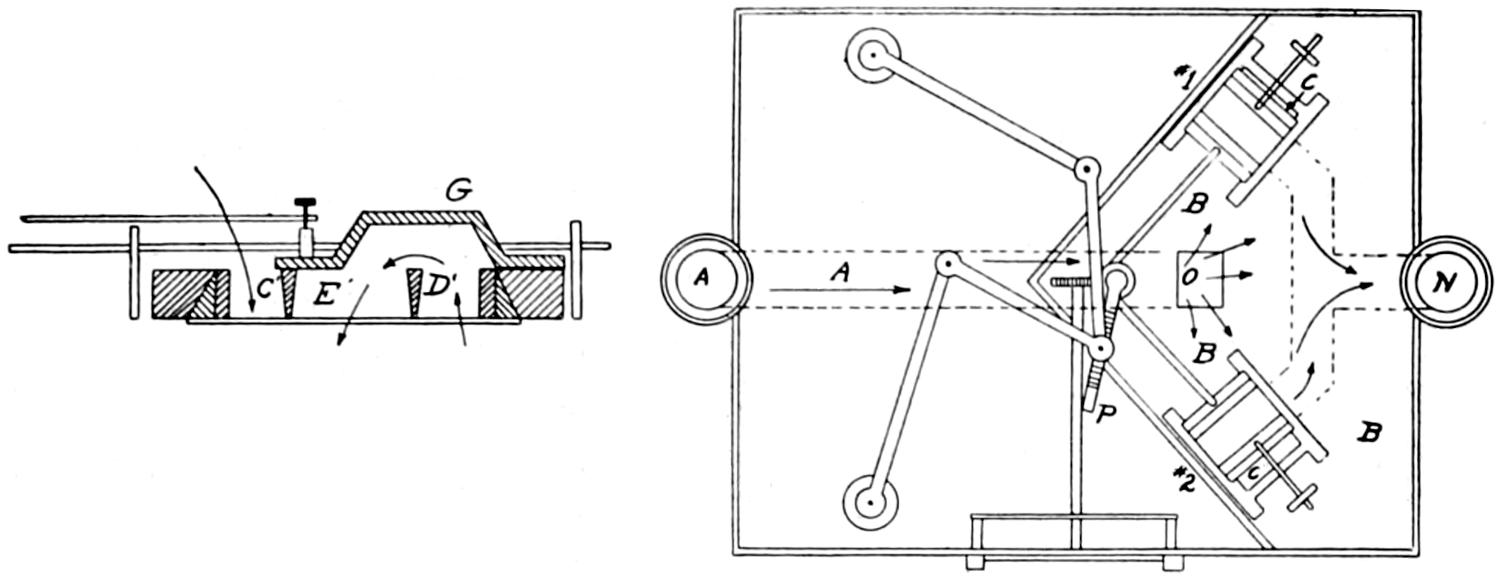

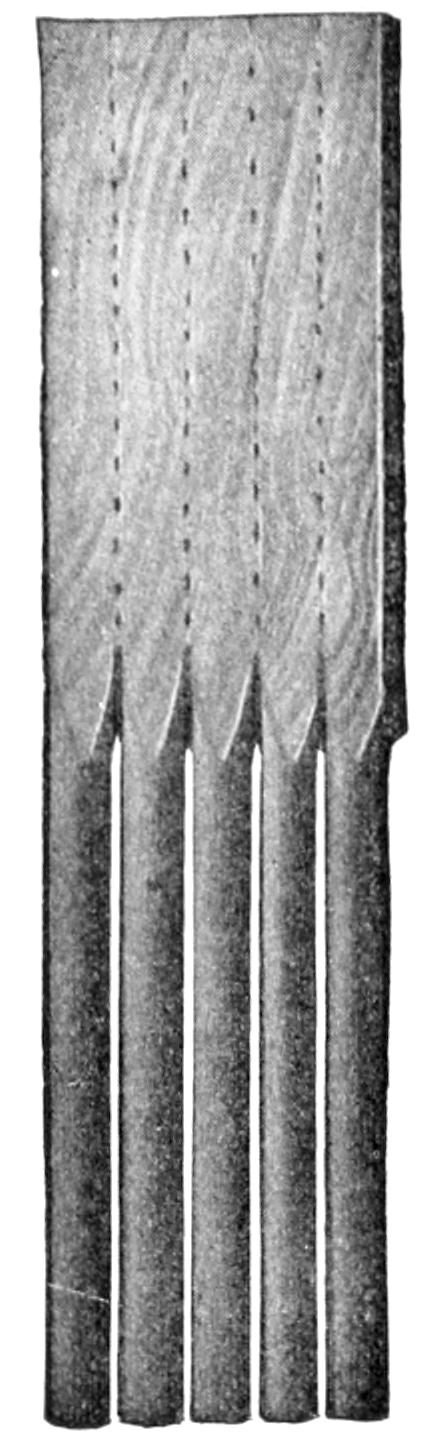

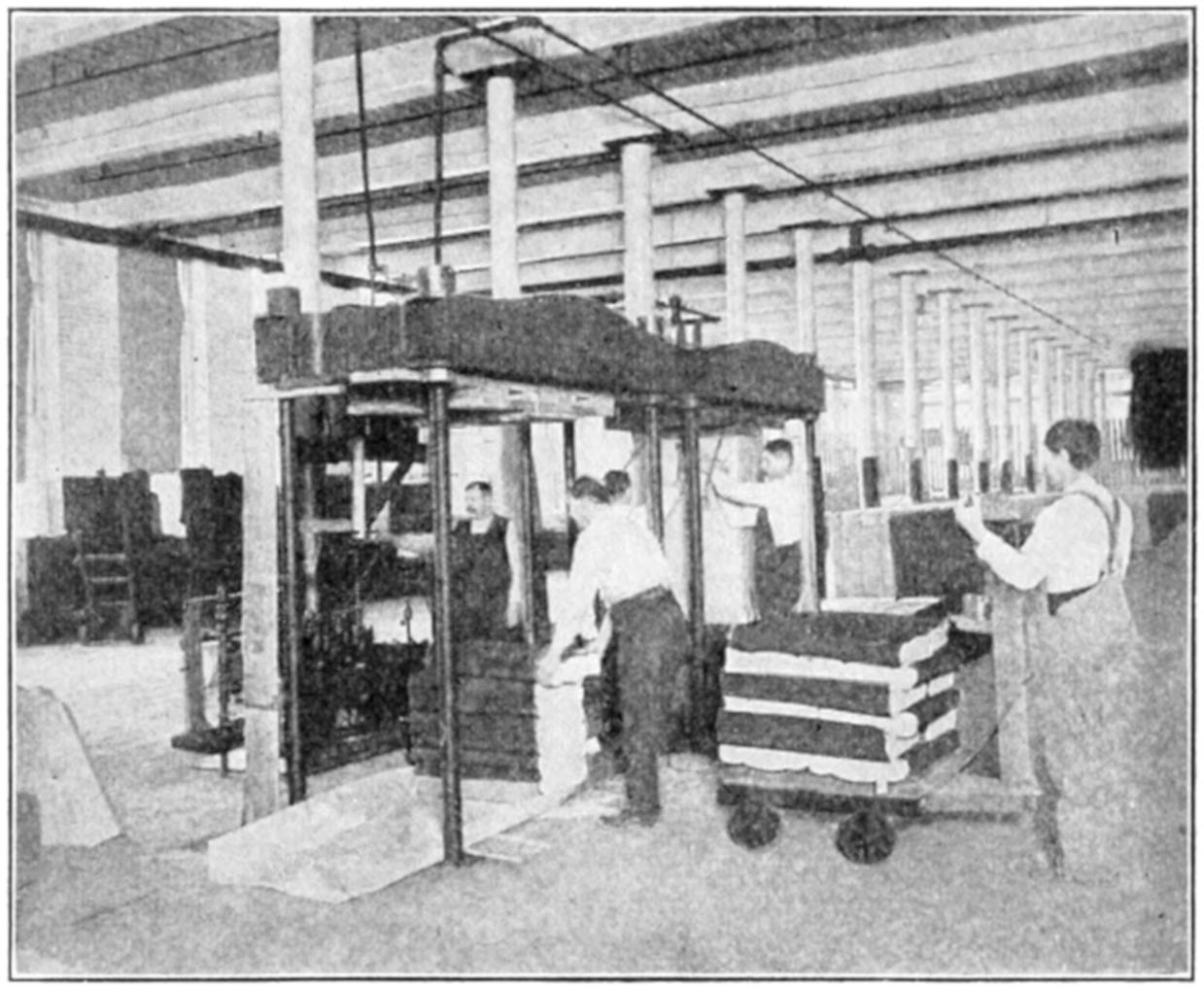

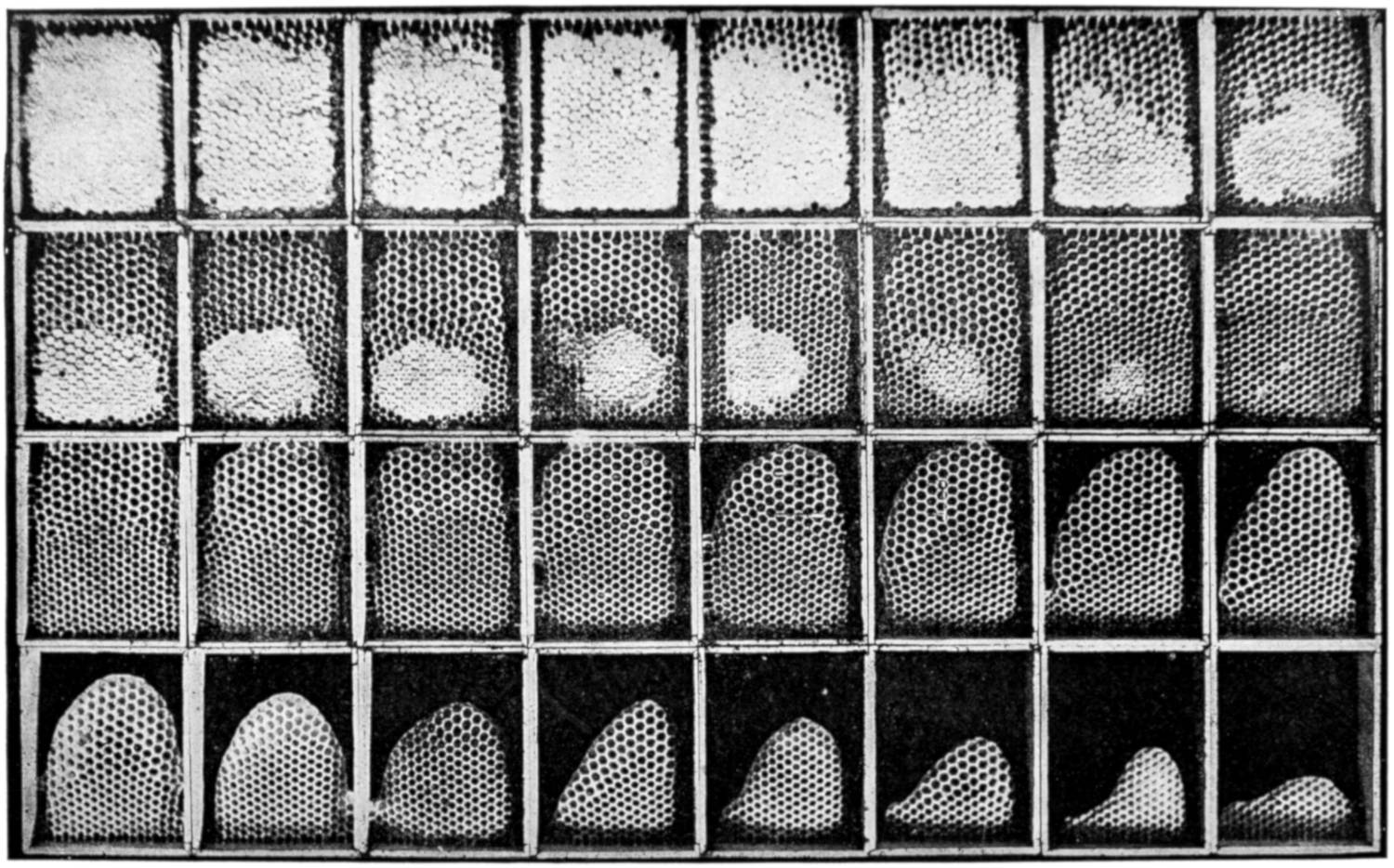

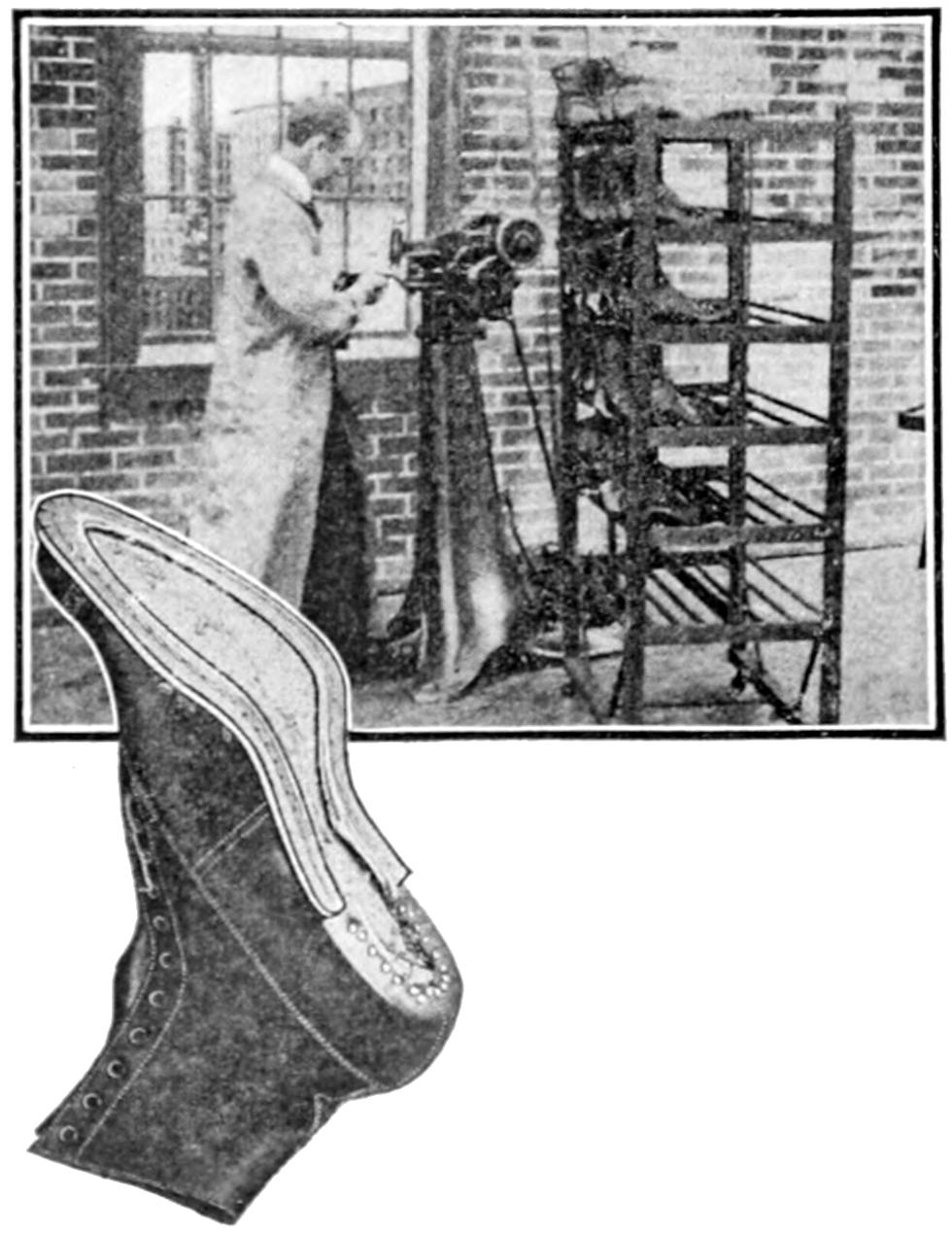

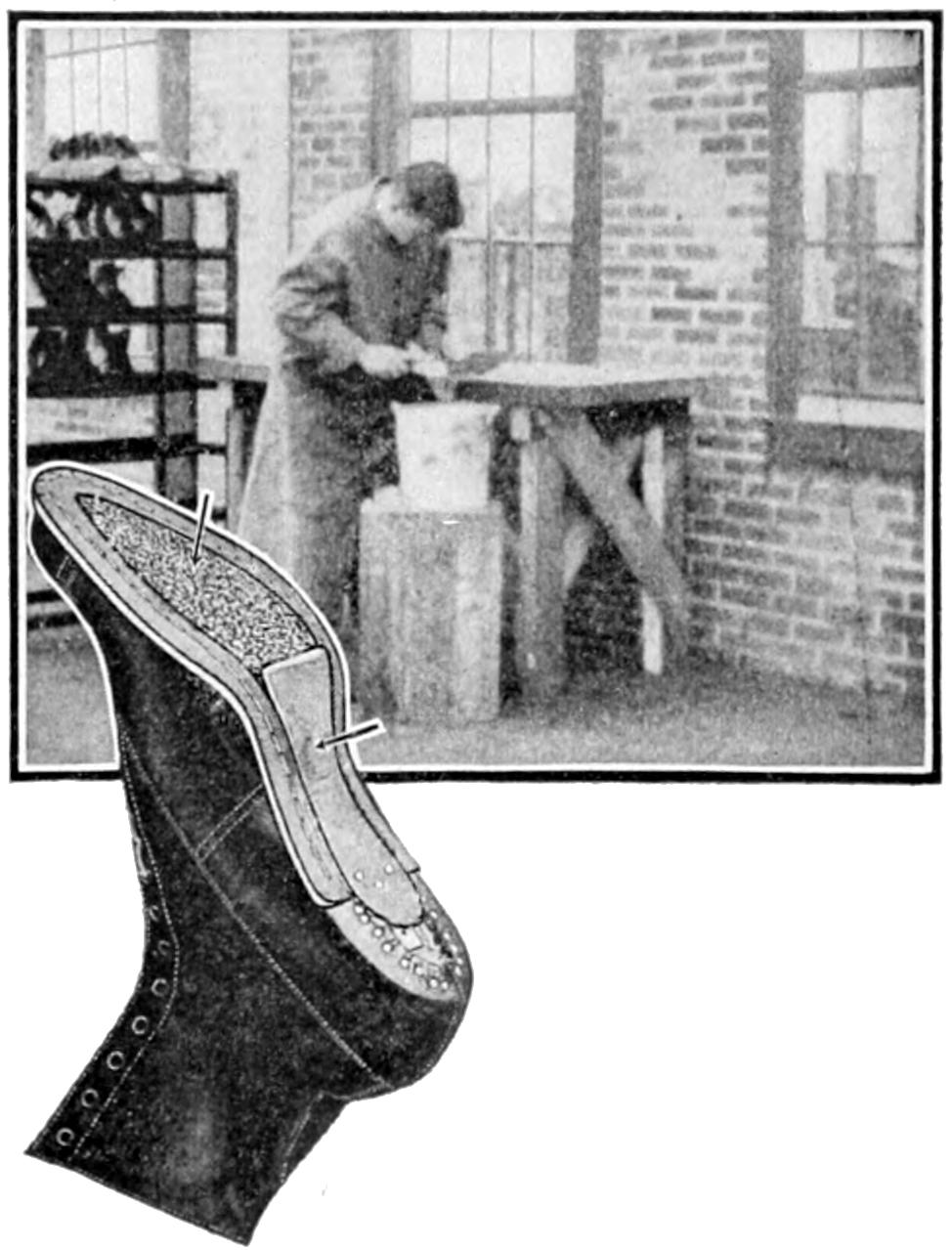

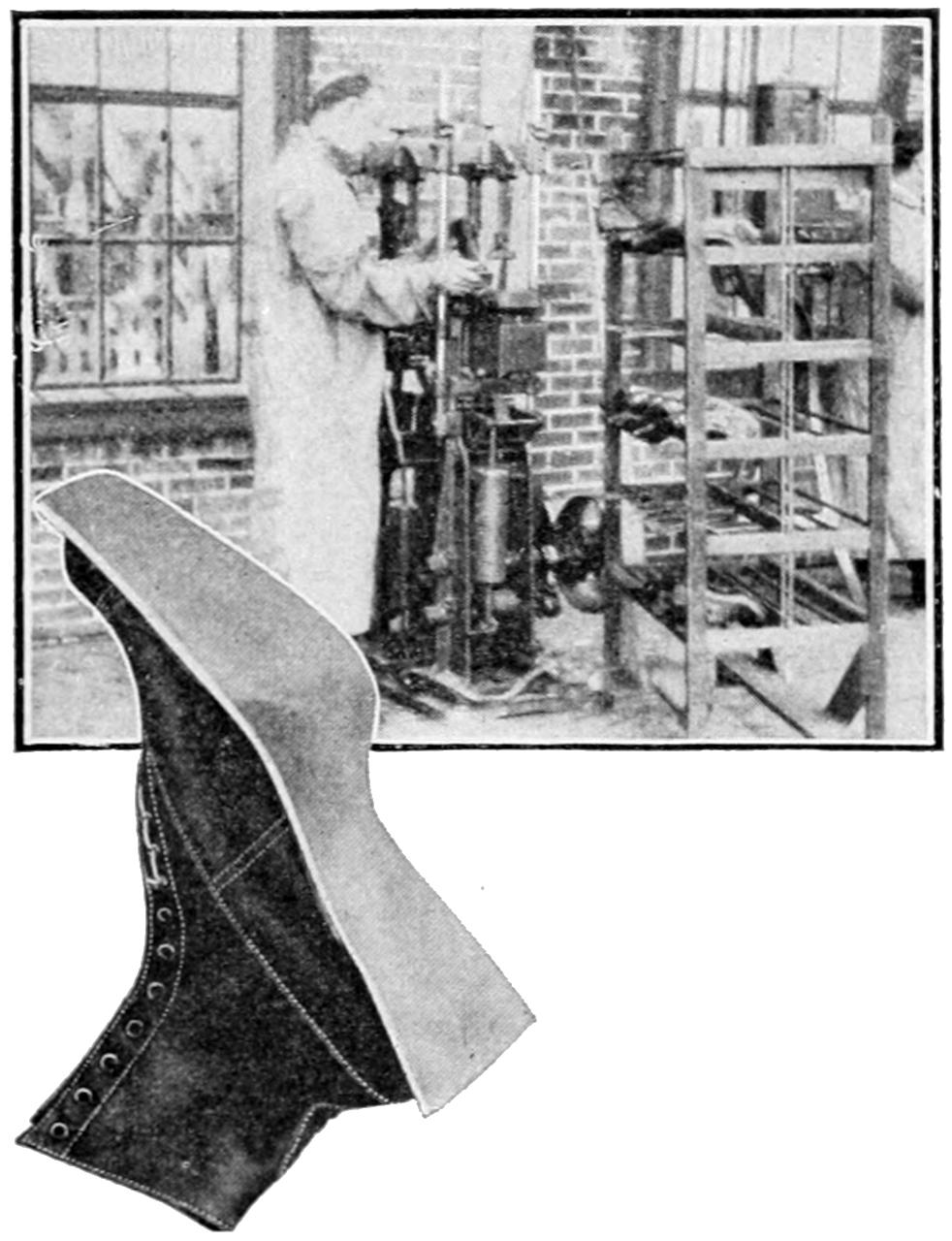

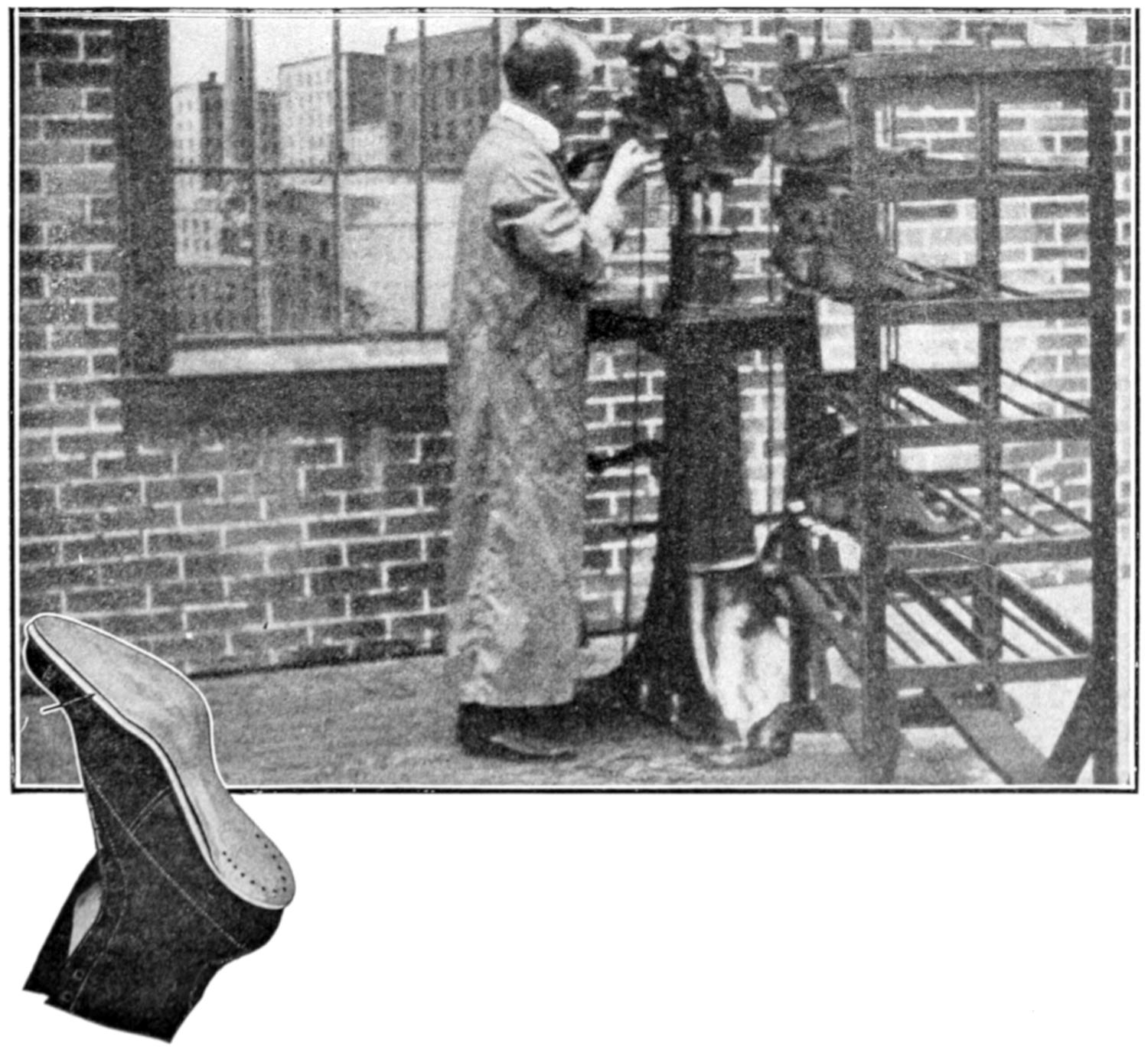

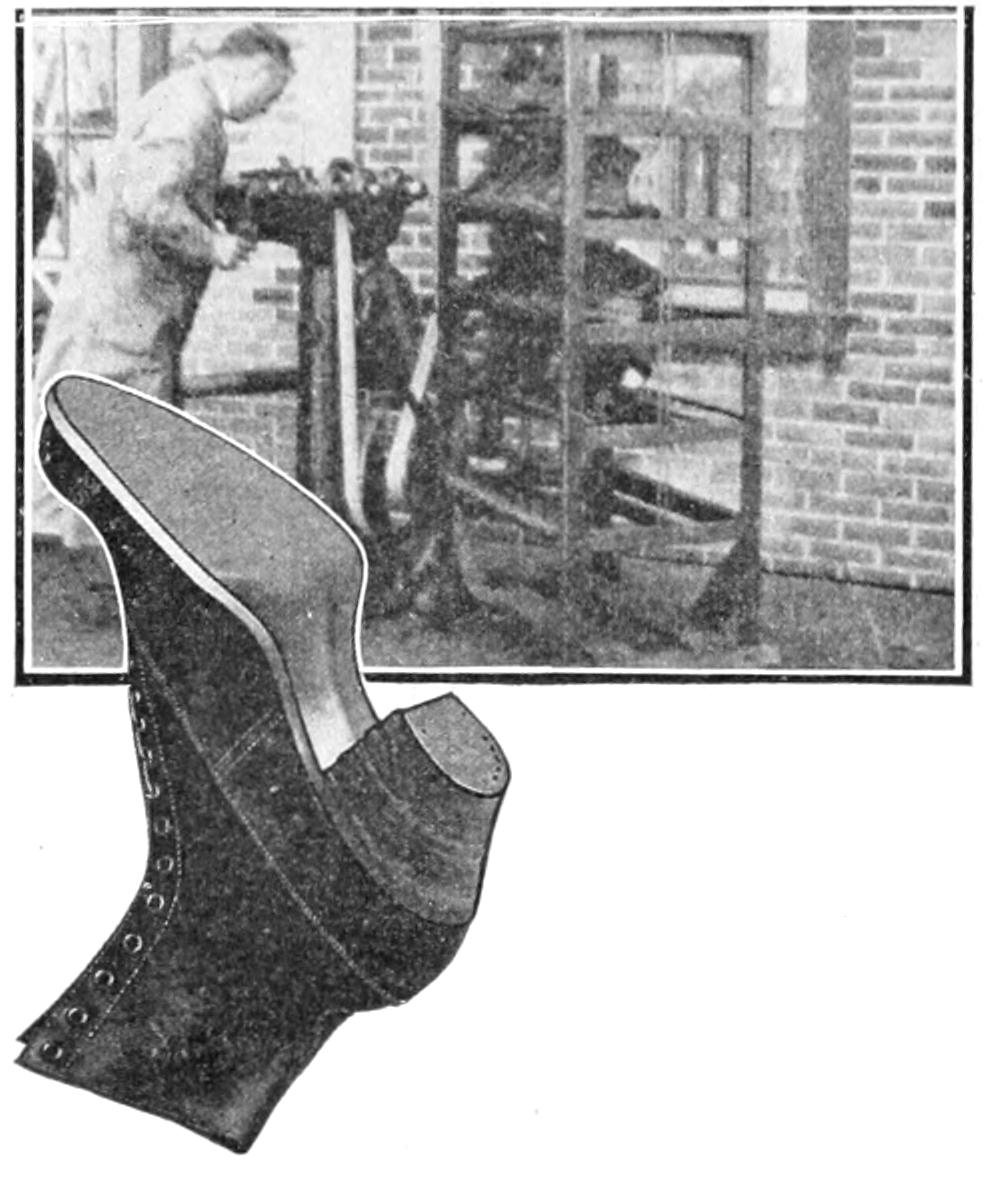

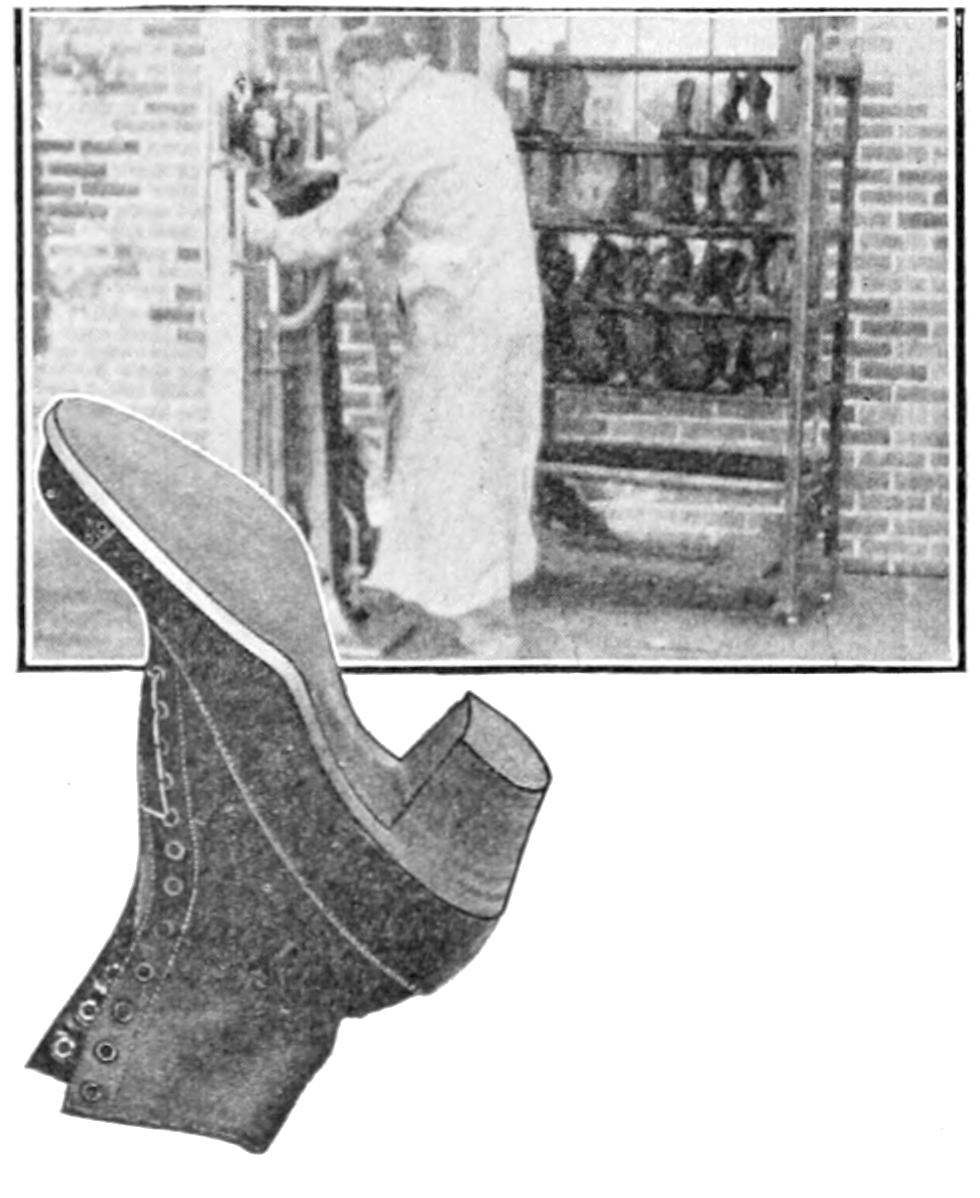

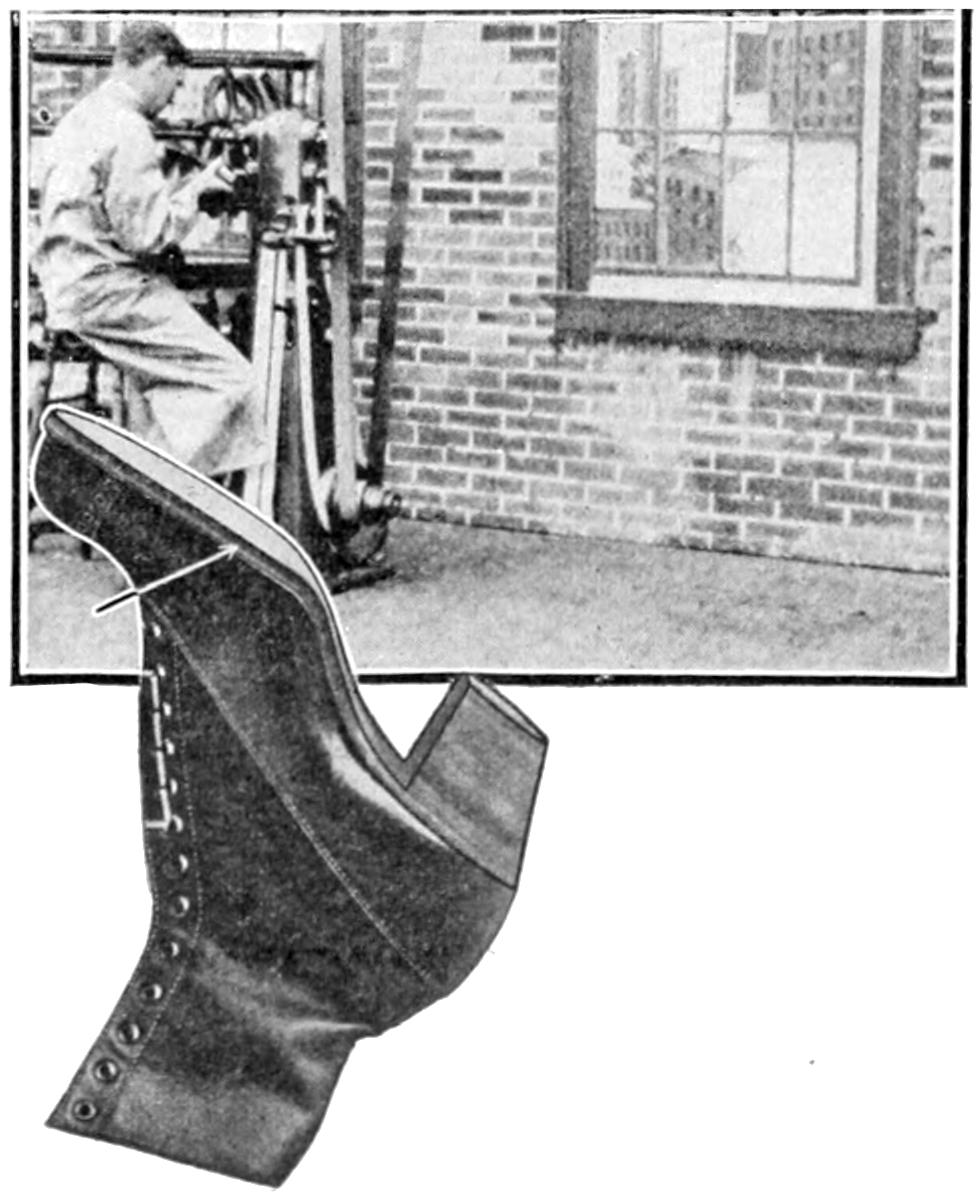

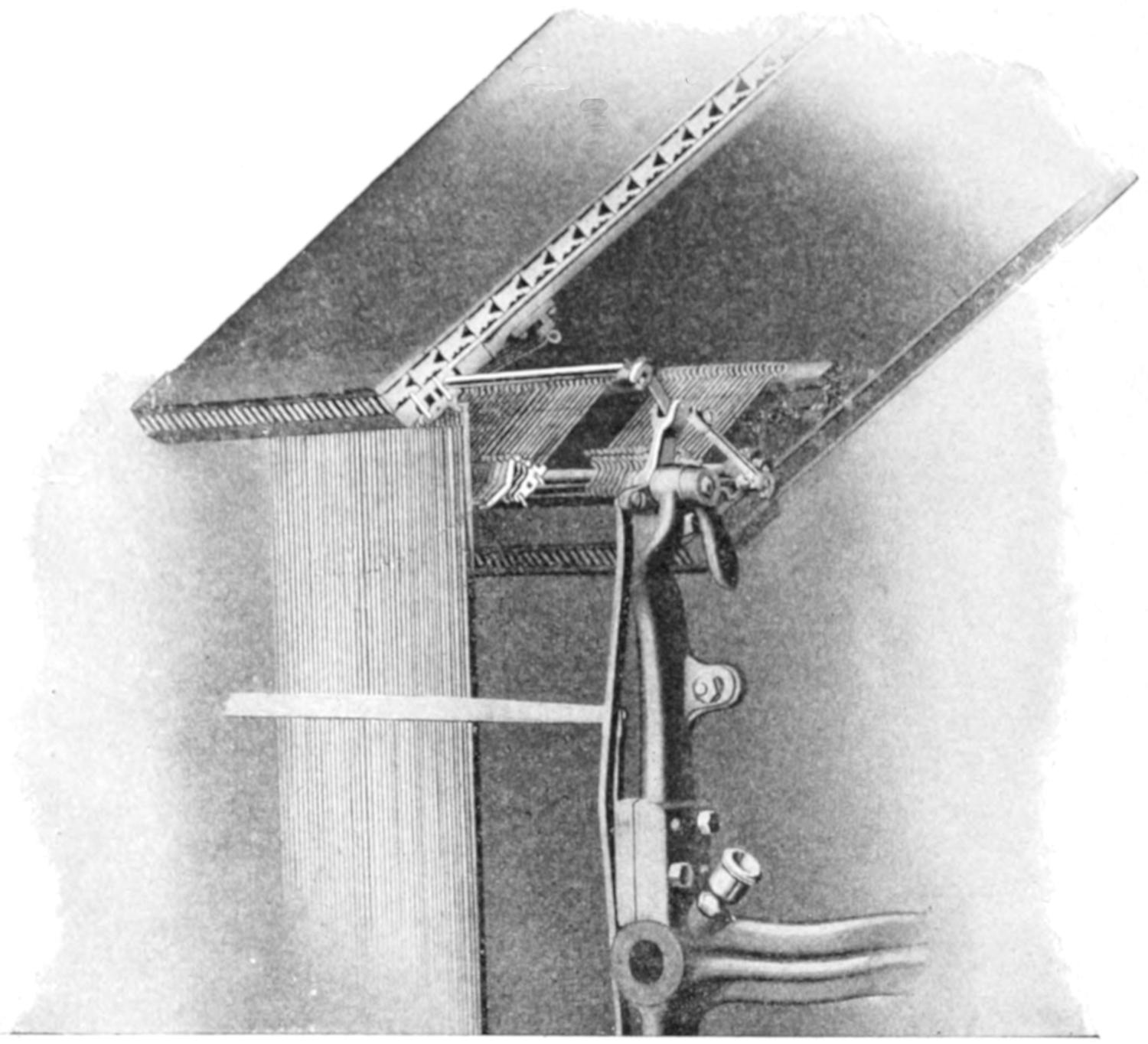

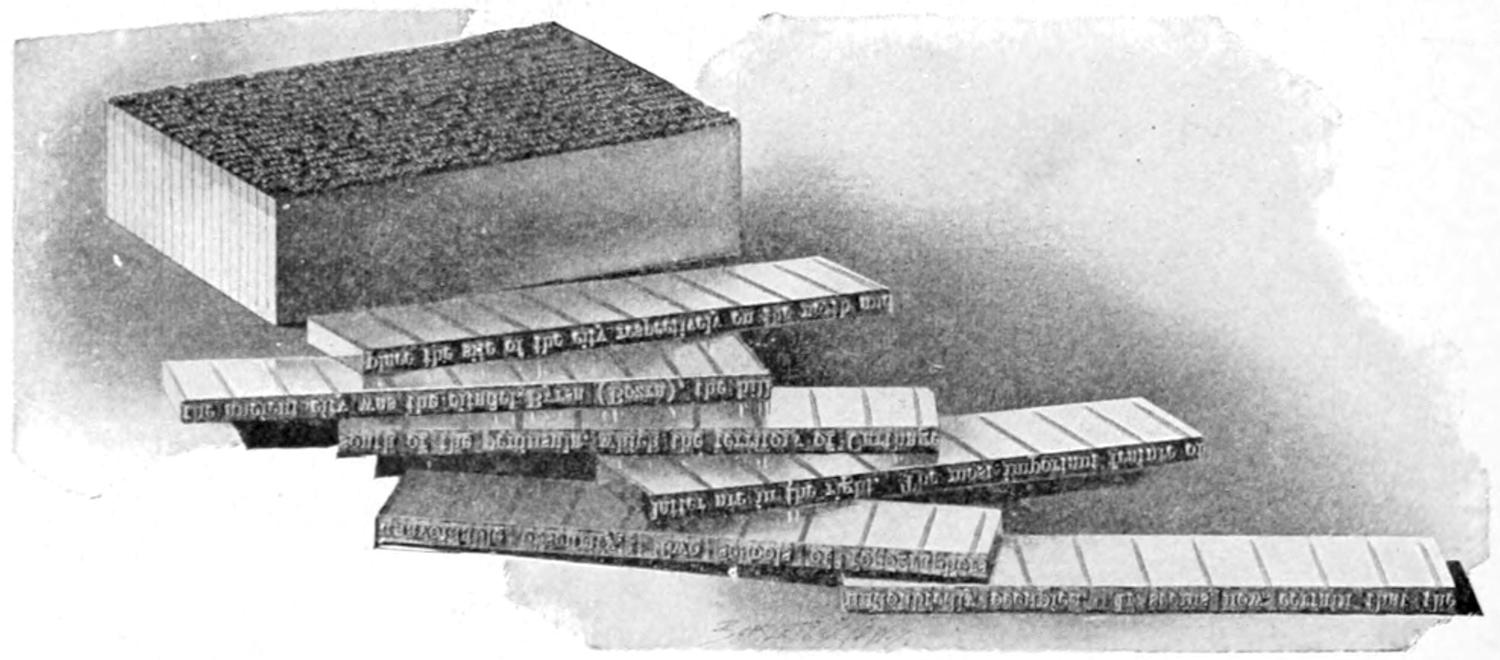

In the picture on the following page, we see the various processes required in making a steel pen, together with a description of each process:

[17]

