CONSISTING OF A SERIES OF ARTICLES ON

Garment

Cutting

and Making

with

Illustrations by Diagrams,

SHOWING THE COMMENCING POINT

AT THE CENTER OF A CIRCLE IN GENERAL,

AND RADIATING ON ESPECIAL ANGLES OF

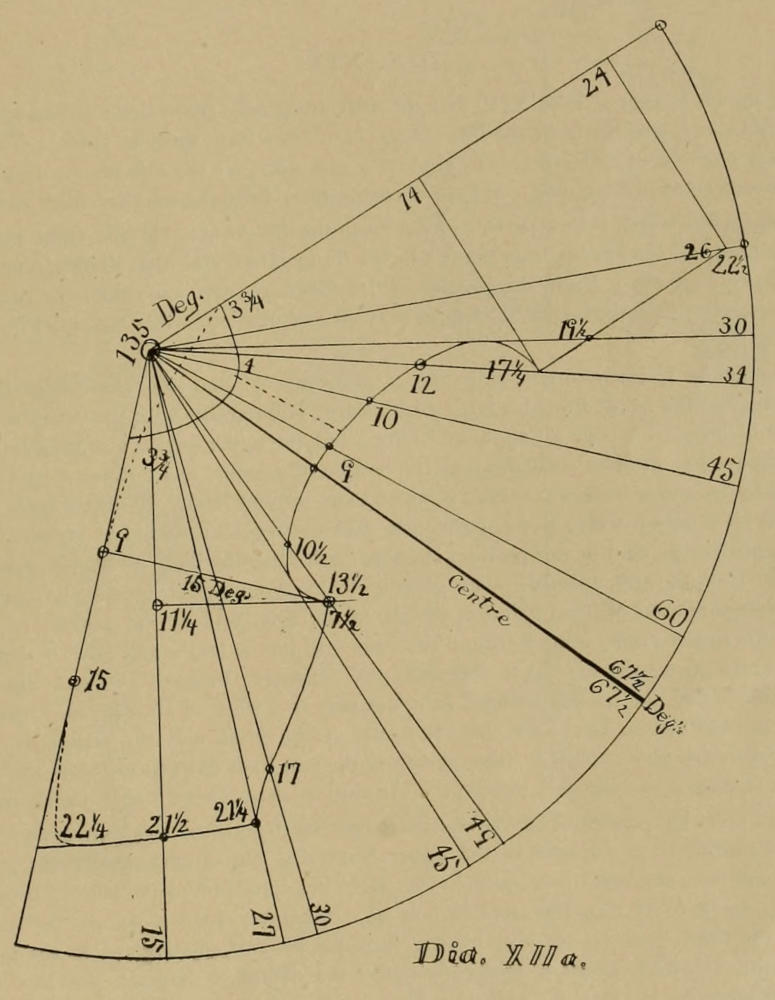

135, 120, 90, 60, 45, 30, 22½, 20, 15, 10, 7½, 5, 2½, Etc.,

BUT MORE ESPECIALLY TWO ANGLES OF FIFTEEN DEGREES EACH,

JOINED AT THEIR WIDEST END.

ALL RIGHTS RESERVED BY

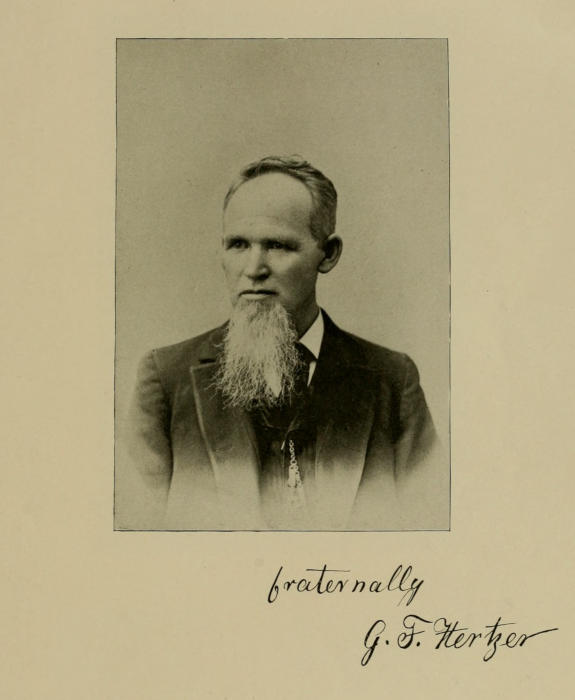

GÜNTHER F. HERTZER,

AUTHOR,

TIFFIN, OHIO.

Copyrighted 1892.

THE B. F. WADE CO., PRINTERS, TOLEDO.

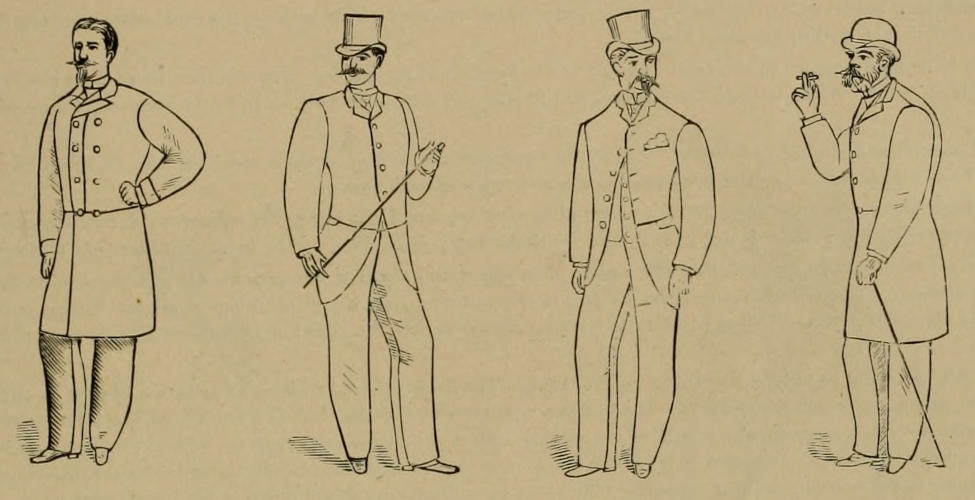

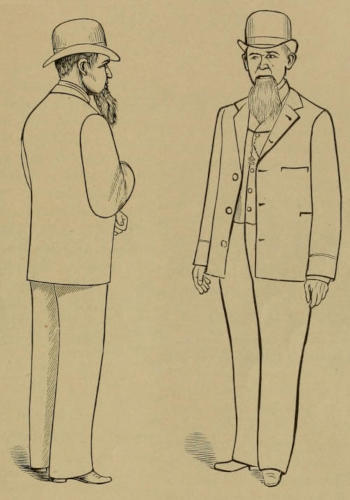

Nothing is claimed in this book pertaining to Styles of Fashions. It is true the fashionable parts of all the diagrams are taken from the latest Fashion Reports; but these will not last, and consequently the fashionable part is of little value. What I claim of my own work is the BASES, which must be considered permanent, and from which all changes must be made for different styles, or for abnormal forms. The principle laid down in this work, is: To fit the form of men, making the change of fashions to conform to the fit. The Bases I have adopted are new, in the science of Garment-Cutting, and all calculations are based upon horizontal, perpendicular and parallel measures and lines. The slope of each shoulder, as 22½ deg., is taken as a Base for a garment worn around the neck and shoulders, and the garments built downward from that Base.