HOW A STEEL PEN IS MADE

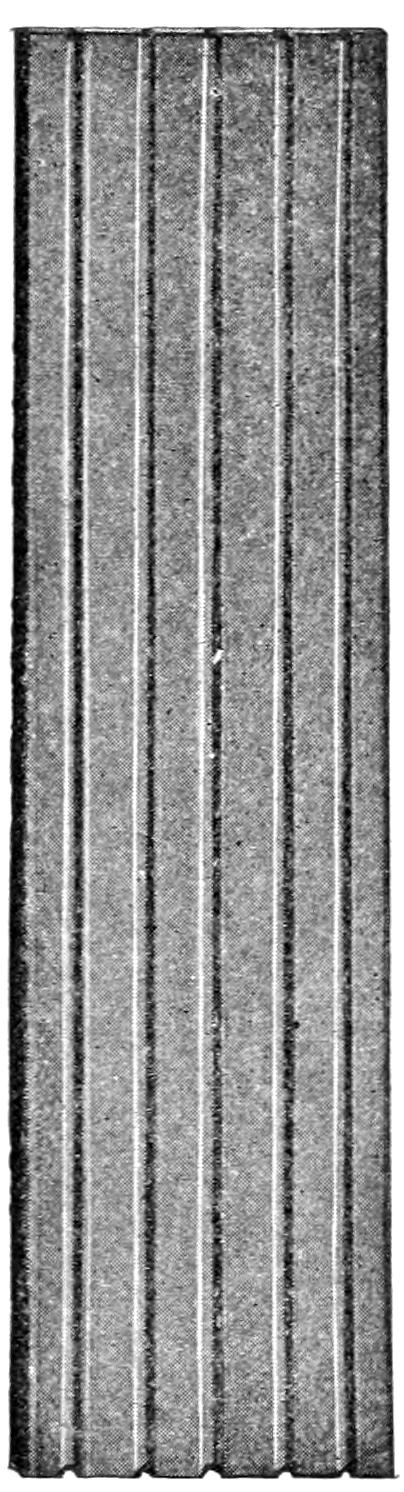

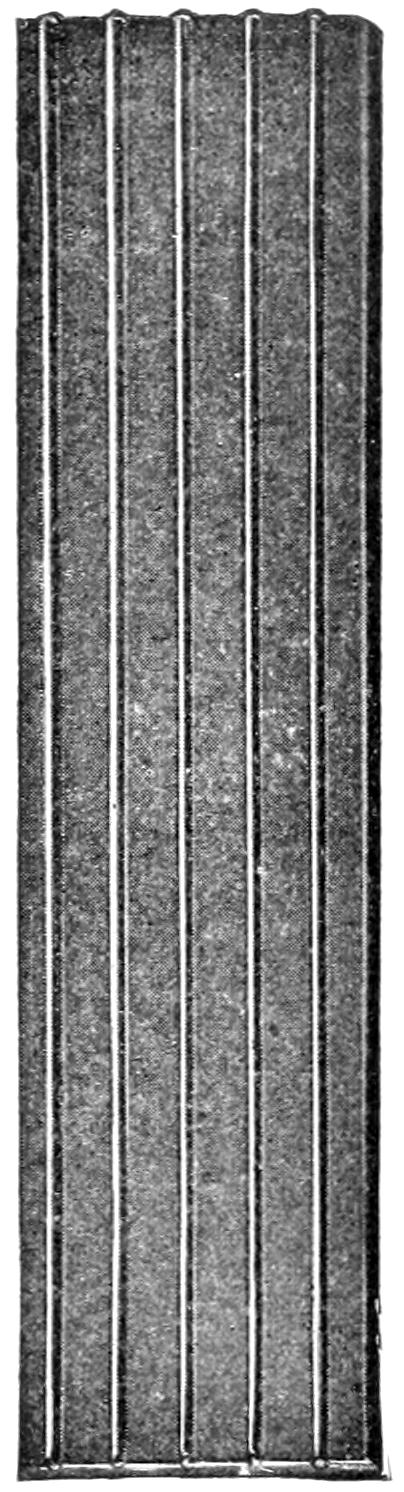

| No. 1. ROLLED STEEL. No. 2. SCRAP. |

No. 7. RAISING. No. 8. HARDENING. No. 9. TEMPERING. |

| No. 3. BLANKS. | No. 10. SCOURING. |

| No. 4. MARKING. | No. 11. GRINDING. |

| No. 5. PIERCING. | No. 12. SLITTING. |

| No. 6. ANNEALING. | No. 1. COLLEGE PEN

No. 5. SCHOOL PEN. No. 13. (FINISHED PENS.) COLORING AND VARNISHING. |

The pictures herewith printed are by the courtesy of the Spencerian Pen Company

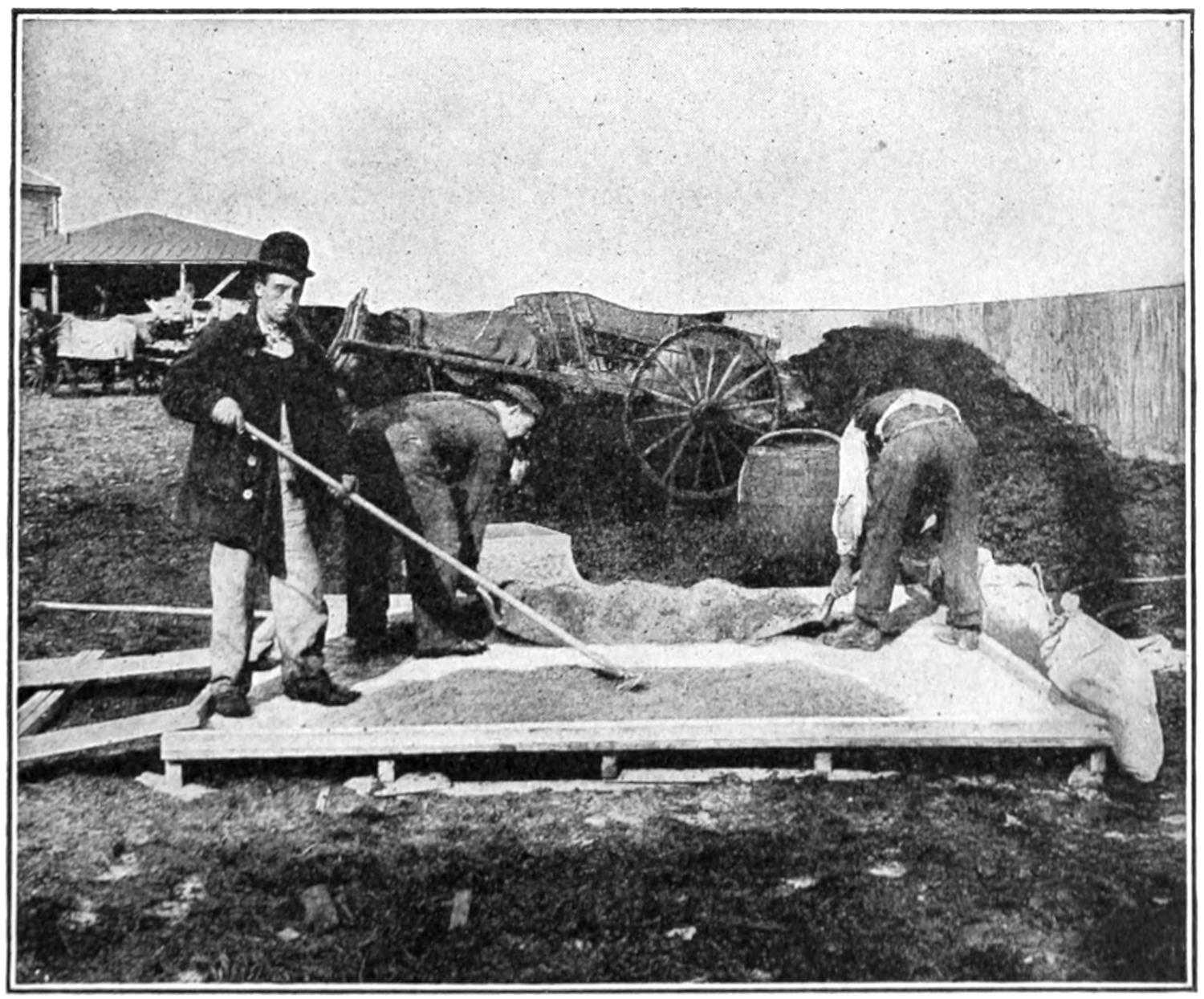

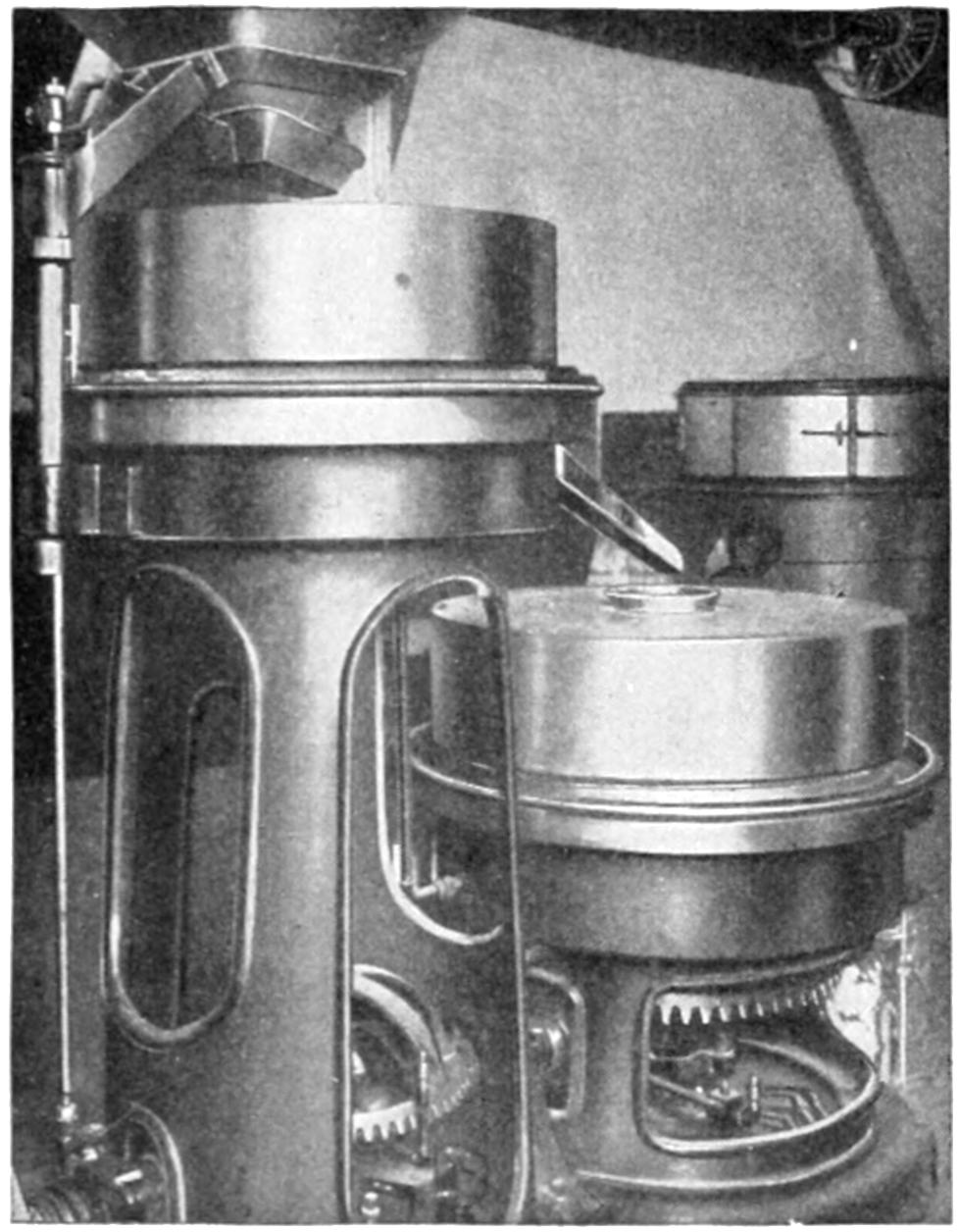

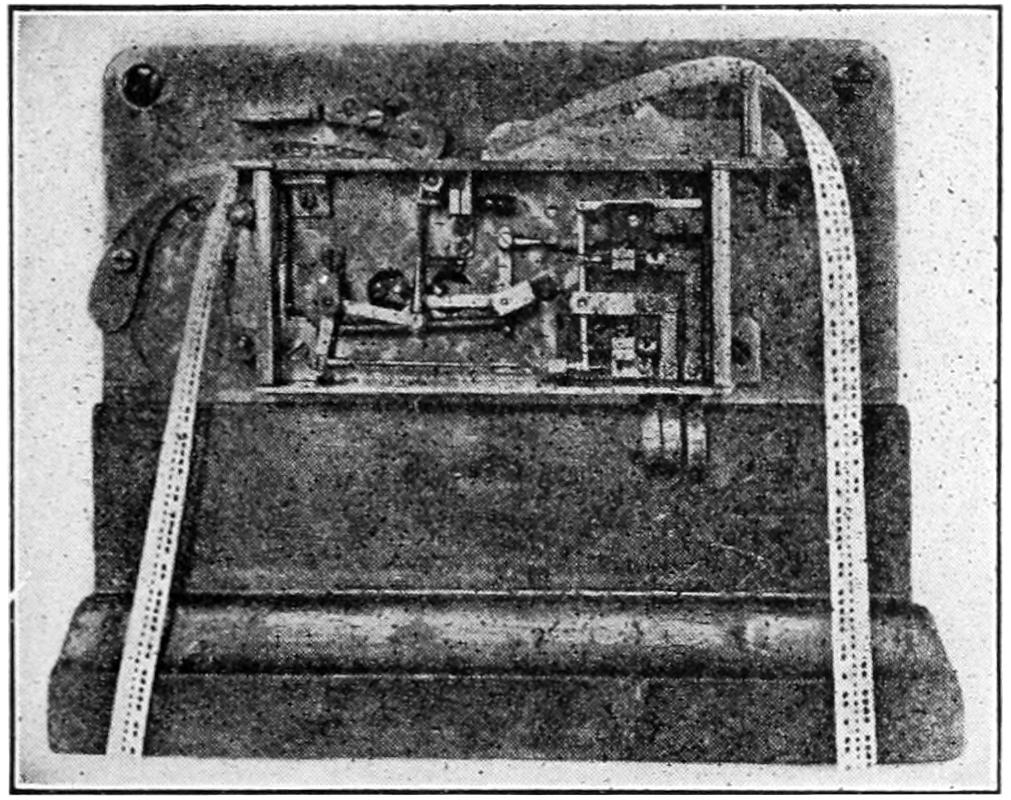

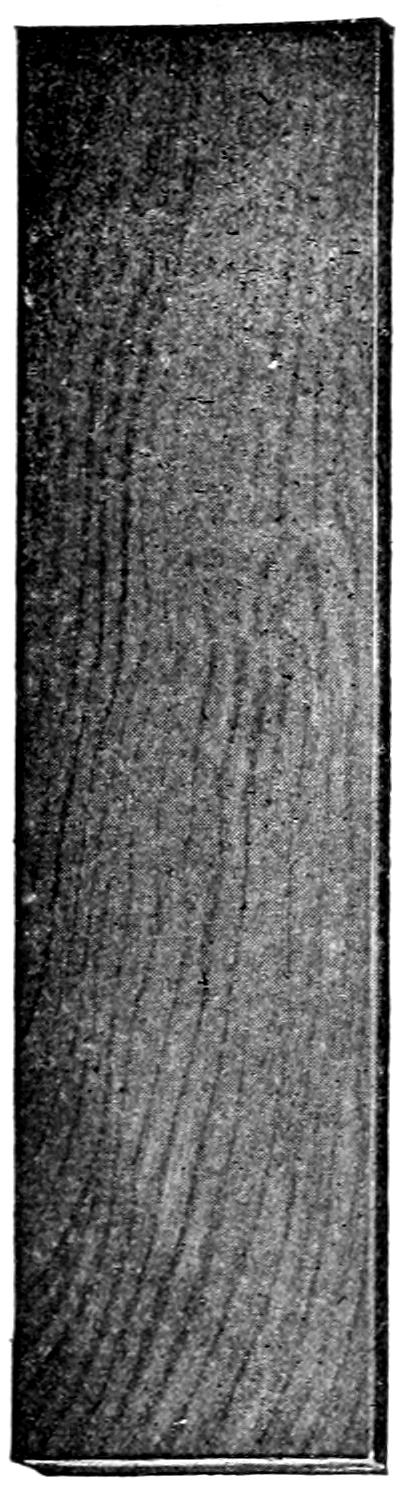

Raw Material.—The sheet steel is cut into strips of a convenient length and width, and then rolled cold to the exact gauge necessary, according to the pen to be manufactured.

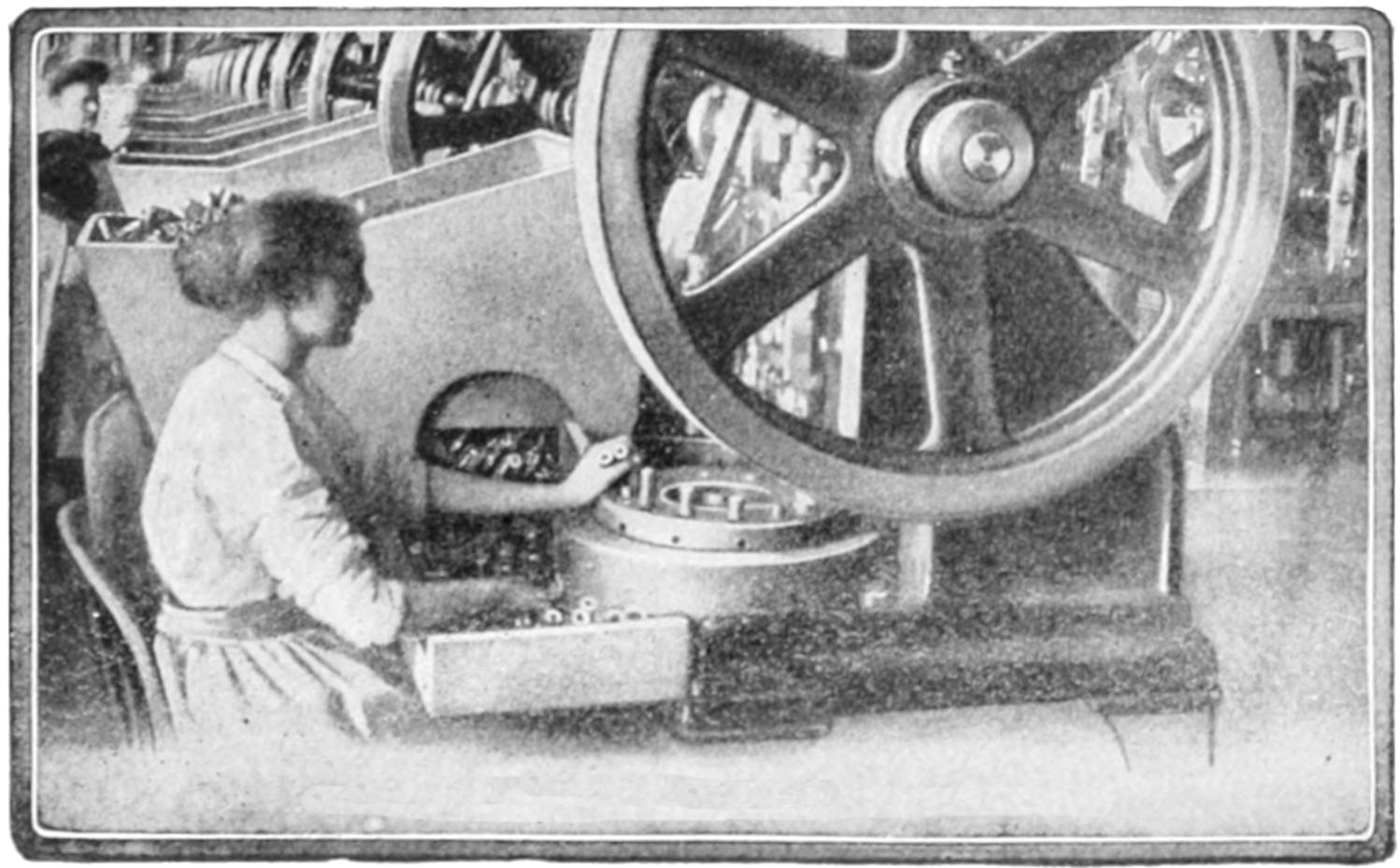

Cutting the Blank.—This is a mechanical operation, and is effected with the aid of a screw press, in which a pair of tools corresponding with the shape of the pen has been fixed. On pulling a lever the screw descends, driving the punch into the bed, which cuts a blank with a scissors-like action, from the strip of steel.

Marking the Name.—This is done by means of a punch fixed in the hammer of a stamp, worked by the foot. The blanks are rapidly introduced between guides fixed on the bed of the stamp, and as soon as the hammer has fallen the blank is thrown out and a new one introduced.

Piercing.—The tools for this operation are of a delicate character. The blanks are fed by hand, as above explained, and the hole punched by a screw press. This is a most important process; the pierce hole and slide slits determine the elasticity and regulate the flow of the ink on the pen.

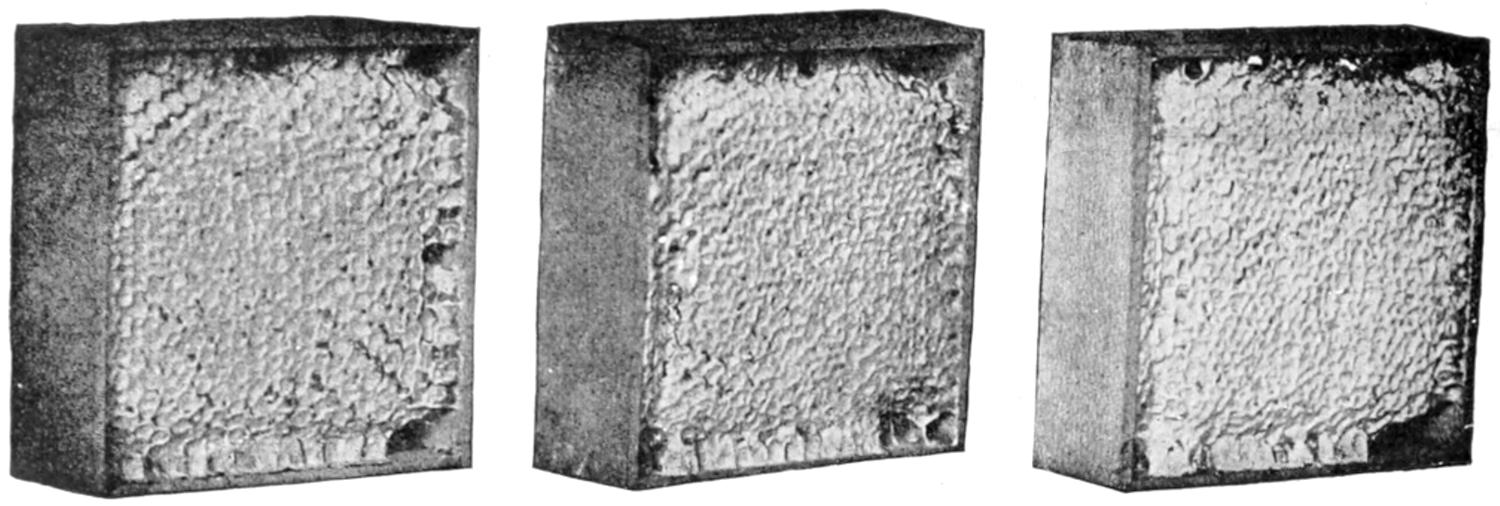

Annealing or Softening.—The blanks are still moderately hard and before raising, it is necessary to soften them by heating to a dull red, and allowing them to gradually cool.

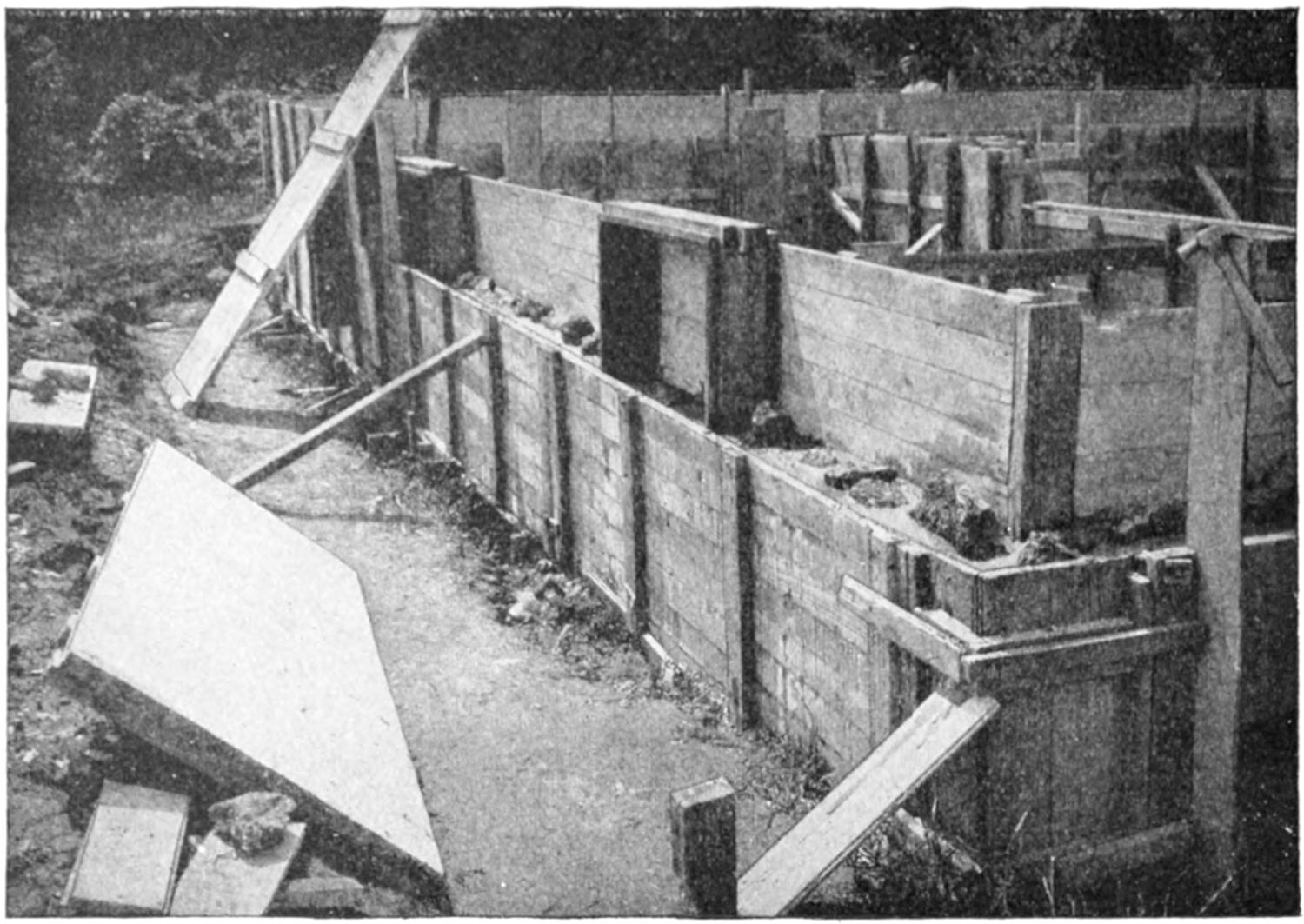

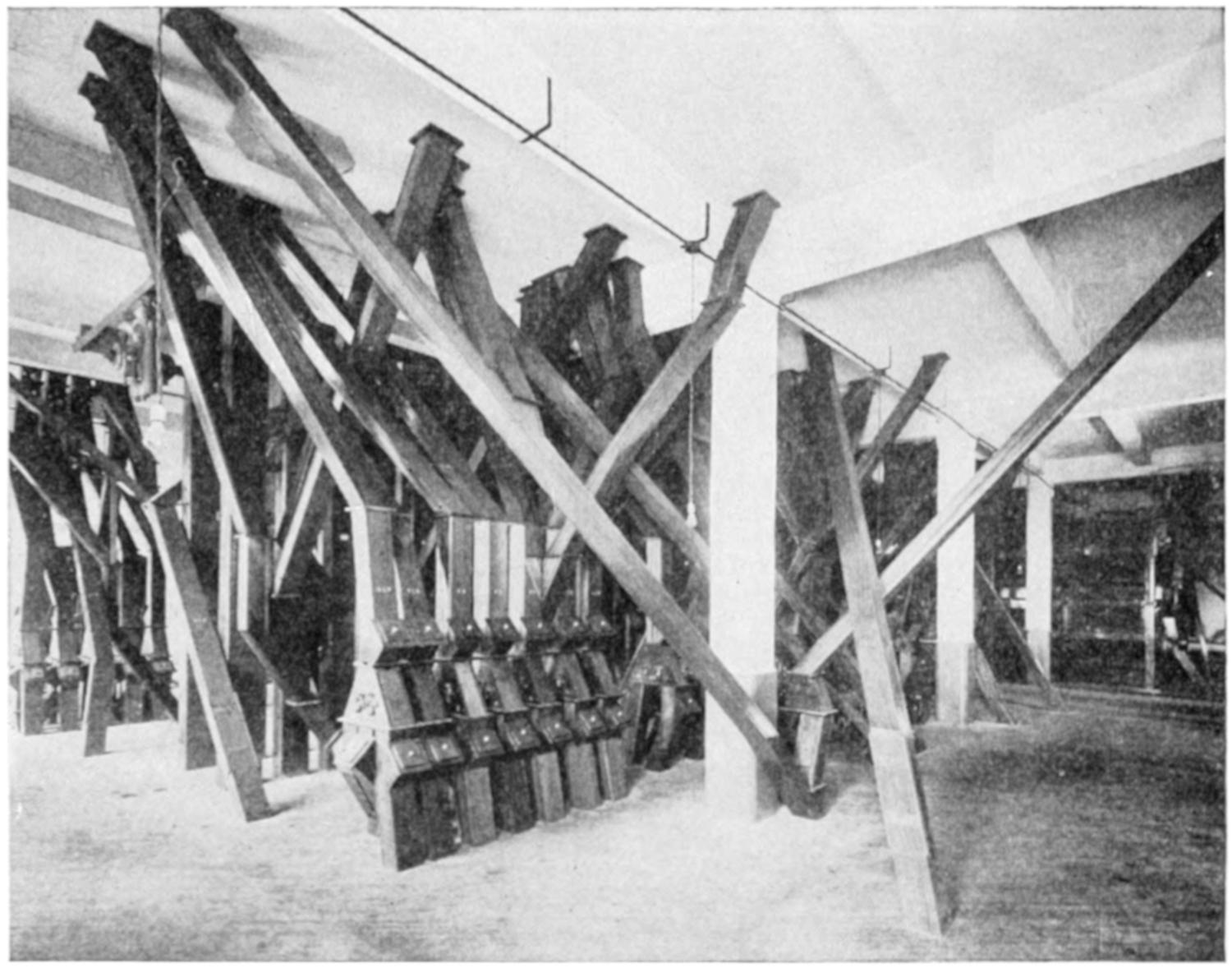

Raising.—The operator places one of the soft blanks on a die to which guides are affixed to keep it in position; then by moving the handle of the press, the screw descends, forcing a die which rounds the blank into the form of a pen.

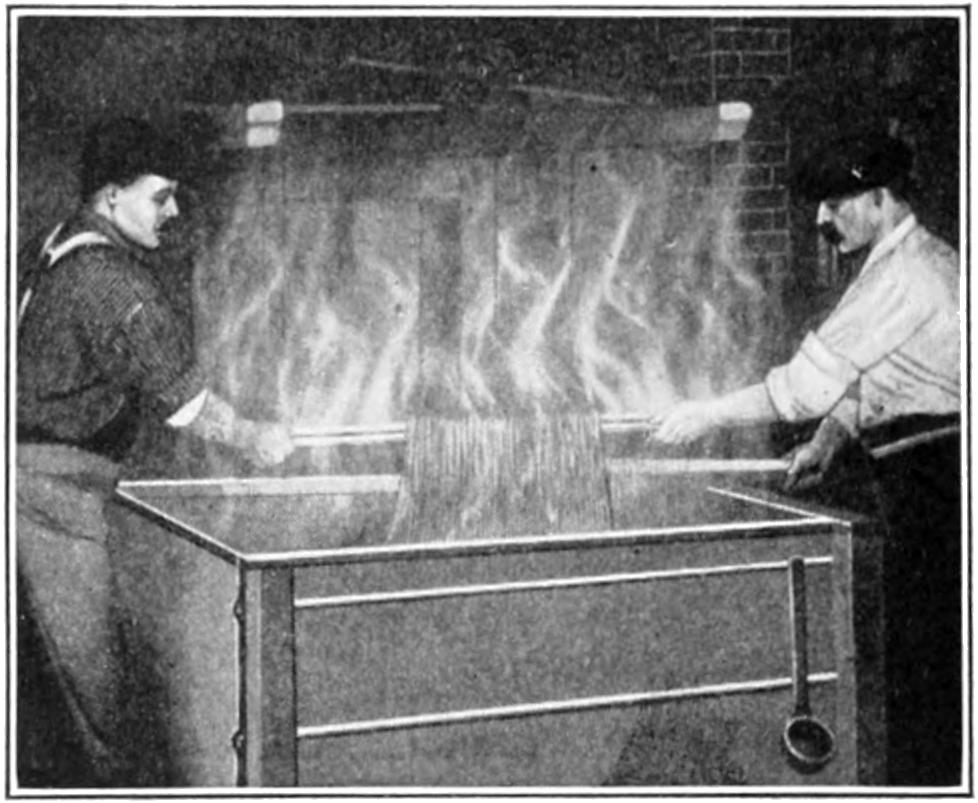

Hardening.—The pen is now too soft, and is hardened by heating and the immersing in oil while hot, after which it is thoroughly cleansed from all grease.

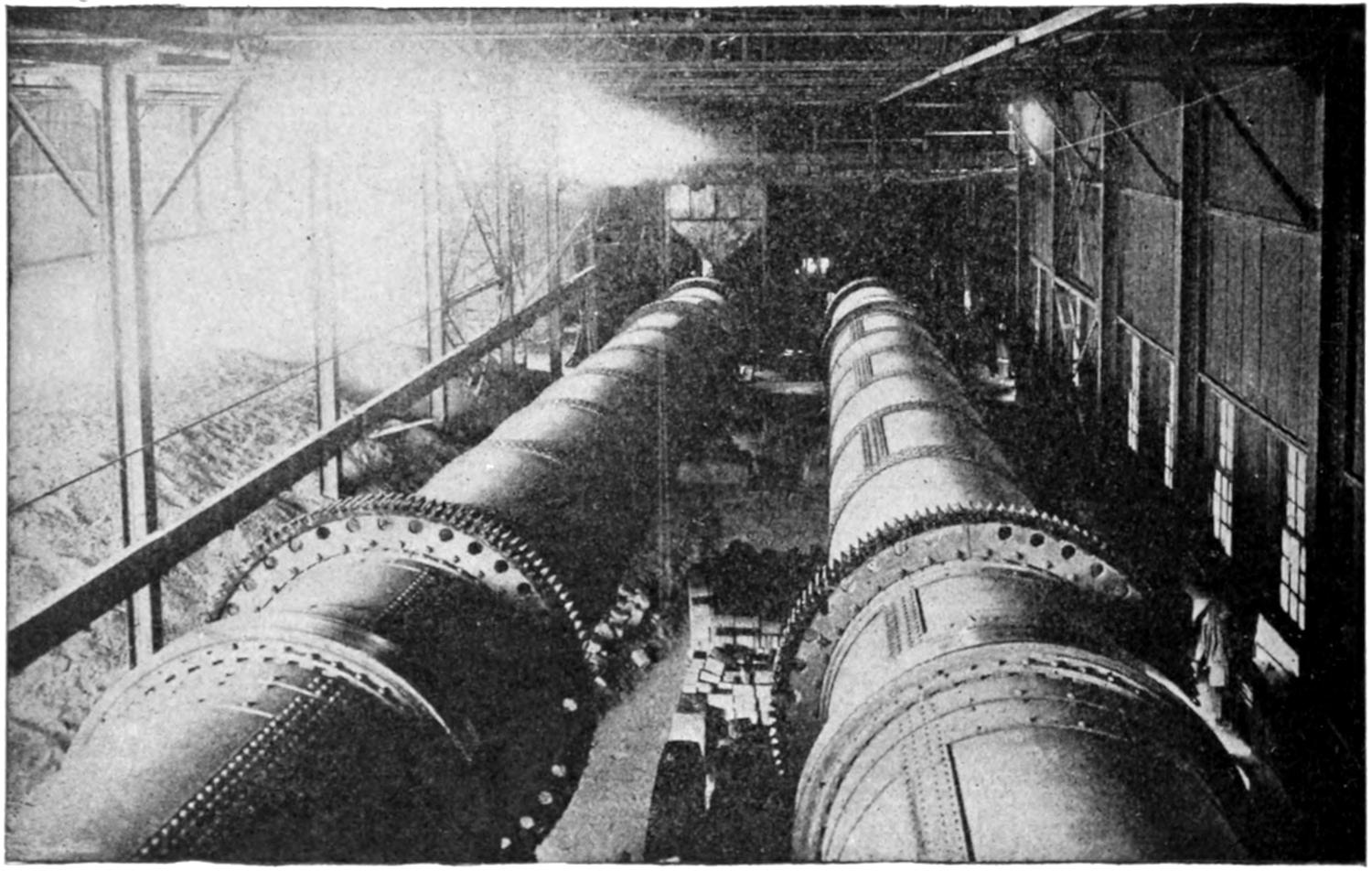

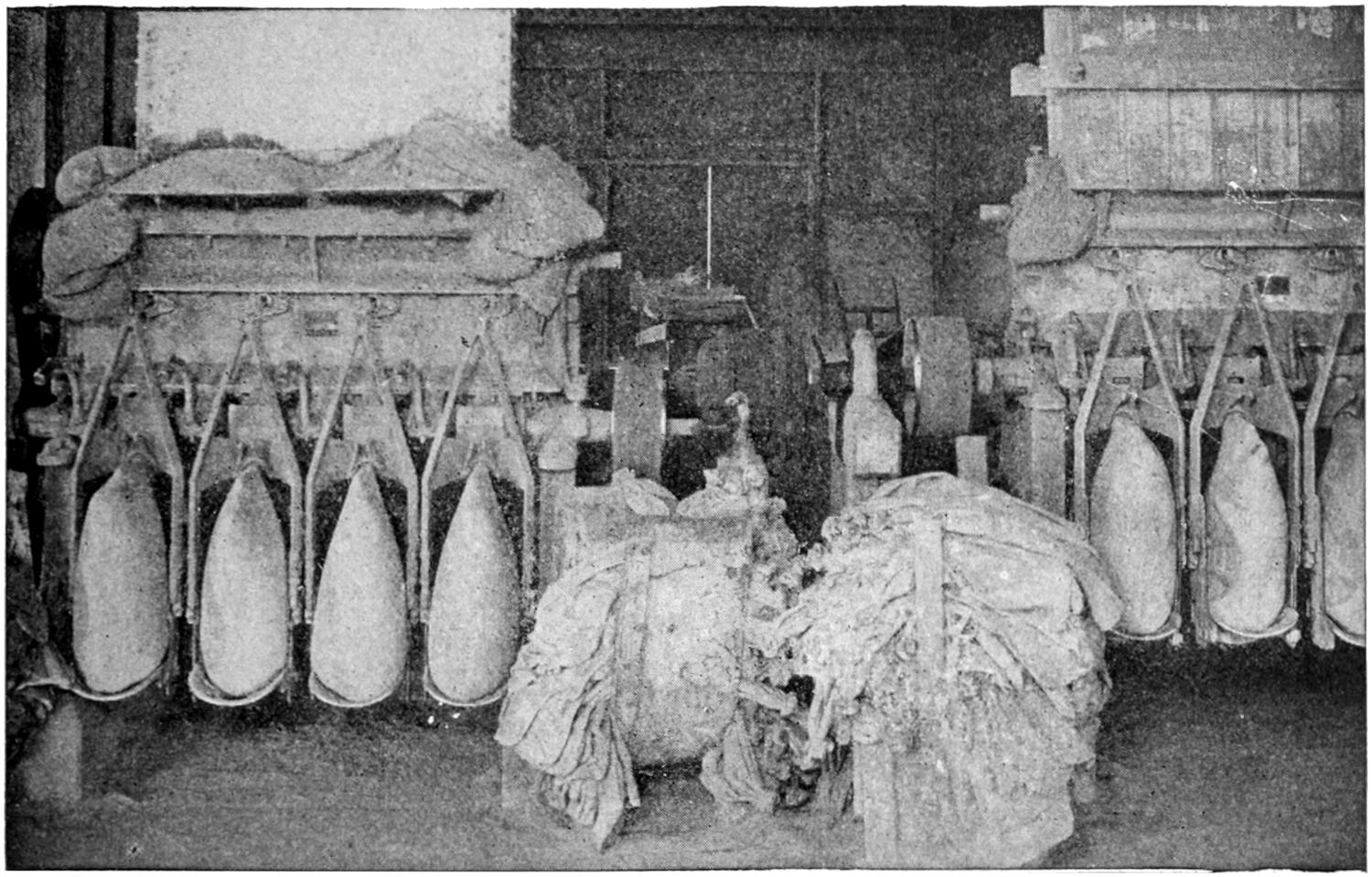

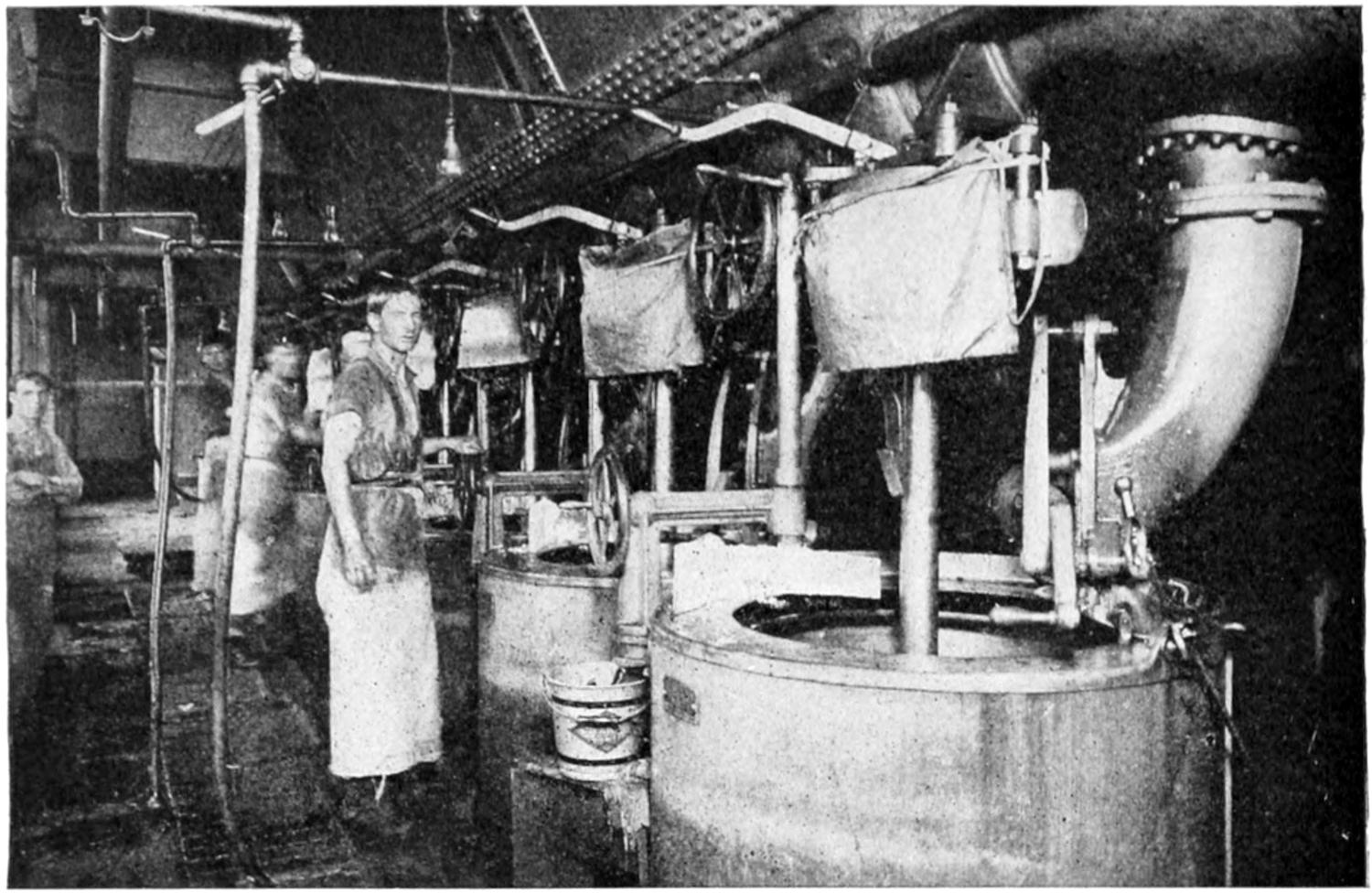

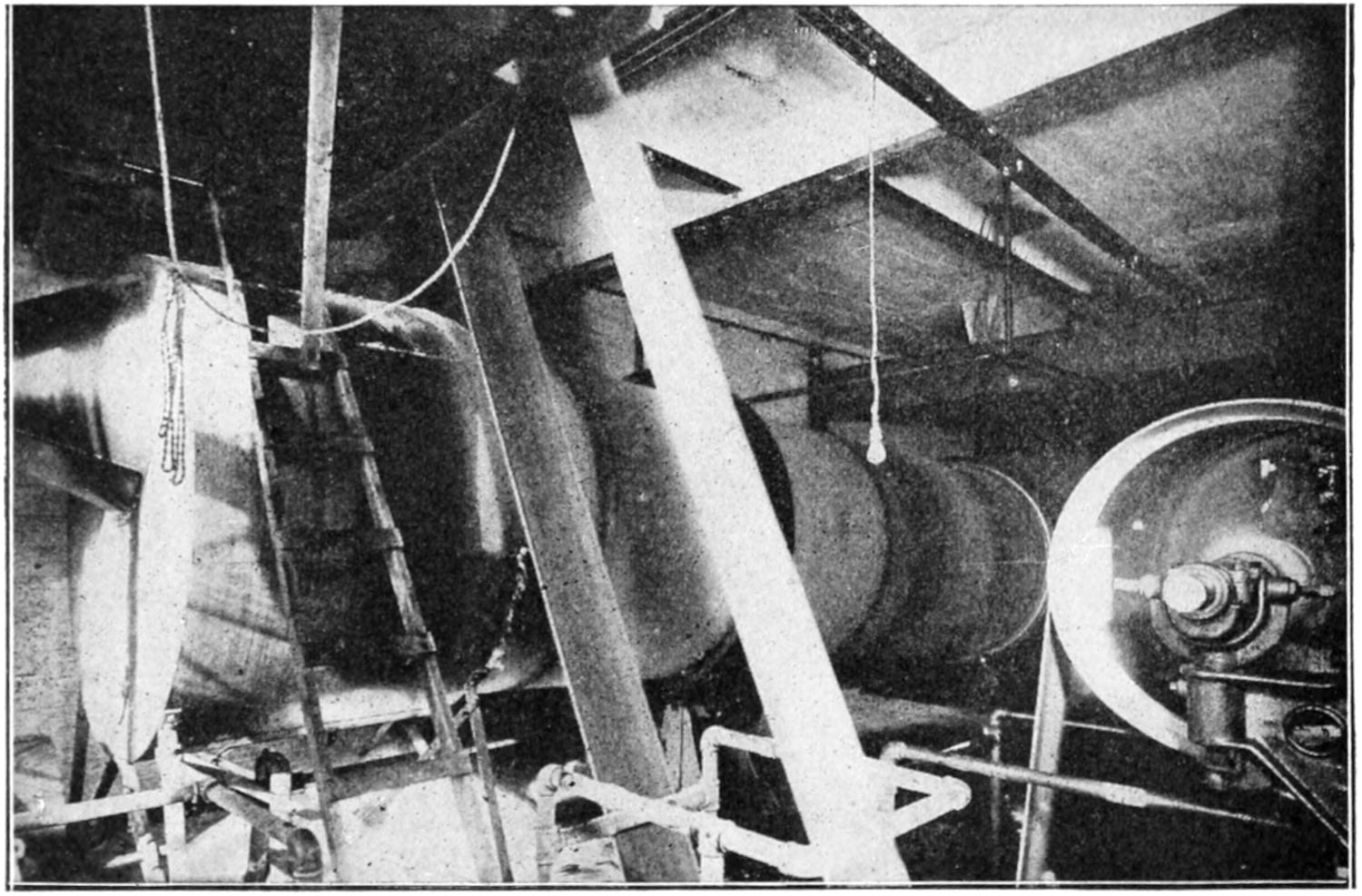

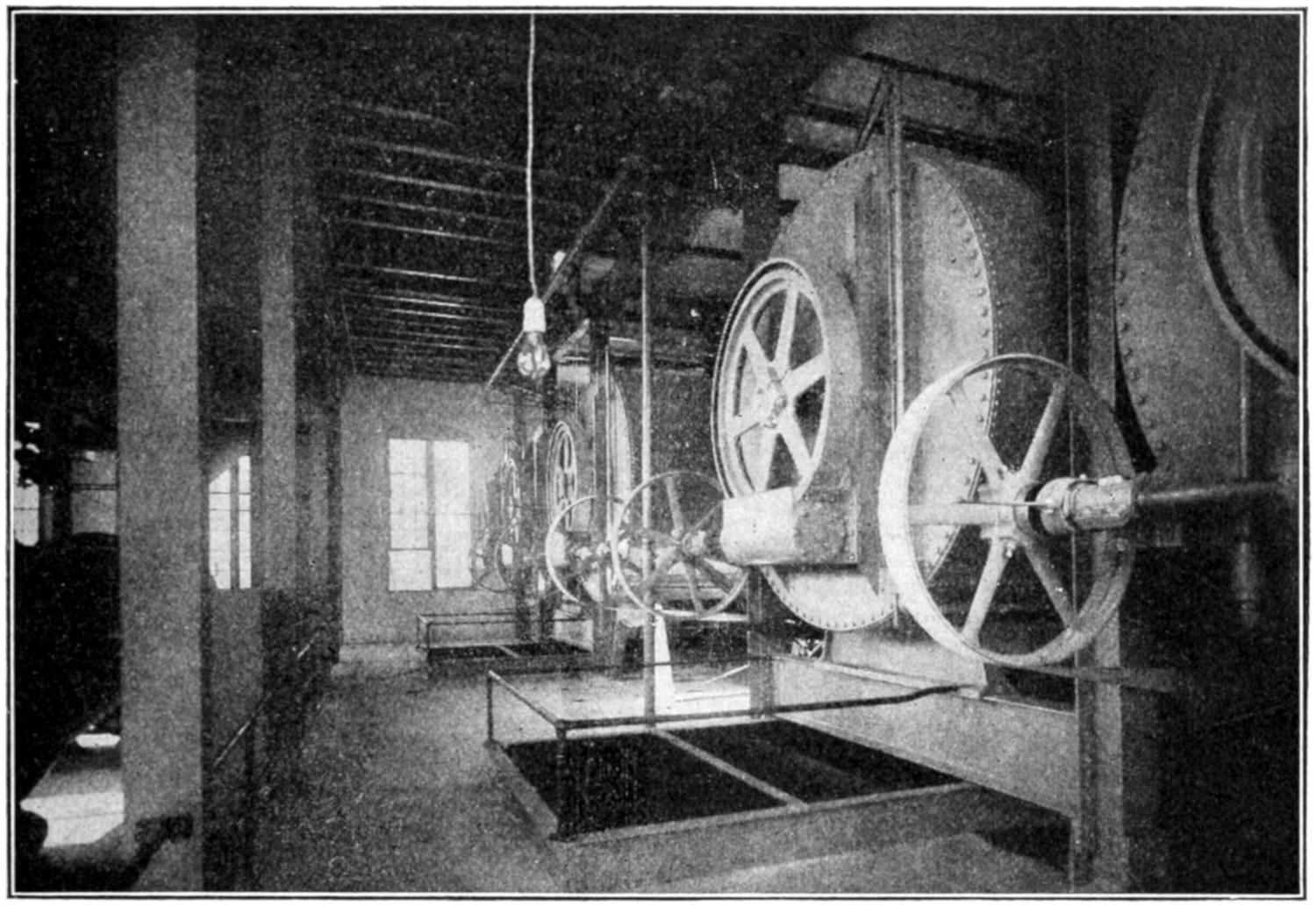

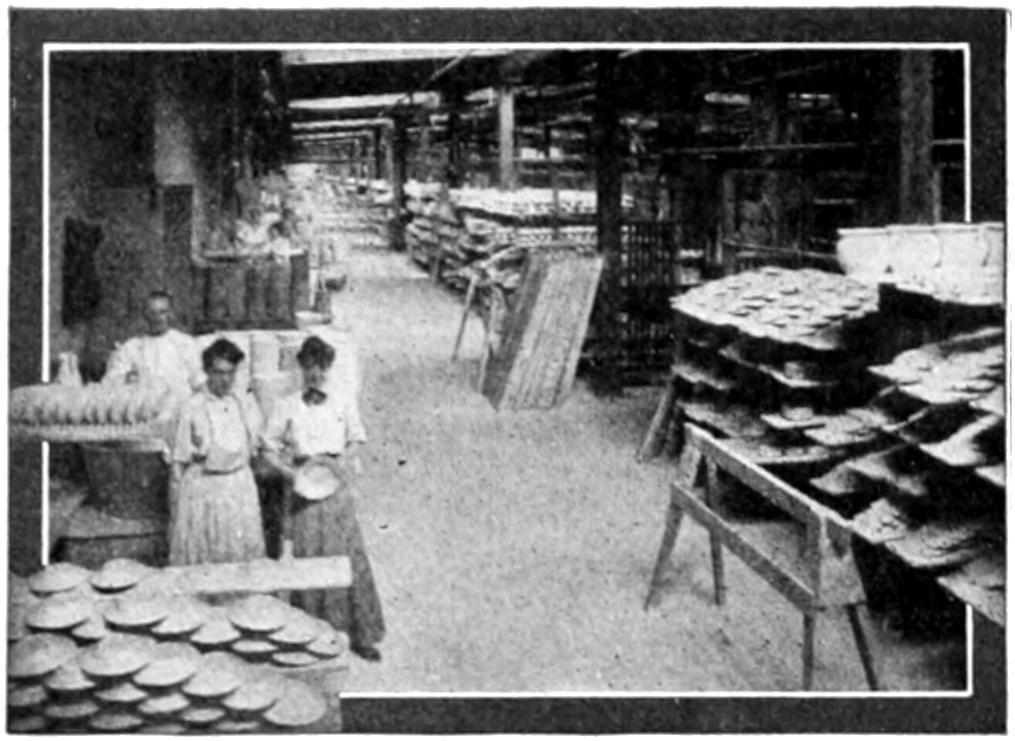

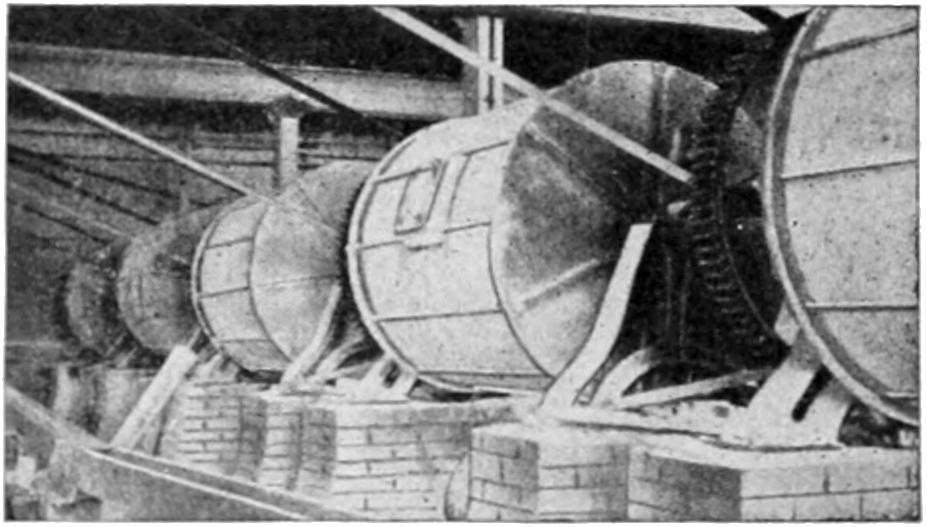

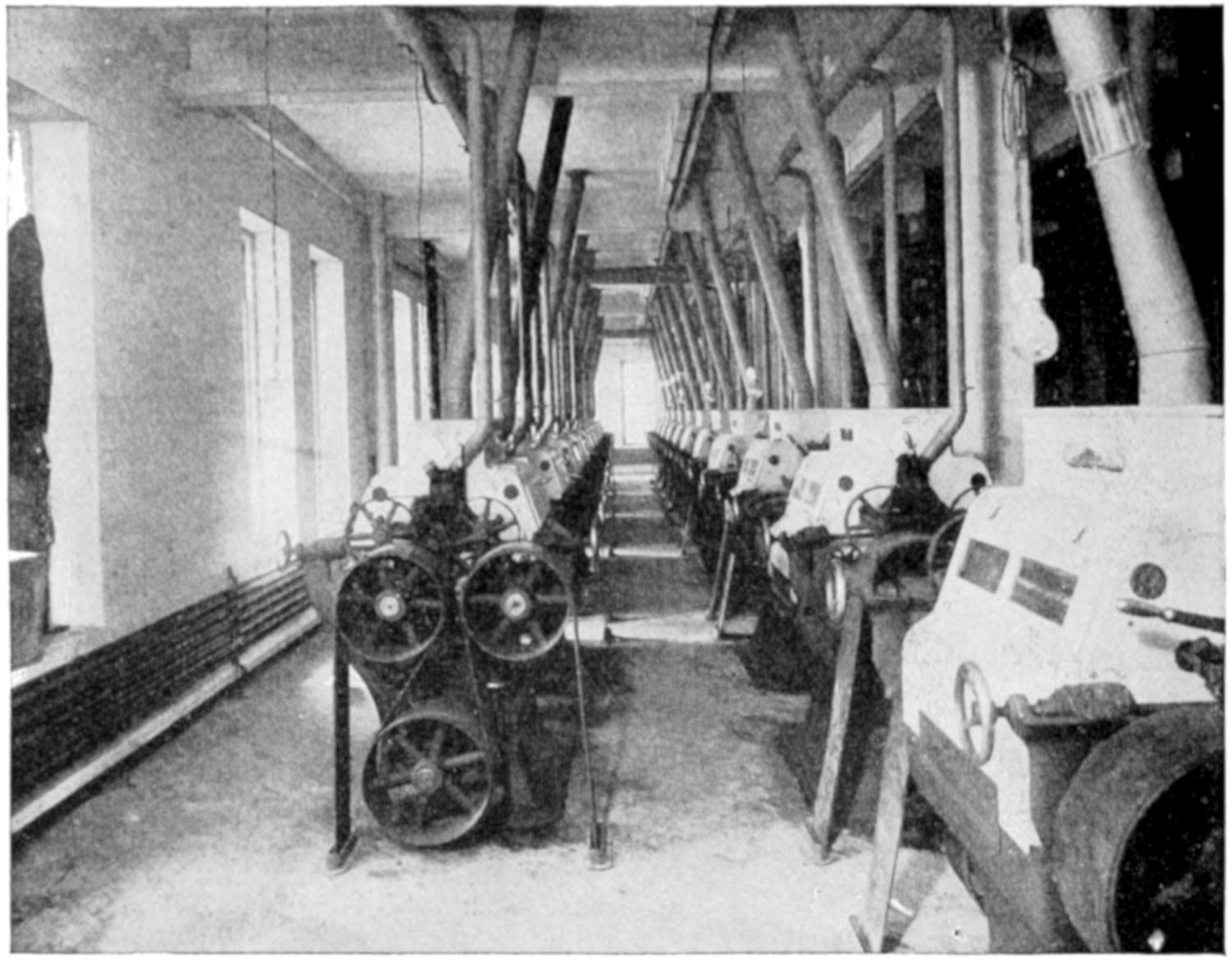

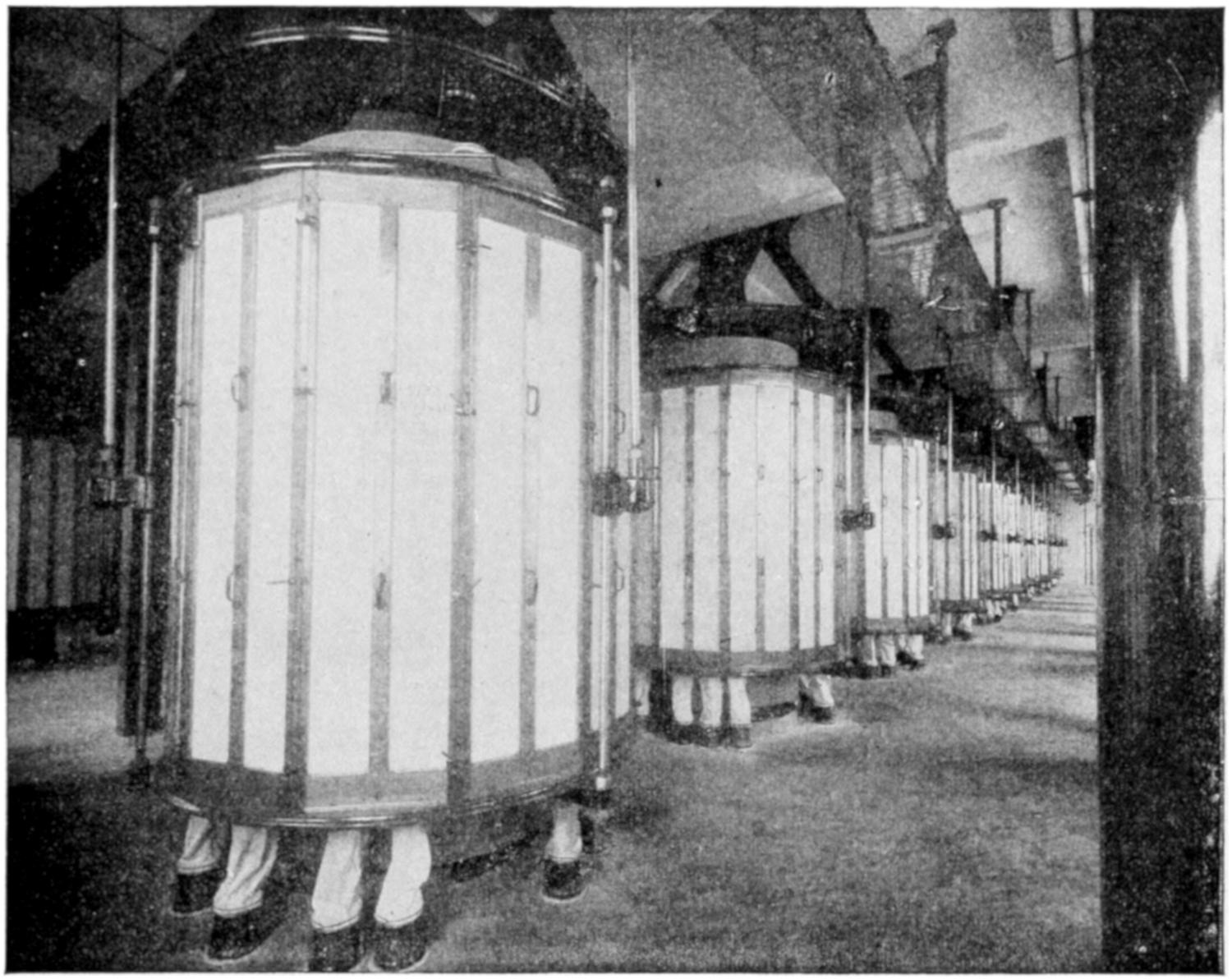

Tempering.—The pens are now hard but very brittle, and in order to correct this defect they are placed in an iron cylinder, and kept revolving over a gas or charcoal fire until they acquire a proper temper.

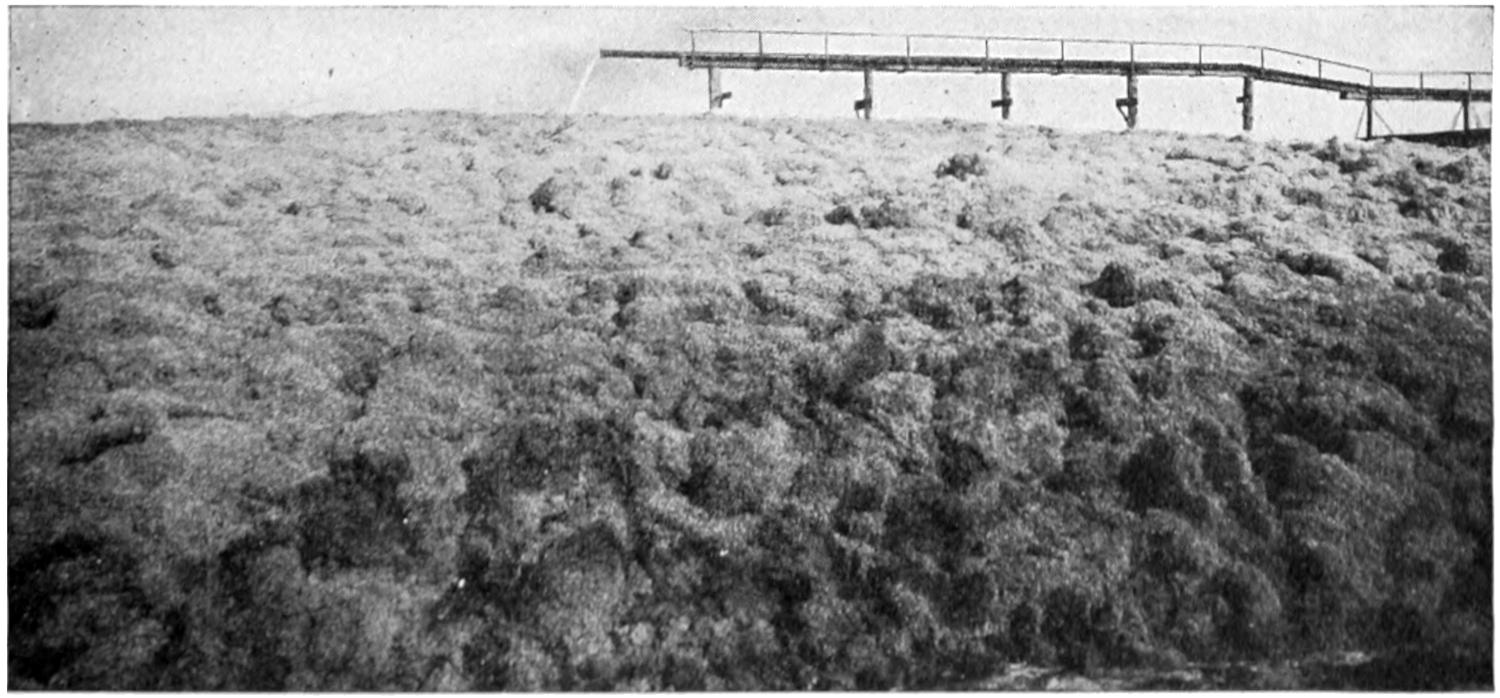

Scouring.—After soaking in diluted sulphuric acid, the pens are placed in iron cylinders containing fine stone and water, or fine sand, and revolved for several hours. When taken from these cylinders they are bright and smooth.

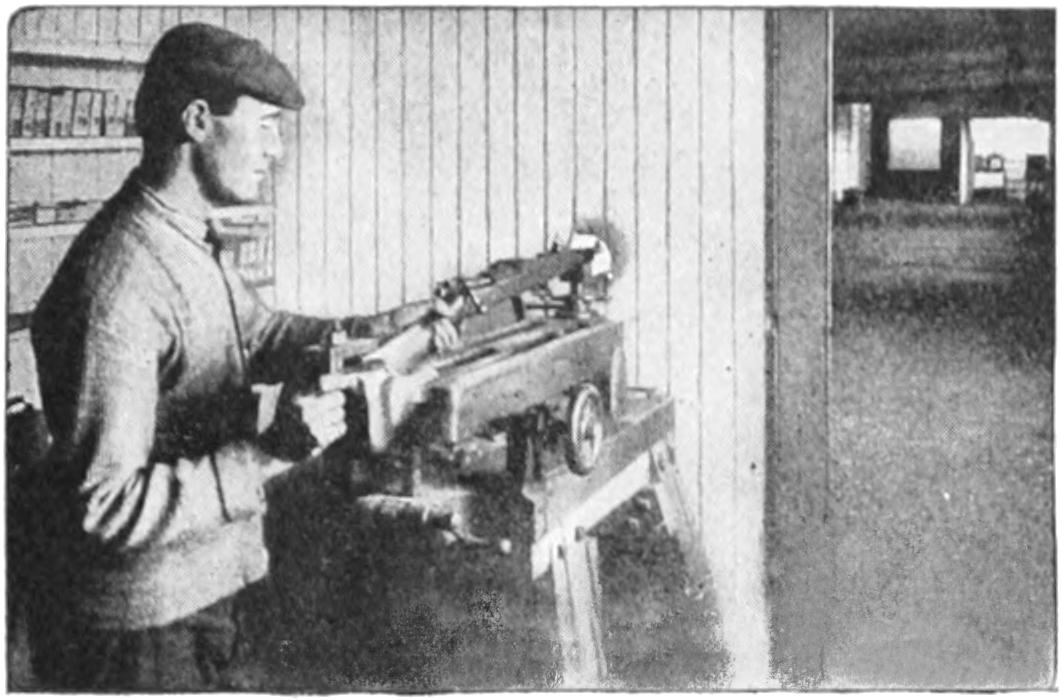

Grinding.—This is a process performed by hand on a “bob,” or wooden wheel covered with leather and dressed with emory, revolving at high speed. A light touch on the emory wheel grinds off the surface between the pierce hole and the point, to obtain proper action and to assist the flow of ink.

Slitting.—This is a hand process performed with a press, the cutters being as sharp as razors. The pen is placed in position by means of guides, and must be cut with utmost precision from the pierce hole to the point, the point must be divided exactly in the middle, the least variation making the pen defective.

Coloring and Varnishing.—The pens having been polished to a bright silver color are placed in an iron cylinder and kept revolving over a gas or charcoal fire until the tint required is produced. They are then immersed in a bath of shellac varnish, and afterwards dried in an oven.

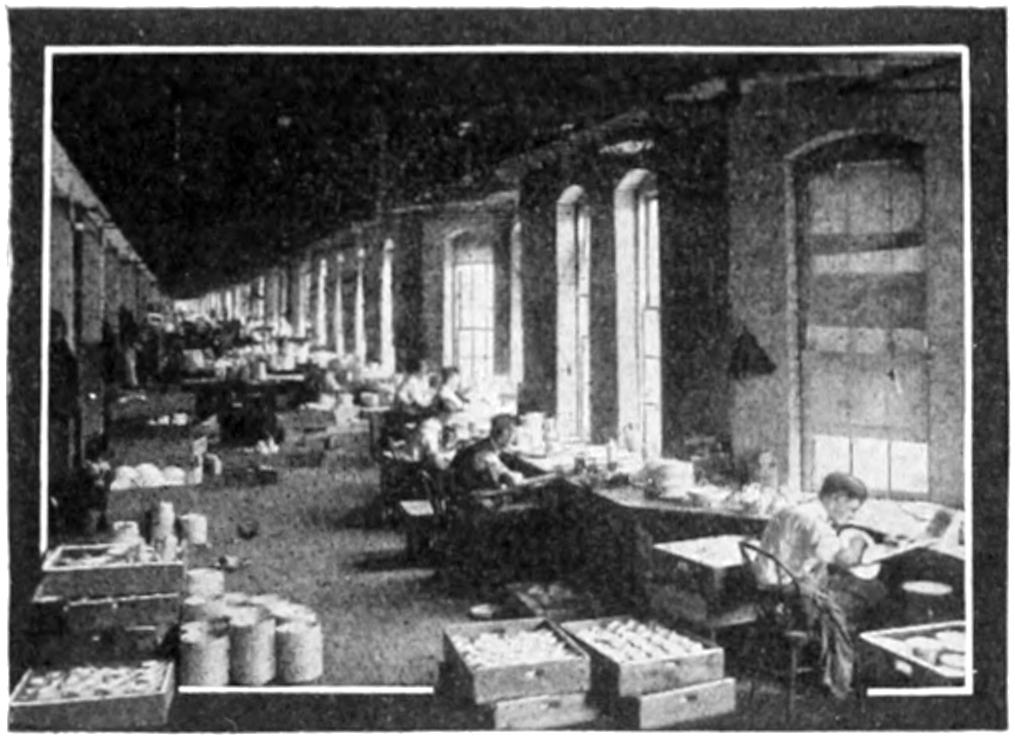

Examination.—Every steel pen passing through the factory is most carefully examined before being boxed, and should the least fault be found, it is at once rejected.

[18]

You can use a pencil to write with or to make marks, because the pencil wears off if you are scratching it on a surface that is rough enough to make it do so. Writing, you know, is only a way of making marks in such a manner as to make them mean something. You cannot write with a pencil on a pane of glass, because the glass is so smooth that when you move the pencil over its surface, the pencil will not wear off. To prove to yourself that the tip of the pencil constantly wears off when you write, you have only to recall that when you write with it a pencil keeps getting shorter and shorter. A slate-pencil will wear down short by merely writing with it, but a lead-pencil must be sharpened—that is, you must keep cutting away the wood in order to get at the lead inside.

You cannot do so, because it takes something with a rougher surface than paper to wear off the point of a slate-pencil. A slate is used to write on with slate-pencils, because slate wears off the end of the pencil easily, and also because you can rub out the writing on a slate with water. Lead-pencils are used for writing on paper, but you must have a rough surface on the paper to write on even with a lead-pencil. Some kinds of papers have such a smooth surface that you cannot write on them with a lead-pencil.

Writing with a pen, however, is quite different from writing with any kind of pencil, because in writing with ink we do not wear off the end of the pen, but have the ink flow from the pen. For this purpose we must have a surface that will absorb the ink from the pen, and draw the ink down off the pen and make it flow. A slate has no power of absorption and therefore cannot draw the ink. A piece of blotting paper is the best kind of paper for absorbing ink, but it is too much so for writing purposes. For writing with ink we need a comparatively hard surfaced paper that has absorbent qualities, but not too absorbent.

It is because the blotter has a very excellent ability to absorb some liquids. The thinner the liquid the more easily the blotter will absorb it. Ink is thin—being mostly water—the blotter is of a loose texture and has a rough surface. This gives the blotter the ability to pick up the ink, just as a sponge would do. A sponge has what is called the power of capillary attraction and so has the blotter.

Deposits of chalk are found on some shores of the sea. A piece of chalk such as the teacher uses to illustrate something on the blackboard at school consists of the remains of thousands of tiny creatures that at one time lived in the sea. All of their bodies excepting the chalk—called carbonate of lime in scientific language—has disappeared and the chalk that was left was piled up where it fell at the bottom of the ocean, each particle pressing against the other with the water pressing over it all until it became almost solid. It took thousands of years to make these chalk deposits of the thickness in which they are found. Later on, through changes in the earth’s surface, the mountain of chalk was raised until it stood out of the water and thus became accessible to man and school teachers.

Talking and the words used came into being through the desire of men to communicate with each other. Before words became known and used man talked to those about him by the use of signs, gestures and other movements of the body. Even to-day when men meet who cannot talk the same language they will be seen trying to come to an understanding by the use of signs and gestures and generally with fair results.[19] The need of more signs and gestures to express a constantly increasing number of objects and thoughts led to the introduction of sounds or combination of sounds made with the vocal cords to accompany certain signs and gestures. In this way man eventually developed a very considerable faculty for expressing himself. Sign by sign, gesture by gesture and sound by sound language was slowly developed. A man would be trying to explain something to another by sign or gesture and to make it more clear would make a sound or combination of sounds to put more expression into his efforts. Finally the other man would understand what was meant and he would tell some one else, using the same signs, gestures and sounds. Later on it would develop that to express thus any certain thought, act or the name of a thing, all of the people in the community would make this same combination of sounds, signs and gestures to express the same thing. Finally the gestures and signs would be dropped and it was found that people understood perfectly what was meant when only the sound or combination of sounds was produced. That made a word. All the other words were made in the same way, one at a time, until we had enough words to express all the ordinary things and the combination of words became a language. The children learned the language by hearing their parents talk it, and that is how men learned to talk.

The origin of this method of indicating “No” is found in the result of the mother’s efforts in the animal kingdom of trying to feed her young. A mother animal would be trying to get her young to accept the food she brought them and tried to put it in their mouths. Perhaps, however, the young animal had had sufficient food or did not fancy the kind of food offered. The natural thing to do under the circumstances would be to close the mouth tight and shake the head from side to side to prevent the mother from forcing the food into the mouth. Thus we get the closed lips and the shaking the head from side to side to mean “No.” In other words, that kind of a way of saying “No” came from an effort to say “I don’t want any.”

The idea of nodding to mean “Yes” comes from the opposite of the action which, as just described, indicates a “No.”

When the young animal was anxious to accept the offered food, it made an effort to get at the food quickly. Hence, the pushing forward of the head and the open mouth (always more or less opened when you nod to indicate “Yes”) and an expression of gladness. You will notice if you see anyone nod the head to indicate “Yes” that the lips are open rather than closed, and that there is always a smile or an indication of a smile to accompany it. In other words, the nod to mean “Yes” is only another way of saying “I shall be pleased.”

When man even in his uncivilized state found it necessary to count, the only implements at hand were his fingers and toes, and as he had ten toes and ten fingers, he naturally began counting in tens, and has been doing so ever since.

When we to-day count on our fingers we confine ourselves to our fingers leaving our toes stay in our shoes, where they naturally belong. But the first men who counted used both fingers and toes, and so he was able to count twenty before he had to begin over again, while little children to-day, when they count with their fingers, must begin where they started after they reach ten.

The expression “counting himself” was originated by the first man who counted. Such a man would count all of his fingers and toes and the result[20] would be twenty. Then, so that he would remember the number of times he had counted himself, he made a mark some place each time he reached twenty. The mark he made was a mere scratch in the dirt or on a hoe or something else. To make a scratch you merely, of course, score the surface of whatever you happen to be scratching on, and that is how it happened that the word “score” in our language to-day means as a term in counting, twenty.

There has been a great effort made to change our system of counting in tens to one where you count in twelves. That would fit in very well with our system of measuring which is based on the foot of twelve inches, and of our calendar for recording the passage of time which has twelve months. There are many arguments in favor of this change, among the principal of which is the fact that it would make our problems of division much easier, for our ten can be evenly divided by but two of our single figures, two and five, whereas twelve can be evenly divided by four of our single figures, viz., two, three, four and six. It is believed that sooner or later the system of counting by twelve instead of ten will be adopted by the entire world for counting everything. As it is now we do part of our counting by one system and part of it by another.

There is no scientific plan by which people get their names. There is not much except curious interest to be gleaned from the study of how people got their names.

In the earliest days of the world, or at least as soon as men had learned to speak by sounds, all known persons, places and groups of human beings must have had names by which they could be spoken of or to, and by which they were recognized. The study of these names and of their survival in civilization enables us in certain instances to tell what tribes inhabited certain parts of the earth now peopled by descendants of an entirely different race and of another speech altogether. We learn such things from the names of mountains and other things, for instance, which still cling to them.

The story of personal names is very complex, but comes from very simple beginnings. The oldest personal names were those which indicated a group of people rather than individuals who may have been actually related to each other or even bound together for reasons of protection or other convenience. In the races of Asia, Africa, Australia and America examination shows that groups of people who considered themselves to be of the same relationship, attached to themselves the name of some animal or other object, whether animate or inanimate, from which they claimed to be descended. This animal or object was called the “totem,” and thus the earliest and most widely spread class and family names are totemistic. Such groups called themselves by names from wolves, turtles, bears, suns, moons, birds, and other objects, and these people wore badges with pictures of the animal or object from which they took their names to identify them to other people.

When, then, we come to investigate the giving of personal names among the tribes, we see that most uncivilized races gave a name to each new-born infant derived from some object or incident. So a new-born member of the “Sun” tribe would be named “Dawn,” and would be known as “Dawn” of the “Sun” tribe; or perhaps a new-born son of the tribe of “Wolf” would be called “Hungry,” and be known as “Hungry Wolf.” A member of the “Cloud” tribe would be named “Morning,” because he was born in the morning. He would always be known as “Morning Cloud.”

Later, as society became more established and paternity became recognized, we find the totem name give way to a gentile name. Among the Greeks and Romans the system was early adopted and proved satisfactory. Thus we have Caius Julius Caesar. Caius indicates[21] that he is Roman; Julius is the gentile name given him and the Caesar a sort of hereditary nickname. On the other hand, the early Greeks began the system of introducing a local name instead of the gentile name. Thus Thucydides (obtained from the grandfather), the son of Olorus, of the Deme (township) of Halimusia.

HOW DIFFERENT NAMES

ORIGINATED

This was all right and suited the purposes of the Greeks and Romans, who had plenty of time to give full explanations in this way. But in Europe, for instance, civilization demanded more speed, and the increase of population demanded more names, so that nicknames and names indicating personal descriptions and peculiarities came into use. Such names as Long, Short, Small, Brown, White, Green and others of the same kind came from this source, and as families grew these surnames stuck to the family and parents gave their children Christian names to further distinguish them as individuals. Other surnames such as Fowler, Sadler, Smith, Farmer, etc., became attached to people because of the occupations in which they were engaged, and yet other names were derived from places. The owner of an extensive estate would be designated by a Christian name which might be George (after his King) and then to indicate his landownership, von (meaning of) Wood, making the combination of George von Wood, meaning George, the owner of the place called Wood. On the other hand, he might have working for him a laborer who lived at the place and, if his name was Hiram, they would, to indicate where he belonged, put the Wood after the Hiram; but, lest there be confusion as to his class, they would put an At before the Wood and make him Hiram Atwood, indicating his Christian name, where he worked and the fact that he was not a landowner.

Many other names were invented in similar manner. When Adams became so common that there would likely be confusion on account of there being so many of them, a son of one of the Adams family would add to the name the fact that he was a son by writing his name Adamson, and thus start a new family name. Thus, in the same way also came Willson, Clarkson, and other names of that kind.

For a long time the Jews had only one word for a name, such as Isaac, Jacob, Moses, etc. They became so numerous that it was impossible to distinguish them, and so a commission was named to give surnames to all the Jews in addition to their other names. As the race was then, as now, held in derision by the rulers of many nations into which the tribe had become scattered, the people who had charge of the naming of the Jews took advantage of the opportunity to make sport of them, and gave them such names as

Rosenstock (Rose bush),

Rosenszweig (Rose twig),

Rosenbaum (Rose tree),

Blumenstock (Flower bush),

Blumenthal (Flower valley),

etc., etc.

Our Christian names are from similar sources, and while many of them are well selected because of their beautiful meanings, there are many of them which mean nothing as words as they were only invented for the purpose of giving a new name to a new child.

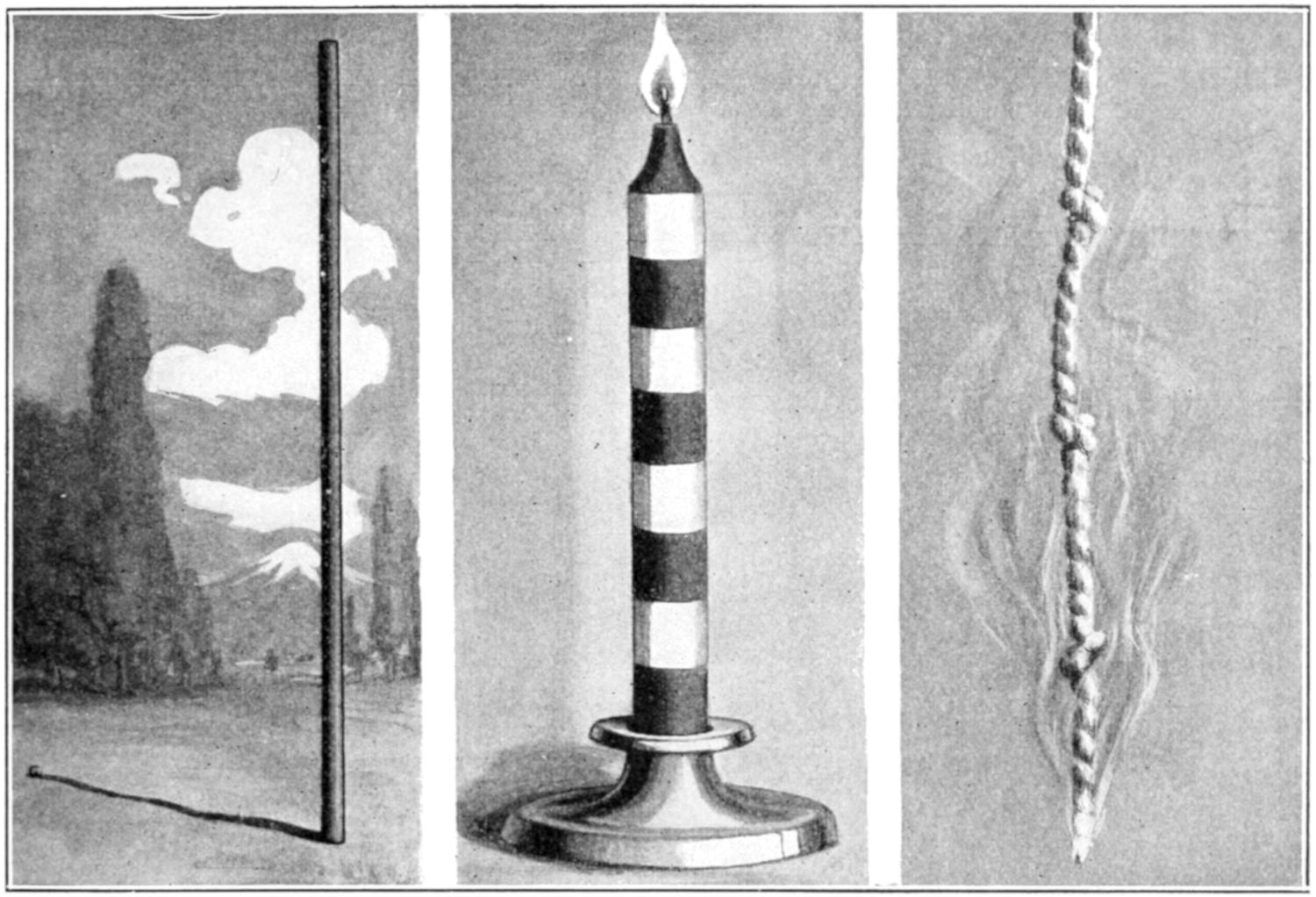

When you light a candle it burns, because the lighted wick heats the wax sufficiently to turn it into gases, which mix with the oxygen in the air and produce fire in the form of light. You know it is not easy to light a candle quickly. You must hold the lighted match to the wick until the wax begins to melt and change to gases. As long as the wax continues hot enough to melt and turn to gas the candle will burn until all burned up; but if there is a break in the continuous process of changing the wax to gas, the light will go out. Now, when you blow at the lighted candle, you blow the gases which feed the flame away from the lighted wick, and this makes a break in the continuous flow of gas from the wax to taper, and the light goes out.

[22]

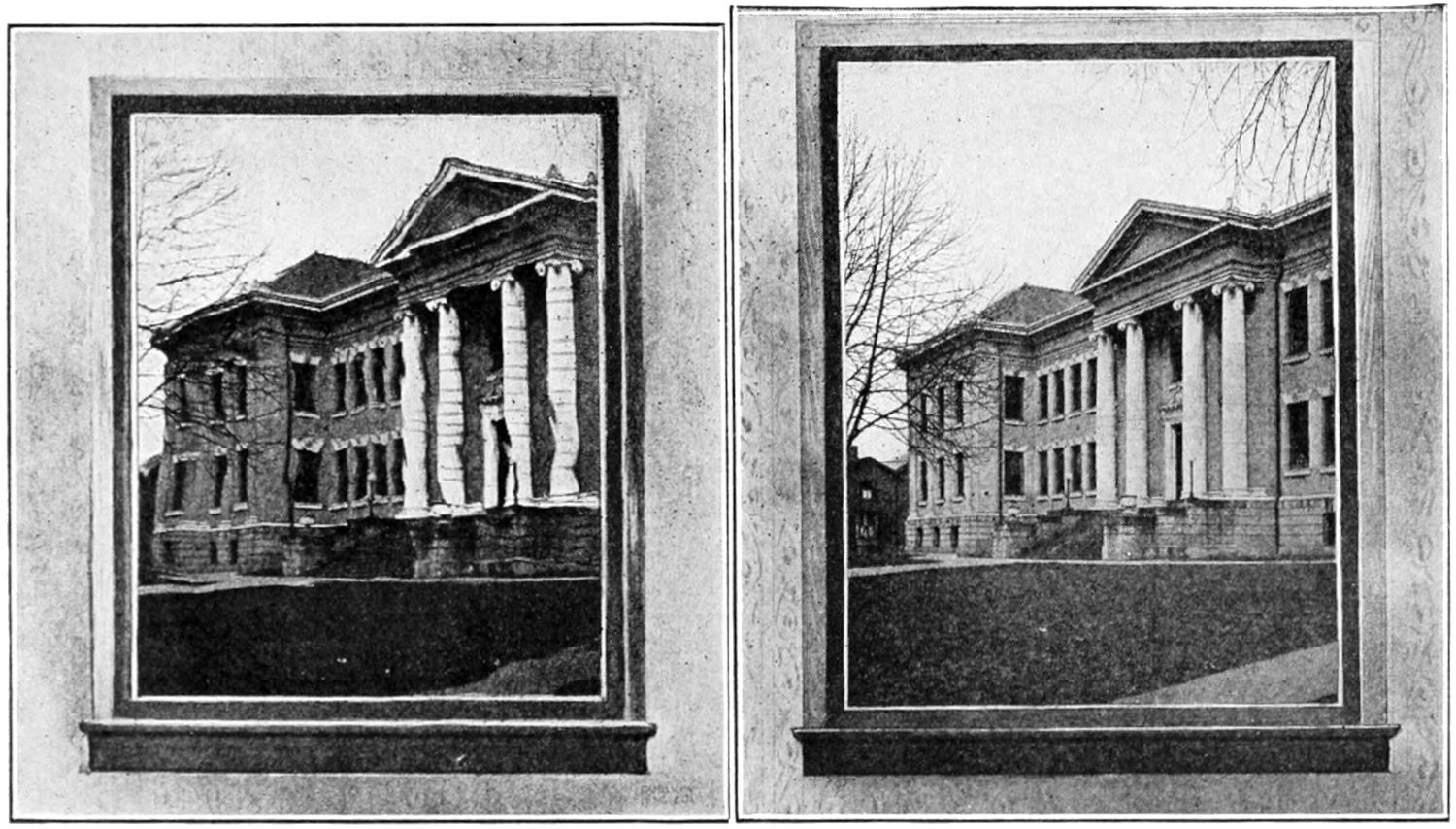

When we look upon the surface of a mirror we see the image of ourself and our surroundings. The extent of the view depends upon the size of the mirror and the distance we are standing from it.

If we hold the mirror close to our face we see only the face, or perhaps but a portion of it, and the farther away we are the more the mirror will reflect, only, of course, the various images will be smaller. The mirror reflecting exactly what the eye sees, without doubt had a great influence in inducing the experiments that resulted in the process we call photography.

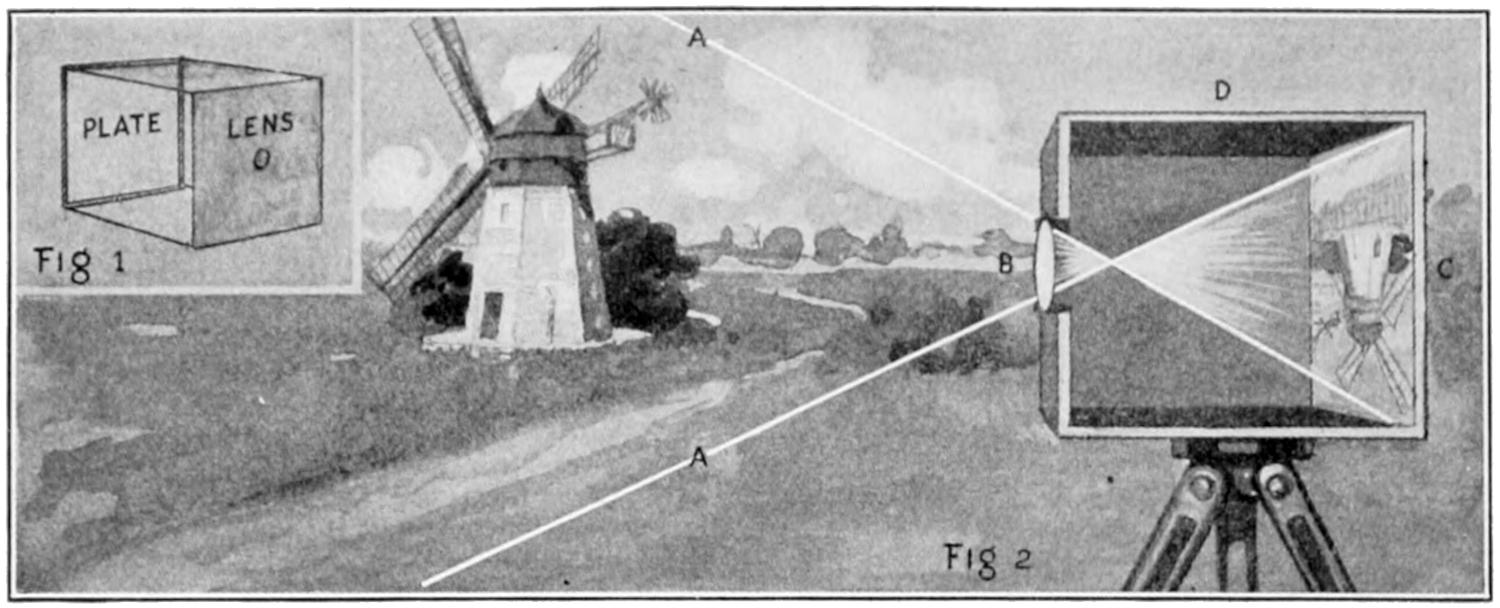

The taking of a photograph with a camera may in a way be compared with the action of your eyes, when you gaze upon your reflection in a mirror, or look at any object or view. Any object in a light strong enough to render it visible will reflect rays of light from every point.

Now, the eye contains a lens very similar in form to that used in a camera. This lens collects the rays of light reflected from the object looked at and brings them to a focus in the back of the eye, forming an image or picture of whatever we see, just as the mirror collects the rays of light and reflects them back through the lens of the eye.

Certain nerves transmit the impression of the image so focused in the back of the eye to the brain and we experience the sensation of sight.

The lens is the eye of the camera, and the process we call photography is the method employed to make permanent the image the eye or lens of the camera presents to a sensitive surface within the camera.

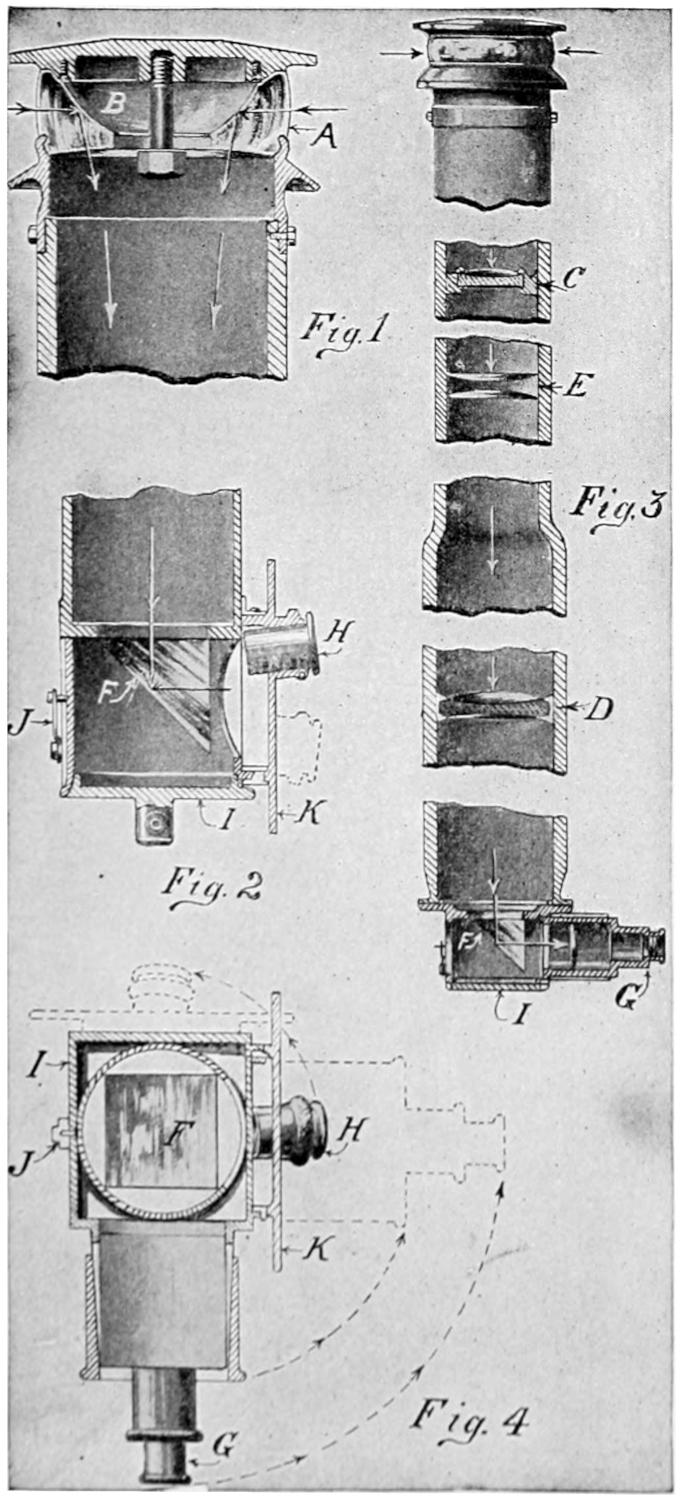

Fig. 1 shows a simple form of camera, it being merely a light tight box with a lens fitted to the front, and a means for holding a sensitive plate at the back, the plate being placed at just the right distance to focus the rays of light admitted through the lens in exactly the same manner as the rays of light pass through the lens of the eye and come to a focus in the back part of the eye.

Now, if we could look inside the camera we would note that the image was inverted, or upside down.

Fig. 2 will explain this.

The rays of light from “A” pass in a straight line through the lens “B” until they are interrupted by “C,” upon which they strike, forming an upside down image of the object “A.” But, you exclaim, “we do not see things upside down.” No, we do not, because some mental process readjusts this during the passing of the impression from the eye to our brain.

Let us suppose we have our camera loaded with its sensitive plate or film.[23] We select some object or view we wish to photograph, uncover the lens for an instant, and let the light impress the image upon the sensitive surface of the plate or film. Now, how are we going to make this image permanent?

If we were to examine the creamy yellow strip of film upon which the picture was taken there would seemingly be no difference between its present appearance and before the snapshot was made.

Now let us suppose that this strip of film is a little trundle bed, and in it tucked securely away from the light are many hundreds of little chaps called silver bromides, little roly-poly fellows lying just as close together as possible, and protected by a coverlet of pure white gelatine.

HOW A PHOTOGRAPH

IS DEVELOPED

Until the sudden flash of light in their faces when the picture was taken, they have been content to lie still and sleep soundly. Now they are seized with a strange unrest, and each little atom is eager to do his part in showing your picture to the world. Alone they are powerless, but they have, all unbeknown to them, some powerful chemical friends, who, organized and aided by the photographer, will bring about their transformation. These chemicals, with the help of the photographer, form themselves into a society called the developer.

The photographer takes just so many of the tiny feathery crystals of pyro, just so many of the clear little atoms of sulphite of soda, and just so many little crystals of carbonate of soda, and tumbles them all into a beaker of clear cold water. Unaided by each other, any one of these chemicals would be powerless to help their little bromide of silver friends. The first of these chemicals to go to work is the carbonate of soda.

He tiptoes softly over to the trundle bed and gently begins turning back the gelatine covers over the little bromide of silver chaps, so that Pyro can find them in the dark.

It is Pyro’s mission to transform the little silver bromides into silver metal, but he is rather an impulsive chap, so he is accompanied by sulphite of soda, who warns him not to be too rough, and whose sole mission is to strain his eagerness to help his friends.

“Go slow now,” says Sulphite, “don’t frighten the little silver bromides, or else you’ll make them cuddle up in heaps, and the picture won’t be as nice as if you wake them up gently and each little bromide stayed just where he belonged.”

After all the little silver bromides that the light shone on have been transformed into metallic silver by the developer, another chemical friend has to step in and carry away all the little bromides that were not awakened by the flash of light.

This friend’s name is “Hypo,” and in a few minutes he has carried away all the little bromides that are still sleeping, so that the trundle bed with the now awakened and transformed silver bromides will, after washing and drying, be called a negative, and ready to print your pictures from.

If we take this negative, as it is called, and hold it up to the light, we will see that everything is reversed, not only from right to left, but also that whatever is white or light in color is dark in the negative, and that what would correspond to the darker parts of our picture are the lightest in the negative, and it is from these facts that we give it the name negative.

Now, to get our picture as it should be, we must place this negative in contact with a sheet of coated paper that is also sensitive to light.

So we place the negative and the sheet of sensitive paper in what is called a printing frame, with the negative uppermost, so that the light may shine through the negative, and impress the image upon the sheet of sensitive paper. Now, it stands to reason that if the lightest parts of our picture are the darkest in the negative that less light can pass through such portions of the negative in a given time, so that with the proper exposure to light the image upon the sheet of sensitive paper will be a correct picture of whatever the lens saw.