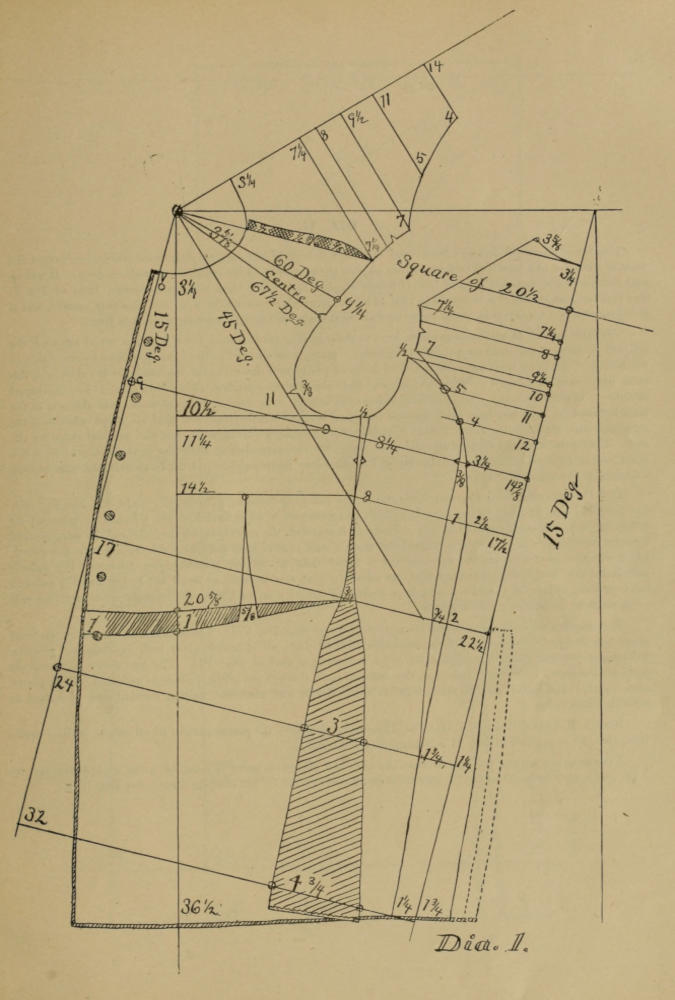

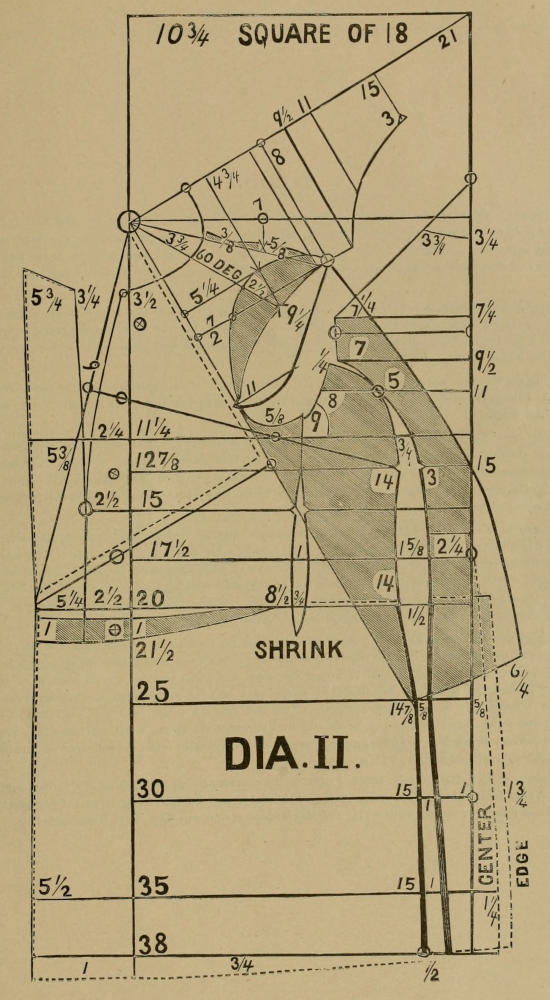

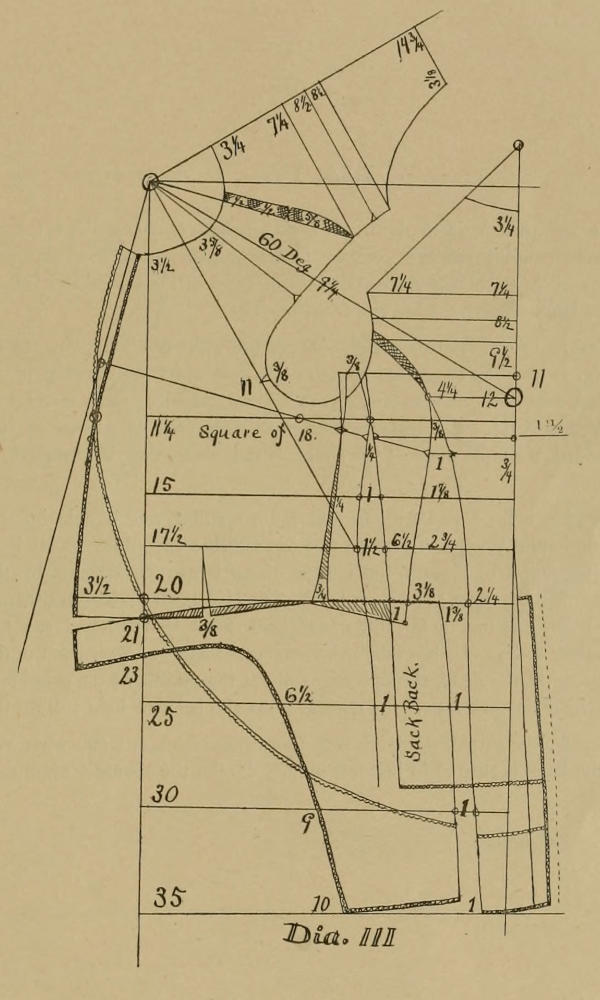

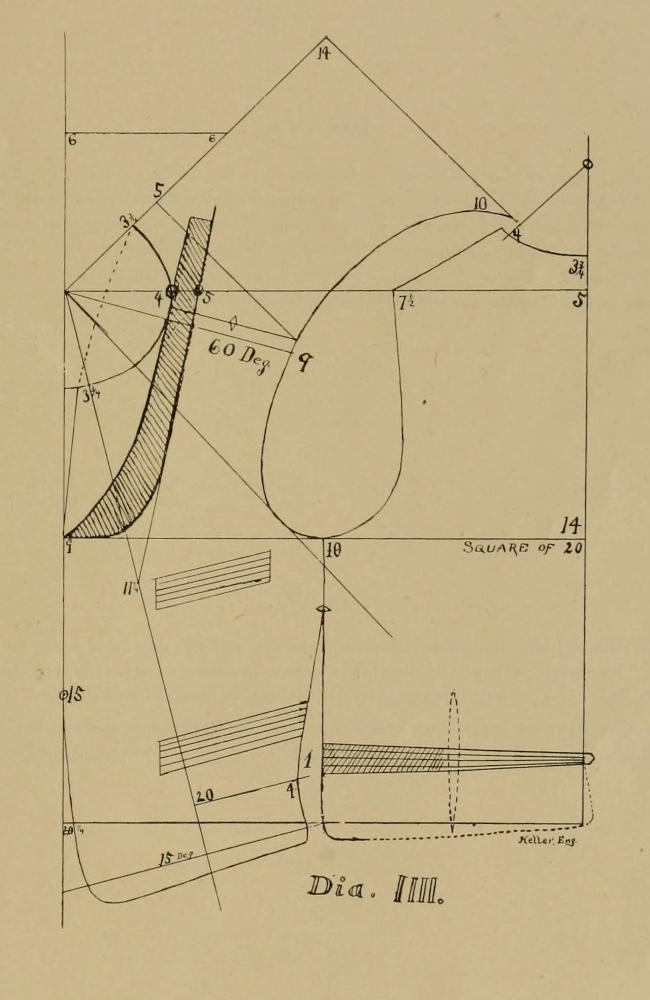

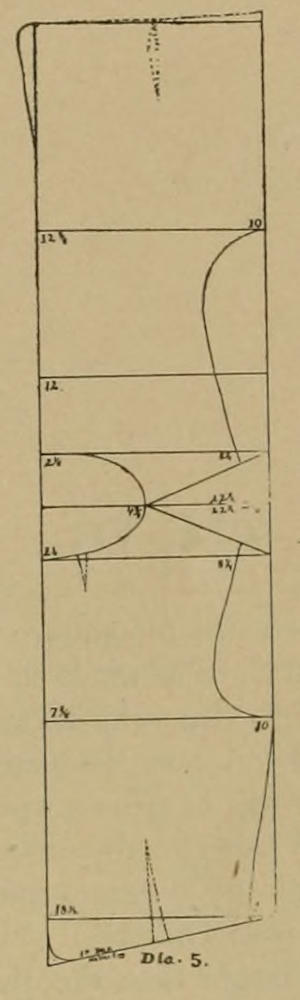

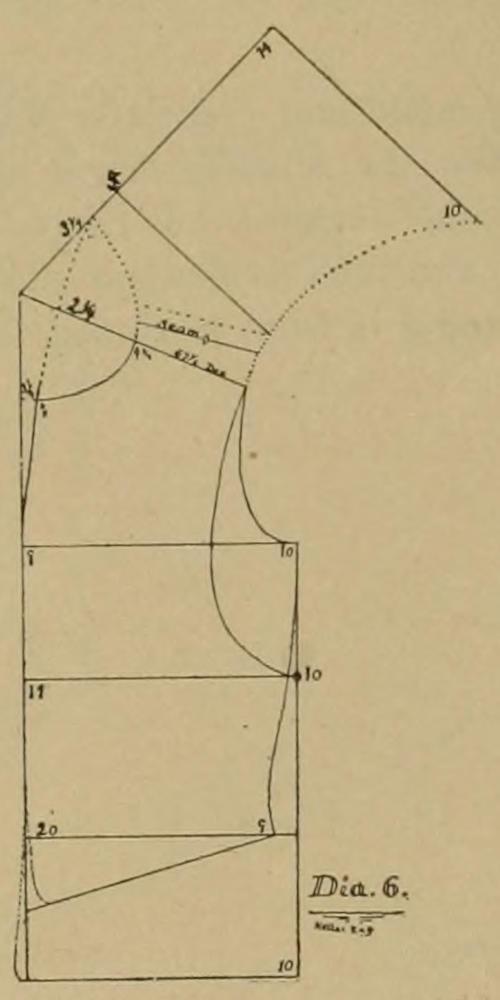

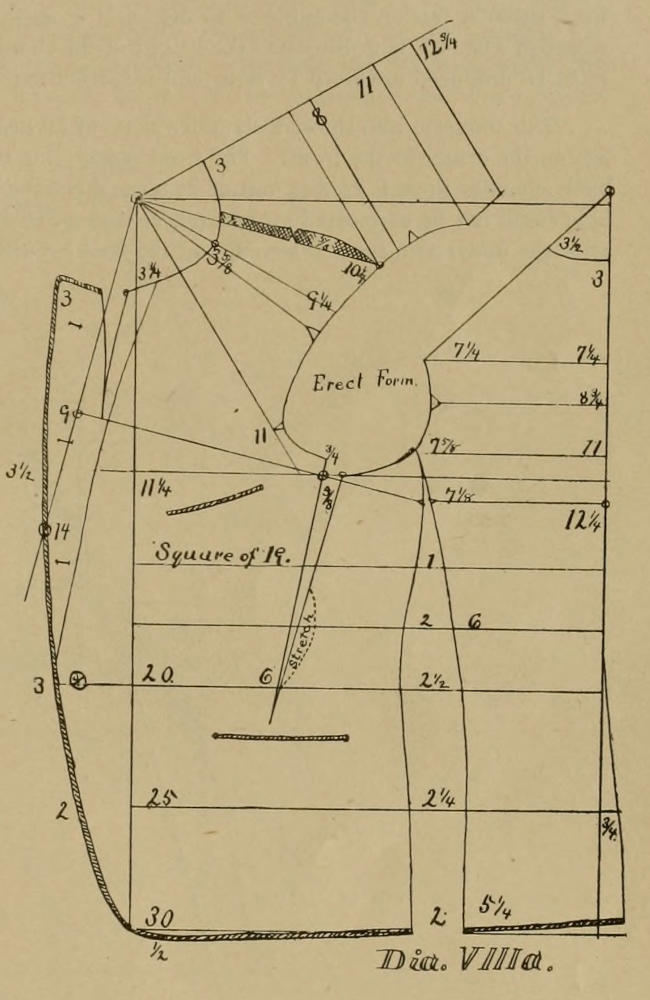

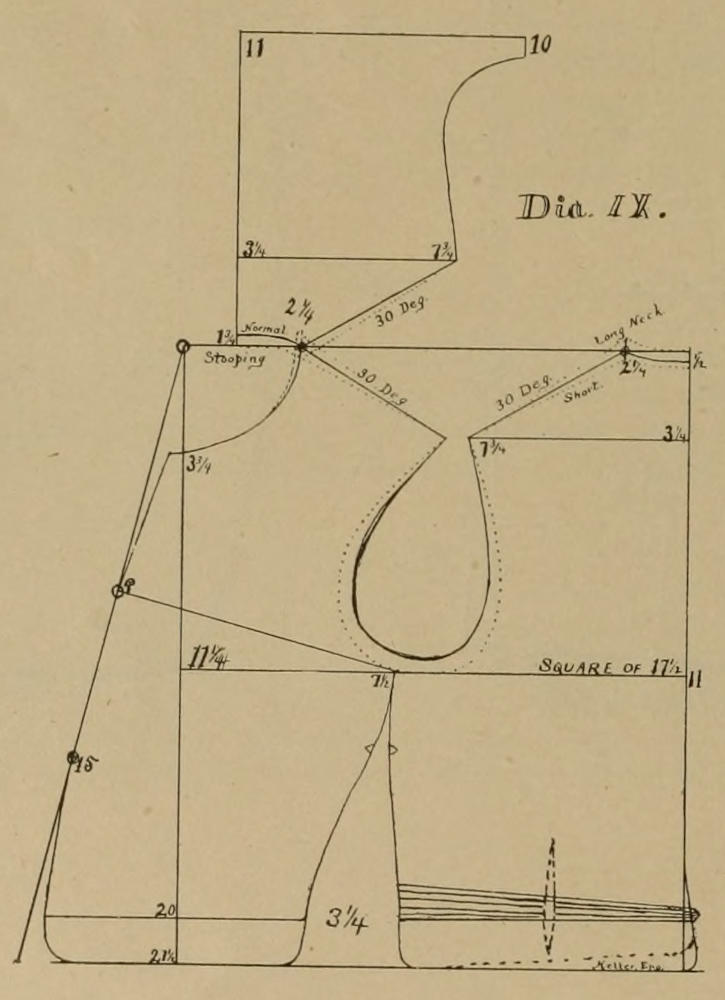

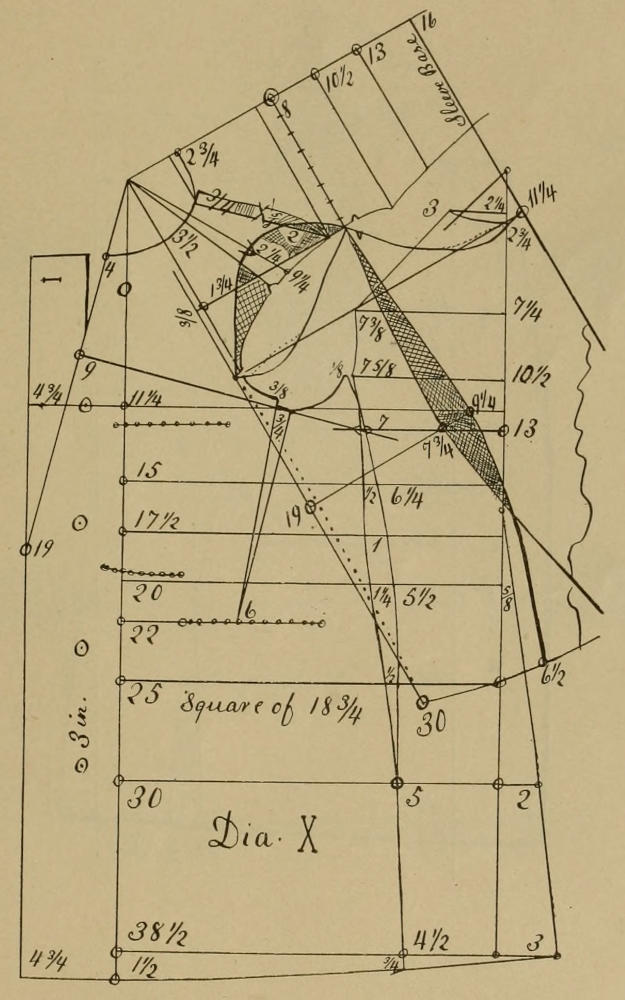

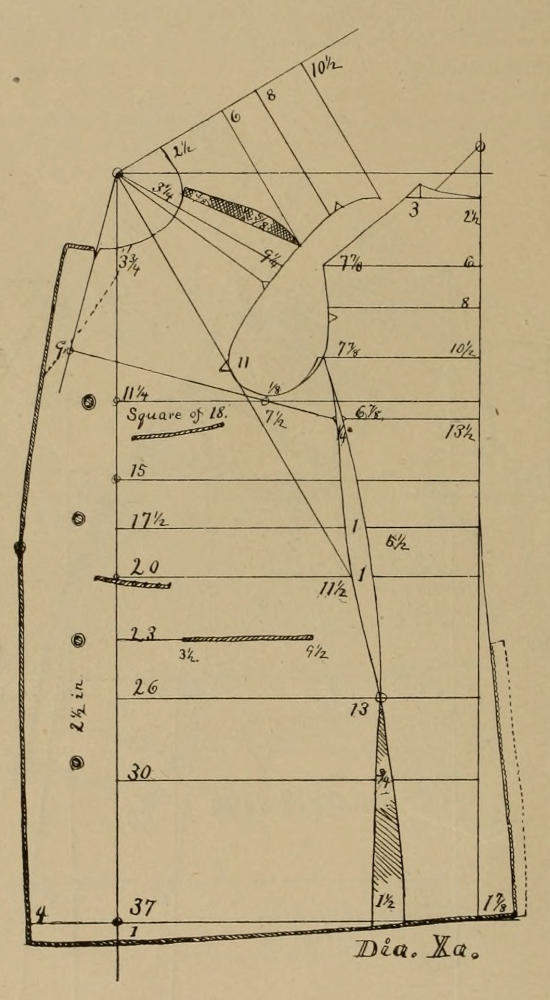

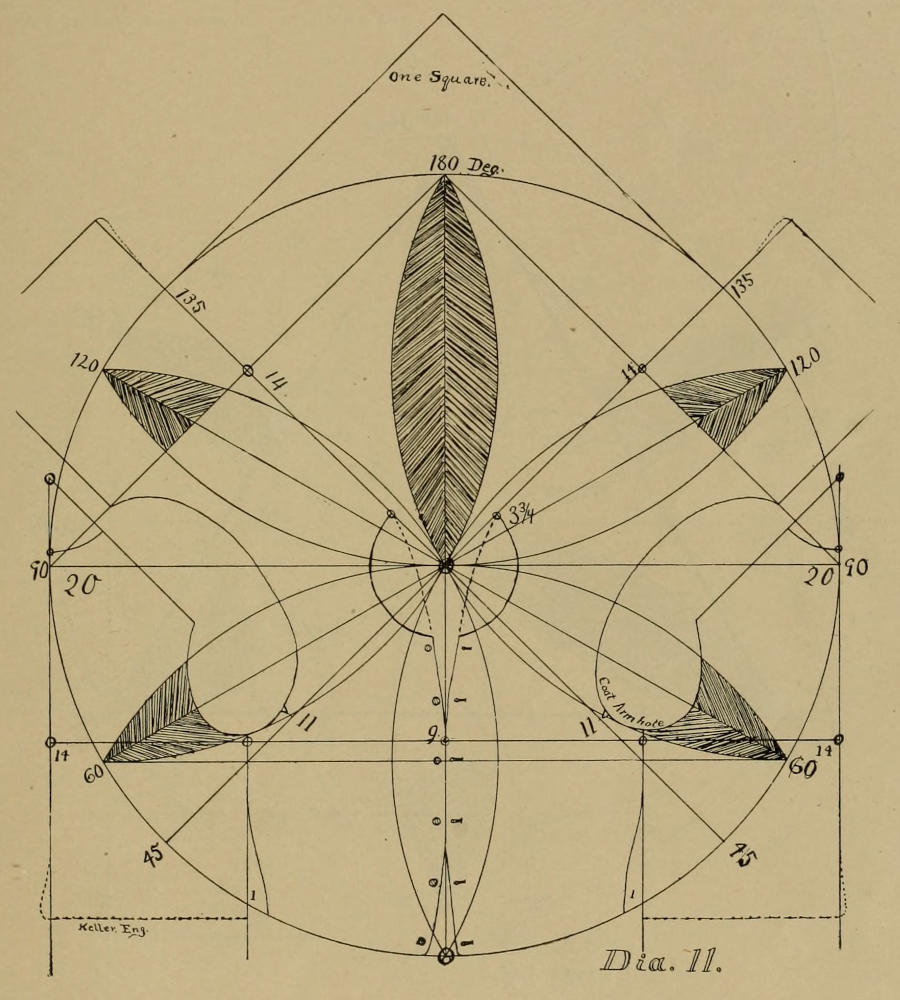

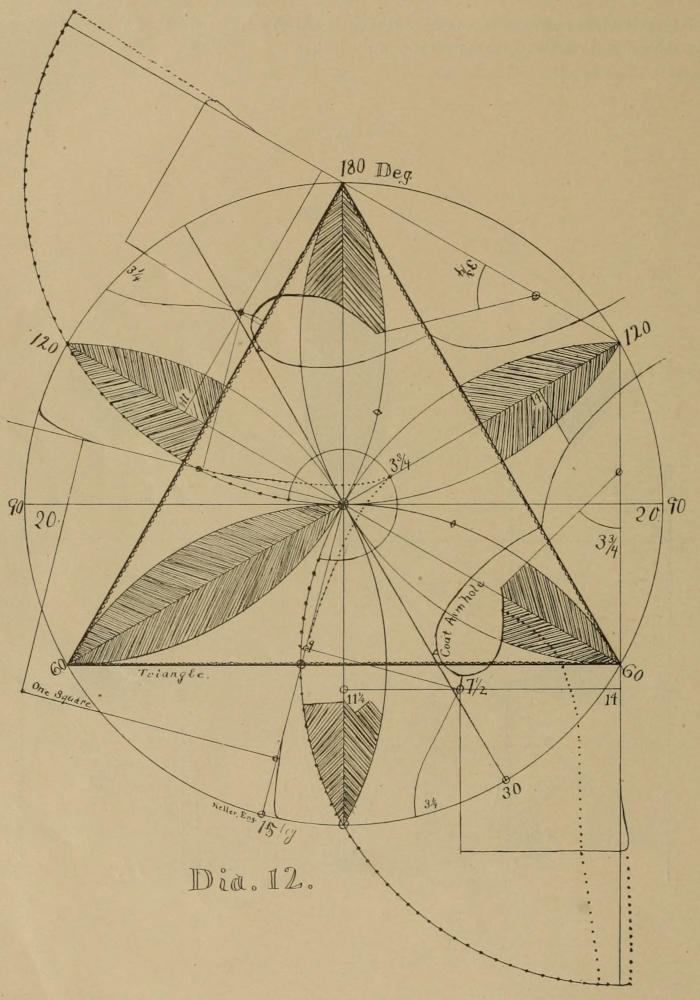

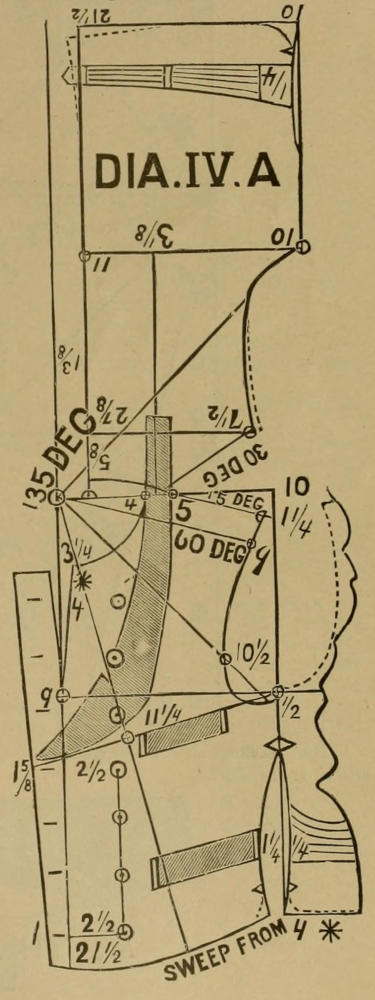

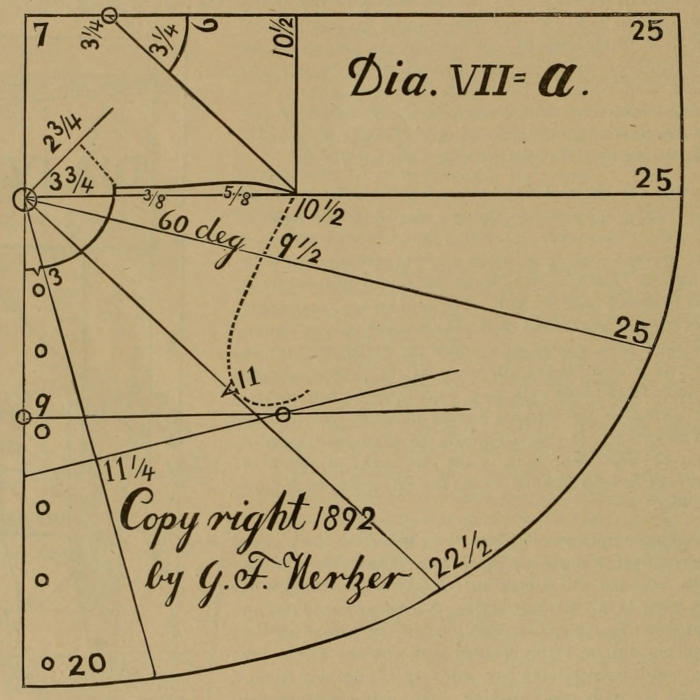

All Bases are clearly defined by illustrations and description; and all gores cut out, or wedges put in, either natural or artificial, are minutely described according to the spreads or hollows of the body. The illustrations or diagrams are given both from a corner of a square, and from the center of a circle, with the same result.

I know that, after the publication of this work, some men will hew off some rough corners, and give it more polish; but this is the case with all inventions and new things, and I do not expect to be exempt from that rule. In fact, I know that this work is incomplete; but I can leave it to future time, either through myself or others, to take up the thread where I leave it at present, to unravel any mysteries that may yet be hidden. But the Bases and their application will remain, and will be so used in the twentieth century and thereafter, as long as clothing is worn and men retain their present general form. Some will no doubt say that certain of my methods cost extra study, all of which I admit; but cutting and making garments have been, are