[24]

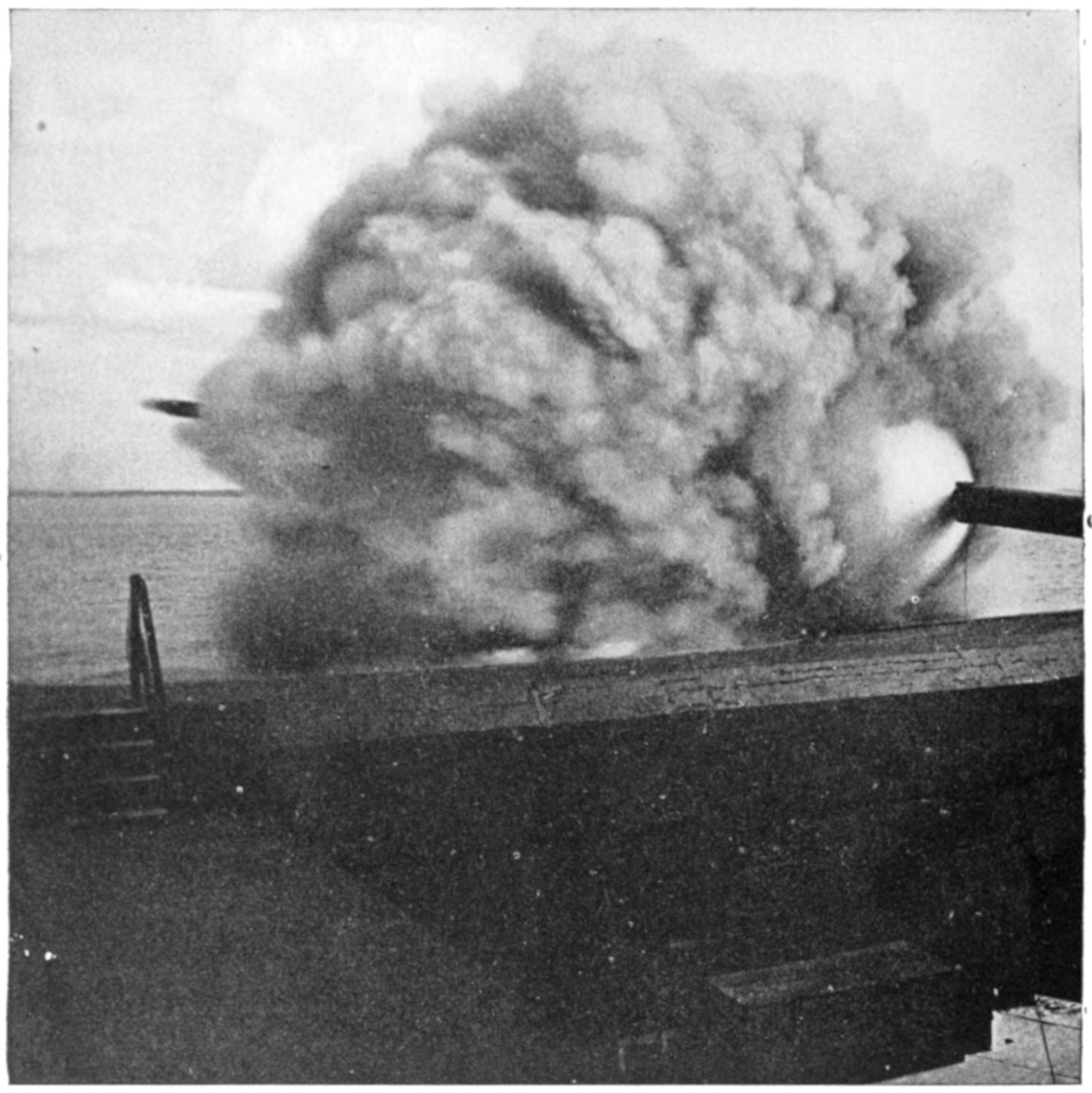

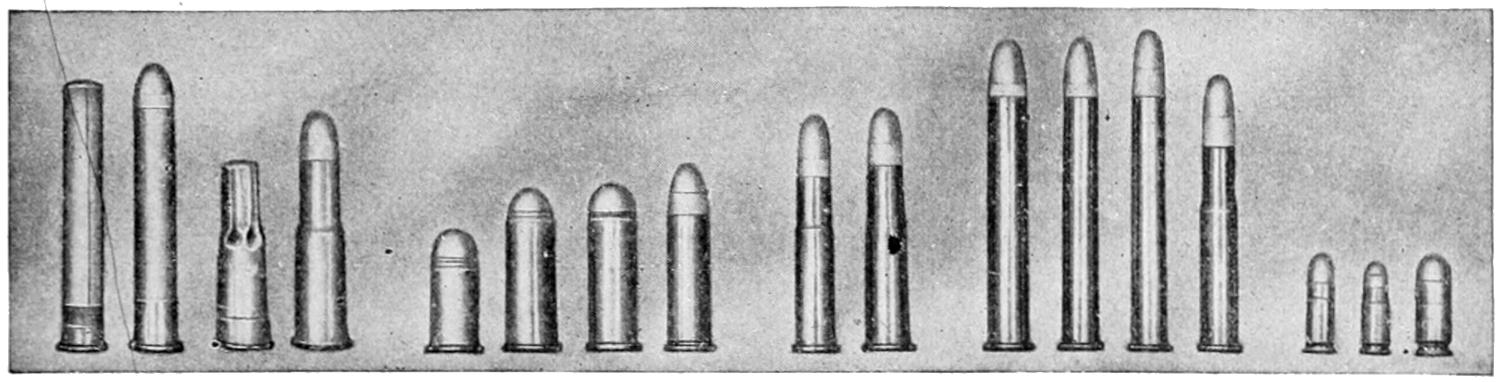

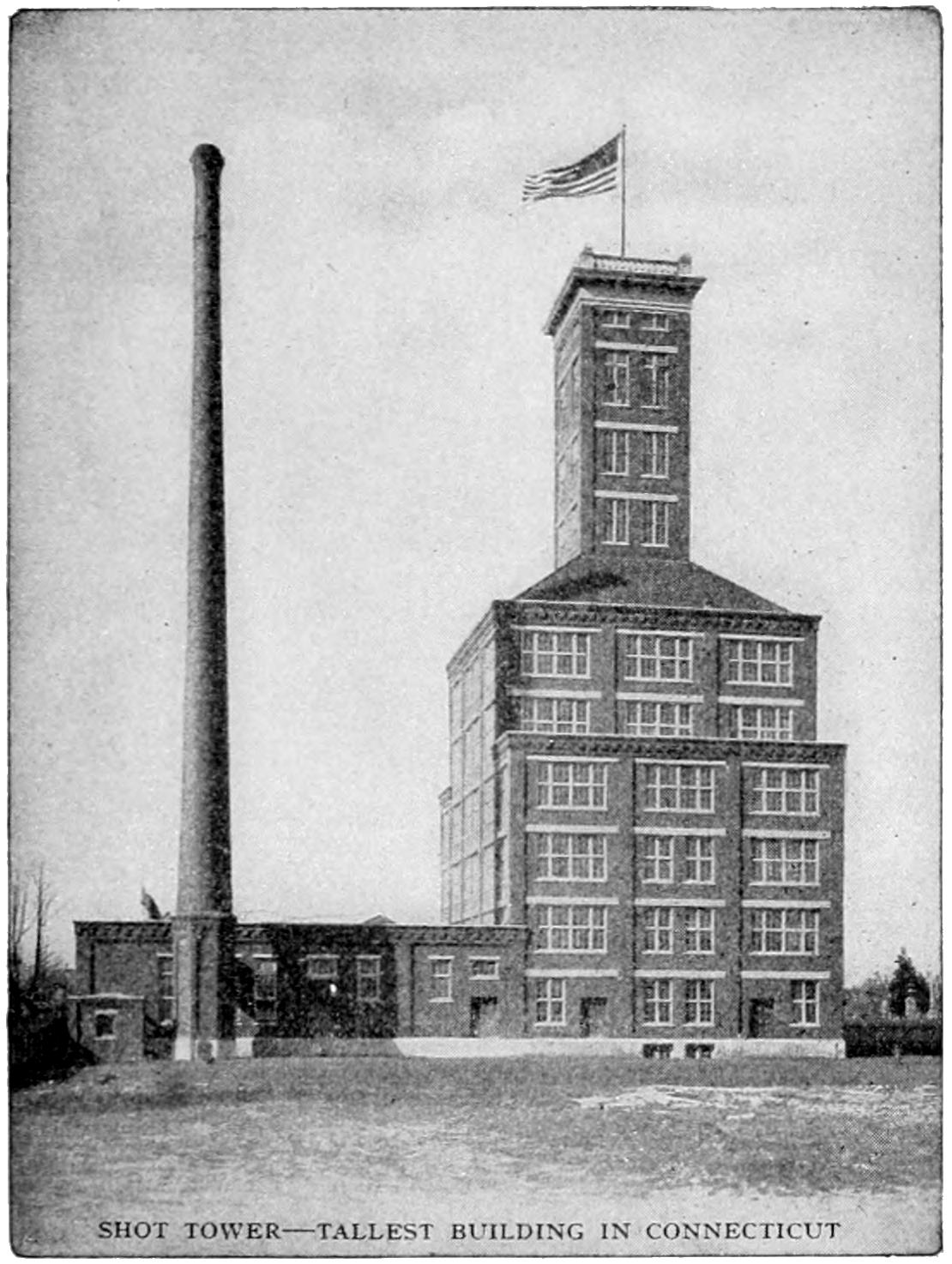

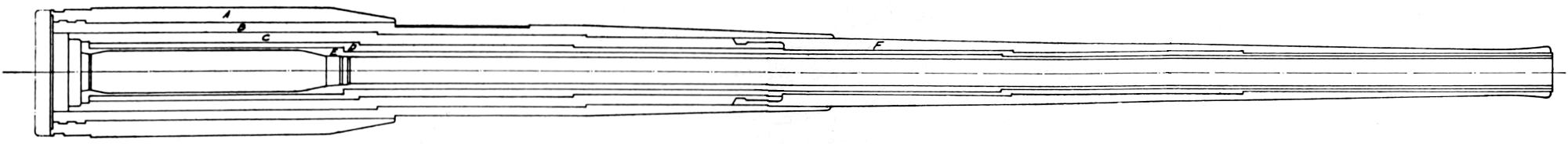

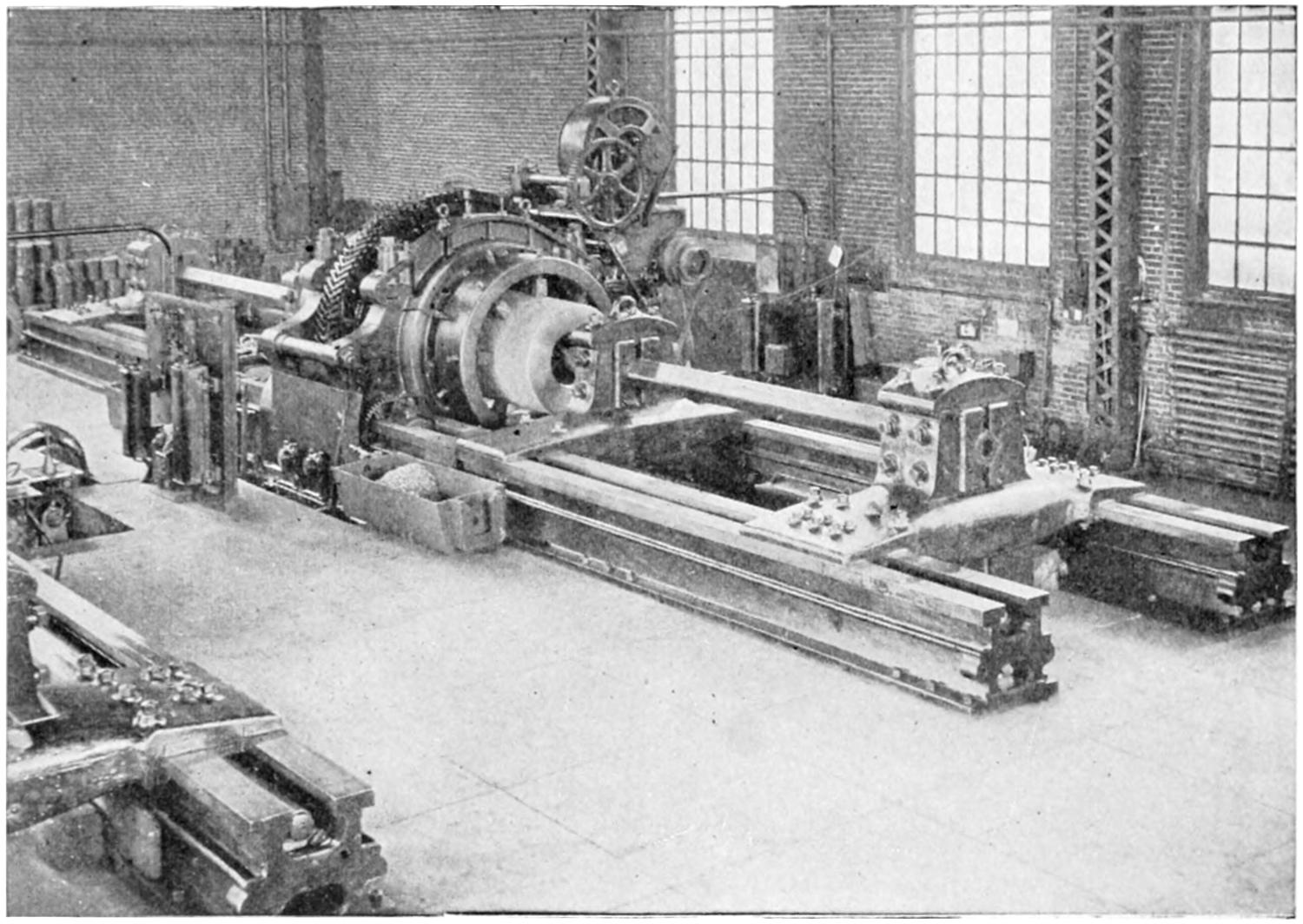

The swiftest thing that the human race has ever put into motion is the steel projectile of a twelve-inch gun. No human eye can follow its flight. Released at a pressure of forty thousand pounds to the square inch—in a heat at which diamonds melt and carbon boils—it hurls through the air at the rate of twenty-five miles a minute, and reaches the mark ahead of its own sound! (Pictures and story by courtesy of McClure’s Magazine.)

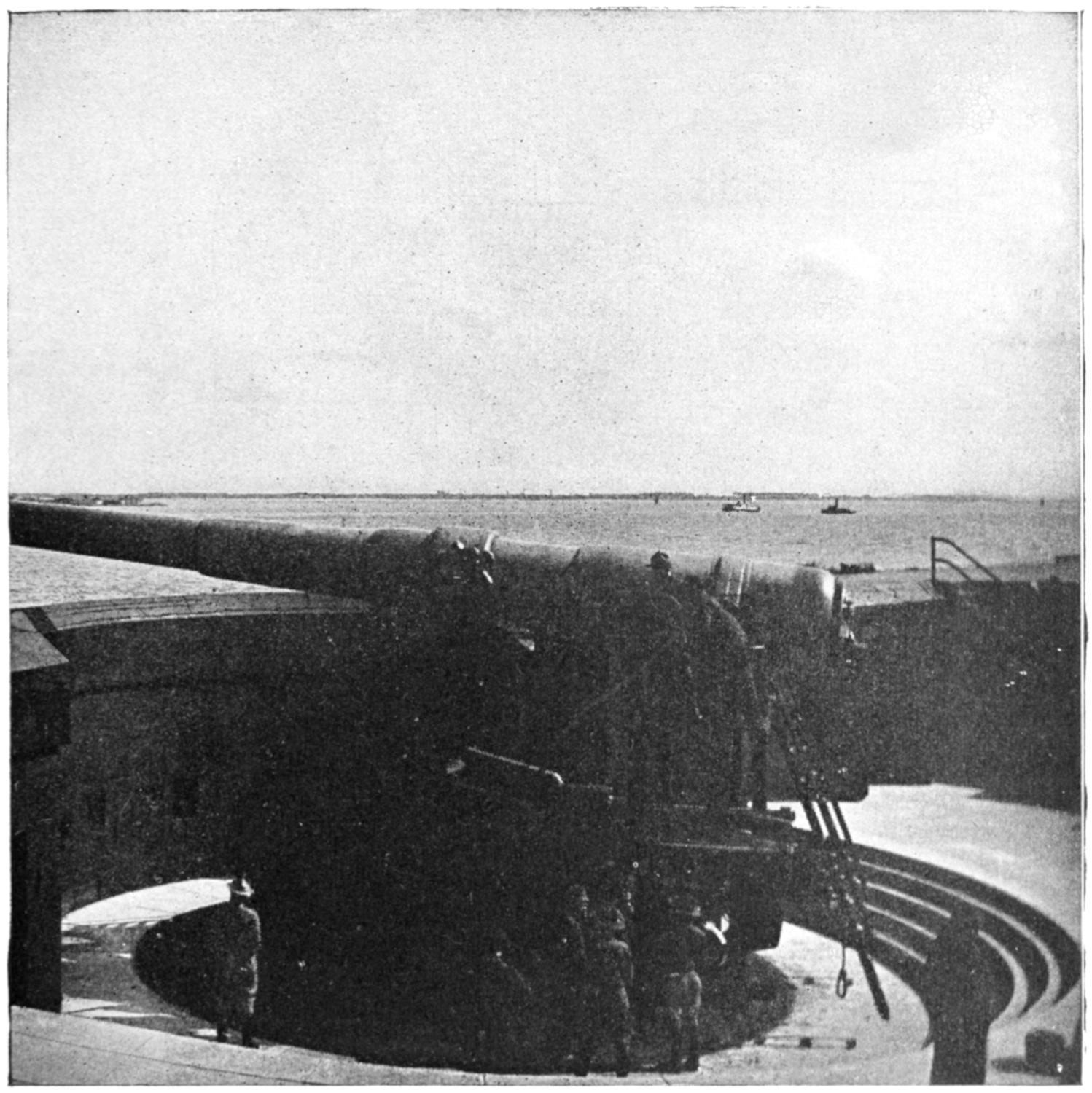

HOW SHOOTING SHELLS

ARE PHOTOGRAPHED

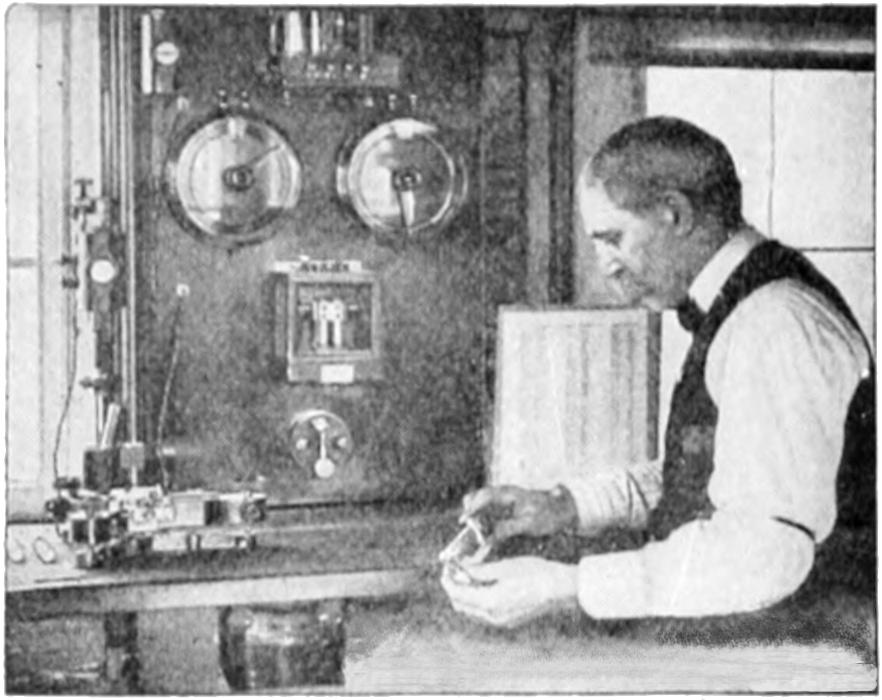

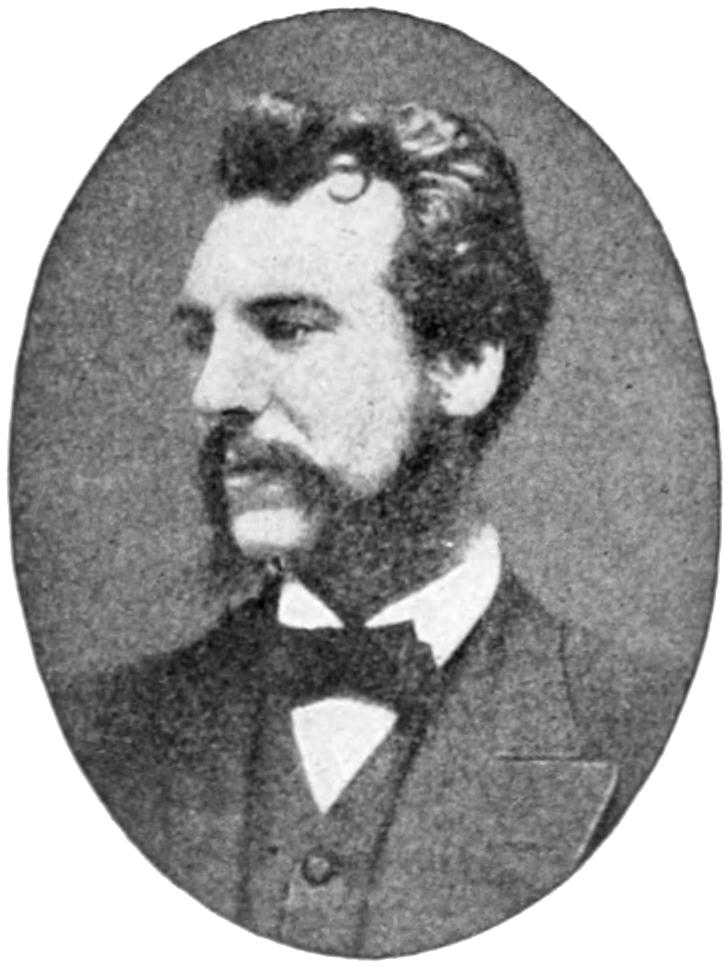

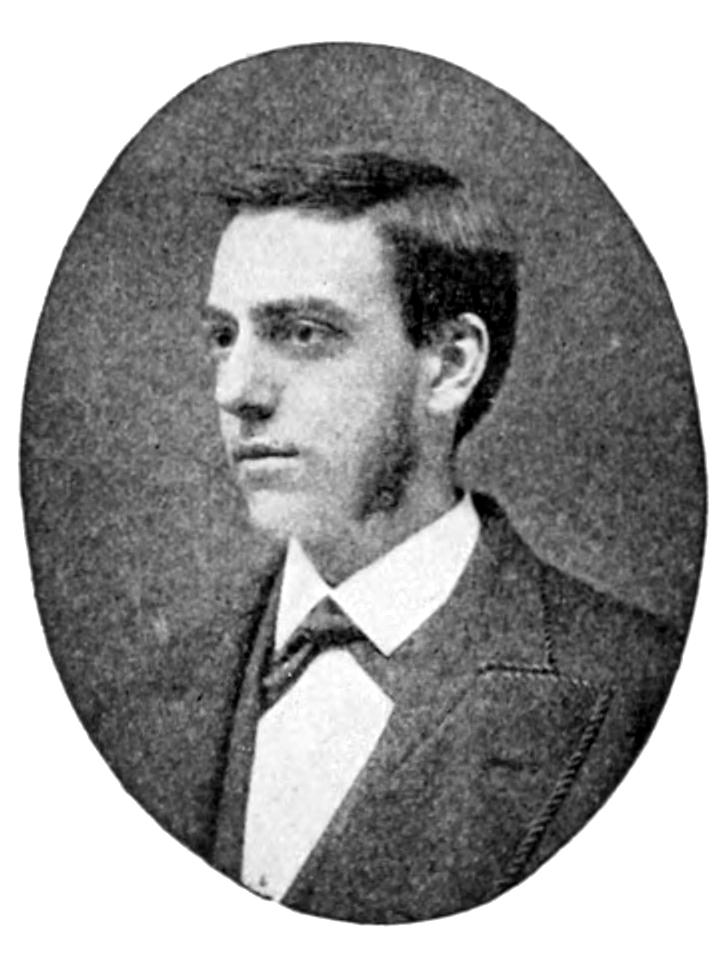

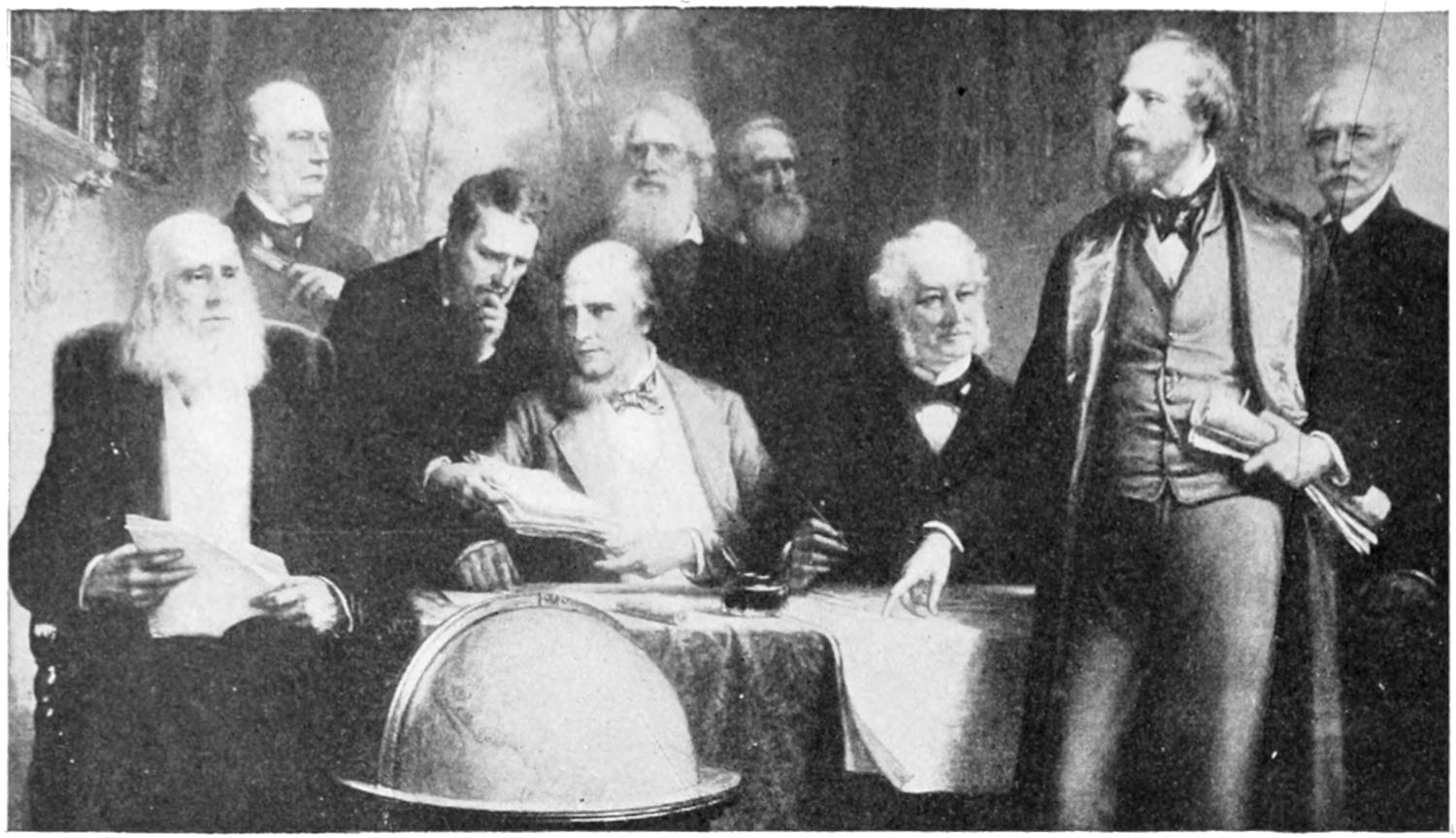

One of the most progressive branches of our military service is the Department of Coast Defenses, which, under the far-seeing guidance of General E. M. Weaver, holds our shores and harbors in a state of alert preparedness against foreign aggression. At Hampton Roads sits the Coast Artillery Board, composed of officers and consulting engineers to whom are referred all problems relating to coast artillery, and who have the responsibility of testing all new instruments proposed for artillery use. The purpose of this article is to describe one among several notable achievements of the Hampton Roads Coast Artillery School, this particular work having been done by Captain F. J. Behr of the Coast Artillery Corps, who, after years of effort, has recently developed a system that makes it possible to take[25] pictures of the swiftest moving bodies, the great steel projectiles of our biggest guns—to seize them with the camera’s eye as they hurl through the air at enormous velocities or at the very moment of their emergence from the gun muzzles, and to preserve these images, never seen before, for military study and comparison. Captain Behr was ably assisted in this work by Engineer J. A. Wilson.

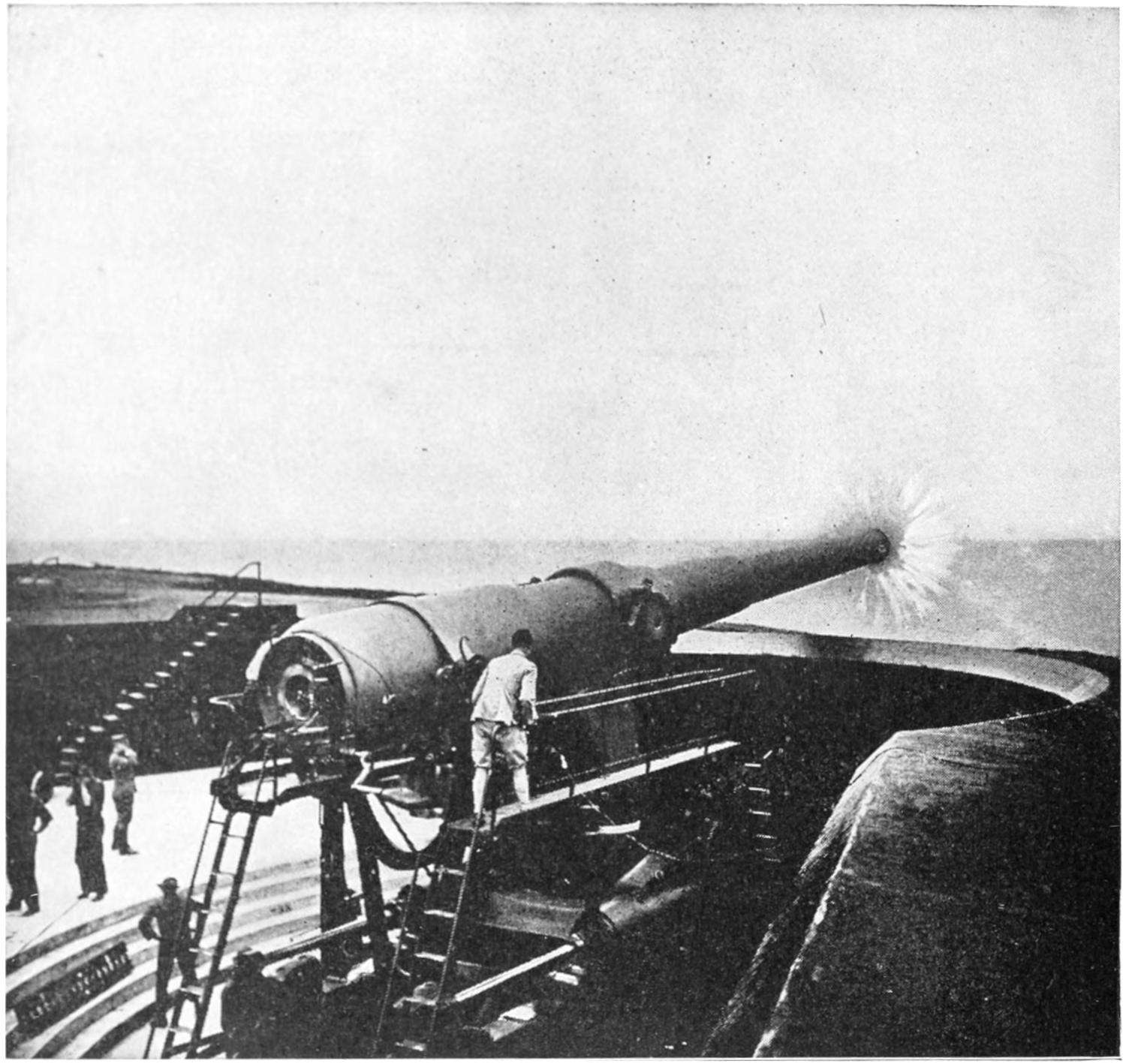

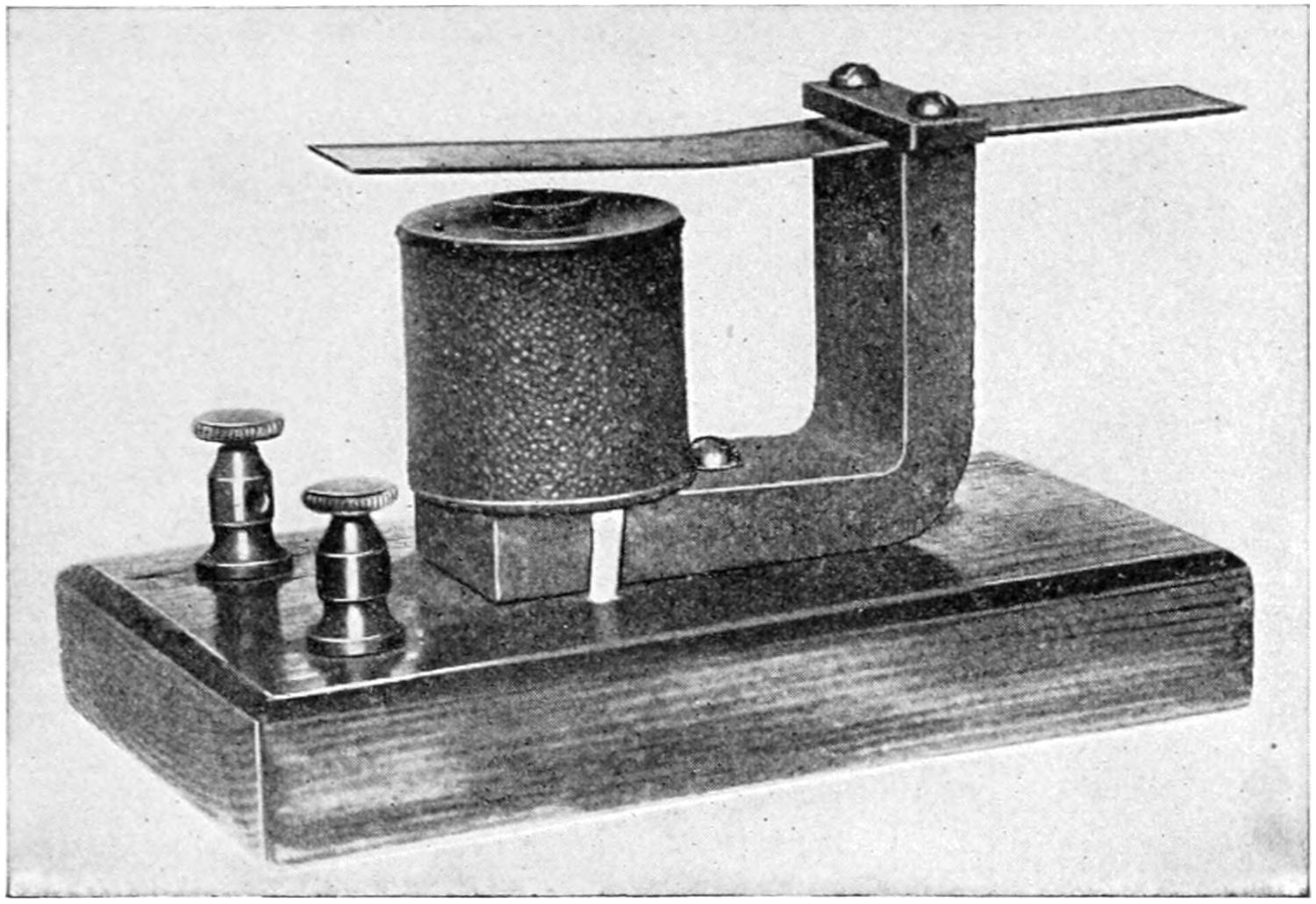

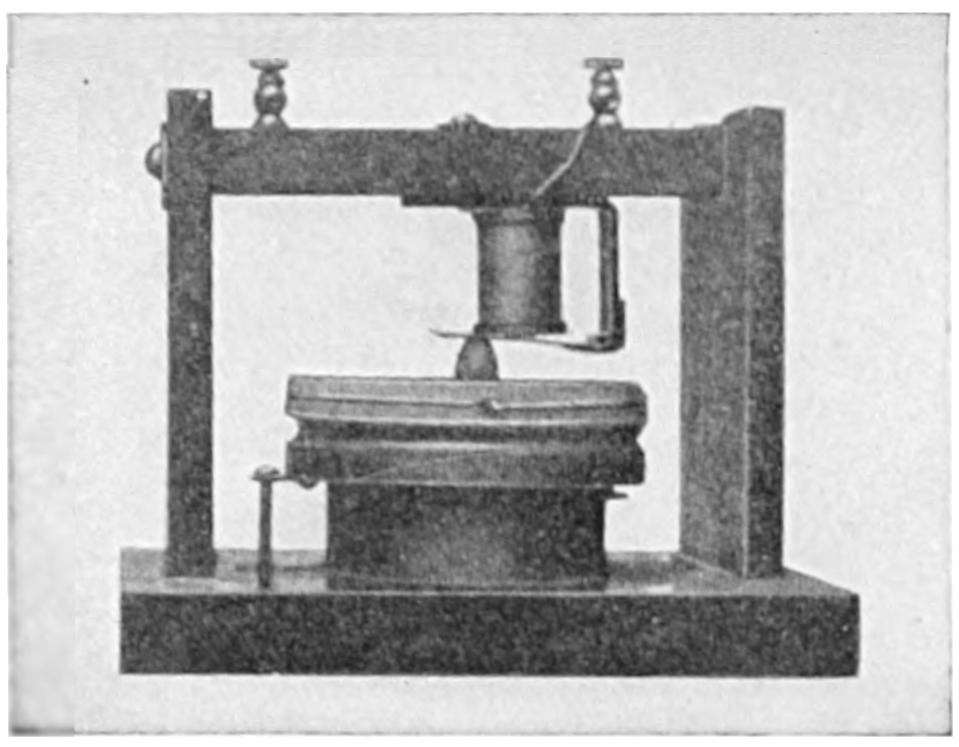

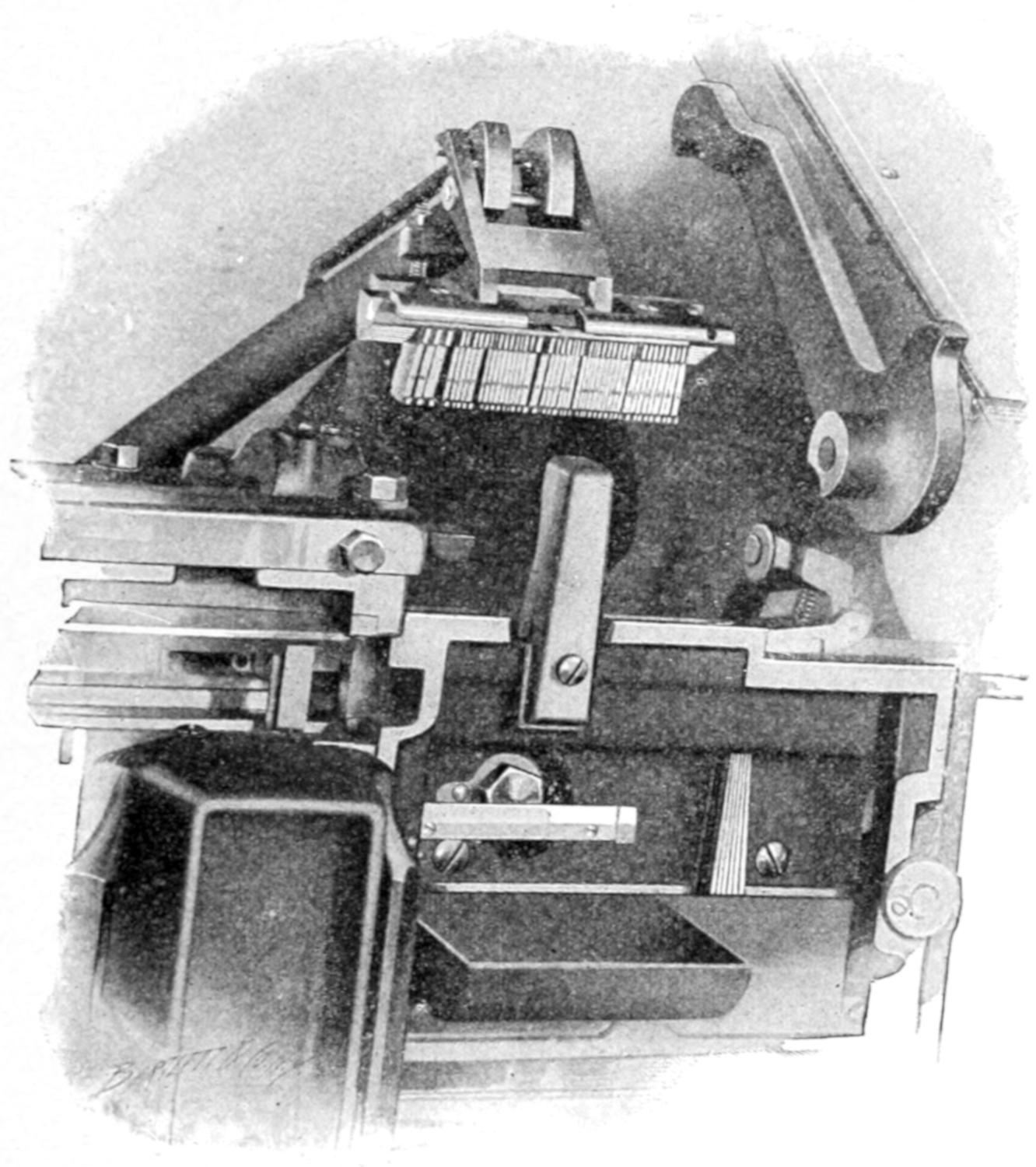

THE FASTEST CAMERA IN THE WORLD

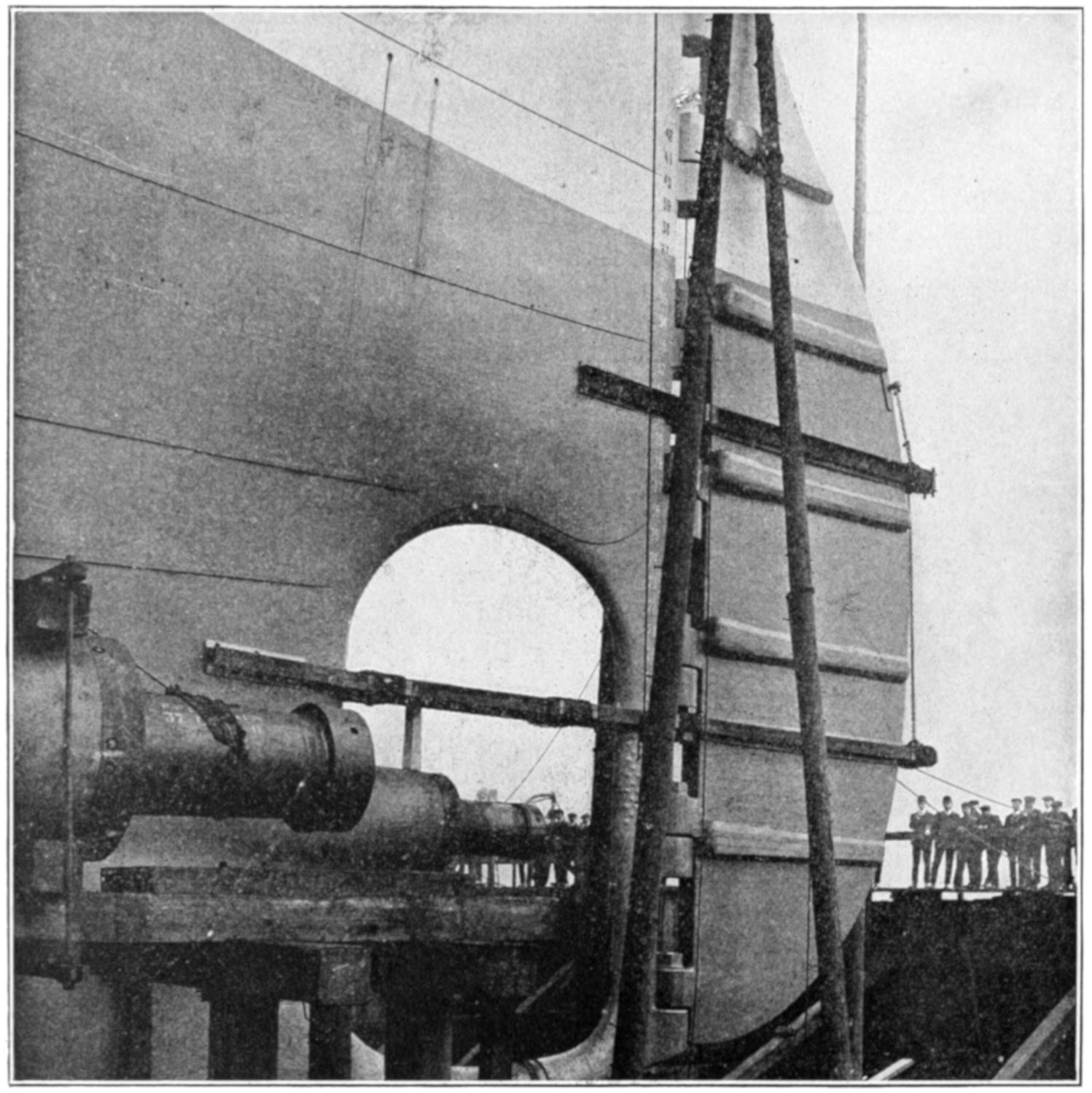

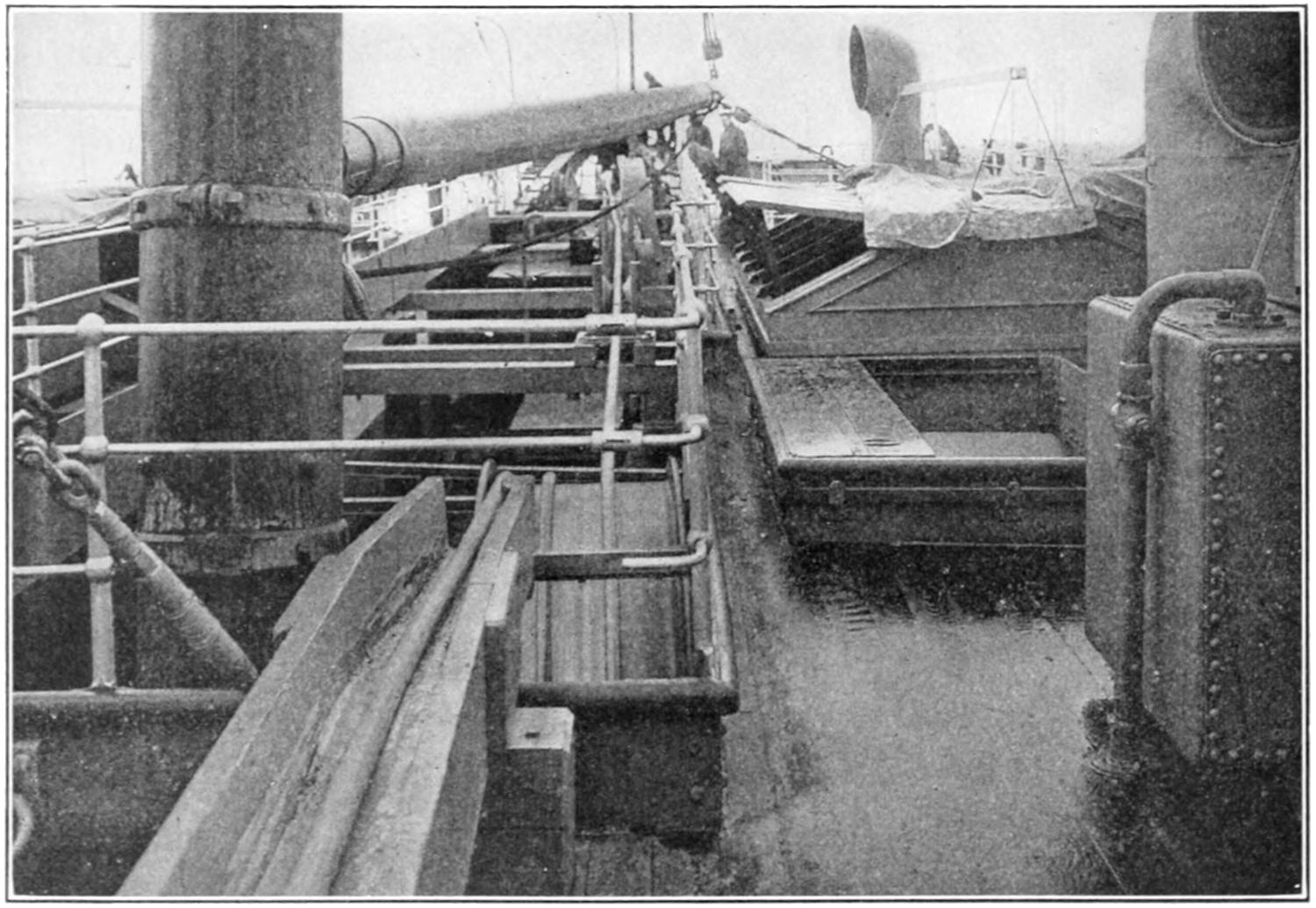

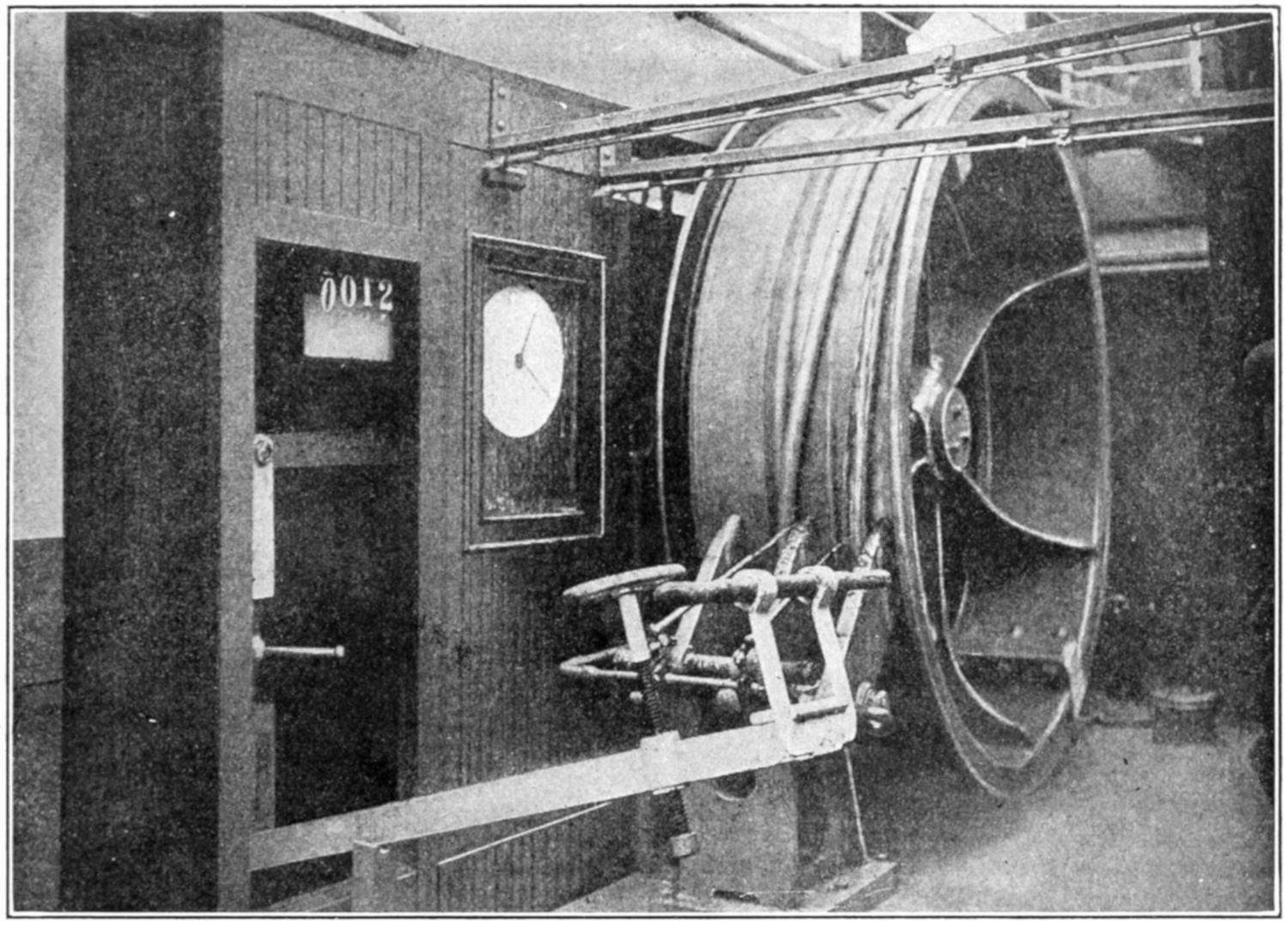

The big gun, equipped with the fastest camera shutter in the world, about to be fired and the shell photographed.

For years a young officer of the Coast Artillery has been trying to devise a camera so incredibly swift that it will record every stage of this lightning flight from the gun-barrel to the target. At last he has succeeded. His photographs—some of them taken one hundred thousandth of a second apart—have revealed remarkable and unsuspected facts to the military world. The story of his invention had never before been told.

Some of the increments and decrements of time involved in the series of photographs herewith published (several of them for the first time) are as small as one ten-thousandth part of a second. And Captain Behr has devised a method of taking photographs of projectiles as they arrive at a steel target and penetrate the target, inch by inch, that involves increments or decrements of time as small as the one hundred-thousandth part of a second. To the uninitiated it seems incredible that such infinitesimal divisions of time can[26] be used in practical calculations; but every trained physicist knows that in wireless work scientists of to-day speak casually of experiments that take account of two-tenths or one-tenth of a millionth part of a second!