now, and always will be, a study; and so far, no man’s life has been long enough, and likely no man’s life hereafter will be long enough, to complete it. This work indicates the right direction for study, and does not allow the cutter’s nor the tailor’s brain to become dormant. My experience is this: Better study one extra hour over a garment than spend a whole day in altering it. The Merchant Tailor’s success depends upon one thing only, viz.: How he succeeds in pleasing his customers. Some cutters will ask for something definite in the shape of a new system; something that requires no study nor constant watching. To such let me say this: Whenever an infallible system of garment-cutting is to be invented, it must be something like a machine, which always does the same thing with the same result. Such an invention cannot be acceptable so long as the fashions and the styles are constantly changing. If, however, such a machine could become acceptable, the occupation of Custom Cutters would be “forever lost.” Nothing of this kind is claimed in this work, but this I do claim: that it is better and more practical, and far more comprehensive, than anything heretofore known. Neither do I claim that it will work equally well in the hands of every cutter, because no machine will work well unless directed and supervised by a skillful operator—one who knows every detail of its construction, and attends to it carefully.

I call this work a scientific calculation within both the square and compass. But I do not claim any knowledge of science, nor even of geometry, except perhaps what may be called “home-made.” What little I know about geometry, I learned after I became forty-five years of age, and had begun to jot down my experience. Neither do I claim to be a Fancy Cutter; I do not even claim to be a Fancy Tailor; nor do I believe that I ever was cut out to be a tailor. But somehow I started to learn the trade, and when I was once at it, I made up my mind to learn it as well as anybody, even if it took me a few years longer perhaps than some others. Yet all of this is no reason why I should not be able to make a better survey of the human form than any other man has done so far; and in fact anyone, not a tailor, could have done so if his interest had been directed that way. It is a fact that the sewing machine was not invented, nor perfected, by tailors. It was accomplished by others, who knew nothing of tailoring, but they learned to make one good stitch in a quick way, and that was all.

I have been on the bench and cutting-board forty-four years, and I do claim that I have observed and learned something in that time which is worth while to preserve, and I have written it in language so plain that all tailors may understand. In 1878 I began to jot down my experience, illustrating everything by diagrams, and have up to this time written and illustrated each year two books like this, all of which I have in my possession and intend to preserve. I presume I could write ten years longer without exhausting the subject; but I feel the weight of fifty-nine years upon my shoulders and have come to the conclusion that I must clear away all old rubbish and publish what I know is reliable. This volume is the result. For the last ten years I have been carrying on a Merchant Tailoring business for the purpose of testing every garment which I cut. Any new idea that came to my mind I carried out by making a garment accordingly; and if I was wrong, and made a misfit, I made the necessary alteration. I could do this because I had no “boss” to curse me—I was my own “boss” and I paid for the music.

The above remarks are made to show that this work is not a mushroom idea, but based upon the experience of nearly half a century. For the reason that this century is nearly ended, and that, at best, this work will not be generally known, until the next century, I have named it Garment Cutting in the Twentieth Century. If any one doubts that I have been working for years to prepare this work, let him look up the “American Tailor” of December, 1883, and November, 1886, or the records of the Patent Office in Washington for 1878.

I will here say that this book has been written between working hours, or at odd hours, or days when I had the time to spare, and that from time to time the manuscript had to be changed as well as the diagrams, and then revised again. This has been the case from 1878 down to the present time. I do not wish to convey the idea to any one, that the Bases, as laid down in this work, were caught on to in one great lump and that this work is the result of the grasping of one great idea. When about eighteen years of age, I came to the conclusion that no system of garment-cutting, then existing, had an intelligible Base to work from, and that all so-called Bases were nothing but imaginary lines, to suit this or that cutter’s fancy, and this is the case to-day. That being my conclusion, I tried to find something on which I might have a better hold.

Like Columbus, I had an idea that there was something beyond, but had no conception of its form. Of geometry I knew nothing, except, that “a square is an angle of ninety degrees, or the fourth part of a circle,” but I found that I was helpless without geometry, and, at so late a day for me, I had to roll up my sleeves, as it were, and learn at least enough of geometry as this work requires. (Who will throw the first stone at my ignorance?) After I was able to divide the circle, the Bases, as laid down in this work, were gradually adopted, one by one, and so arranged that they harmonize with the slopes of the body. I have a hold now, and I can always tell whence I came, and whither I am going. I have a starting point at the center of a circle, I can tell that I sink my shoulders twenty-two and a half degrees; that the center of back and the center of front rest on one angle of one hundred and thirty-five degrees; that the front of armhole is forty-five degrees from the front, etc.; all of which may be understood by the whole civilized world. And if some cutters and tailors do not understand it, they can learn it in a few hours, and can learn it as quickly as they can any other rule.

It may be asked, can such angles always be drawn correctly? to which I will answer: No, not always; but it serves the purpose. Our grocer never sells us an actual pound of coffee, nor does our dry goods dealer sell us an actual yard of calico, but what they sell us is as near as they can come—it serves the purpose, and everybody is satisfied. The variations of the lines from the center of a circle are not greater than are the right angles from a square or from a straight line.