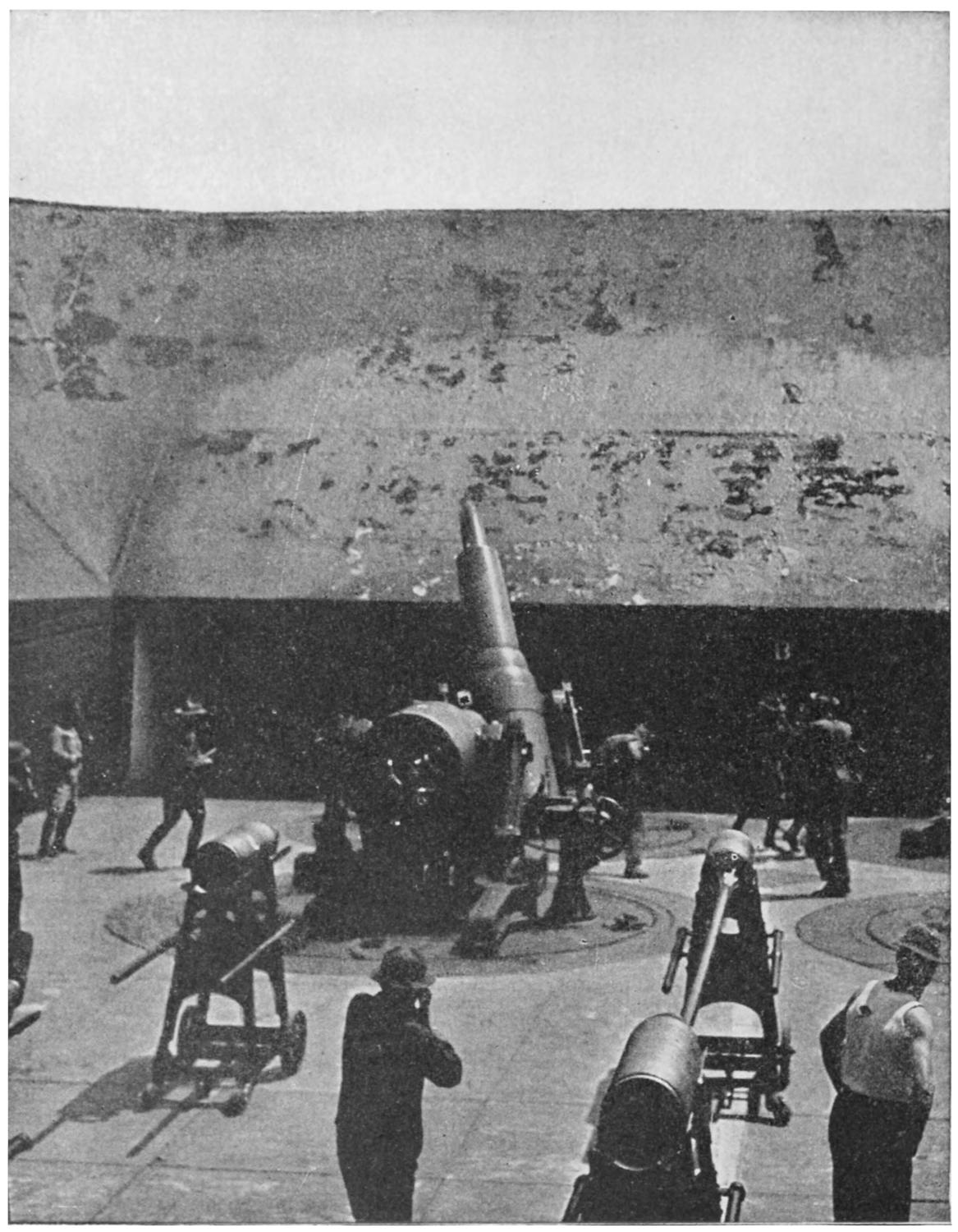

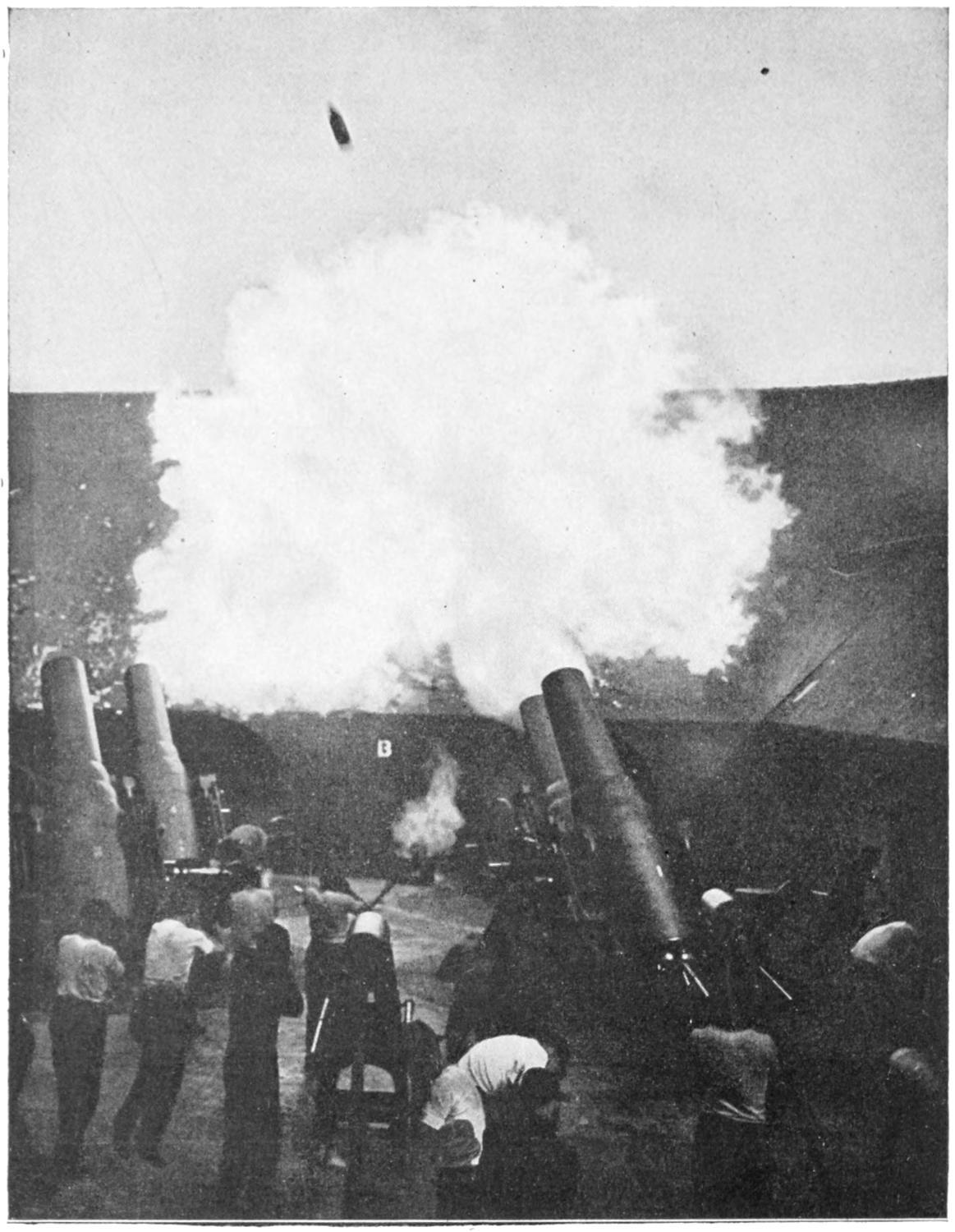

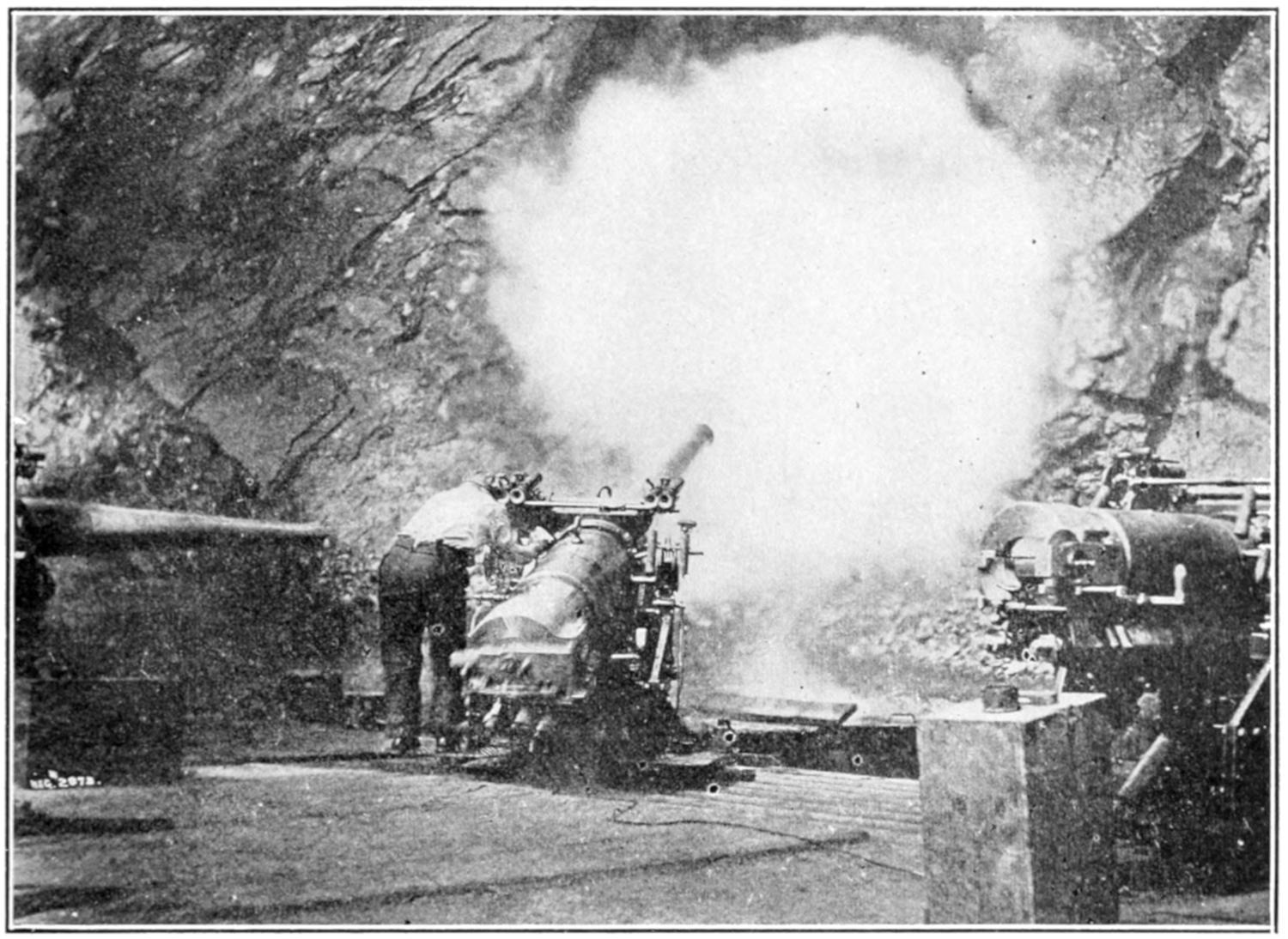

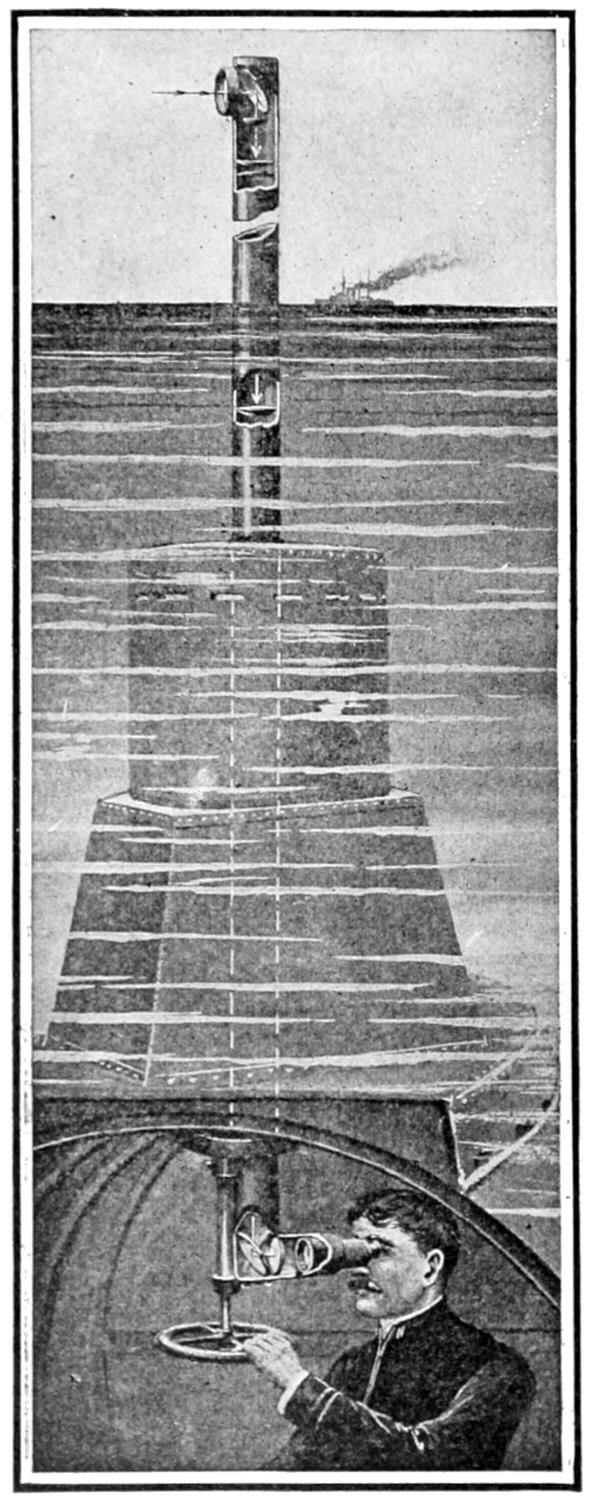

THE PROJECTILE EMERGING FROM MORTAR

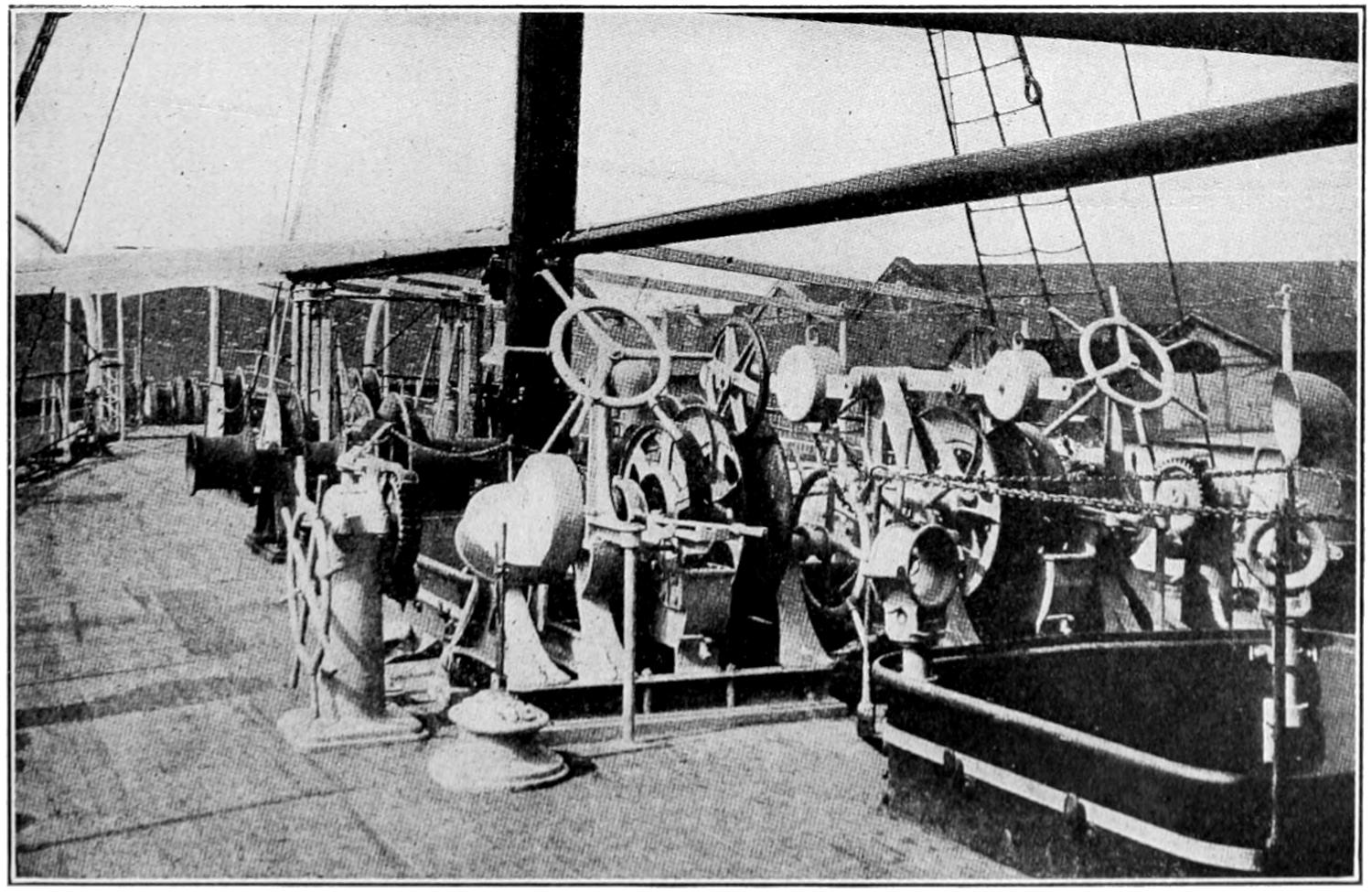

In this photograph—the first of a remarkable series showing five stages of a moving projectile—the half-ton projectile seems to be standing still, but really it is traveling at the rate of 900 miles an hour. The gunners here work in concrete pits 34 feet high. Underneath the mounts are the powder magazines. Each pit has four mortars usually served by an entire Coast Artillery Company. The projectiles are the same as those used in the twelve-inch guns, but less powder is required because mortar projectiles are hurled high in the air, not straight at a vessel, and deliver their destructive blows downward from a great height.

[27]

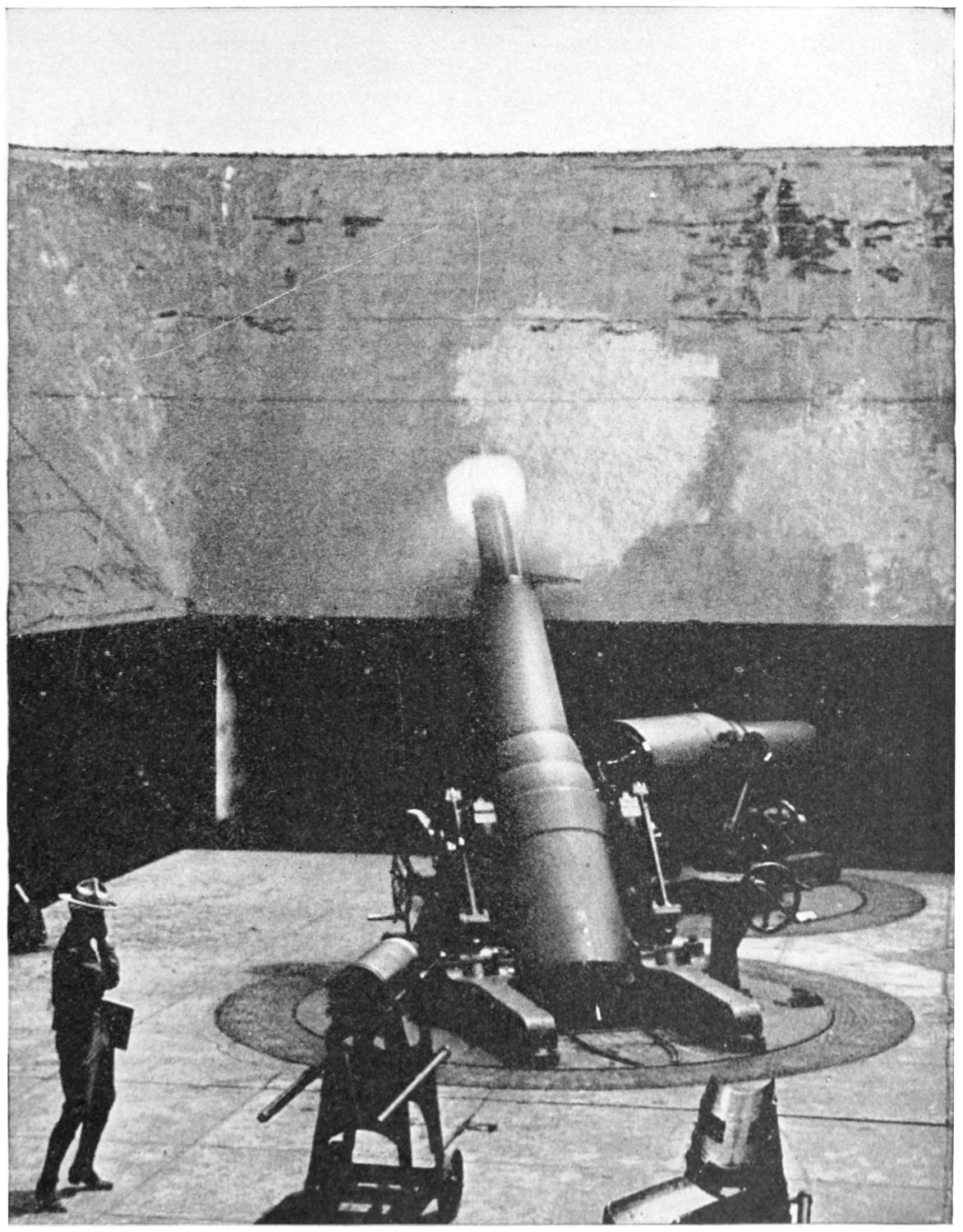

THE SMOKE RINGS WHICH APPEAR

This second photograph shows the projectile almost entirely out of the mortar. Its sharp nose may be seen above the “gas-ring” forming at its upper end. These “gas-rings,” or “smoke-rings,” come without warning, and only occasionally, perhaps once in eight or ten shots. They rise swiftly to the height of fifty or a hundred feet, growing larger and larger, and giving forth a weird, shrieking sound like a second projectile. Some insist that these “smoke-rings” are as hard as steel, owing to the enormous compression of their composing gases, and the story is told of a bird caught in the path of one of them and torn to pieces.

What happened to the projectile after it leaves the gun, or after the discharge of the gun, and before the projectile has had time to issue from the gun-barrel? What is the action at the muzzle of gases generated? What shape do these gases assume as they leave the gun? What causes the much-discussed “gas-rings” that sometimes form when a mortar is fired, and oftener do not form? What phenomena attend the arrival of the projectile at a solid steel target? Is the steel actually fused by the heat of impact? Is it vaporized? Or what? These are some of the questions that Captain Behr set himself to solve, or to help in solving, as he worked out his methods of rapid photography. His aims were strictly military, but his results make fascinating appeal to the general imagination. Fancy doing anything in the one hundred-thousandth part of a second!

[28]

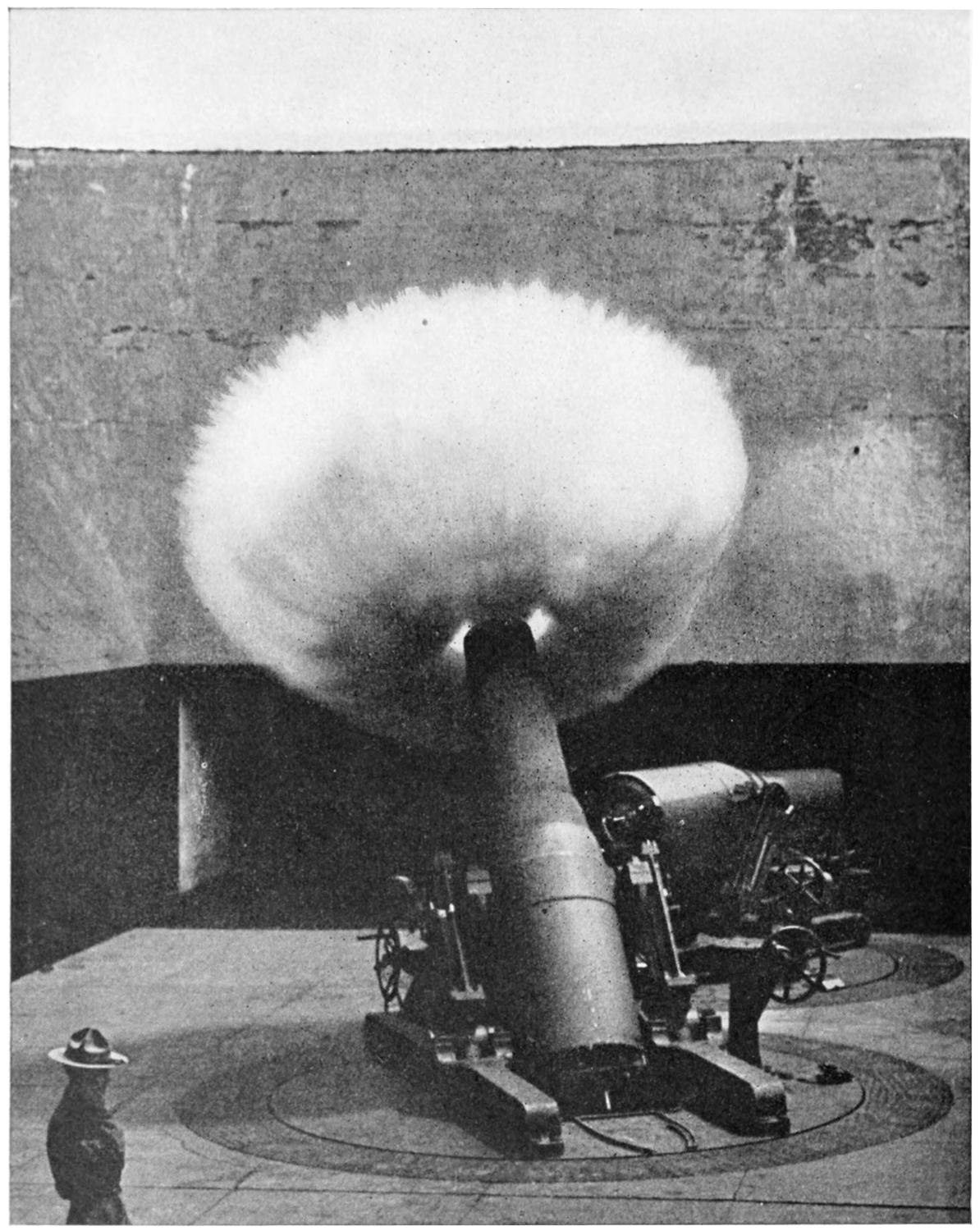

THE PROJECTILE HIDDEN BY THE SMOKE CONE

In the third photograph the smoke-cone is almost perfect and gives the famous “powder-puff” effect. It still hides the projectile, although the latter is traveling at a velocity that would take it from New York to Chicago in one hour. At night the “gas-rings” present a startling and fascinating appearance, burning with a reddish orange glow, and whirling with a complicated double motion, strange opalescent balls, like rings of Saturn. A study of these photographs—the first record ever made of the “gas-rings”—has led some experts to the conclusion that the cause of the rings is defective ramming of the projectile.

[29]

THE PROJECTILE EMERGING FROM SMOKE CONE

The fourth photograph shows the projectile emerging from the smoke-cone about thirty feet above the muzzle of the mortar. The men who fire these mortars from the mortar-pits never see the distant target or vessel they are firing at, but point their mortars according to directions transmitted to them (usually by telephone) from observers at distant stations. And so great a degree of precision has been attained that, on certain practice occasions at Hampton Roads, a record of nine hits out of ten shots has been scored on a moving target five miles out in the ocean. This picture shows the smoke-cone as first seen by the human eye.

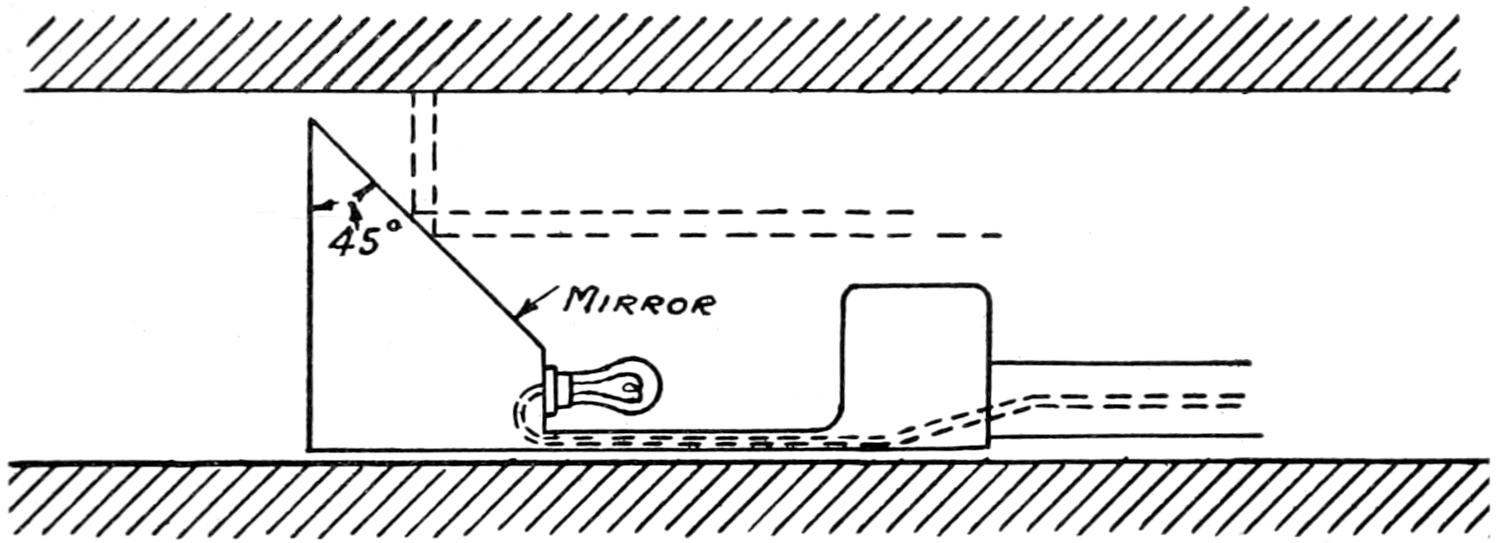

Captain Behr’s general idea was to utilize some phenomena connected with the discharge to actuate, by electrical connections, a mechanism that would work a rapid shutter in a properly placed camera. The phenomenon of concussion was tried first—the smash of air against a little swinging door; but this was much too slow. The projectile was hundreds of yards away before the camera had registered its picture. And that chance was gone!

[30]

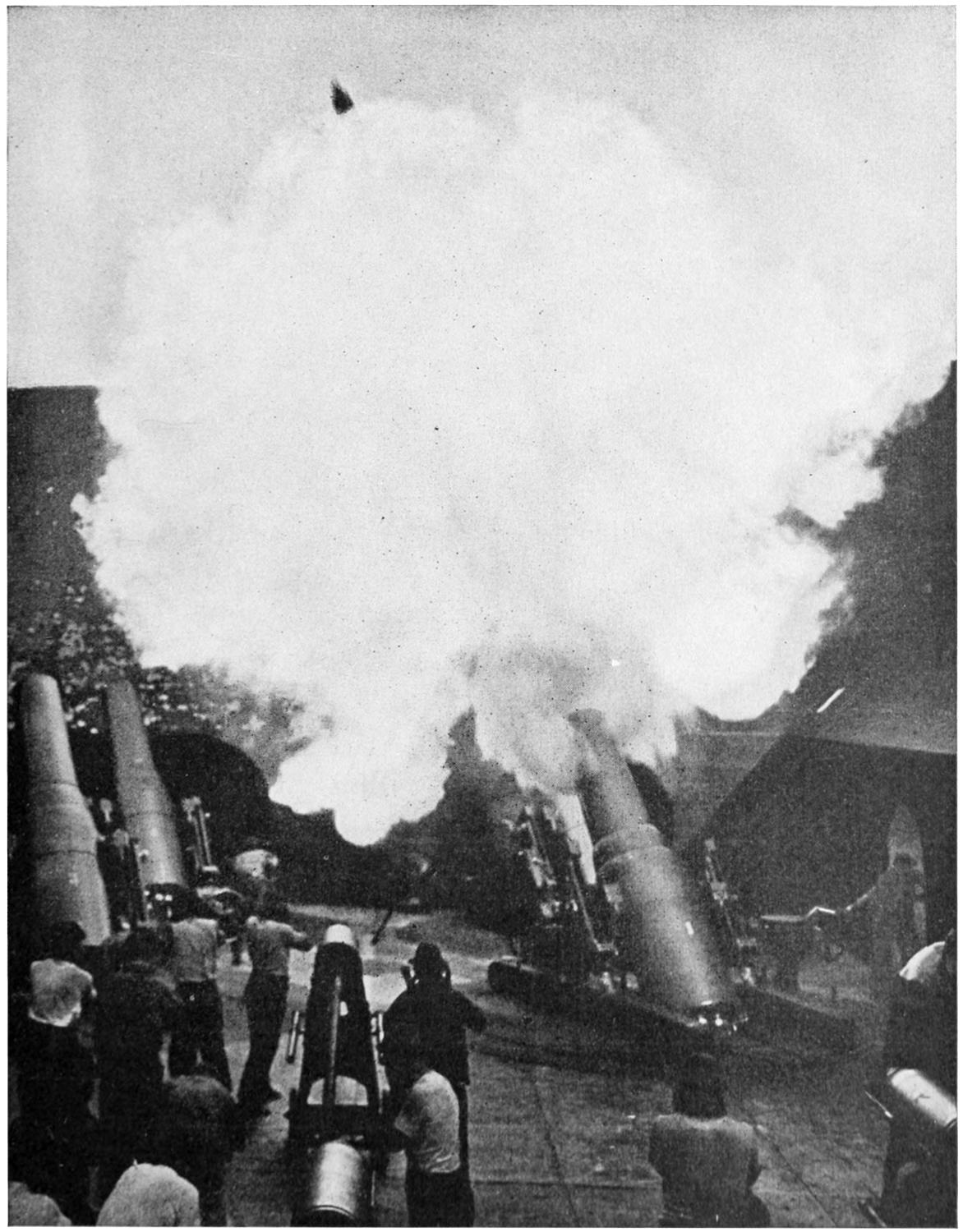

THE PROJECTILE HIGH IN THE AIR

In the fifth photograph the projectile is seen entirely clear of the smoke-cone and well started on its long flight. Climbing into the sky at this steep angle, it will reach a height of from three to six miles before it begins to descend. There are harbors on our coasts guarded by so many guns and mortars that if these were fired simultaneously they could hurl against a given small area a converging rain of projectiles aggregating more than fifty tons in their combined mass. A minute later they could hurl another fifty tons against the same small area; and so on as long as the ammunition lasted.

[31]

In the next trial, several months later, Captain Behr arranged to have the electrical connections made or broken by the movement of the gun-carriage itself in recoiling; but the result was unsatisfactory. Nor was he more fortunate at the succeeding target practice, when, having placed the apparatus farther forward on the parapet, he had the camera demolished by the force of the concussion and several blades of the rapid shutter broken. He was satisfied, now, that his effort to actuate the camera mechanism from the gun-carriage would never give the requisite precision in results, and he saw that he must work with a device functioning more reliably.

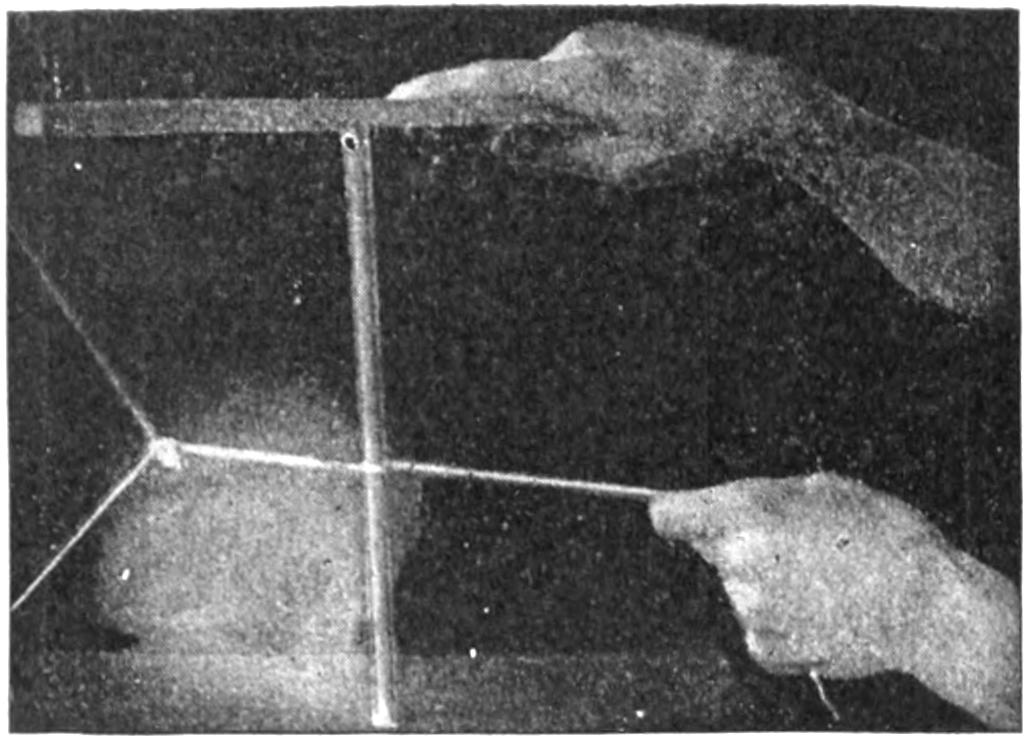

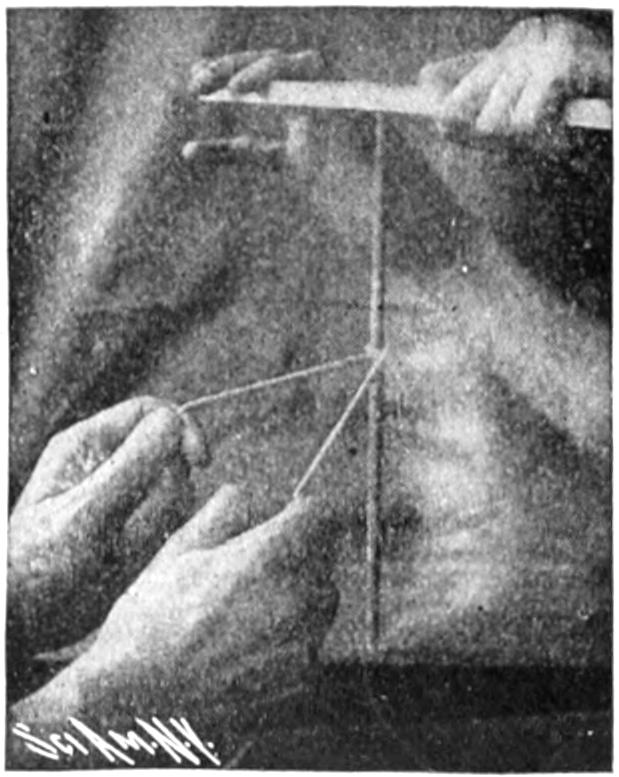

In the months that followed before the next target practice, the Captain did some experimenting, and finally determined making the projectile itself displace a length of piano-wire fixed across the muzzle of the gun, and thus actuate the electrical system and operate the shutter. In this way he eliminated troublesome variables of recoil, elasticity of the carriage, etc., leaving to determine only the time element of the electrical system to function. This result was admirable, and, after taking several similar pictures, the captain found that he could now operate with great precision—that is, he could get the same phase of the discharge with almost identical shapes of gas-cone and smoke-cloud, and he could get these every time.

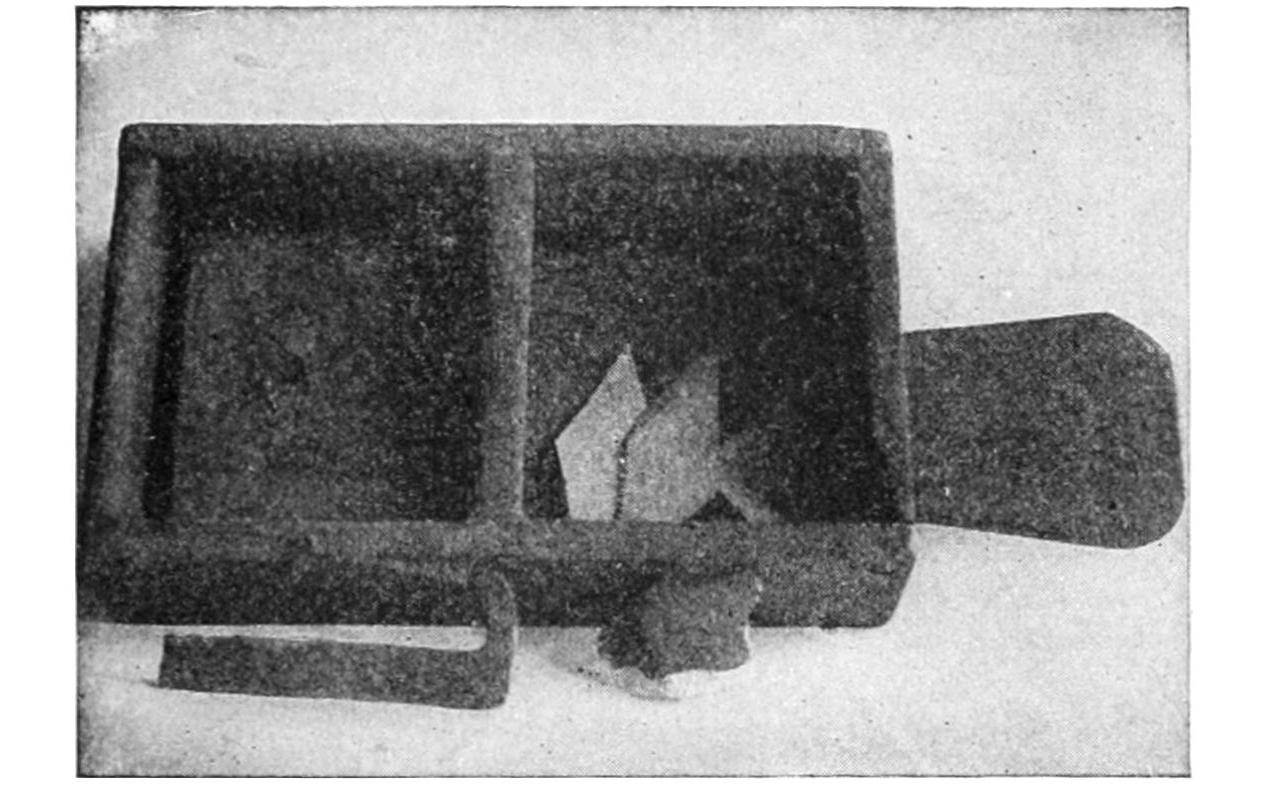

In the fall of 1912 Captain Behr succeeded in obtaining a series of extremely rapid photographs showing a twelve-inch mortar battery in action. In taking these pictures the camera was placed on an elevation about ten feet above the concrete floor and about sixty feet back of the mortars. The electrical device for working the shutter was actuated by the mortar itself in its recoil. These pictures were taken in about one five-thousandth of a second—which is the more remarkable as the last two were taken in the shade after 4.30 A.M. The first three were taken about noon, in the sunshine, as the shadows show.

So great was the precision of the electrical device as to render possible the photographic recording of these mortar projectiles, moving at great velocities, in almost any desired position after the discharge, say two feet away from the muzzle, or six feet away, or twenty feet away, or right at the muzzle, as shown in the first mortar picture, where the great projectile has been caught in its flight half way out of the mortar.

A CAMERA THAT IS

FASTER THAN THE EYE

It is interesting to note that of these five mortar pictures, representing five phases of the firing, only the last two are ever seen by the human eye. The far swifter camera, acting in about one five-thousandth of a second, has caught all these phases as reproduced here; but, to the ordinary observer standing by, the first visible impression after firing is that of the smoke-cone as developed in Number Four. The strange “powder-puff” effect shown in Number Three is never seen; nor the earlier effects in Numbers One and Two. Nor is any sound heard by an observer or by the gun crew until the third or fourth phase has been reached. This is a matter of simple calculation.

Sound travels through the air very slowly as compared with light, and in Numbers One, Two, and Three, although the crashing explosion has taken place and the projectile is already started on its long journey, the men (even the lanyard man, who is nearest), have heard nothing, since the sound-waves have not yet had time to reach their ears. Nor has the mortar itself had time to recoil, as it does presently, down into the well in the floor of the pit.

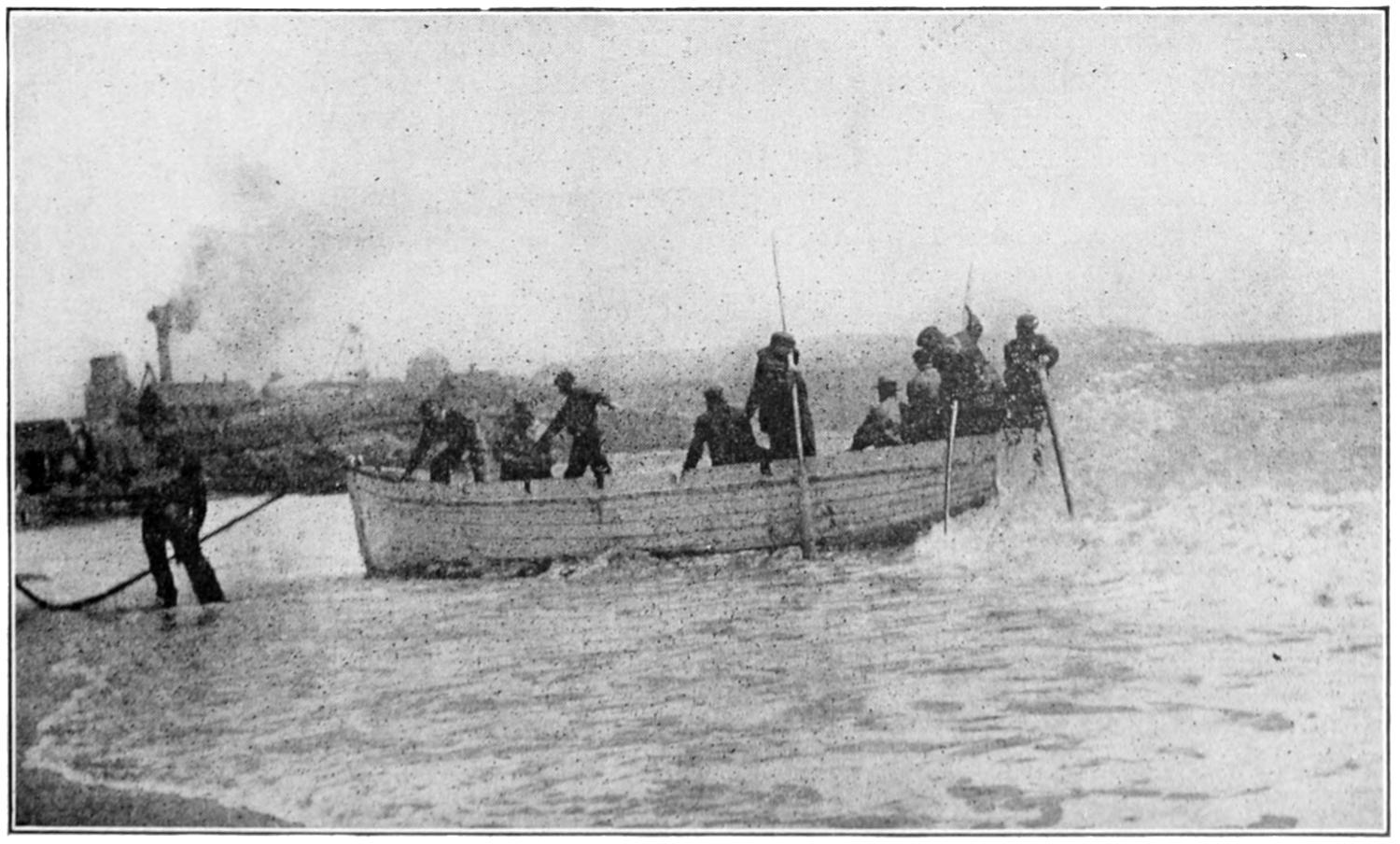

The men aboard the towing vessels that drag the floating targets during gun and mortar practice would seem to be in a dangerous position, since the tow-line is not more than two hundred yards long for guns and five hundred yards long for mortars, and a very[32] slight error in aim or adjustment might cause a deviation of several hundred yards when the range is eight or ten thousand yards. As a matter of fact, such errors do not occur, and a gun-pointer who would make a right or left deviation from the target of ten yards, or at the most fifteen yards at a distance of five miles, would be considered unfit for his job. In one or two rare instances a towing vessel has been struck when a projectile has fallen short and then ricochetted to the right, as it invariably does owing to its rotation in that direction. The rifling of the gun-barrel causes this rotation.

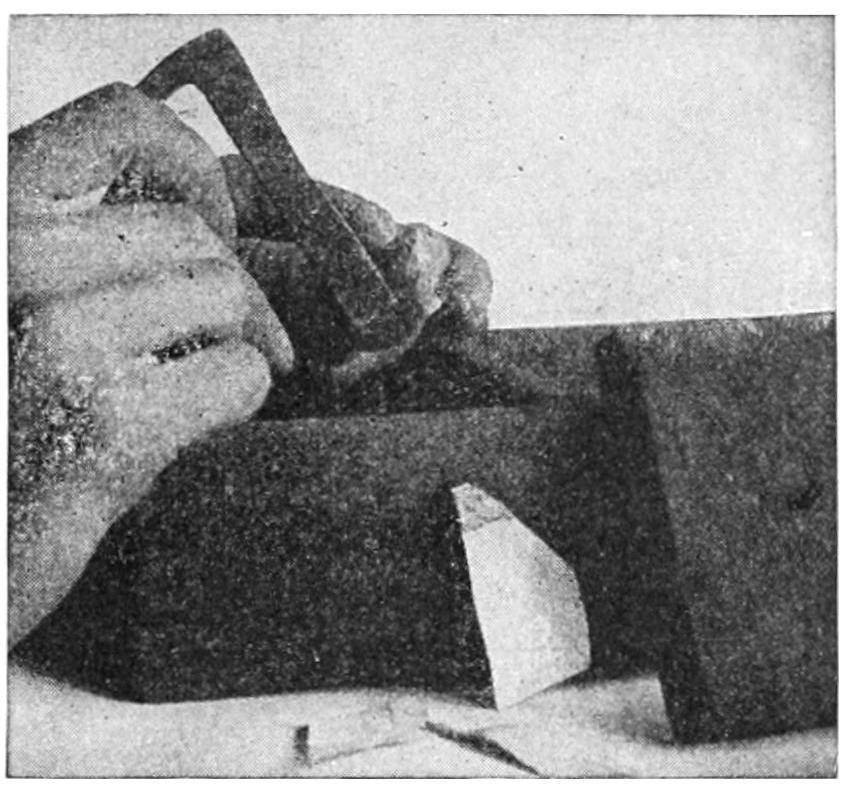

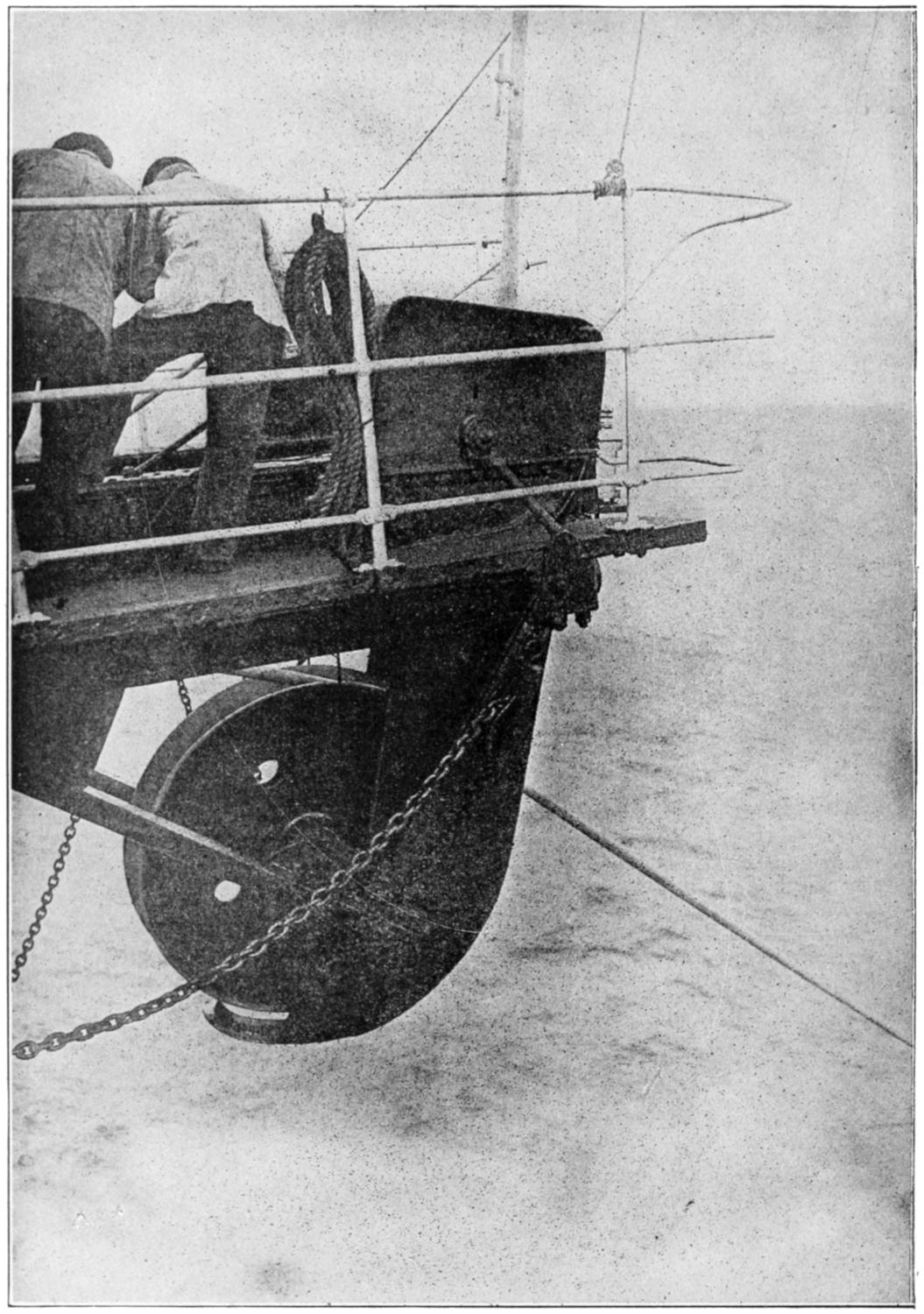

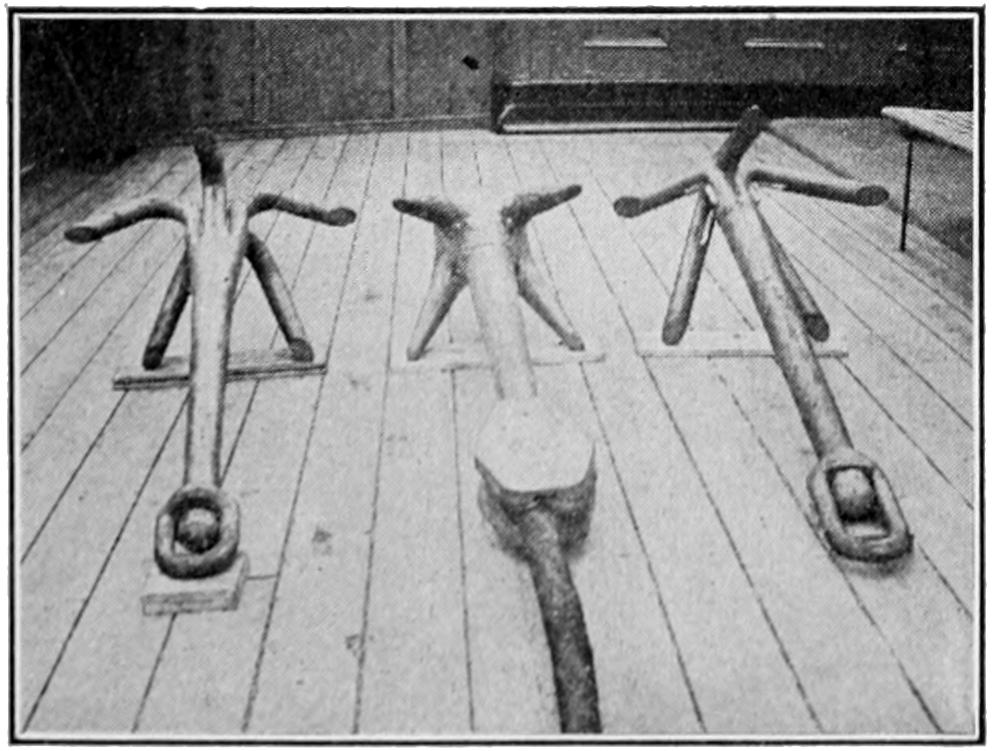

This shows one of Captain Behr’s earliest efforts to photograph the projectile from a twelve-inch gun. The man on the platform has been adjusting the electrical connections that actuate the camera mechanism. The halo effect at the muzzle of the gun is due to compressed air caused by the forward rush of the projectile. The projectile has not yet emerged from the muzzle of the gun. On the right is the place where the “Merrimac” and the “Monitor” had their famous fight.