I have been advised to write this book as though it were written by a person residing in a large city, but I do not deceive any one, and admit that at the present time “Tiffin” has only about twelve thousand inhabitants, but that it is located in the big State of Ohio, and that Tiffin has more natural “gas” than New York and Chicago together. I do anticipate the question, “How much knowledge may come from a small city like Tiffin?” but I console myself with the fact that a like question, “What good can come out of Nazareth?” was asked two thousand years ago, and it has been answered in favor of that little village, and to-day these questioners are regarded as a set of conceited asses.

Advanced ideas do not necessarily come from large cities, or come to a focus there. Moses, the great law giver, caught his inspiration while among his flocks; and so did the poet, King David. St. John, the Baptist, and Christ himself took to solitude in the wilderness before entering upon their mission. St. John, the evangelist, wrote his Revelations on the lonely island of Patmos. Dr. Luther formed his reformatory ideas within the walls of[v] a cloister. The great emancipator, Abraham Lincoln, no doubt caught some of his ideas while working on a flat boat, or while splitting rails. In the face of such facts, I do not see why a common tailor, living and working in a small city, cannot have some advanced ideas about Garment Cutting, even if they are written down without a perfect knowledge of English grammar.

I was born in the village of Niederwillingen, in the Principality of Schwartzburg, Sondershausen, Germany, on the 10th day of April, A. D. 1833. I received a good common school education. In the spring of 1848, when the revolutionary cannons were shaking Germany for freedom, I was sold as a slave (apprenticed) for three years to learn the tailor’s trade, and came to America on the 17th day of September, 1852, then but nineteen and one half years old, and have never had any schooling in the English language,—but what I know I have picked up here and there, in the tailor’s shops, stores, lodges and churches. For this reason, this book may contain words which might have been different, but it is written plainly, and in such terms that tailors and cutters will comprehend.

During the year 1891 I have worked mostly on this book, comparing diagrams and writings, and changing anything that I thought would improve it. But I find that if I keep on comparing and trying, I shall never be done, for I always find something else to write. A little over a year ago, I thought I would go to work and cut it shorter, the manuscript then having about fifty thousand words, and now it contains about one hundred and twenty thousand words. This is the way I have cut it shorter. But I do not see what I could strike out again, even if I should make the attempt.

G. F. HERTZER.

Tiffin, Ohio, March 2d, 1892.

All dimensions mean numbers of the scale, unless specially called inches or referring to the size.

All scales are one-half breast or one-half seat, and two and one-half inches, divided into twenty even parts. The two and one-half inches addition to the one-half breast or seat measure makes the small sizes large enough and the large sizes small enough for all purposes.

Take the breast measure over the vest for both undercoat and vest.

The circumference measure of the breast and seat must be taken tightly over the vest and pants. The breast measure is to be taken with the tape touching the extreme point of the shoulder blade, with the lungs empty. The seat measure must be taken over the largest part of the seat, which is about three to three and a quarter above the fork or junction of the legs.

The half coat as well as the half pants take up about one and a fourth inches for seams, leaving about one and a fourth inches slack for other purposes on the half garment. This measure is to be taken with a small tape, and all the diagrams are calculated accordingly.

In taking a measure around the human form, there will be found a difference of from one and one-half to two inches between a narrow tape and a strip of cloth ten inches wide. The narrow tape cuts deeper into the flesh, and therefore will record less surface measure than a strip of cloth ten inches wide. If we take a narrow tape and a strip of goods, say ten inches wide, and with both measure over the seat or chest, drawing one as tightly as the other, we will find that the broad strip will record about one and a half inches more on the whole circumference. Now, if the broad measure gives three-fourths of an inch more over the half breast than the narrow tape, then it follows that, after sewing seams, there will be left half an inch on the half frock coat only for expansion of the lungs and the movements of the arms.

The same is true of the pants, and though they require nothing for expansion of lungs or movement of the arms, yet it requires a certain space for expansion while sitting, for it will be found while a person is in that position his seat, hips and waist will expand anywhere from one to five inches, but the waist will expand the most. The seat, hips and waist require their circumference measure while sitting—nothing more nor less—and, consequently, seams must be added to that measure, and must be applied at the point which I have termed “the seat line,” as shown in Dia. XIV., and on the back on the upper line. If stitches are drawn in, on that line, it will be found that when the pants are on the body said line is a horizontal one all around, and at the largest part of the seat.

A large and fleshy person, particularly one with an extra large abdomen, cannot be fitted with the old maxim, viz.: Make the half-waist one-half the measure and add three-fourths of an inch. This usually holds good as to persons with small waists, who do not spread much in sitting, but when a large-waisted person, who perhaps weighs 250 to 300 pounds, assumes such a position, his legs will press his stomach upward, decreasing it in length and expanding it in circumference. There may be persons with sole-leather stomachs who can stand any pressure for a short time, or while taking a meal, but when compelled to sit most of the time, they want their pants large enough to be comfortable while in that position. It is true, such pants must hang loosely while standing, and must be supported by suspenders, but this difficulty cannot be overcome.

This work takes the seat measure as a guide to select a scale, no matter if the hips are larger or smaller than the seat; nor if the waist and hips are larger than the seat, proper allowance must be made there. And it should be observed here that whenever the hip measure is larger than the seat measure, it may be concluded at once that said large hip measure is caused by the unusually large abdomen directly in front.

In regard to the taking of measures close or tight, the following must be observed: A person may be measured over the breast very close, like a stove pipe, and will not object to that pressure, for it lasts only a short time; but subject him to that pressure for five minutes and he will not endure it. He cannot endure it, and the pressure would be still more intolerable if the tape should be ten inches wide. It is very important for the cutter to know what he is measuring, and with what he is measuring. Old and experienced cutters have learned this at[7] much cost, therefore young cutters should be told this in the beginning. Young cutters should be instructed to always request their customers to remove their coats at the time of measuring, and take the breast and waist measure from behind, because the breadth of the two will not always agree.

To obtain satisfactory length of sleeve is often a difficult job. There is the style, then the notion of the cutter, then the notion of the customer, and lastly the notions of the wife, mother and aunt—all of which frequently have a word to say in the end. Therefore the best of cutters are often obliged to alter the sleeve length. The young cutter should locate for himself a permanent mark at the wrist, so that he is able to take such measure always the same, and whenever he finds that his sleeves become too long or too short, he can readily make the necessary change in measuring. But to obtain a thoroughly satisfactory sleeve length, the cutter must know at what point to transfer the measure to the cloth. Different systems produce different sleeves, and the seams are located differently. The sleeve, as given in this work, has its centre at eight on the back, and there the sleeve length must be transferred, no matter where the seam is located; for if the back sleeve seam is further down, and the sleeve length is transferred at the seam, then the sleeve will become too long, and vice versa.