Sometimes these great projectiles ricochet several times, and go bounding over the water as a pebble skips along the surface of a mill-pond, only there may be the distance of a mile or more between these giant leaps.

A strange phenomenon is witnessed by the observer on a towing vessel as he looks, rather uneasily perhaps, toward the distant shore battery, that seems to be firing straight at him. First there is a flash and a puff of smoke; then nothing for a period of seconds, while the projectile is on its way; then suddenly[33] a great splash as the mass of iron strikes the water. Up to this moment there has been no sound of the discharge, no sound of the projectile, since it travels faster than the sound-waves; but now, after it has buried itself in the ocean, is heard its own unmistakable voice, a low, buzzing um-m-m-m approaching from the shore. The projectile itself has arrived before the sound that it makes in transit, and the sound arrives afterward. Last of all is heard the boom of the discharge.

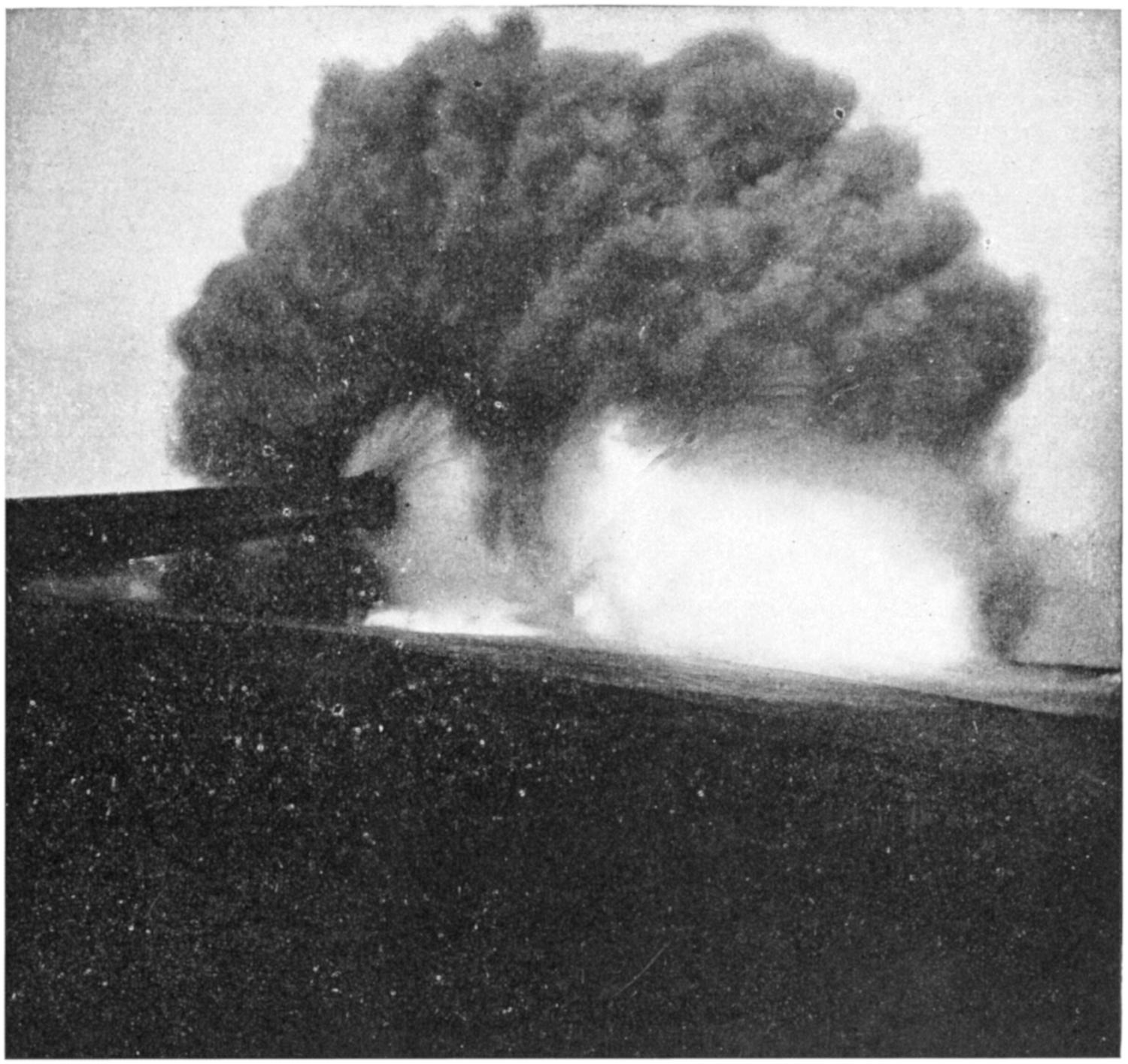

A GUN THAT PHOTOGRAPHED ITS OWN SHOT

In this beautiful picture the hurling projectile was itself the photographer: that is, in passing out of the gun-barrel, it broke a length of piano-wire stretched across the muzzle and thus automatically closed an electrical circuit that actuated the camera mechanism. And so rapid was the shutter that the great shot hurled forth in the discharge photographed here has not yet had time to issue from the smoke-cone, where it is still hidden.

Owing to the great velocity of gun projectiles, it is almost impossible for an observer near the target to see them as they approach; but a trained eye can discern the slower moving mortar projectiles as they drop out of the sky, shrieking as they come, curving downward from a height of four or five miles, half a ton falling from a height of four or five miles.

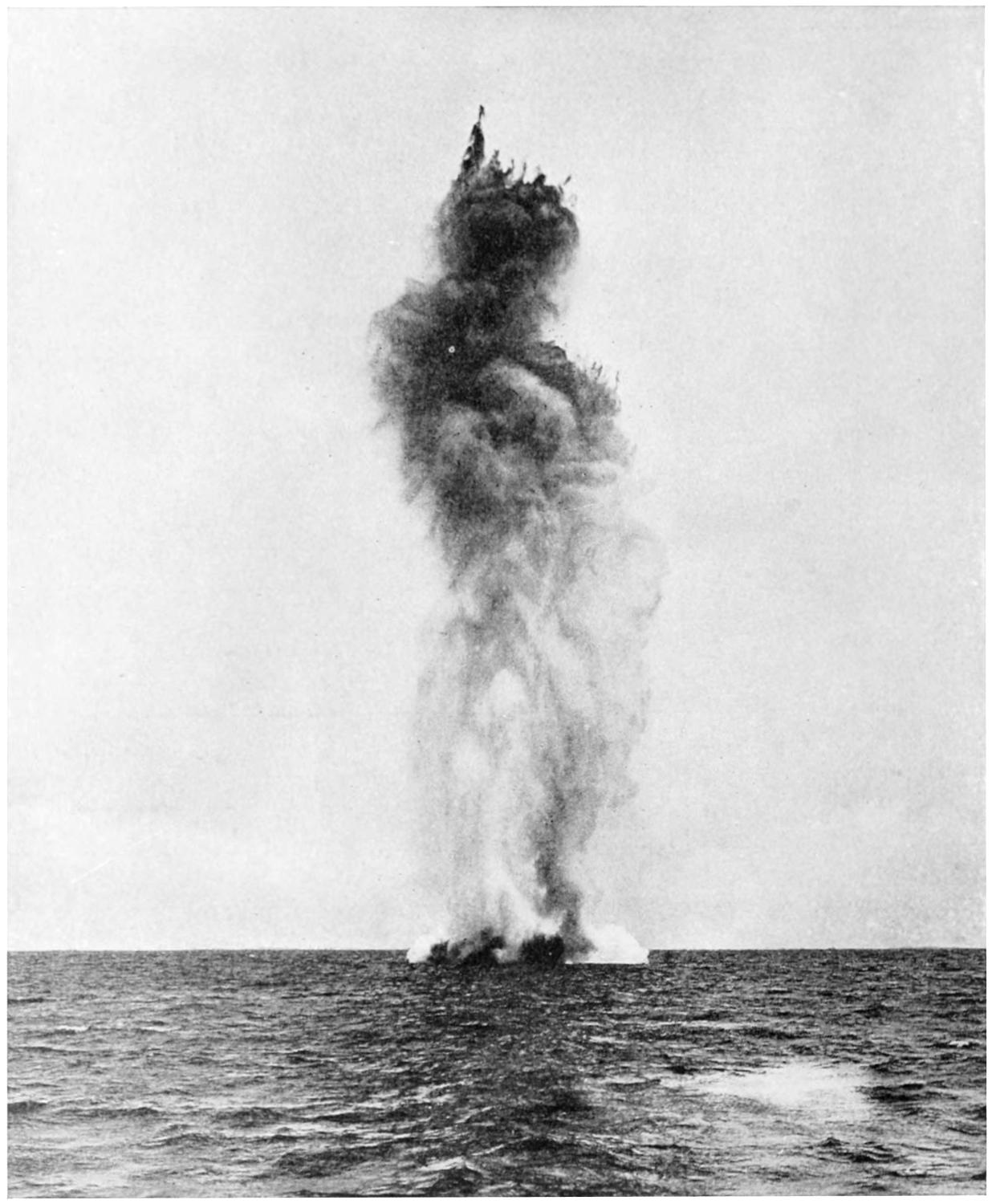

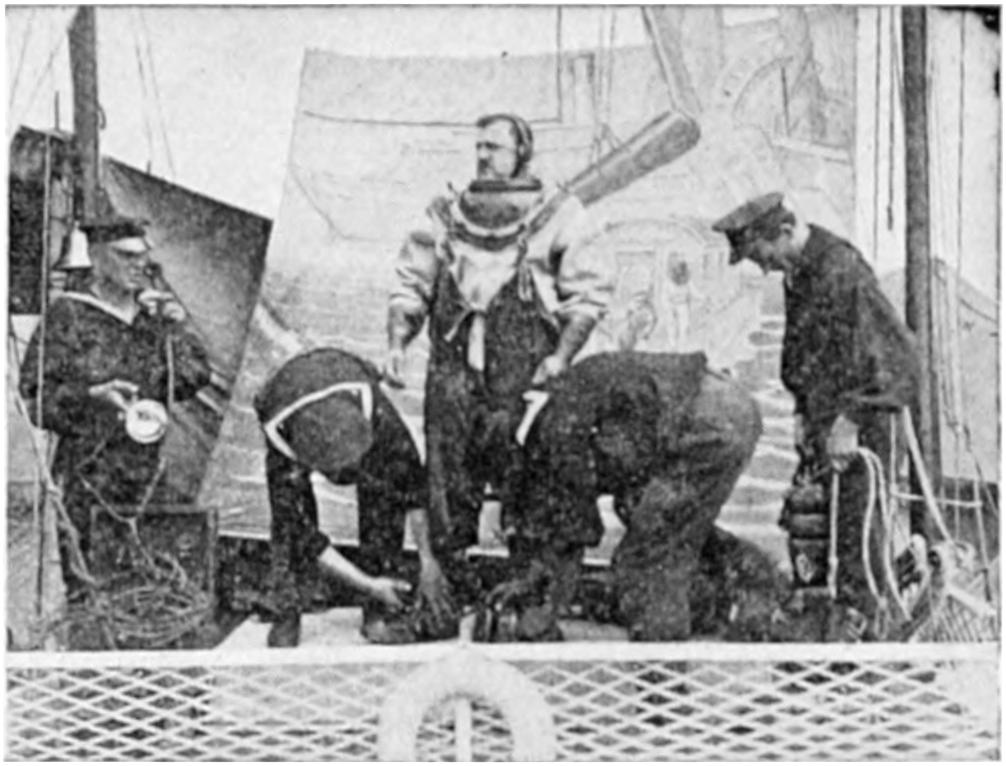

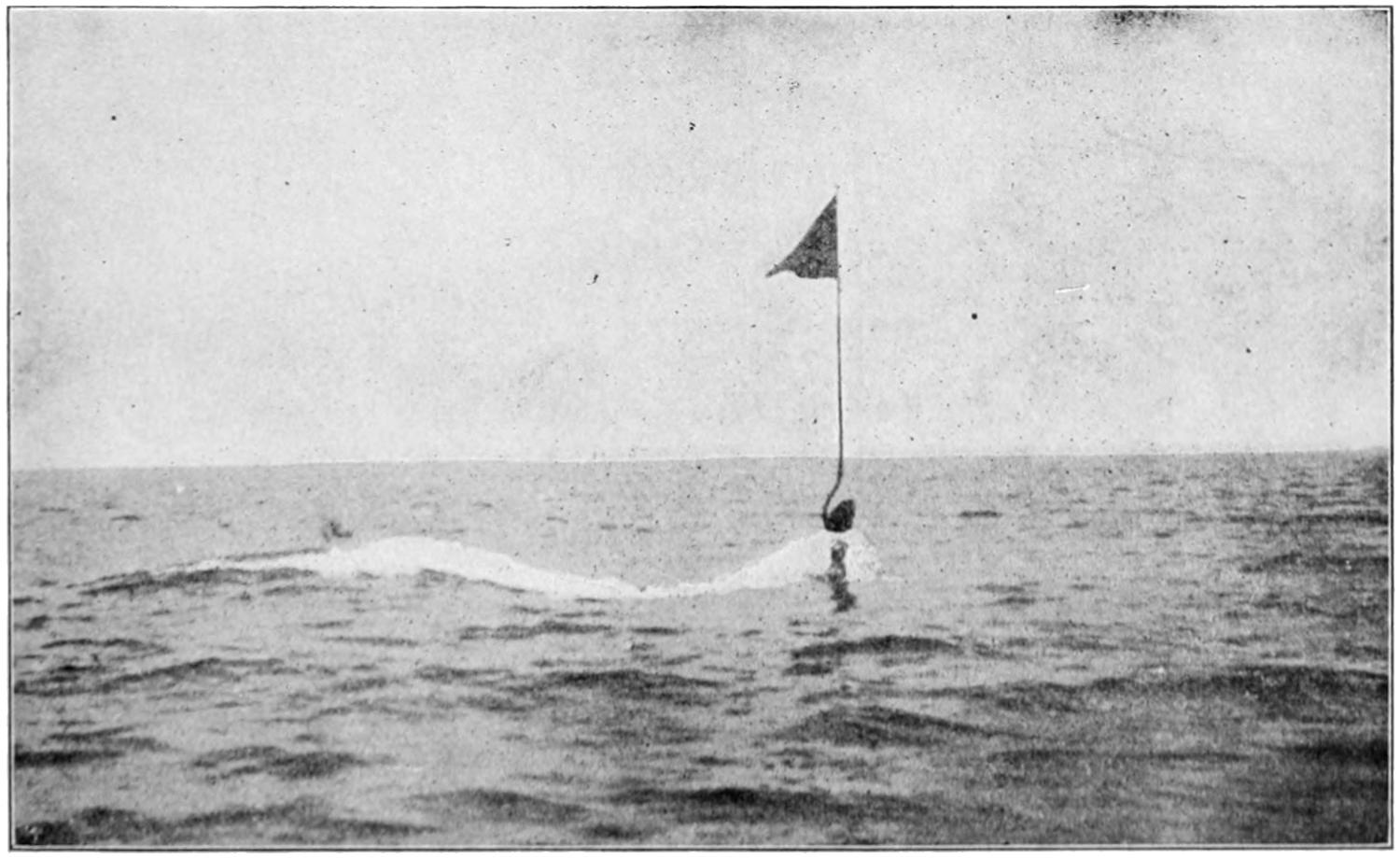

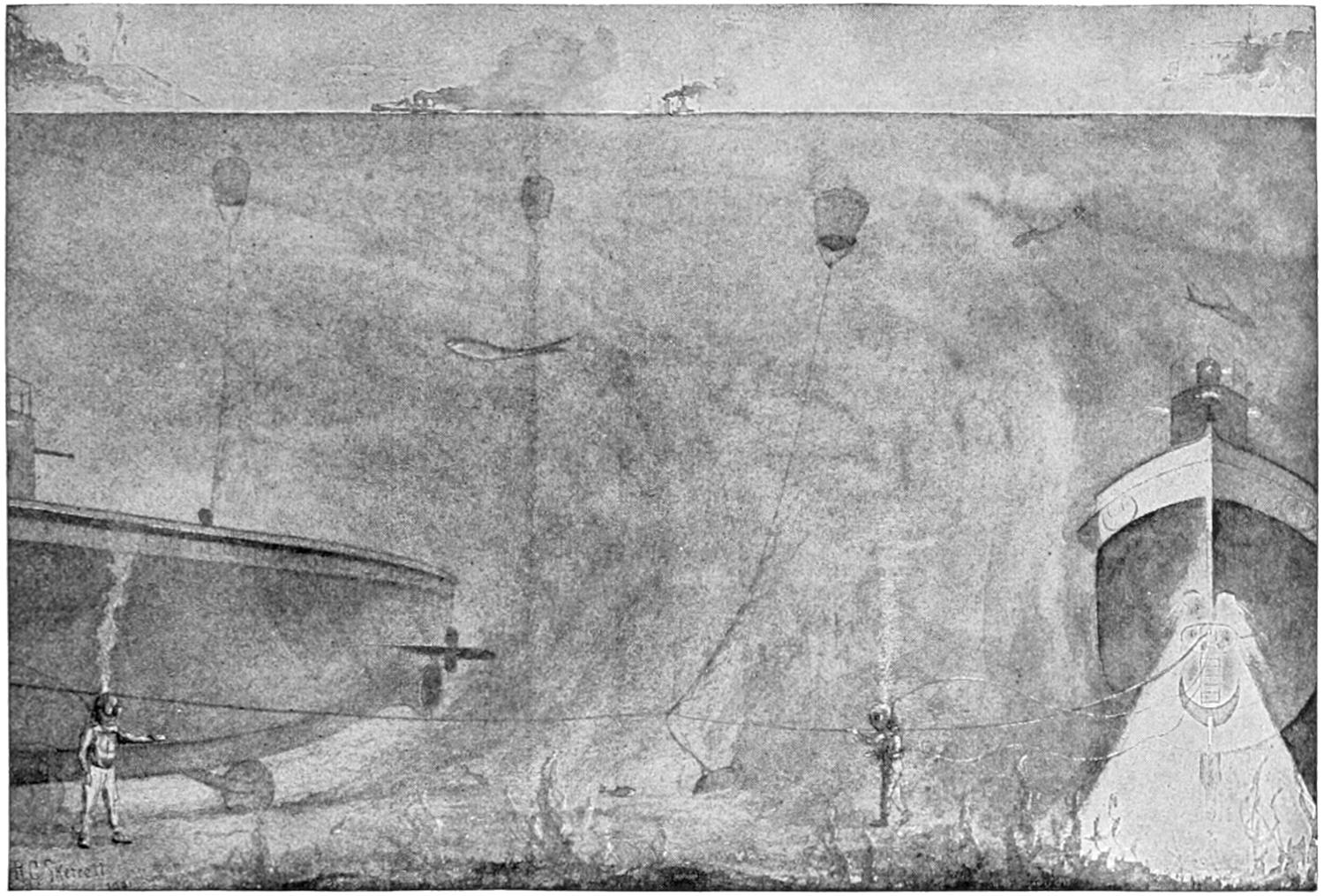

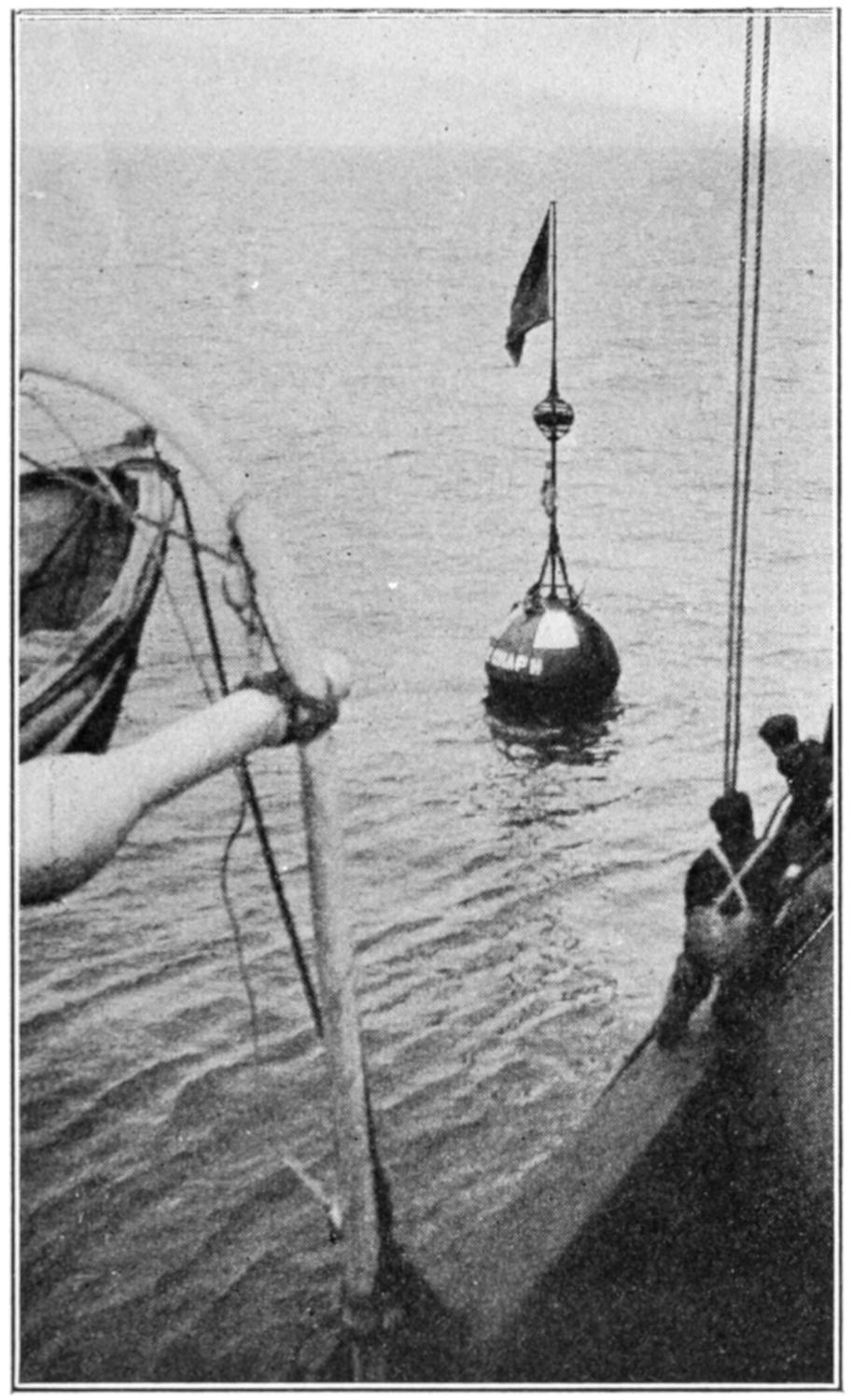

EXPLODING A SUBMARINE MINE

This photograph illustrates another important form of coast defense—the submarine mine. A target about 5 by 5 feet, with a red flag at its apex, is towed across the mine-field, the mines being exploded electrically from a shore station several miles away. The methods of laying and exploding these mines are carefully kept secrets. In this case a charge of five hundred pounds of the newest explosive was used. Fragments of the shattered target and mine-buoy are seen at the right of the picture. Tons of water are hurled into the air by these explosions, and hundreds of fish are killed or stunned.

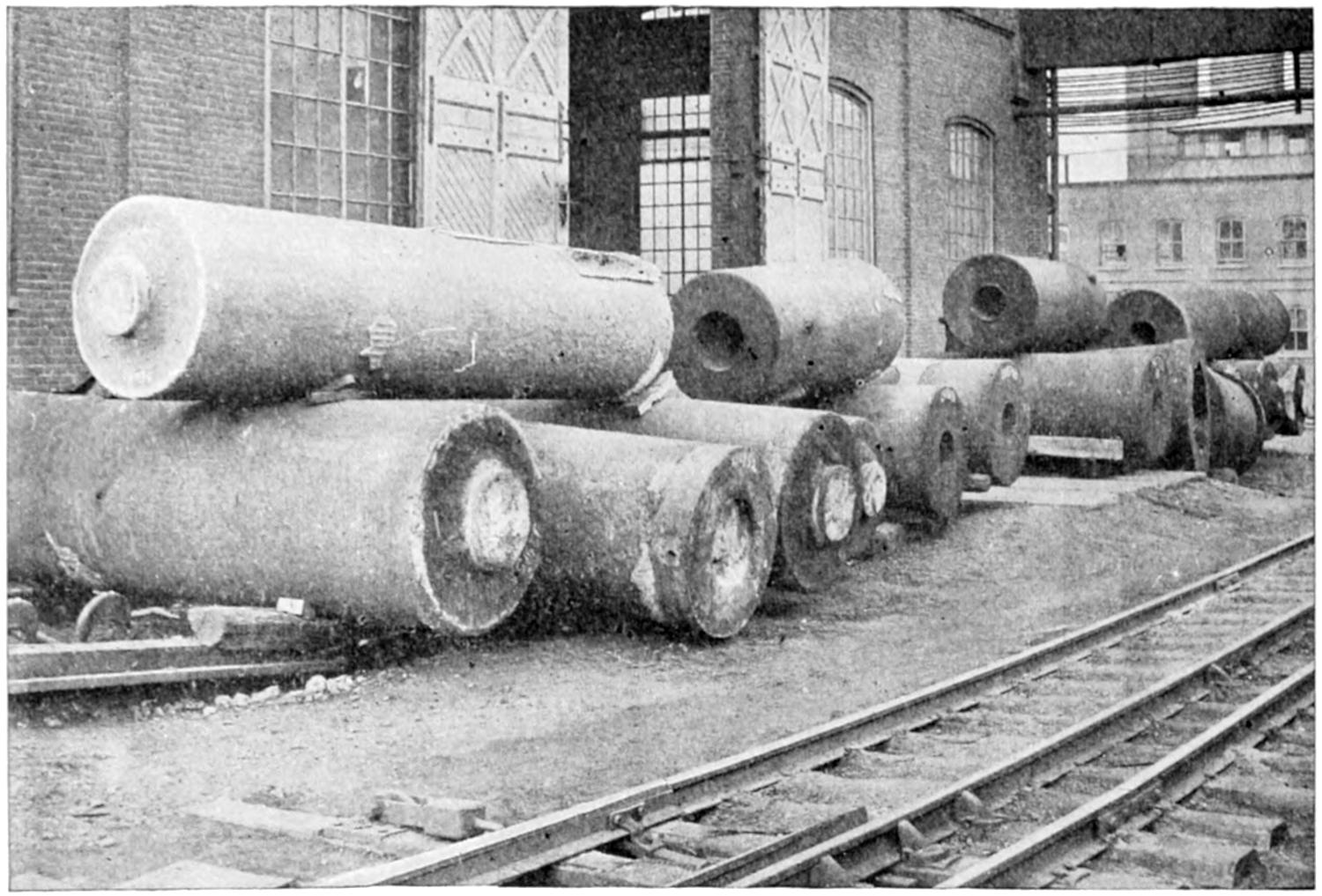

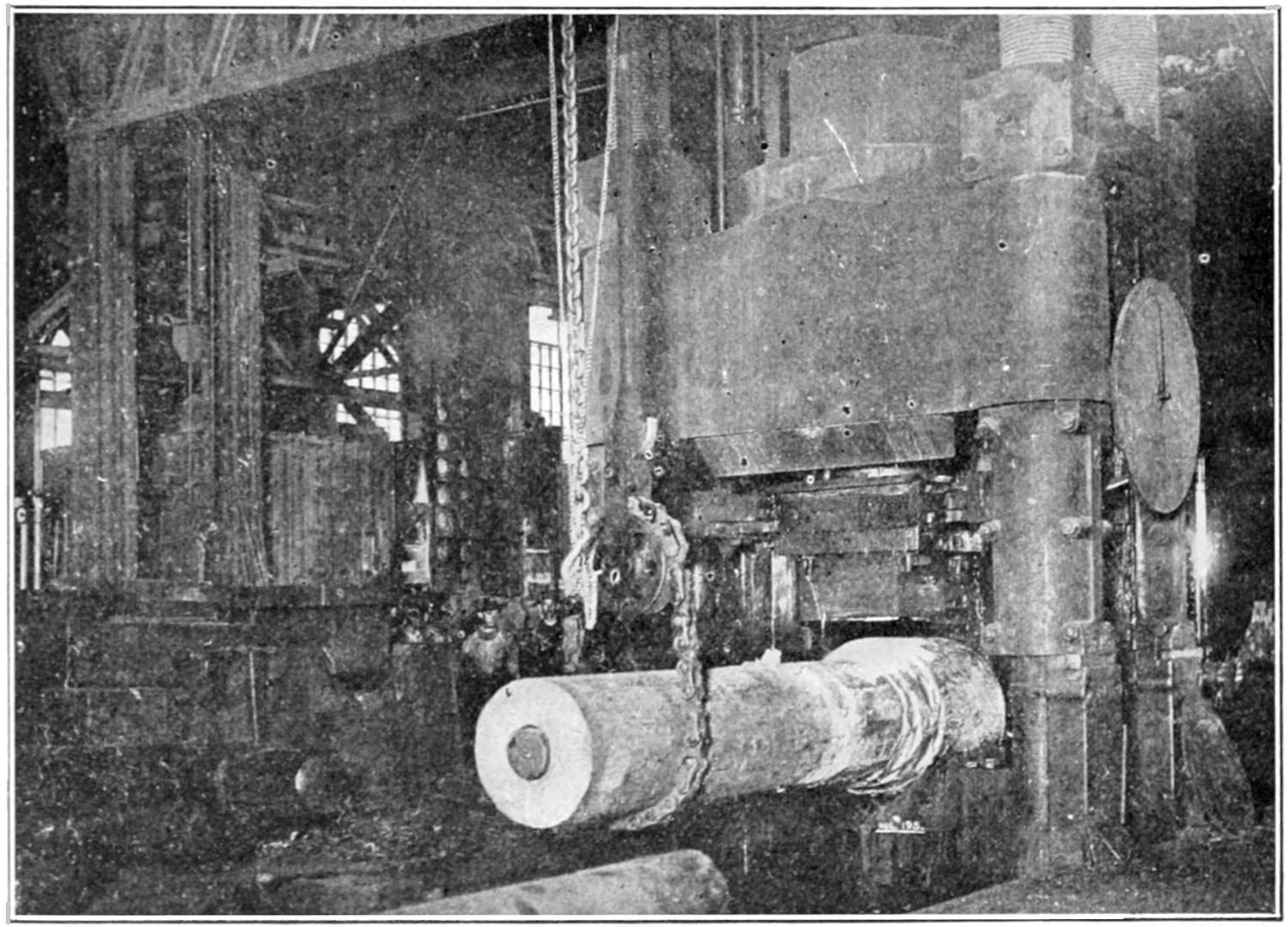

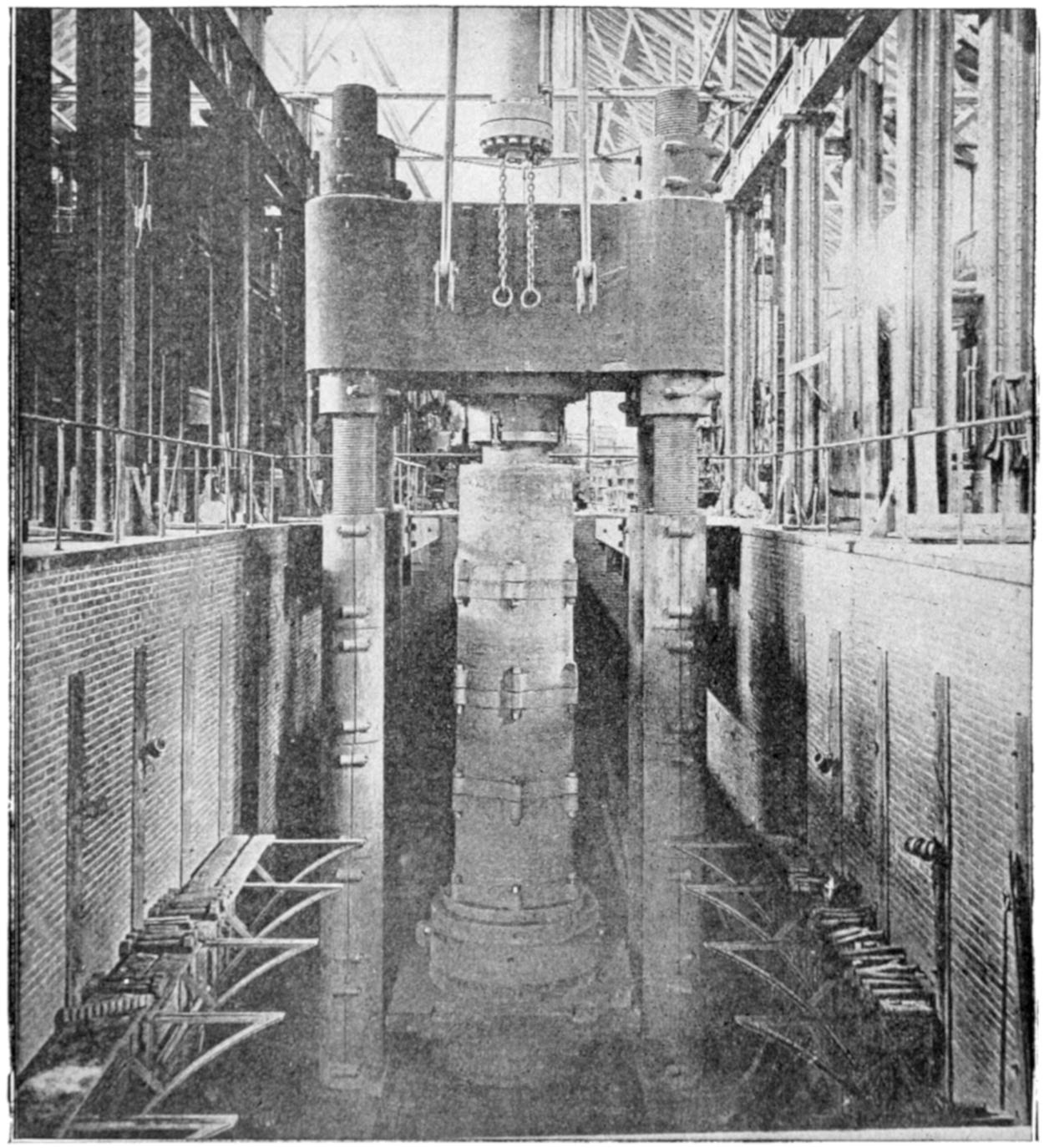

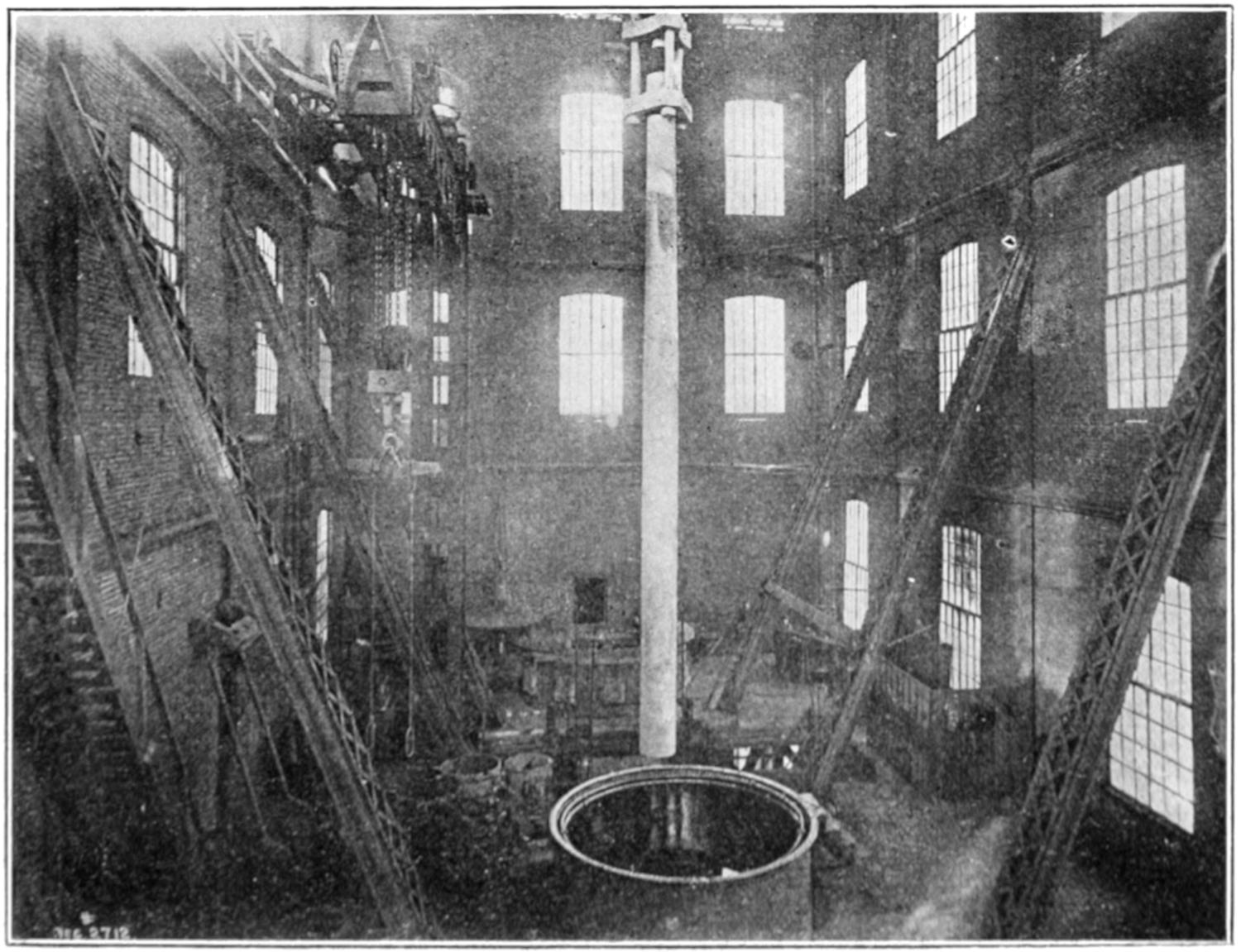

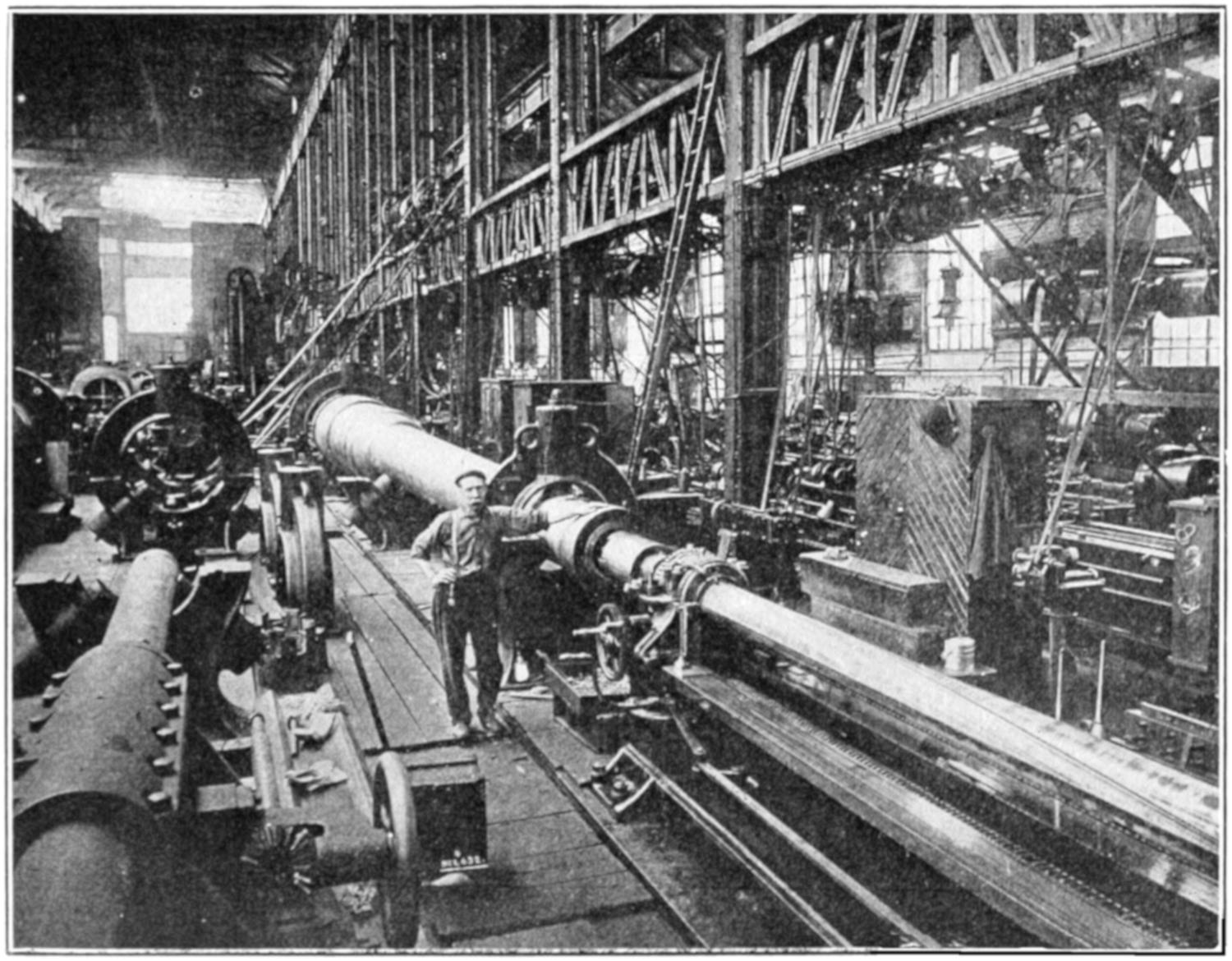

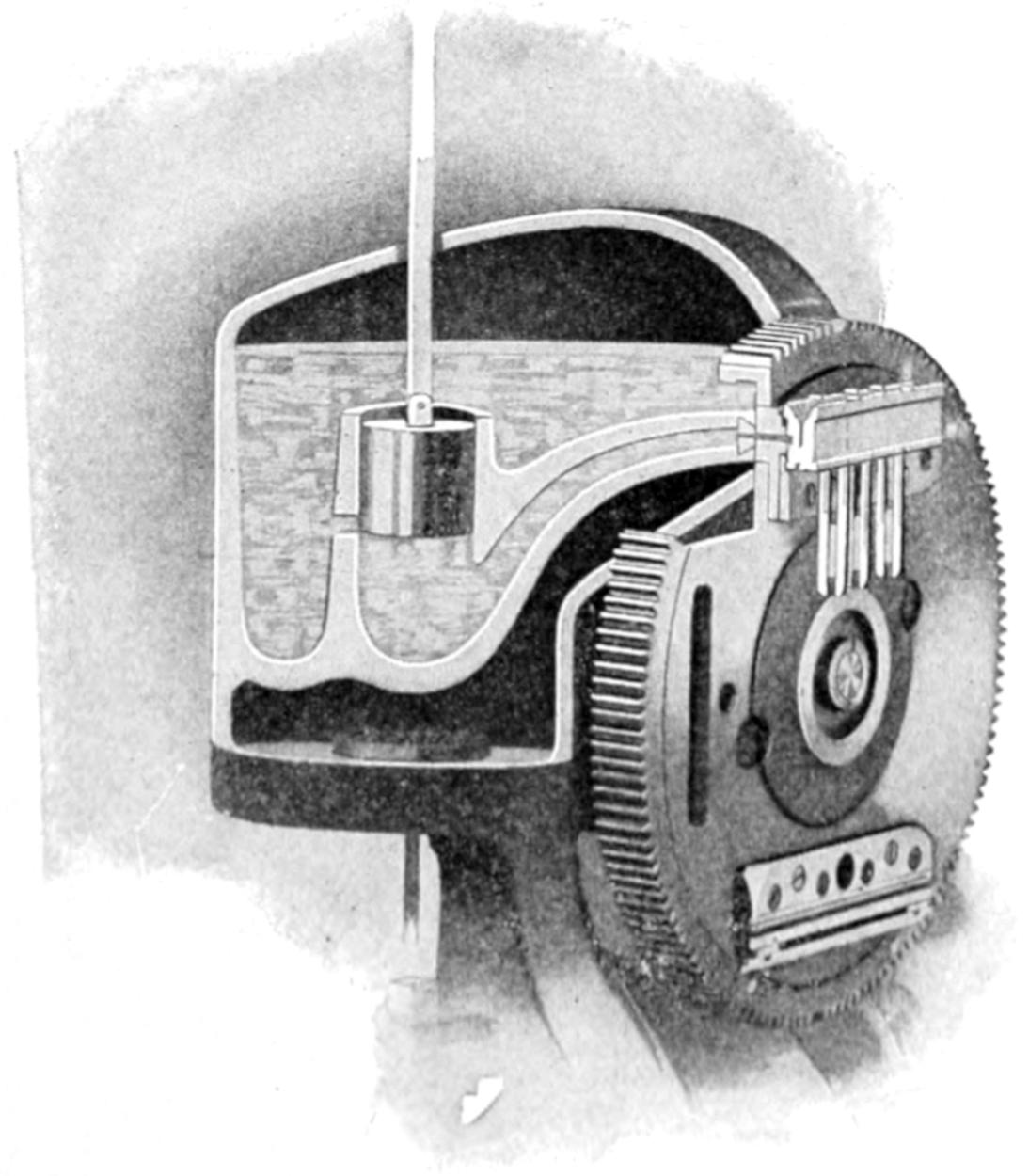

It is difficult to realize what an enormous force is released when one of these twelve-inch guns is discharged. The pressure inside of the gun behind the projectile is between thirty-five and forty thousand pounds to the square inch. No engine or machine made by man produces anything like this pressure. The boiler pressure in steam-engines, or in big turbines driven by superheated steam, does not exceed two[34] hundred or three hundred pounds to the square inch. The huge hydraulic presses that would crumple up a steel girder do not exert a pressure of more than one thousand pounds to the square inch. The only reason a gun-barrel can resist this pressure (forty thousand pounds to the square inch) is that it is built up in a series of concentric steel hoops or tubes shrunk one over the other until there is a resistance capacity of from seventy thousand to ninety[35] thousand pounds to the square inch. Even at rest, the barrels of these great guns are under such enormous compression, from being thus squeezed within these outer steel coverings, that, if the retaining steel jackets were suddenly cut, the tubes would blow themselves into pieces from the violent reaction of release.

Not only does this smokeless powder, burning inside these guns, produce enormous pressure, but it generates inconceivably great heat. Water boils at 100° Centigrade; iron melts at 1400°; platinum and the most resistant metals at 2900°; while the hottest thing on earth is the temperature of the electric arc, in which carbon boils. This temperature is between 3000° and 4000° Centigrade, and is believed to be the same as that of these great powder chambers when the gun is fired. Thus a diamond, the hardest substance known, would melt in the barrel of a twelve-inch gun at the moment of discharge. The consequence is that at each discharge of a big gun a thin skin of metal inside the barrel is literally fused, and this leads to rapid erosion of the softened surfaces under the tearing pressure of gases generated. The rifling is worn away; the band over the projectile becomes loose-fitting; and soon the huge gun, that has cost such a great sum, is rendered unfit for service. The life of a twelve-inch gun is only 450 rounds, that is, the gun would be worn out if fired every three minutes for a single day. After that a new life may be given it by boring out the inner tube and putting in a new steel lining.

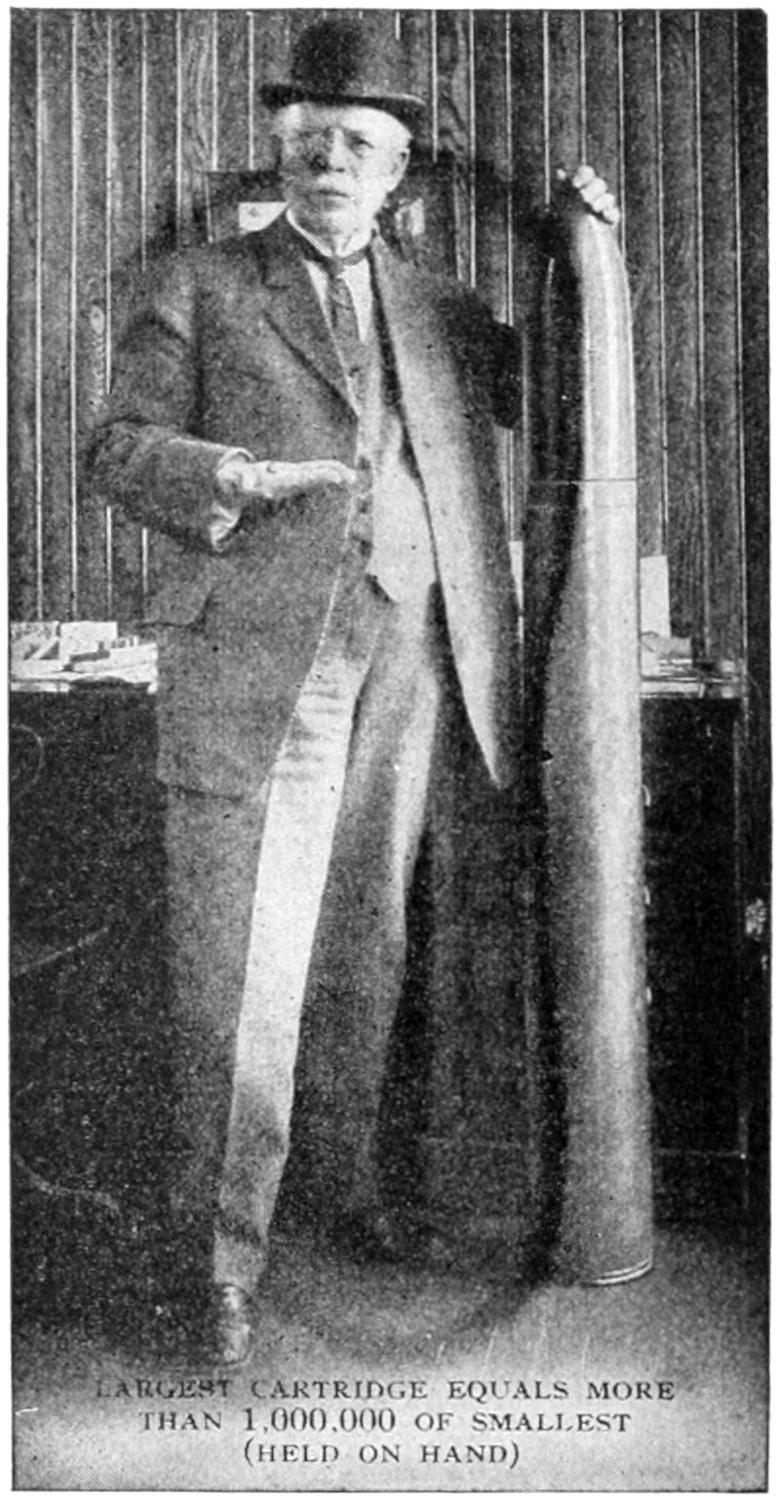

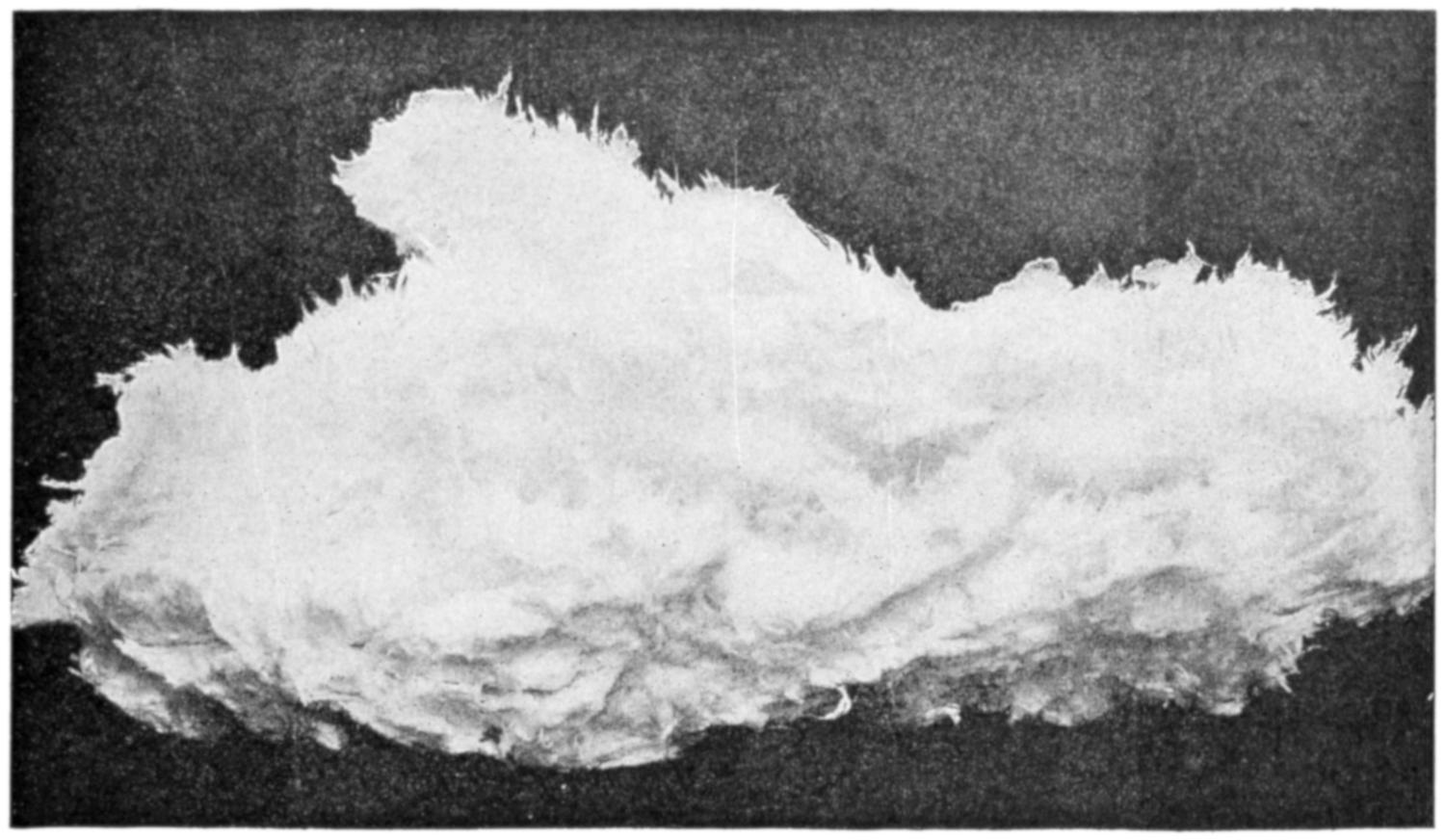

A few words may be added about the formidable smokeless powder used in these great guns. This powder, in spite of its terrible power, is of innocent appearance, and a small stick of it may be held safely in the hand while it burns with a vivid yellowish flame. There is no danger of its exploding or detonating like gun-cotton, and yet it is made from gun-cotton, treated by a colloiding process that is one of our jealously guarded military secrets. There are foreign governments that would give millions to know exactly how this powder is made and how it is preserved for years without deterioration. The recent destruction of two ships of the French navy was due, it is believed, to deterioration of their smokeless powder.

If a person’s picture is taken with the eyes of the person looking directly into the lens or opening of the camera, then the eyes in the picture will always[36] be directly on and appear to follow whoever is looking at it. This is also true of paintings. If a subject being painted is posed so as to look directly at the painter, and the artist paints the picture with the eyes so pointed, then the eyes of the picture will follow you. When you are looking at a picture of a person and the eyes do not follow you, you will know at once that he was not looking at the camera or artist when the picture was being taken or painted.

WHY YOU CAN BLOW

OUT A CANDLE

To understand the answer to this question fully you will first have to learn what light is, and particularly that it is not the flame from the gas jet or of the lamp or candle that is actually the light, but that light consists of rays or waves in the ether, which is constantly in all space and even in our bodies, coming from the something that is burning. This in the instance above mentioned would be the gas burning as it comes out of the gas jet, the oil in the lamp as it comes up through the wick or the flame of the candle. We are apt to call a lighted gas jet a lamp, or a candle, light, because it is steady. Really, however, there is no such thing as keeping light in a room in an actual sense, for rays of light travel from the substance which produces them faster than anything else we know of in the world. The first thing a light wave does when it is once created is to go some place, and it does this at the rate of 186,000 miles per second. If it cannot penetrate the walls of the room it is either reflected back in the direction from which it came or transformed by the objects which it strikes into some other kind of energy.

When you look at the rays coming from a gas jet, you do not see one ray for more than, say the millionth part of a second, but because these rays of light come so fast one after the other from the burning jet and spread in all directions, they seem to be continuous.

So you see that the rays of light are going away as fast as they are coming from the gas jet. They either go on as light or, as said above, are changed into other forms of energy when they strike things they cannot penetrate in the form of light, or rather one thing, which is heat. A large part of it goes into the air in the room in the form of heat, as you well know, now that it is called to your attention. Some of it goes into the furniture and some of it is changed into another form of heat, which, combining with the chemicals in other things it mixes with, changes their appearance and usefulness. As, for instance, the carpets and hangings in the room, the colors of which become faded when exposed to light rays too much. The heat from the light rays is responsible for the fading of colors in our garments as well.

When you “put out the light,” as we say, or turn off the gas, you cut off the source of light. Really, then, our expression that “the light goes out” is only true while the gas is lighted, for from the flaming gas jet the light is going out all the time, whereas when the gas is turned off no light is being produced, and when you turn off the gas you do not turn out the light, but only that which makes light.

[37]

Fire will go out naturally when there is nothing left to burn, or it will go out if it cannot secure enough oxygen out of the air to keep it going. In the first case it dies what we might call a “natural death,” and in the latter case the fire practically suffocates. The fire in the open fireplace, if it has plenty of air, will burn up everything burnable that it can reach. The stones of the fireplace or other parts of a stove will not burn, because they have already been burned, and you cannot burn anything a second time, if all of the oxygen in it was burned out of it the first time.

Now, then, to burn up a thing, you must first start a fire under it, and then keep a constant draft of air playing on it from beneath, or the fire will die out. The more difficult a thing is to burn, the more important it is that you have plenty of draft. If the ashes accumulate under the fire the air cannot go through them in sufficient quantity and the fire will go out. Other things which prevent the current of air from going up through the fire will cause it to go out. That is why we close the lower door of the furnace, to keep the fire from burning out. When we shut off the draft of air from below, the fire in the furnace burns slowly, i. e., it just hangs on, so to speak.

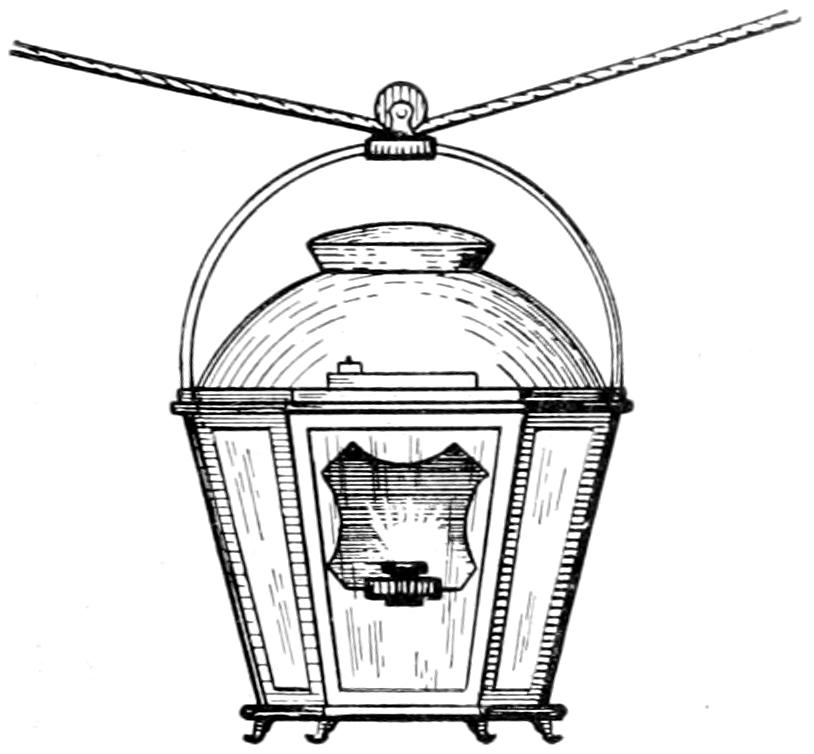

When a lamp is burning without a chimney it generally smokes. That is because the oil which is coming up through the wick is being only partially burned. The carbon, which is about one-half of what the oil contains, is not being burned at all, and goes off into the air in little black specks with the gases which are thrown off. The reason the carbon is not burned when the chimney is off is that there is not sufficient oxygen from the air combining with it, as it is separated from the oil in the partial combustion that is going on. To make the carbon in the oil burn you must mix it with plenty of oxygen at a certain temperature, and this can only be done by forcing sufficient oxygen through the flame to bring the heat of the flame to the point where the carbon will combine with it and burn. When you put the chimney on the lamp you create a draft which forces more oxygen through the flame, brings the heat up to the proper temperature and enables the carbon to combine with it and burn. When you take the chimney off again the heat goes down, when the draft is shut off and the lamp smokes again.

The chimney also protects the flame of the lamp from drafts from the sides and above, and helps to make a brighter light, because a steady light is brighter than a flickering one.

The draft created by the chimney also forces the gases produced by the burning oil up and away from the flame. Some of these gases have a tendency to put out a light or a fire.

To get at the answer to this question we must go back to the definition of light. Light is a wave in the ether and contains no particles of matter. It, therefore, does not weigh anything at all.

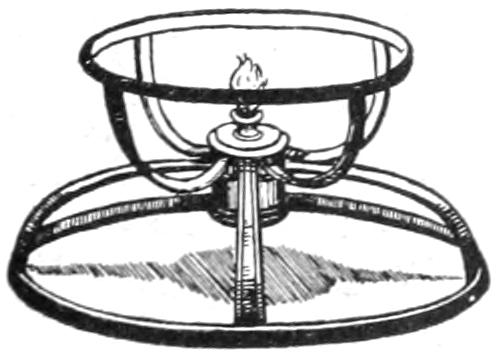

When men had studied light thoroughly, however, they came to the conclusion that it must have the power of pressure, which, from the standpoint of results, would amount to the same thing as having weight. They reasoned that if you had a perfect balance and let sunlight shine down on one of the sides of the balance, that side should go down under the pressure of light. In their first experiments along this line men failed to show that under such conditions the side of the balance on which the light shone did go down, but by continuous experiments it was proved finally that the light did exert a sufficient pressure to cause the scales to go down, and in effect this is the same as having weight; but this has been found to be a common property of rays of various kinds, including heat,[38] and we, therefore, do not speak of this quality as weight, but as the power of radiating pressure.

When light passes from one medium to another, as for example from glass or water to air, or from air or glass to water, the rays of light change their course, thus making them seem to be bent or broken. The rays of light from the part of the stick in the water take a different direction from the rays from the part which is out of the water, giving the appearance of breaking or bending at the place where the air and water meet. It is, of course, the light rays which are bent and not the object itself.

This bending or changing of the path of light rays is called refraction. If you place a coin in a glass of water so that it may be viewed obliquely, you can apparently see two coins, a small one through the surface of the water and another apparently magnified through the side of the glass.

This is due only to the absolute principle that rays of light change their direction in passing from one thing to another, and on this principle of the rays of light our optical instruments, including the microscope, the telescope, the camera and eyeglasses are based.

I might tell you, just to show how clever I am, that stars do not twinkle at all, and leave you with that for an answer. But since they really do seem to twinkle, and that is what causes your question, I will tell you. As we have already learned in our talks about the stars and the sky in general, the stars are suns which are constantly throwing off light, just as our sun gives us light, and when this light strikes the air which surrounds the earth it meets many objects—little particles of dust and other things always floating about in it. The light comes to us in the form of rays from the stars and some of these rays strike particles of various kinds in the air and are thus interfered with. If you are looking at a lighted window some distance away and there are a lot of boys and girls or men and women running past the window, one after the other, rapidly, it will make the light in the window appear to twinkle. The twinkling is due to the interference which the rays of light encounter while traveling toward the eye.

That is nature’s way of protecting the eyes from the smarting which the onion would cause in your eyes if the tears did not come quickly and overcome the bad effect so produced. Tears are provided for washing the ball of your eyes. Every time you wink a little tear is released from under the eyelid, and the wink spreads it all over the eyeball. This washes down the front of the eyeball and cleanses it of all dust and other things that fly at the eye from the air. Then the tear runs along a little channel, much like a trough, at the lower part of the eye, and out through a little hole in the eye, and in this case the tear is really only an eye-wash. Many things, but more often sadness or injured feelings, start the tears coming so fast from under the eyelid that the little trough at the bottom and the hole in the corner of the eye are too small to hold them or carry them off, so they roll over the edge of the lower eyelid and down the face. These are what we call tears. Among other things that will cause tear-glands to cause an over-supply of eye-wash to come down, are onions. What they give off is very trying to the eyes, and so, just as soon as the something which an onion throws off hits the eyeball, the nerves of the eye telegraph the brain to turn on the tears quickly, and they come in a little deluge and counteract the bad effect of the onion.

[39]

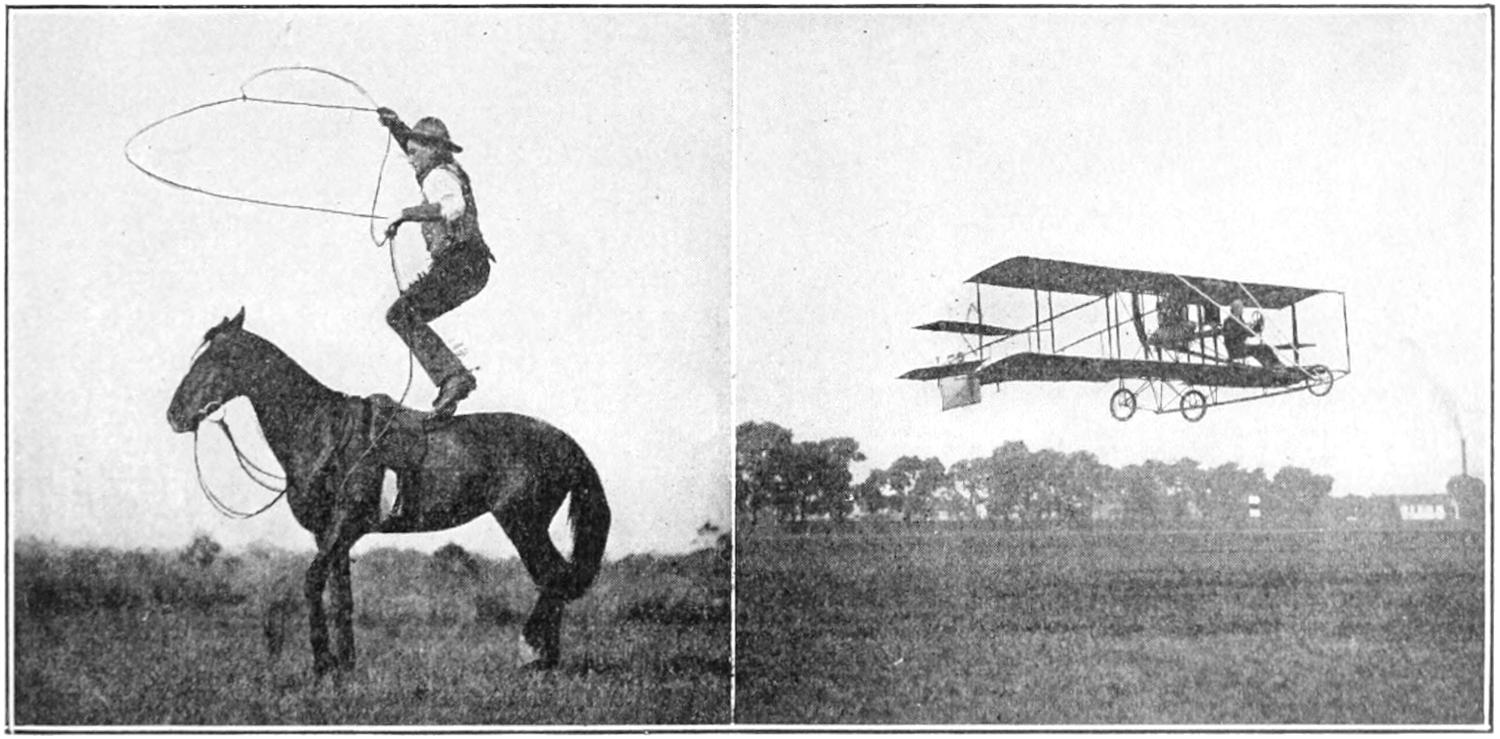

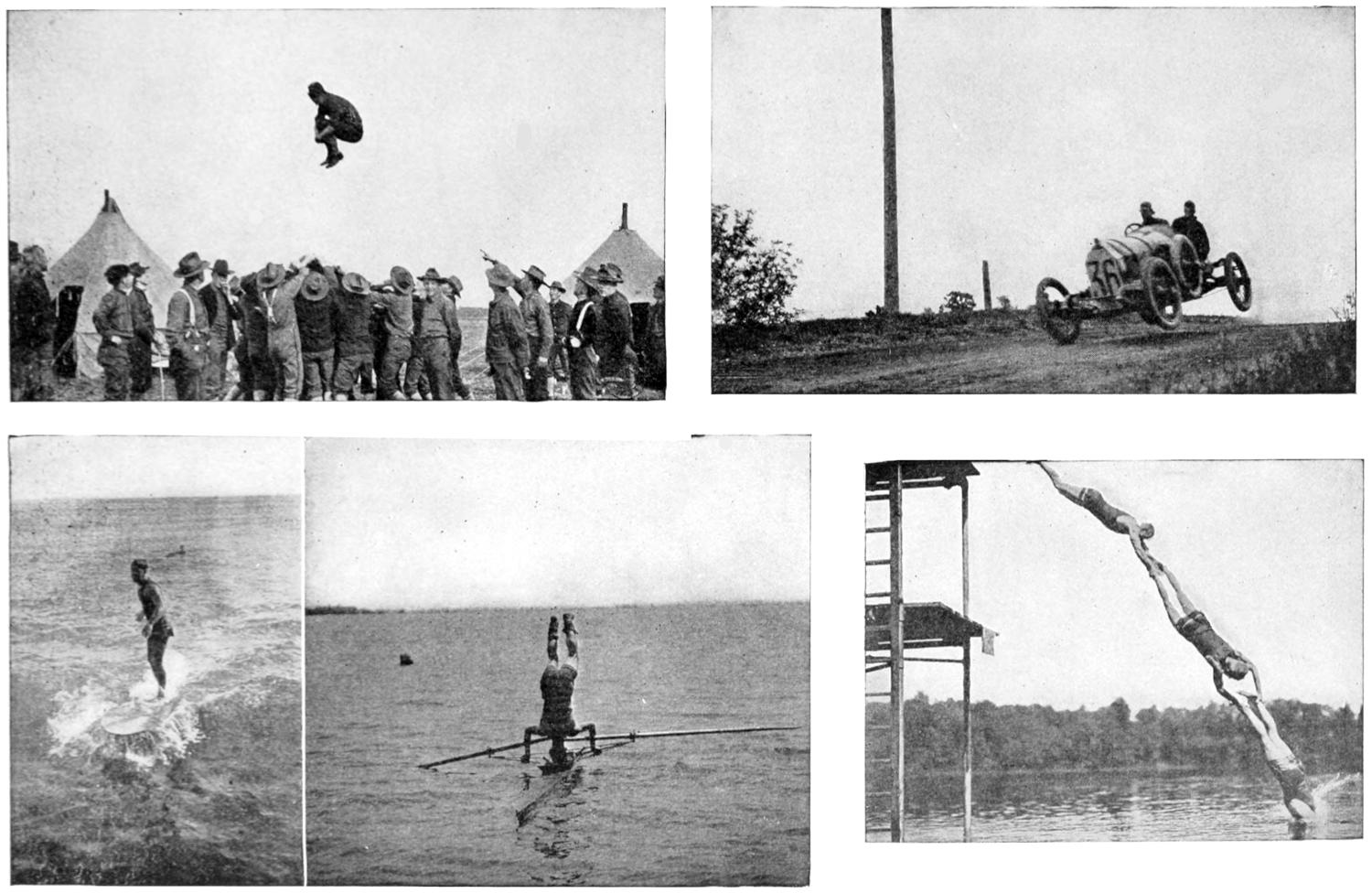

SOME REMARKABLE PICTURES WITH A FAST CAMERA

[40]

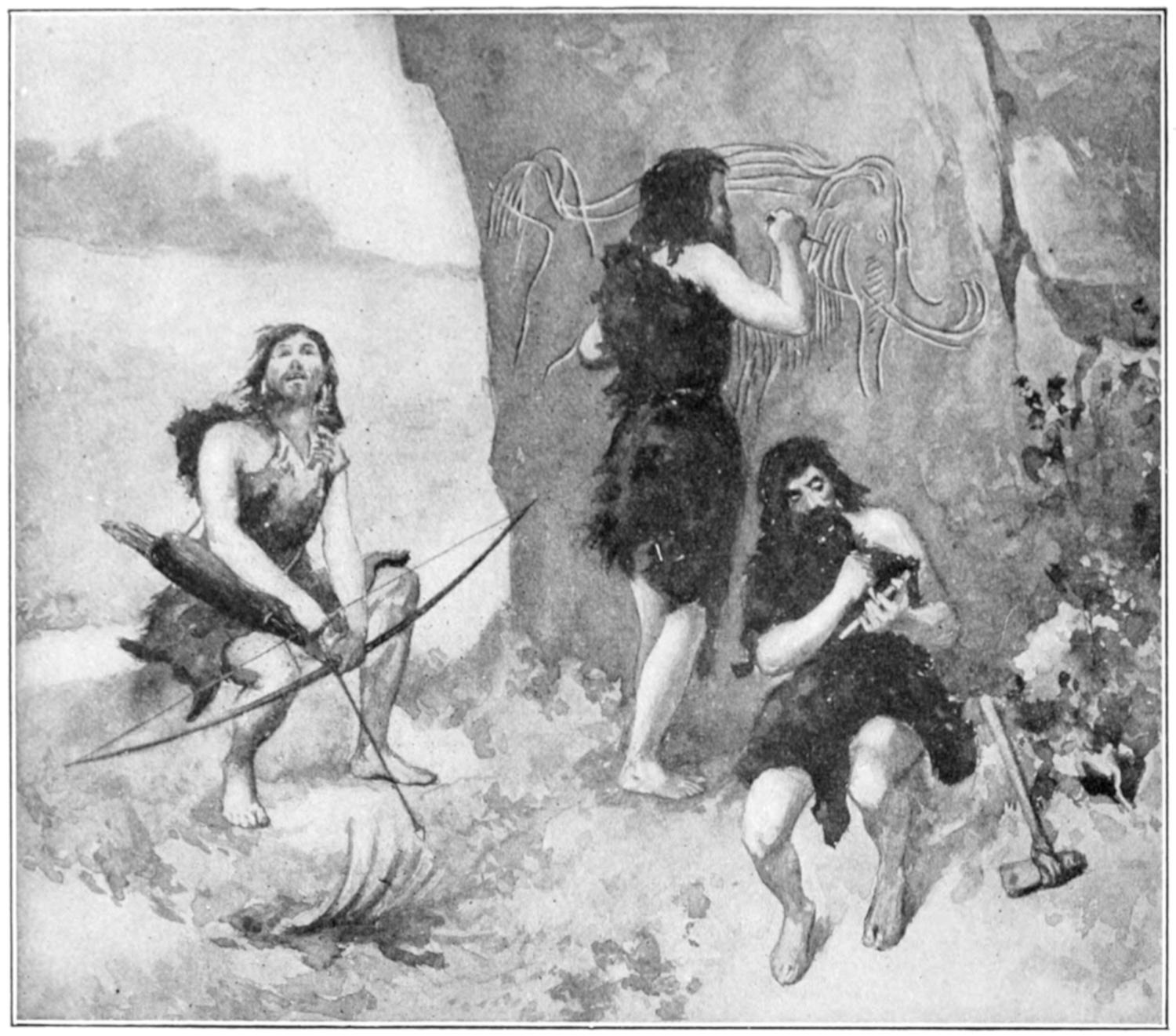

THE CAVE MAN OF PREHISTORIC TIMES WHO UNCONSCIOUSLY INVENTED AMMUNITION

HOW MAN LEARNED

TO SHOOT

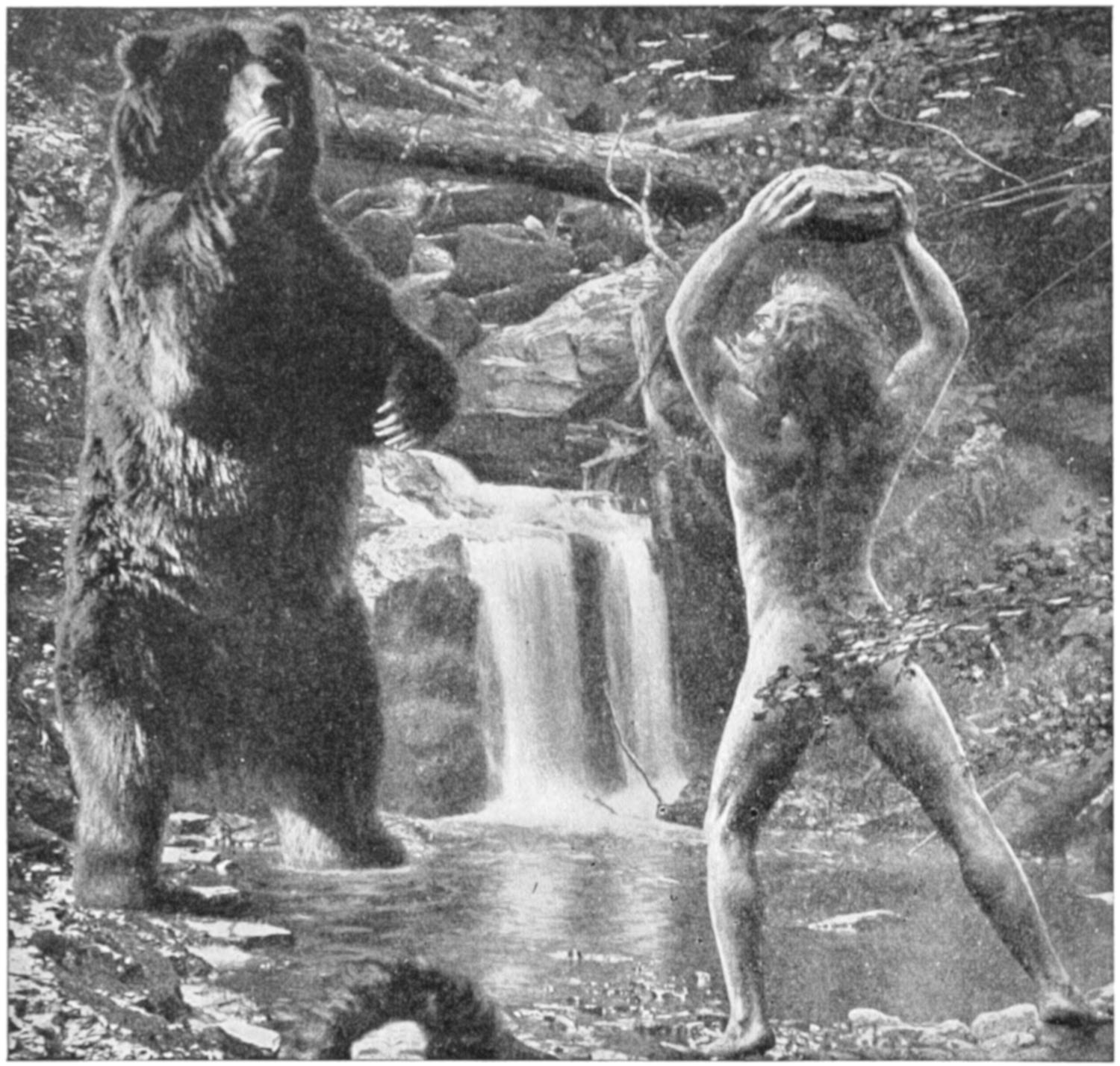

A naked savage found himself in the greatest danger. A wild beast, hungry and fierce was about to attack him. Escape was impossible. Retreat was cut off. He must fight for his life—but how?

Should he bite, scratch or kick? Should he strike with his fist? These were the natural defences of his body, but what were they against the teeth, the claws and the tremendous muscles of his enemy? Should he wrench a dead branch from a tree and use it for a club? That would bring him within striking distance to be torn to pieces before he could deal a second blow.

There was but a moment in which to act. Swiftly he seized a jagged fragment of rock from the ground and hurled it with all his force at the blazing eyes before him; then another, and another, until the beast, dazed and bleeding from the unexpected blows, fell back and gave him a chance to escape. He knew that he had saved his life, but there was something else which his dull brain failed to realize.

He had invented arms and ammunition!

In other words, he had needed to strike a harder blow than the blow of his fist, at a greater distance than the[41] length of his arm, and his brain showed him how to do it. After all, what is a modern rifle but a device which man has made with his brain permitting him to strike an enormously hard blow at a wonderful distance? Firearms are really but a more perfect form of stone-throwing, and this early Cave Man took the first step that has led down the ages.

This strange story of a development has been taking place slowly through thousands and thousands of years, so that today you are able to take a swift shot at distant game instead of merely throwing stones.

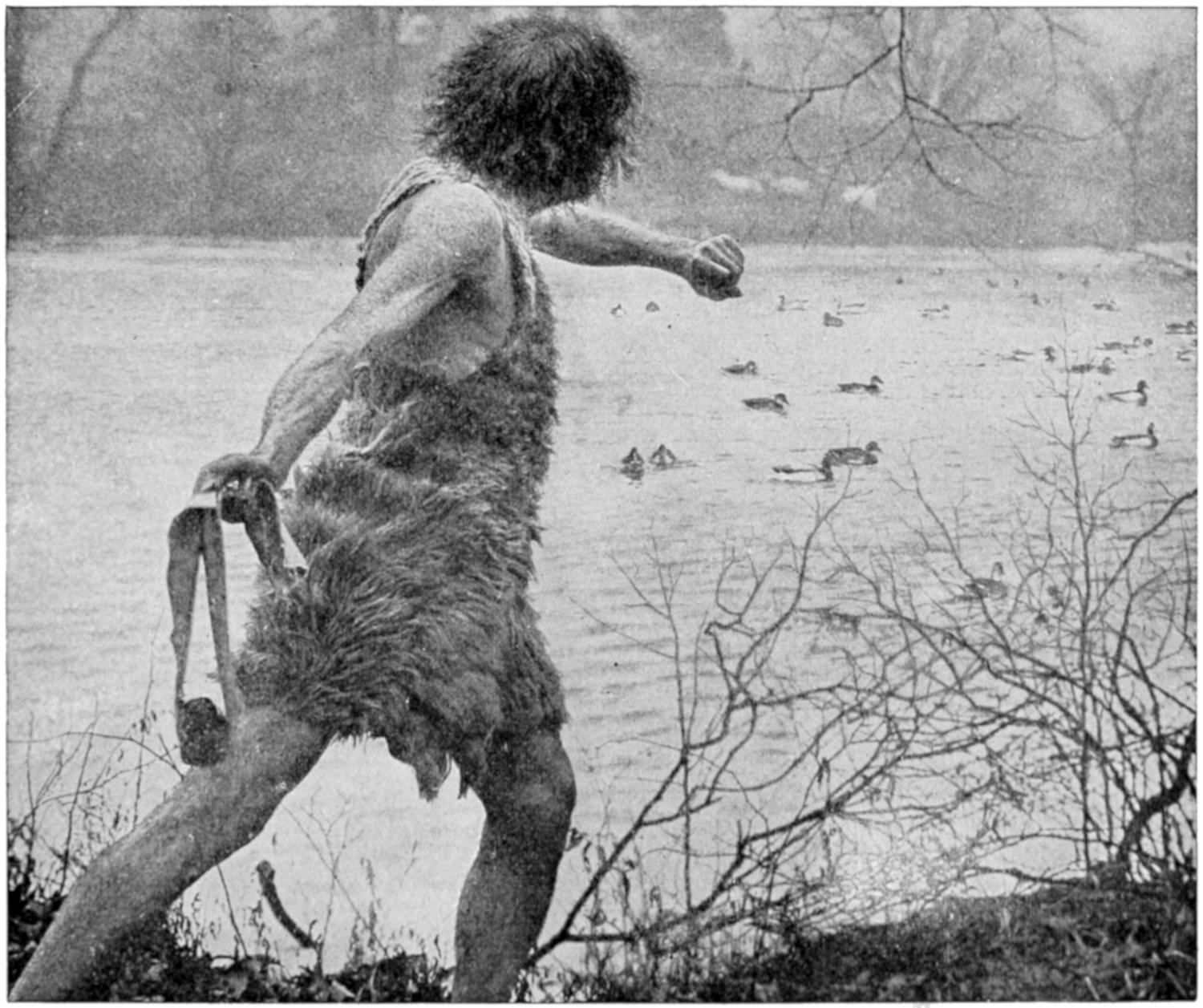

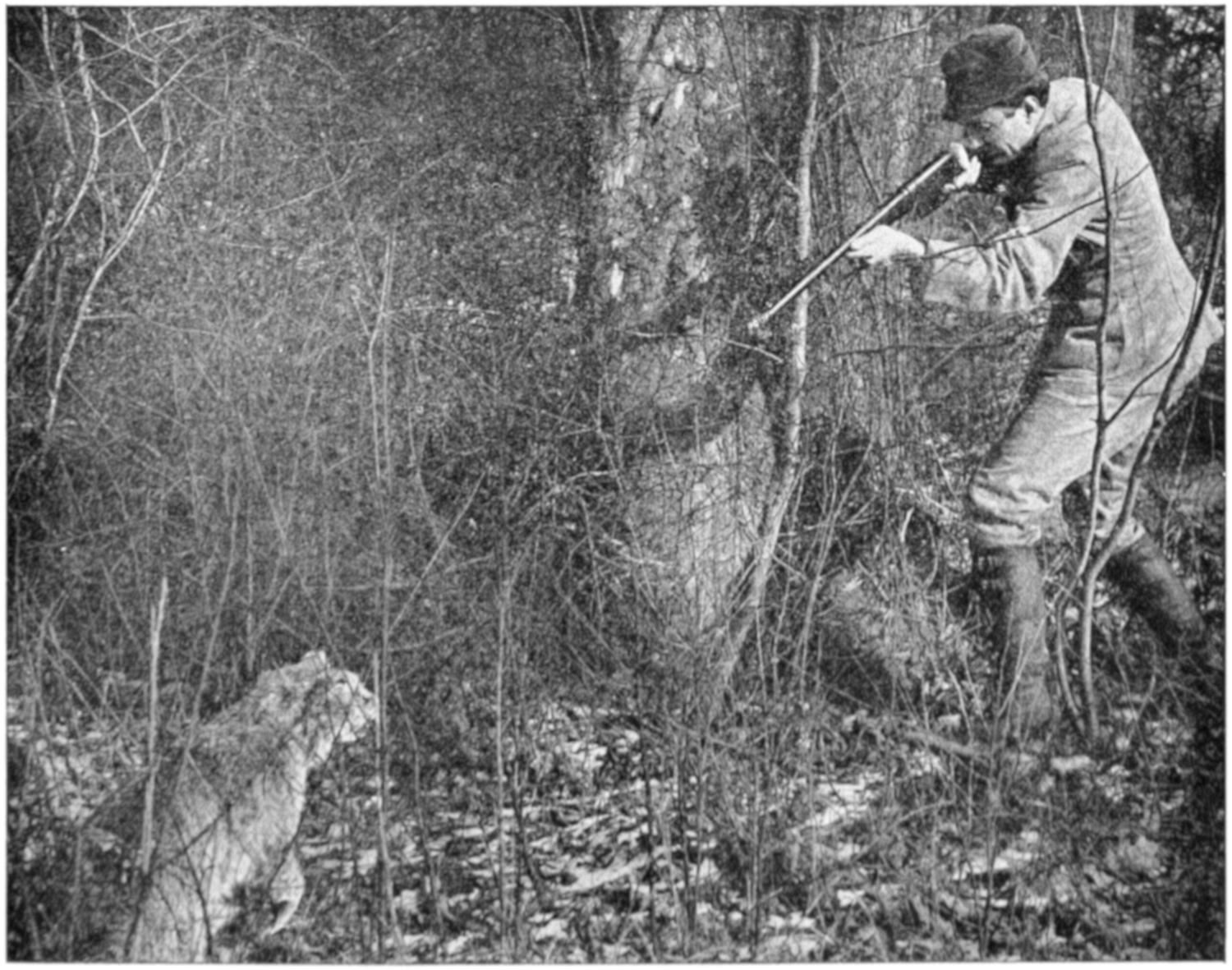

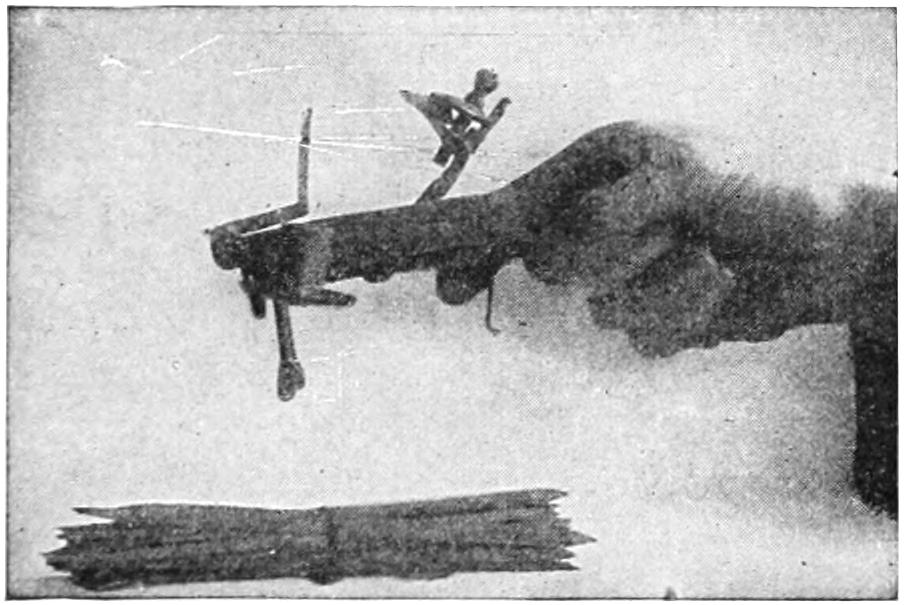

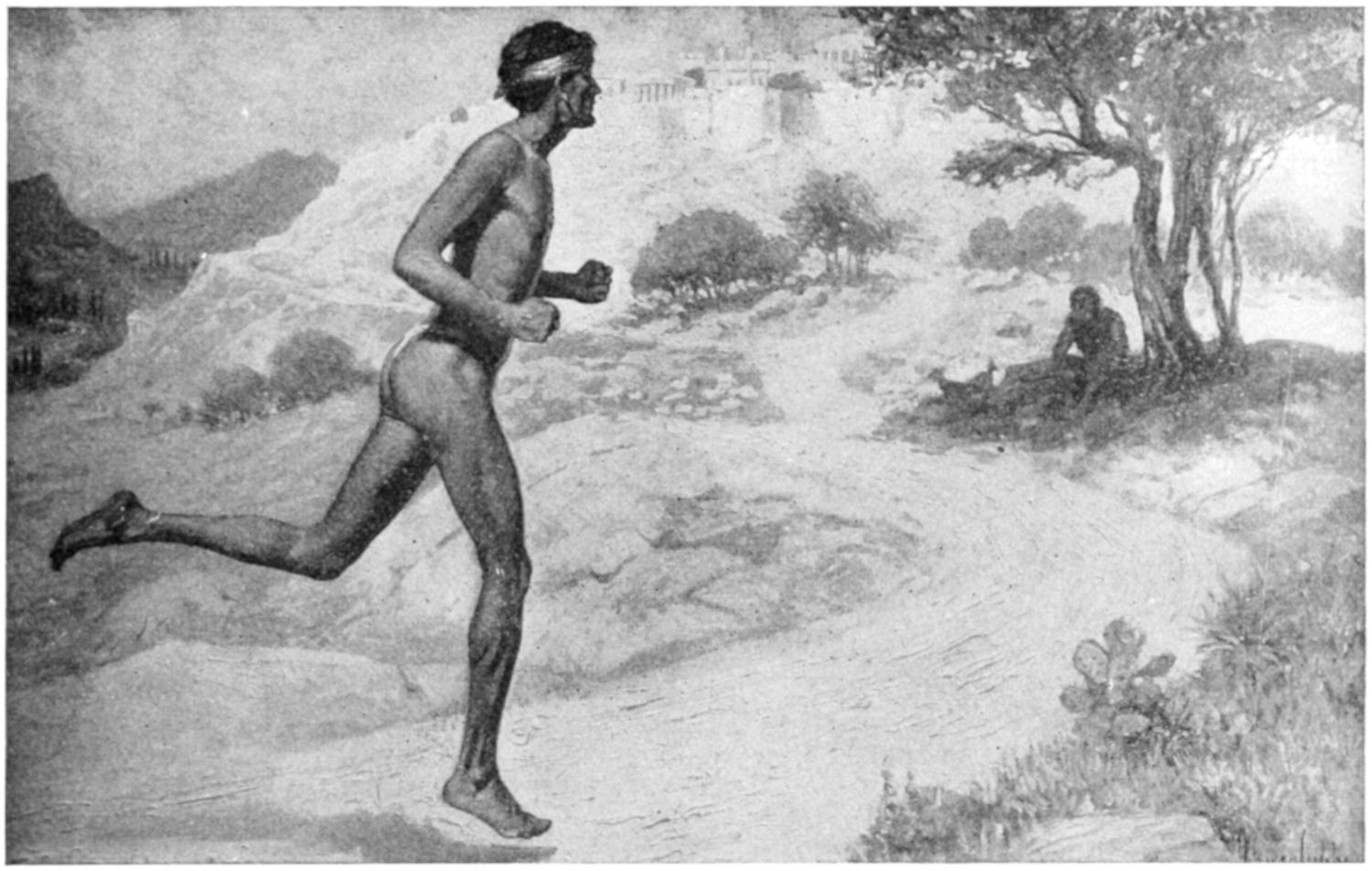

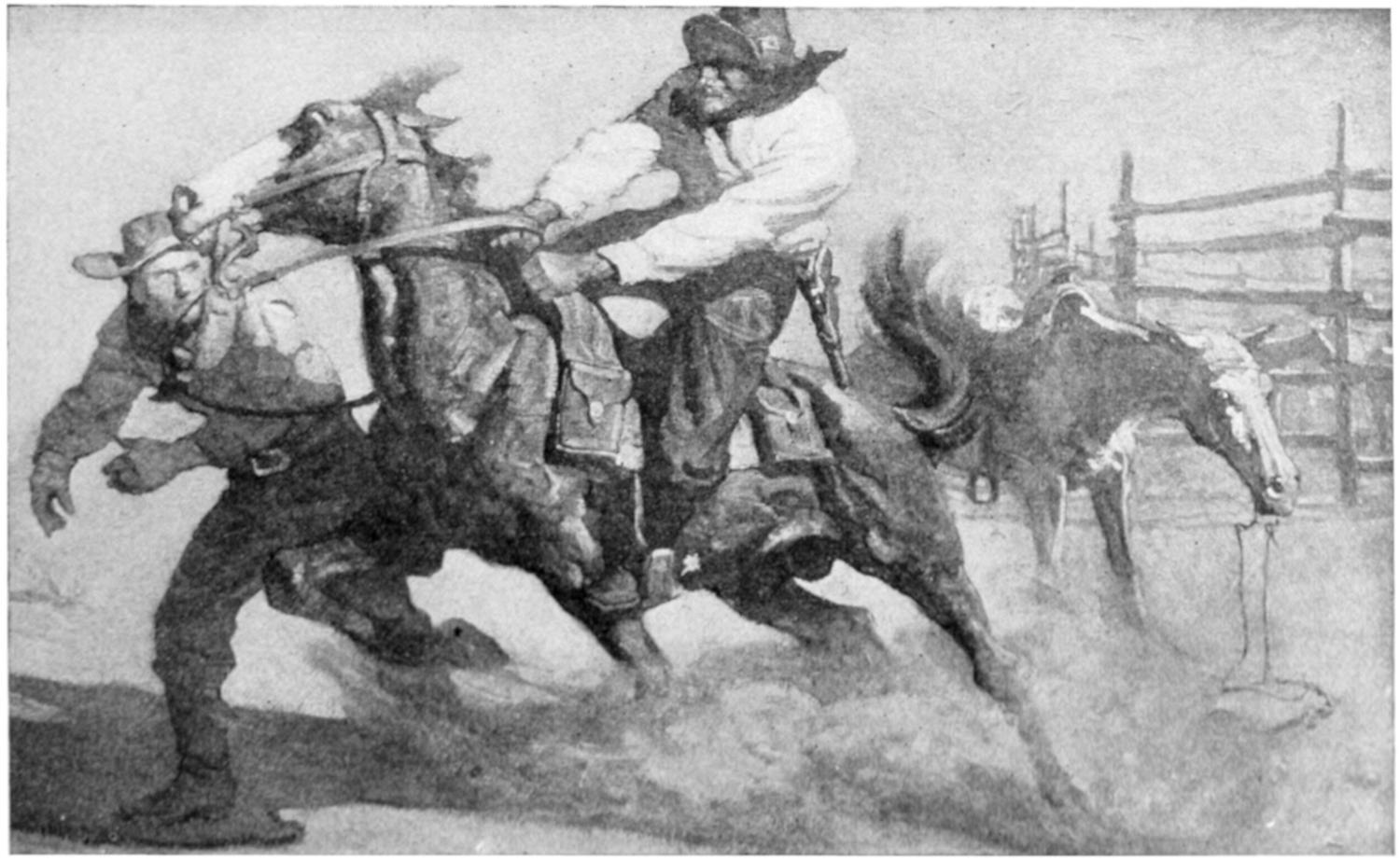

THE SLING MAN IN ACTION

PRACTICE DEVELOPED SOME WONDERFUL MARKSMEN AMONG THE USERS OF THIS PRIMITIVE WEAPON

We do not know the name of the man who invented the sling. Possibly he did not even have a name, but in some way he hit upon a scheme for throwing stones farther, harder, and straighter than any of his ancestors.

The men and women in the Cave Colony suddenly found that one bright-eyed young fellow, with a little straighter forehead than the others, was beating them all at hunting. During weeks he had been going away mysteriously, for hours each day. Now, whenever he left the camp he was sure to bring home game, while the other men would straggle back for the most part empty-handed.

Was it witchcraft? They decided to investigate.

Accordingly, one morning several of them followed at a careful distance as he sought the shore of a stream where water-fowl might be found. Parting the leaves, they saw him pick up a pebble from the bank and then to their surprise, take off his girdle of skin and place the stone in its center, holding both ends with his right hand.

[42]

Stranger still, he whirled the girdle twice around his head, then released one end so that the leather strip flew out and the stone shot straight at a bird in the water.

The mystery was solved. They had seen the first slingman in action.

The new plan worked with great success, and a little practice made expert marksmen. We know that most of the early races used it for hunting and in war. We find it shown in pictures made many thousands of years ago in ancient Egypt and Assyria. We find it in the Roman Army where the slingman was called a “funditor.”

Surely, too, you remember the story of David and Goliath when the young shepherd “prevailed over the Philistine with a sling and with a stone.”

Yet slings had their drawbacks. A stone slung might kill a bird or even a man, but it was not very effective against big game.

What was wanted was a missile to pierce a thick hide.

Man had begun to make spears for use in a pinch, but would you like to tackle a husky bear or a well-horned stag with only a spear for a weapon?

No more did our undressed ancestors. The invention of the greatly desired arm probably came about in a most curious way.

Long ages ago man had learned to make fire by patiently rubbing two sticks together, or by twirling a round one between his hands with its point resting upon a flat piece of wood.

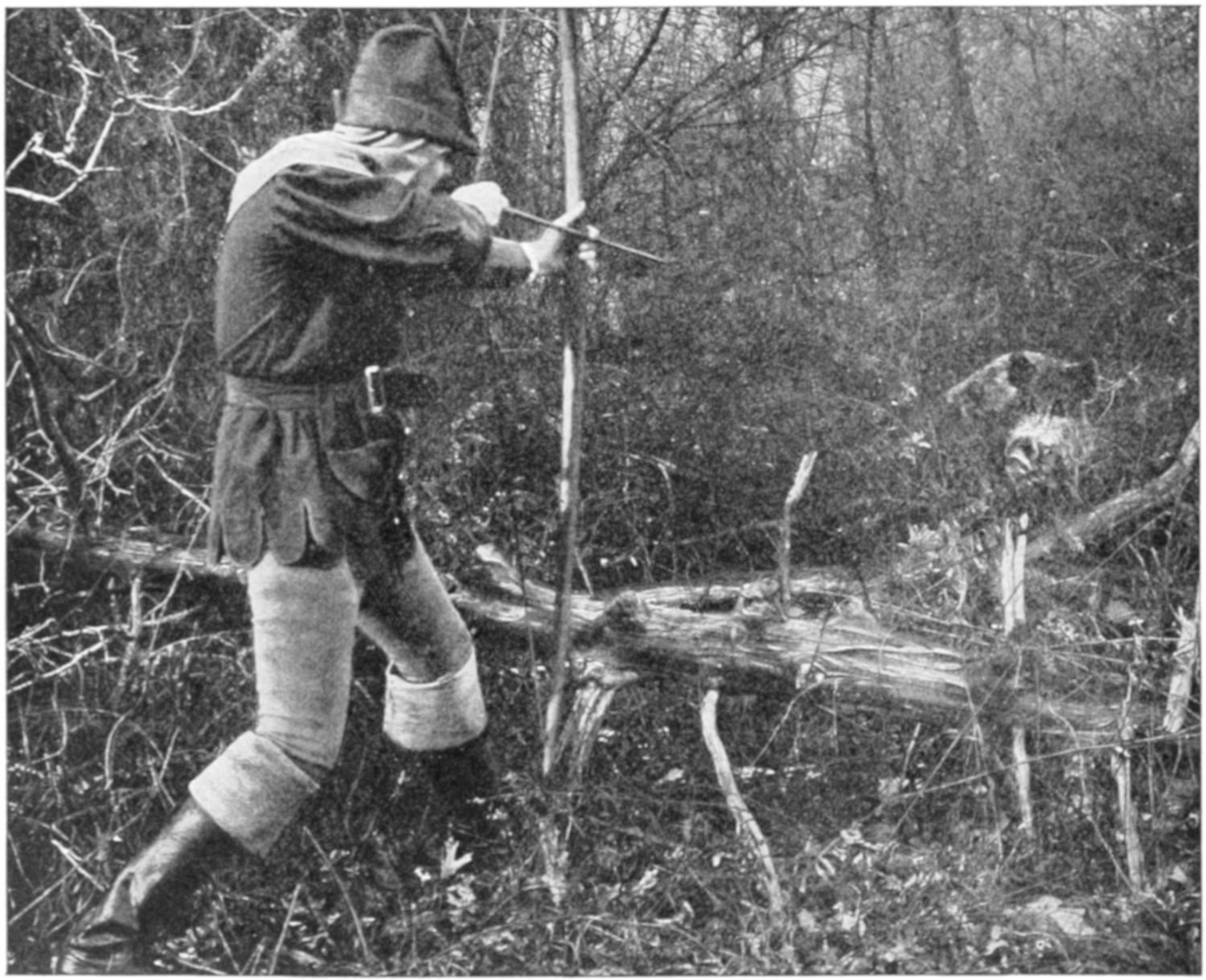

THE “LONG BOW” IN SHERWOOD FOREST

ONE OF ROBIN HOOD’S FAMOUS BAND ENCOUNTERS A SAVAGE TUSKER AT CLOSE RANGE

In this way it could be made to smoke, and finally set fire to a tuft of dried moss, from which he might get a flame for cooking. This was such hard work that he bethought him to twist a string of sinew about the upright spindle and cause it to twirl by pulling alternately at the two string ends, as some savage races still do. From[43] this it was a simple step to fasten the ends of the two strings to a bent piece of wood, another great advantage since now but one hand was needed to twirl the spindle, and the other could hold it in place. This was the “bow-drill” which also is used to this day.

But bent wood is apt to be springy. Suppose that while one were bearing on pretty hard with a well-tightened string, in order to bring fire quickly, the point of the spindle should slip from its block. Naturally, it would fly away with some force if the position were just right.

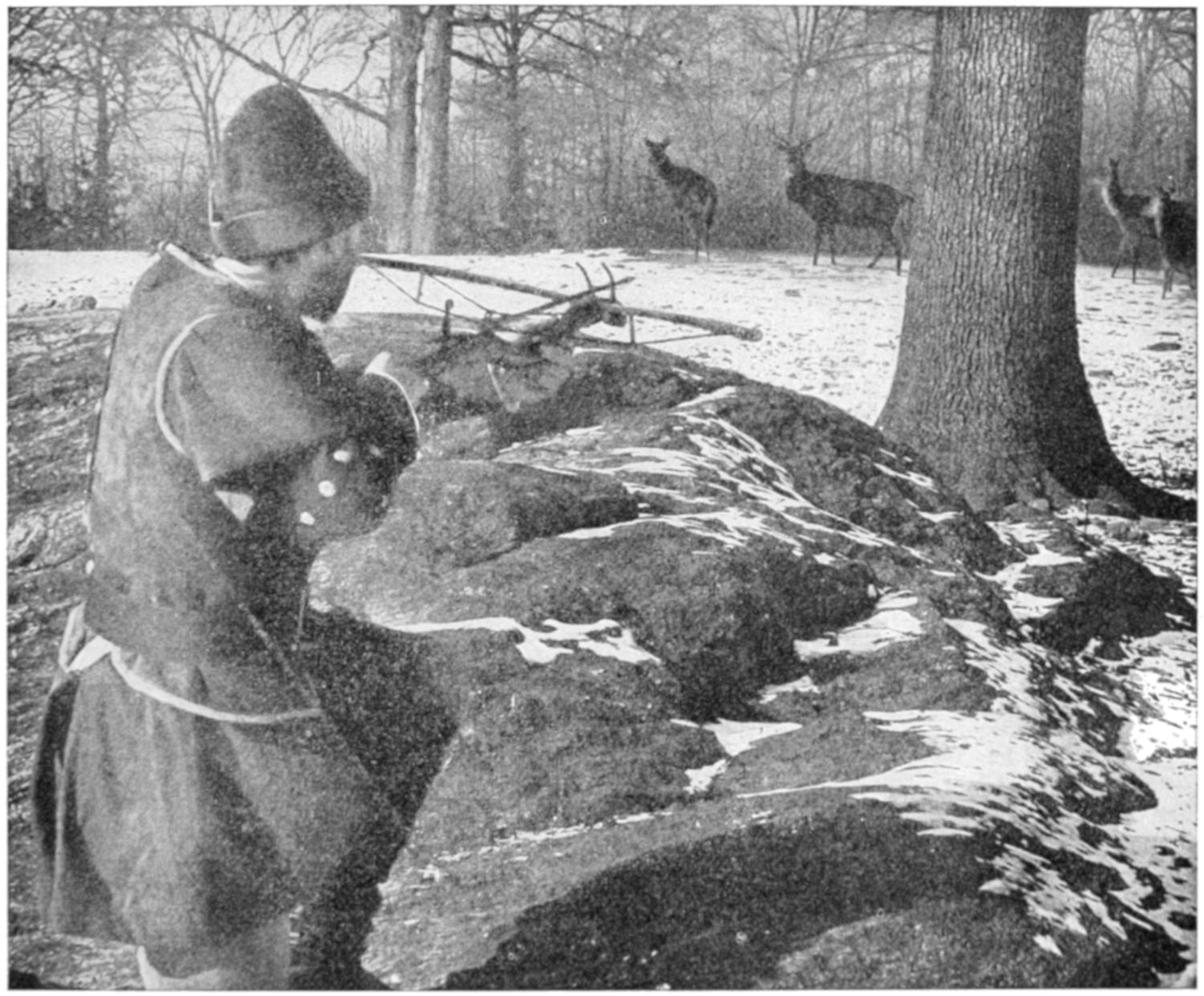

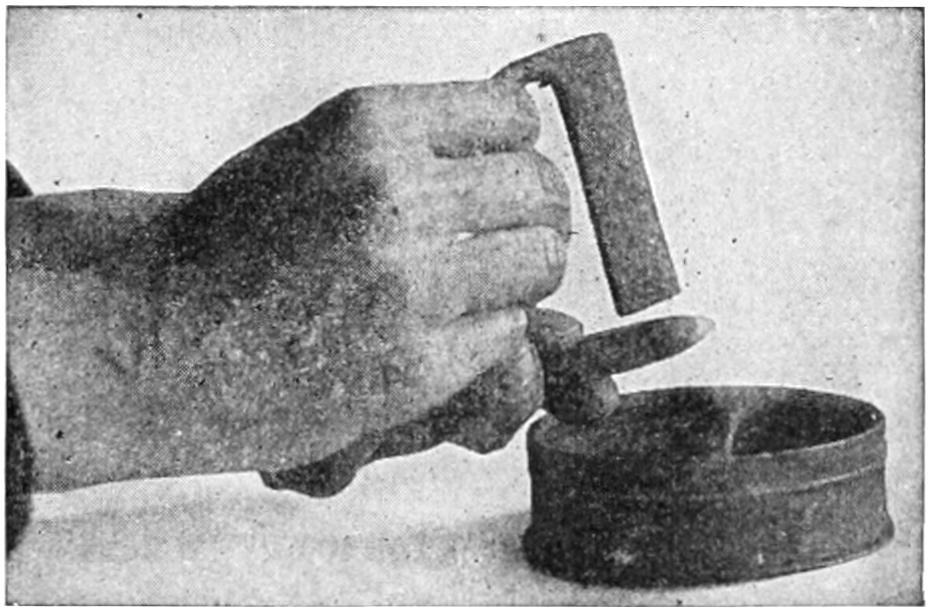

DEER STALKING WITH THE CROSSBOW

THIS COMPACT ARM WITH ITS SMALL BOLT AND GREAT POWER WAS POPULAR WITH MANY SPORTSMEN

There was one man who stopped short when he lost his spindle, for a red-hot idea shot suddenly through his brain.

Once or twice he chuckled to himself softly. Thereupon he arose and began to experiment. He chose a longer, springier piece of wood, bent it into a bow, and strung it with a longer thong. He placed the end of a straight stick against the thong, drew it strongly back, and released it.

The shaft whizzed away with force enough to delight him, and lo, there was the first Bow-and-Arrow!

Armed with his bow-and-arrow, man now was lord of creation. No longer was it necessary for him to huddle with his fellows in some cave to avoid being eaten by prowling beasts. Instead he went where he would and boldly hunted the fiercest of them. In other words, his brain was beginning to tell, for though his body was still no match for the lion and the bear, he had thought out a way to conquer them.

Also he was better fed with a greater variety of game. And now, free to come and go wherever he might find it,[44] he was able to spread into various lands and so to organize the tribes and nations which at last gave us civilization and history.

A new weapon now came about through warfare. Man has been a savage fighting animal through pretty much all his history, but while he tried to kill the other fellow, he objected to being killed himself.

Therefore he took to wearing armor. During the Middle Ages he piled on more and more, until at last one of the knights could hardly walk, and it took a strong horse to carry him. When such a one fell, he went over with a crash like a tin-peddler’s wagon, and had to be picked up again by some of his men. Such armor would turn most of the arrows. Hence invention got at work again and produced the Crossbow and its bolt. We have already learned how the tough skin of animals brought about the bow; now we see that man’s artificial iron skin caused the invention of the crossbow.

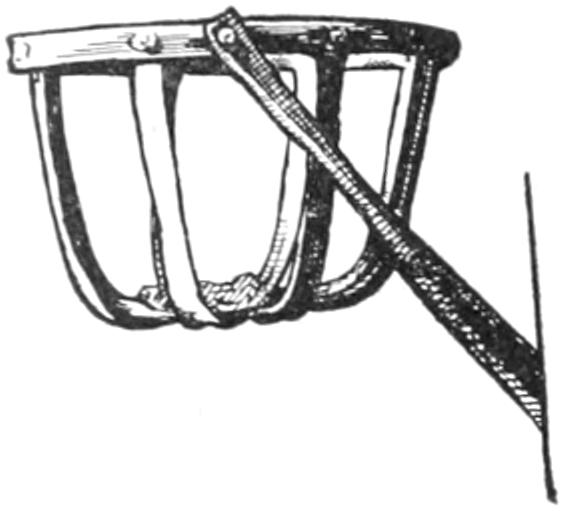

What was the Crossbow? It was the first real hand-shooting machine. It was another big step toward the day of the rifle. The idea was simple enough. Wooden bows had already been made as strong as the strongest man could pull, and they wished for still stronger ones—steel ones. How could they pull them? At first they mounted them upon a wooden frame and rested one end on the shoulder for a brace. Then they took to pressing the other end against the ground, and using both hands. Next, it was a bright idea to put a stirrup on this end, in order to hold it with the foot.

Still they were not satisfied. “Stronger, stronger!” they clamored; “give us bows which will kill the enemy farther away than he can shoot at us! If we cannot set such bows with both arms let us try our backs!” So they fastened “belt-claws” to their stout girdles and tugged the bow strings into place with their back and leg muscles.

Probably the Chinese, although all authorities do not agree. Strange, is it not, that a race still using crossbows in its army should have known of explosives long before the Christian Era, and perhaps as far back as the time of Moses? Here is a passage from their ancient Gentoo Code of Laws: “The magistrate shall not make war with any deceitful machine, or with poisoned weapons, or with cannons or guns, or any kind of firearms.” But China might as well have been Mars before the age of travel. Our civilization had to work out the problem for itself.

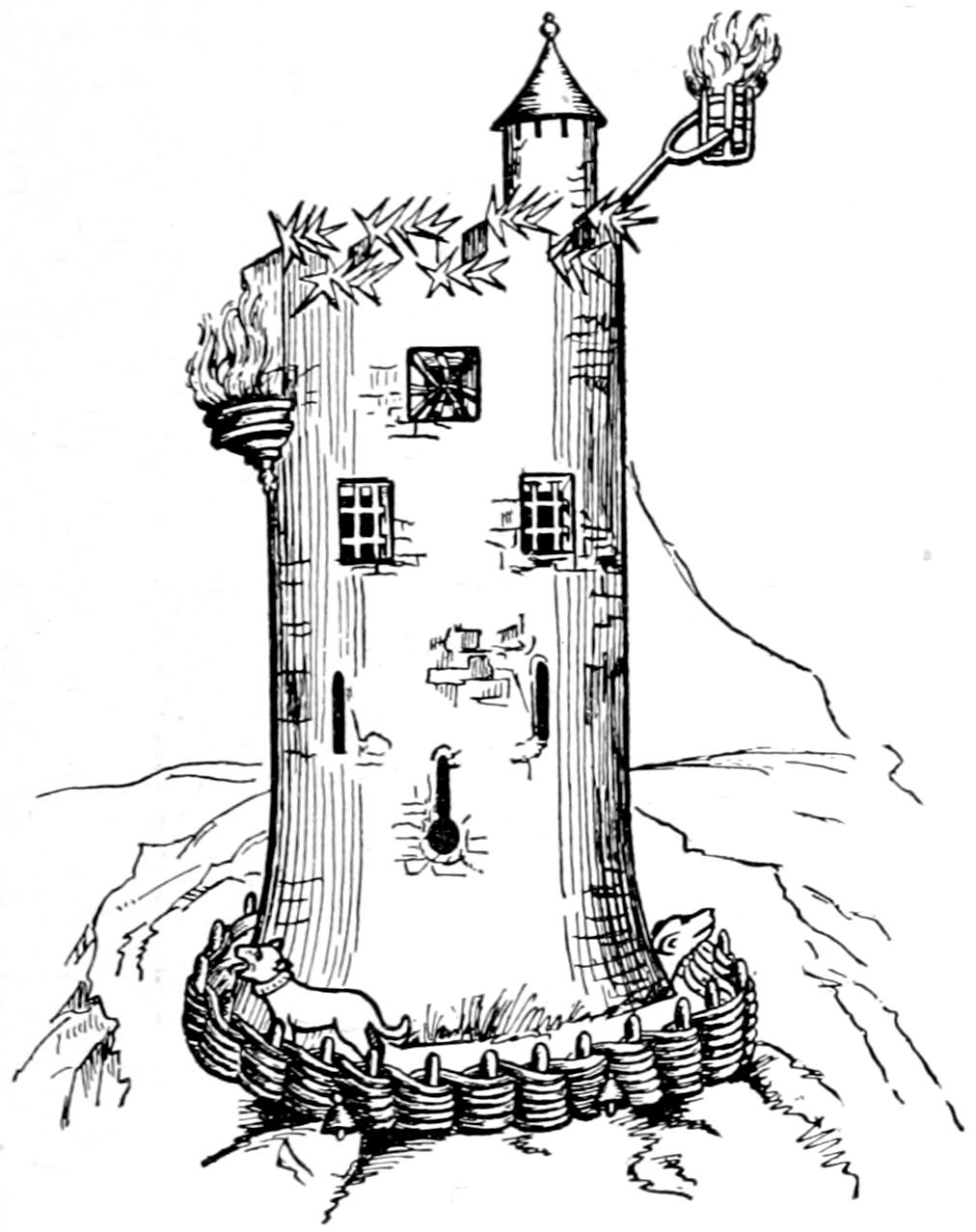

It all began through playing with fire. It was desired to throw fire on an enemy’s buildings, or his ships, and so destroy them.

Burning torches were thrown by machines, made of cords and springs, over a city wall, and it became a great study to find the best burning compound with which to cover these torches. One was needed which would blaze with a great flame and was hard to put out.

Hence the early chemists made all possible mixtures of pitch, resin, naphtha, sulphur, saltpeter, etc.; “Greek fire” was one of the most famous.

Many of these were made in the monasteries. The monks were pretty much the only people in those days with time for study, and two of these shaven-headed scientists now had a chance to enter history. Roger Bacon was the first. One night he was working his diabolical mixture in the stone-walled laboratory, and watched, by the flickering lights, the progress of a certain interesting combination for which he had used pure instead of impure saltpeter.

Suddenly there was an explosion, shattering the chemical apparatus and probably alarming the whole building. That explosion proved the new combination was not fitted for use as a thrown fire; it also showed the existence of terrible forces far beyond the power of all bow-springs, even those made of steel.

Roger Bacon thus discovered what was practically gunpowder, as far back[45] as the thirteenth century, and left writings in which he recorded mixing 11.2 parts of the saltpeter, 29.4 of charcoal, and 29 of sulphur. This was the formula developed as the result of his investigations.

Berthold Schwartz, a monk of Freiburg, studied Bacon’s works and carried on dangerous experiments of his own, so that he is ranked with Bacon for the honor. He was also the first one to rouse the interest of Europe in the great discovery.

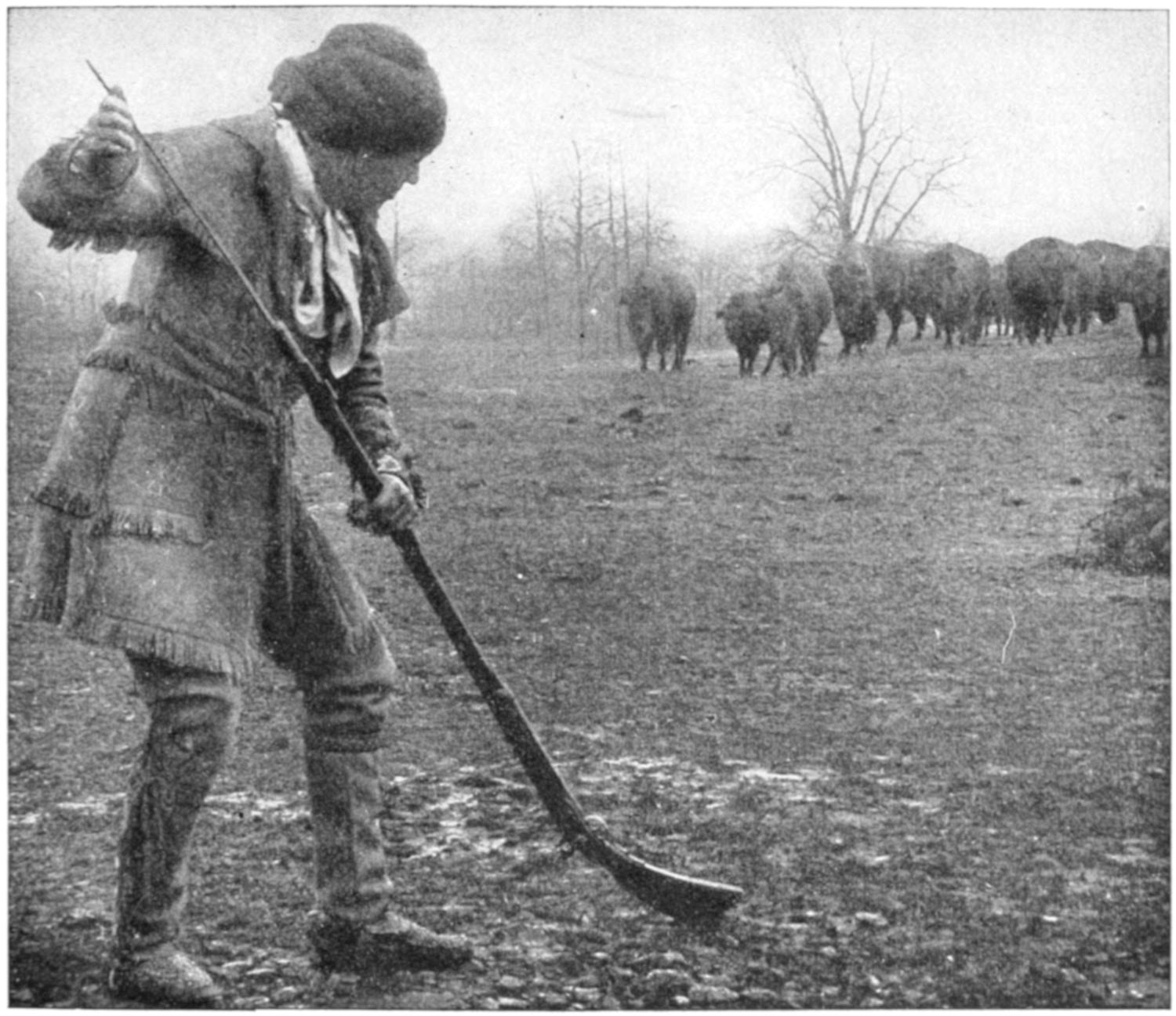

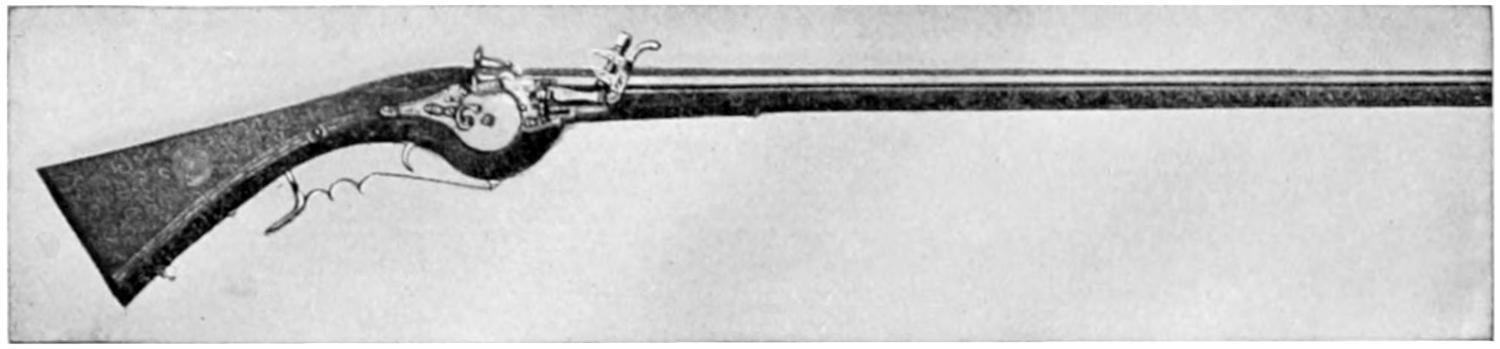

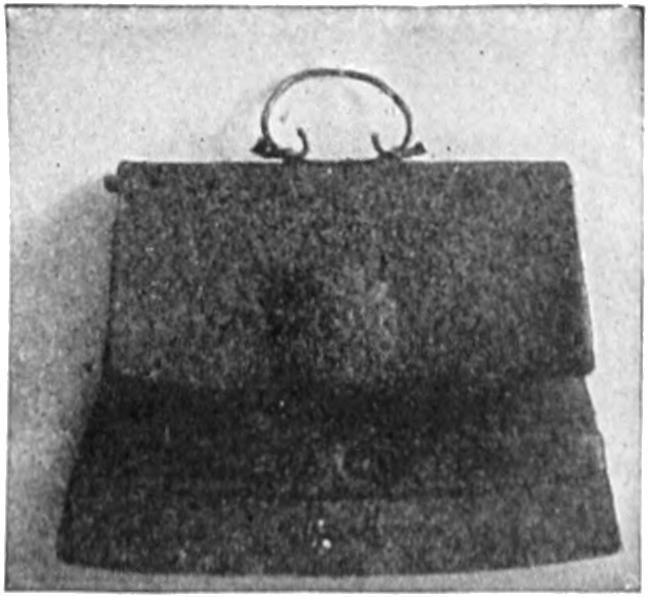

THE “KENTUCKY RIFLE” WITH ITS FLINT-LOCK WAS ACCURATE BUT MUST BE MUZZLE-CHARGED

THE FIRST

REAL FIRE ARMS

And then began the first crude, clumsy efforts at gunmaking. Firearms were born.

Hand bombards and culverins were among the early types. Some of these were so heavy that a forked support had to be driven into the ground, and two men were needed, one to hold and aim, the other to prime and fire.

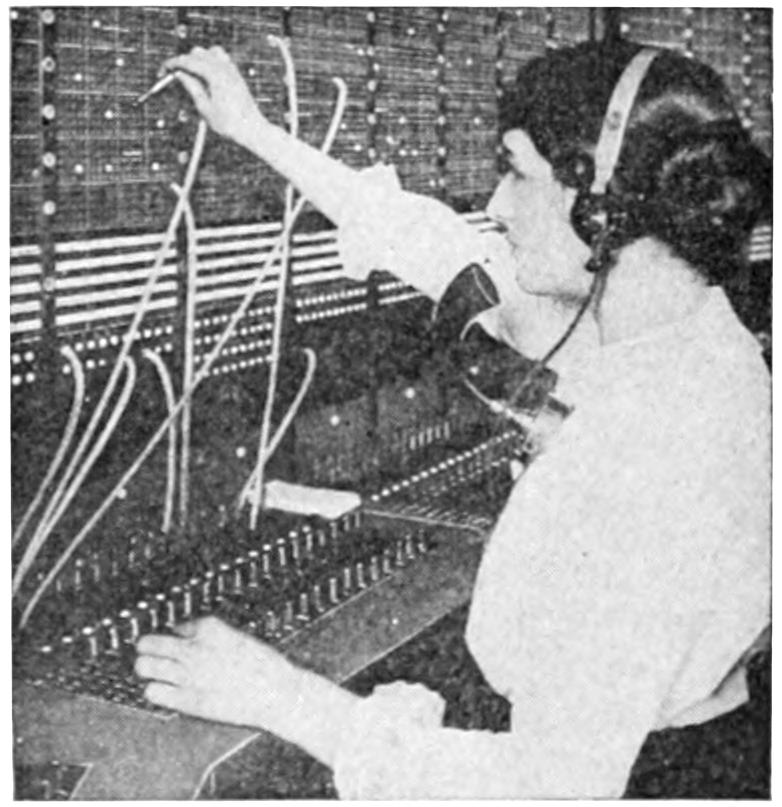

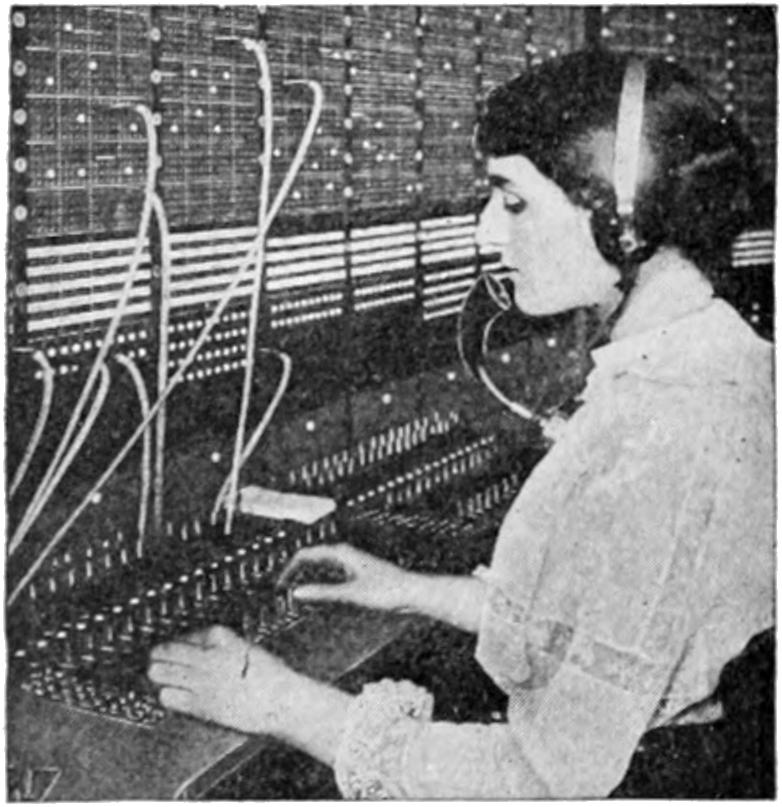

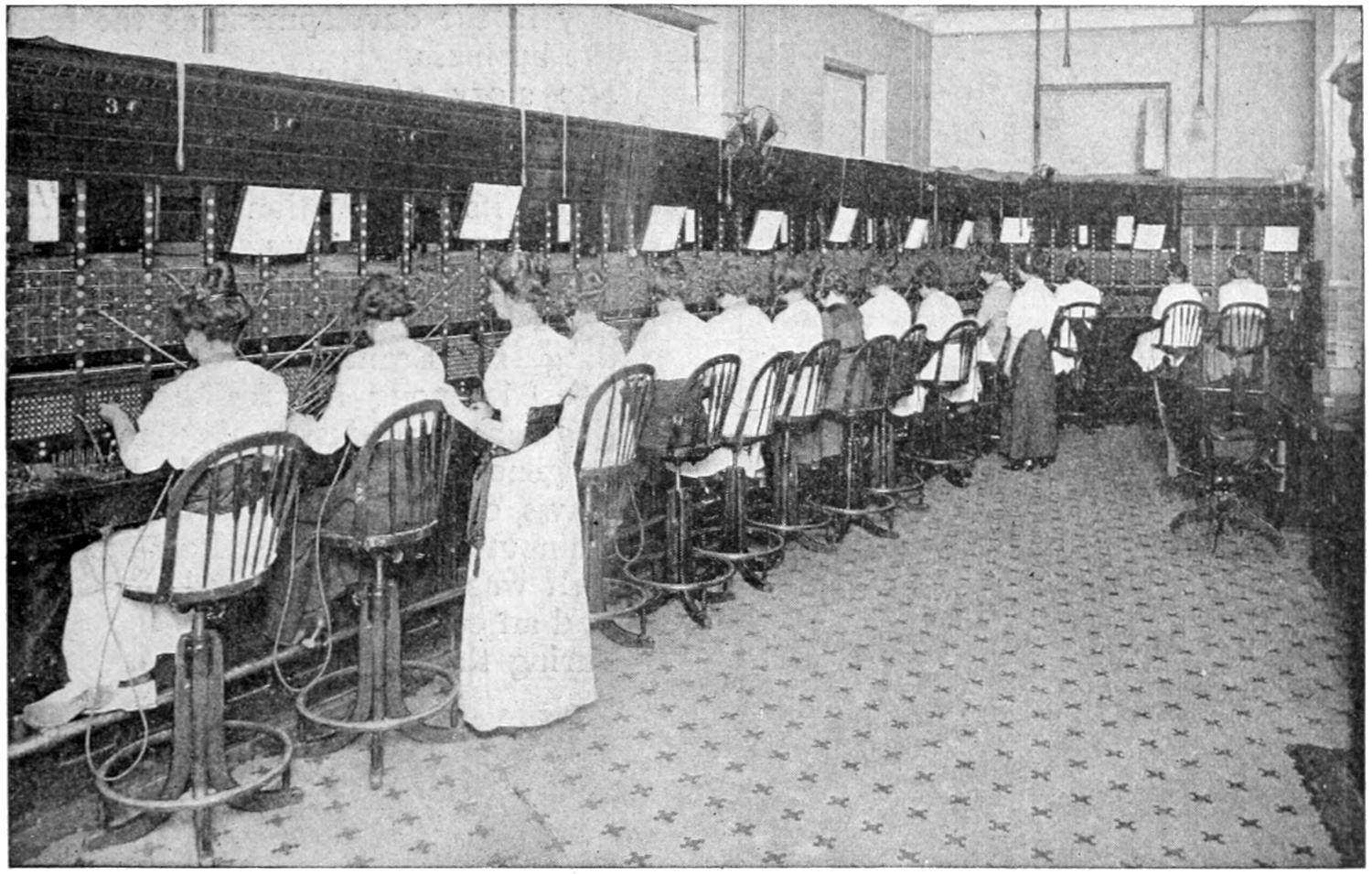

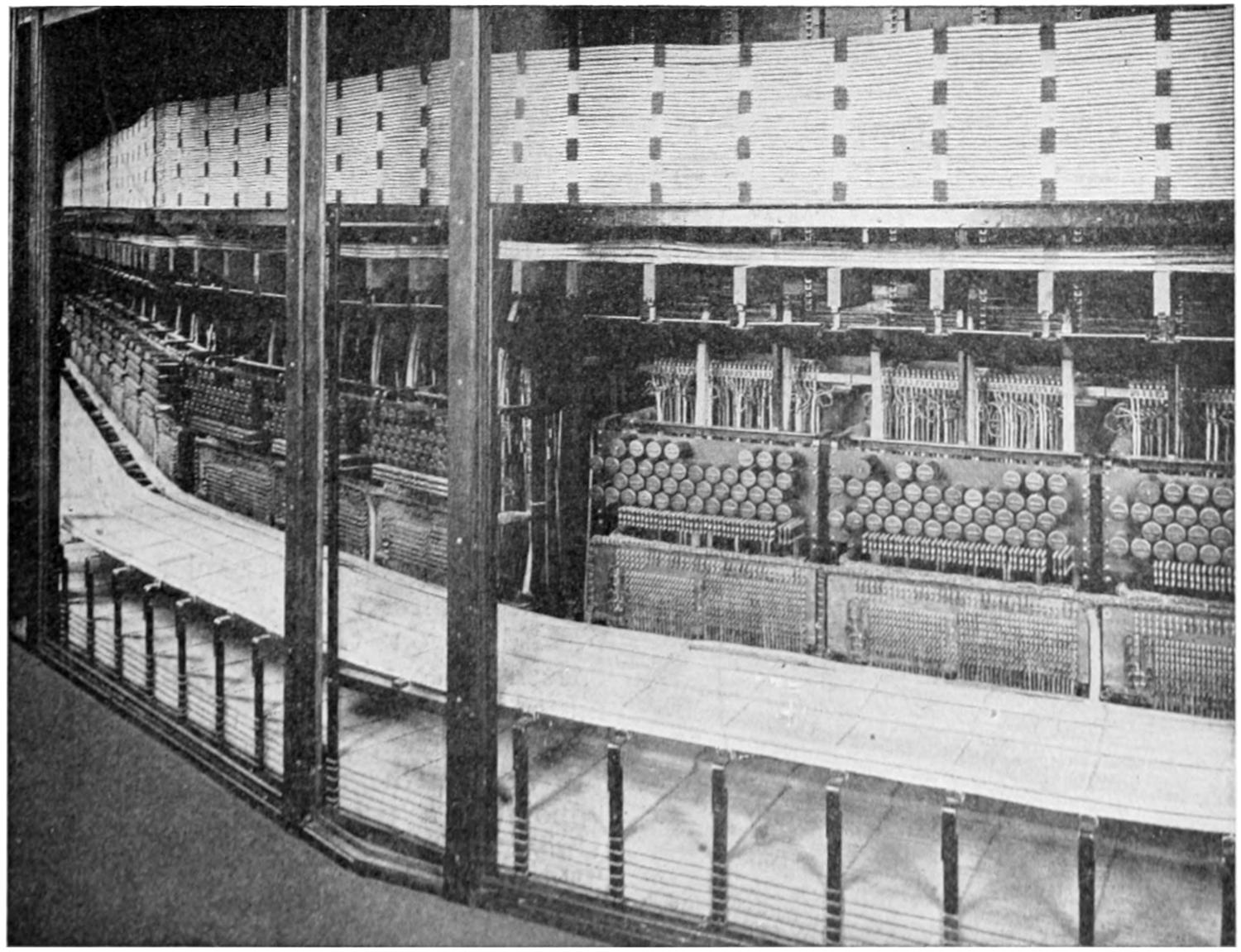

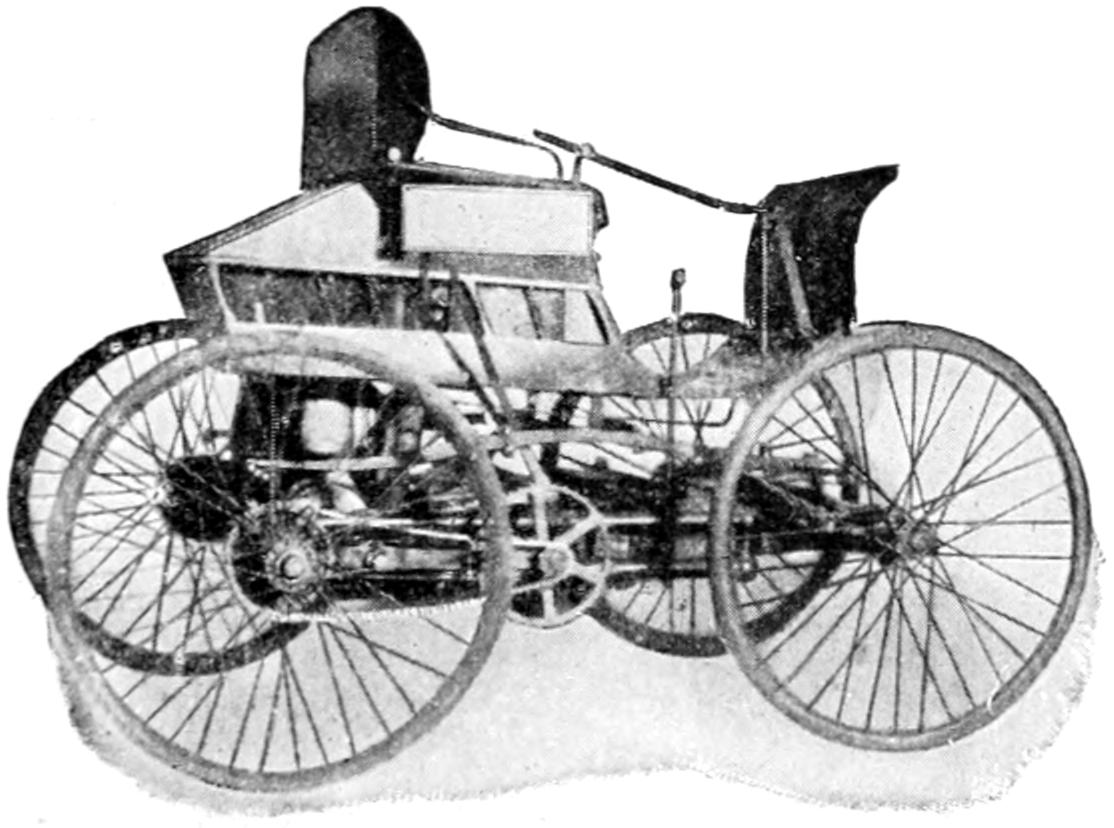

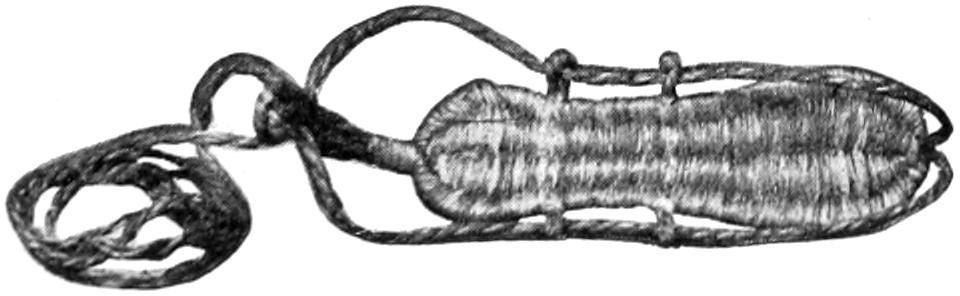

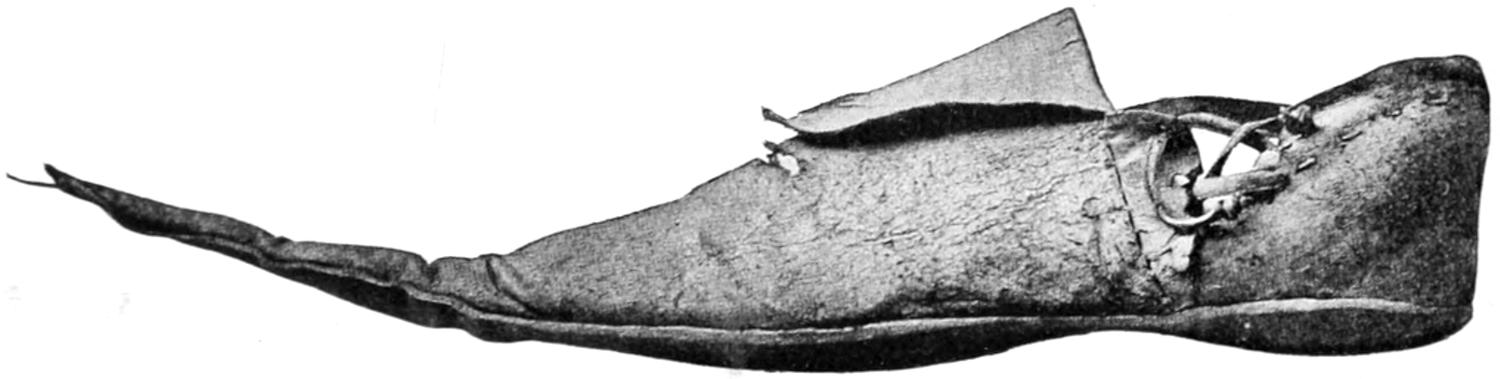

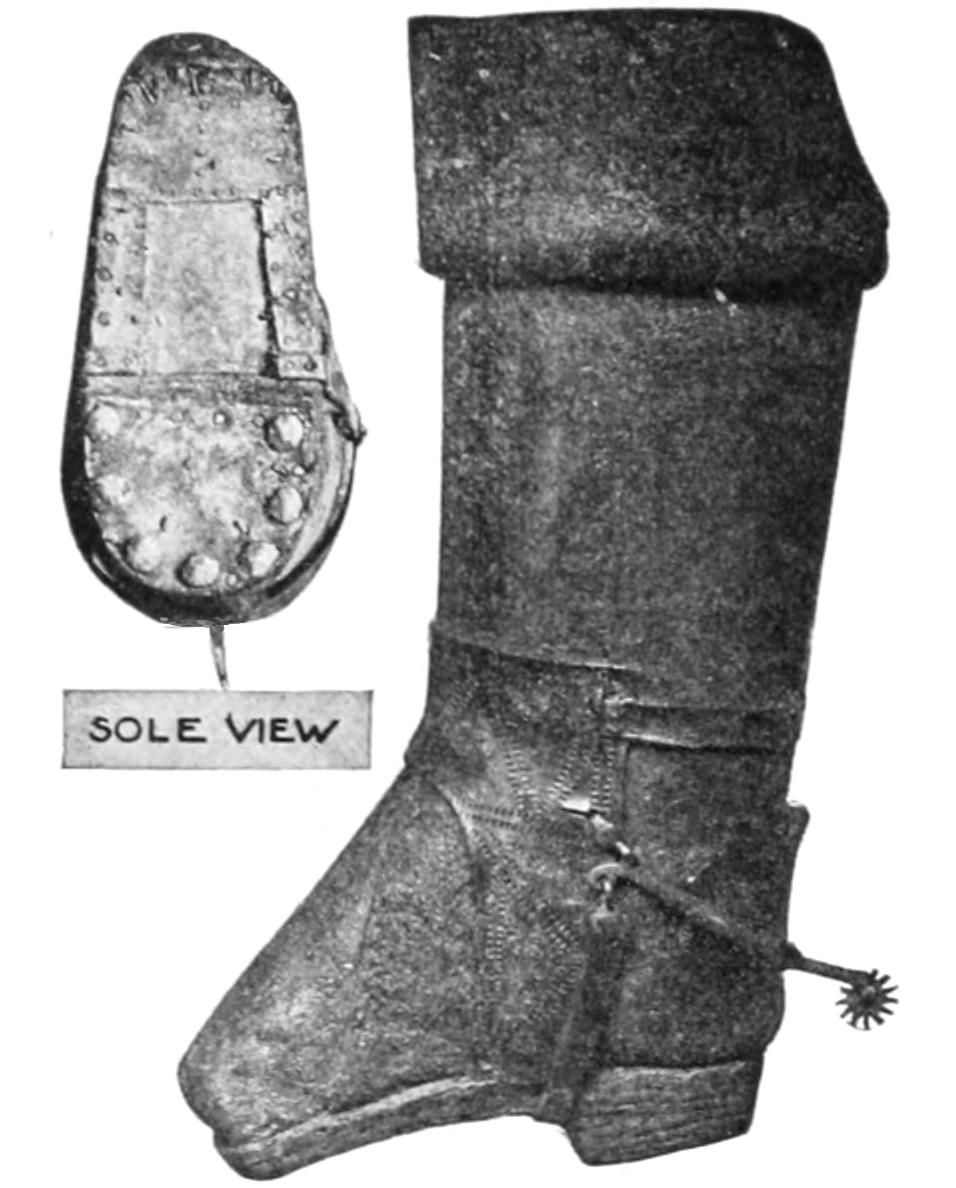

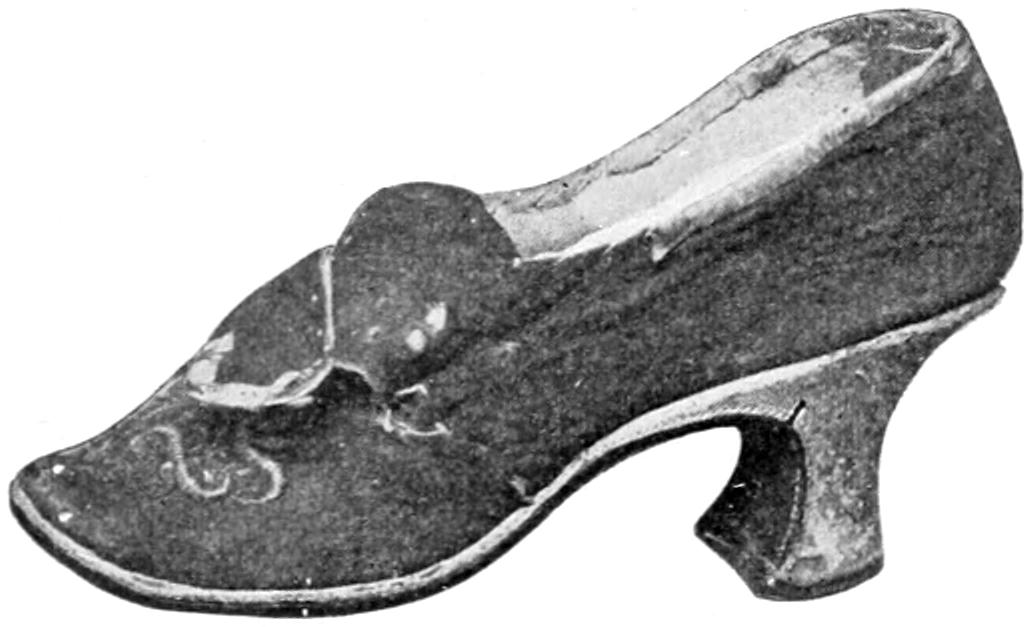

Improvements kept coming, however. Guns were lightened and bettered in shape. Somebody thought of putting a flash pan, for the powder, by the side of the touch-hole, and now it was decided to fasten the slow-match in a movable cock upon the barrel, and ignite it with a trigger. These matches were fuses of some slow-burning fiber, like tow, which would keep a spark for a considerable time. Formerly they had to be carried separately, but the new arrangement was a great convenience and made the match-lock. The cock, being curved like a snake, was called the “serpentine.”