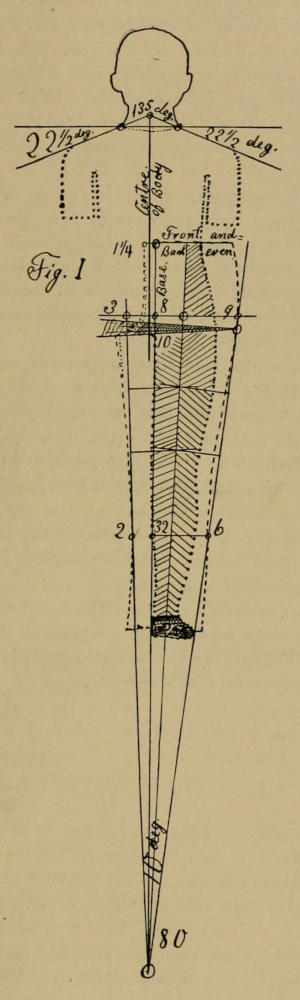

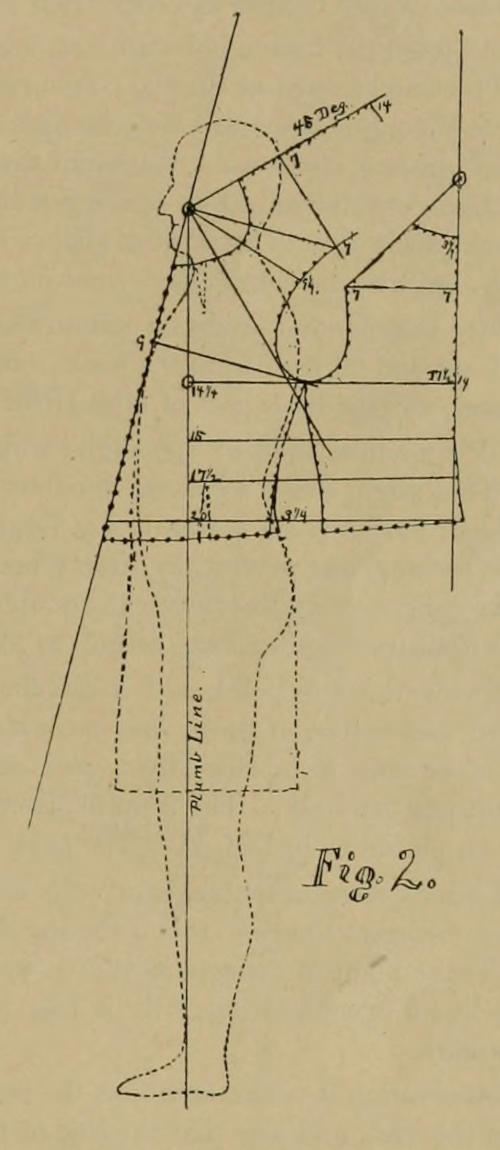

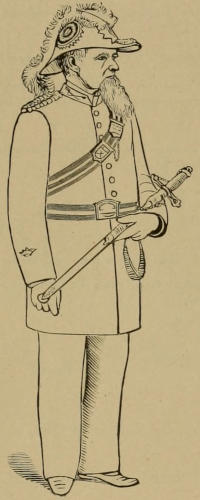

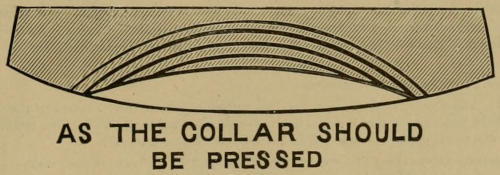

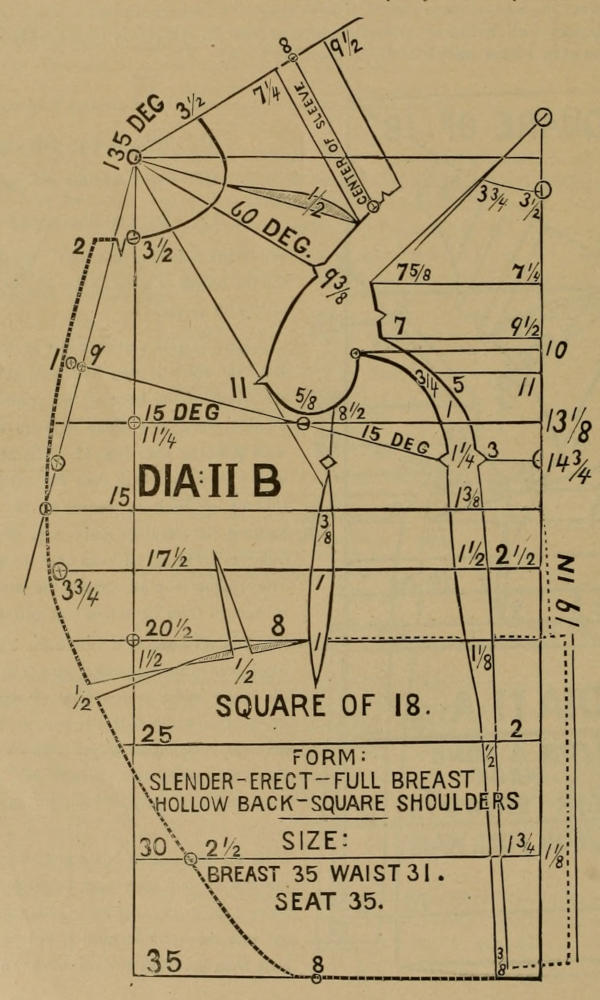

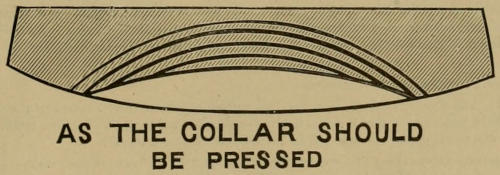

The angle of one hundred and thirty-five degrees, cut from a piece of pasteboard or tin, and as large as both shoulders, is a very important measure, and should be applied as shown in Fig. I. I do not claim that this measure can always be taken exact even over a good-fitting coat, but it can be taken with as much certainty as the breast measure, and it serves the purpose.

To measure the slope of the shoulders, the angle must be adjusted at the highest points of both arms at the side of the shoulders, and if the sides of the neck extend up higher, or lower, that amount is to be noted down, and it will be found that only extreme cases require alterations. Extreme cases, and I should call all such in which the difference is three-quarters higher, as on low shoulders, or that much lower, as on high or square shoulders. No attention is to be paid to the variation, if it is only one-quarter inch more or less, as in fact the sides of the shoulders, at the arms, are not to be fitted as close as the body itself indicates. It may not be out of place to mention here how to draw that angle of one hundred and thirty-five degrees, for it is a new measure and an unknown quantity to the great majority of cutters at present:

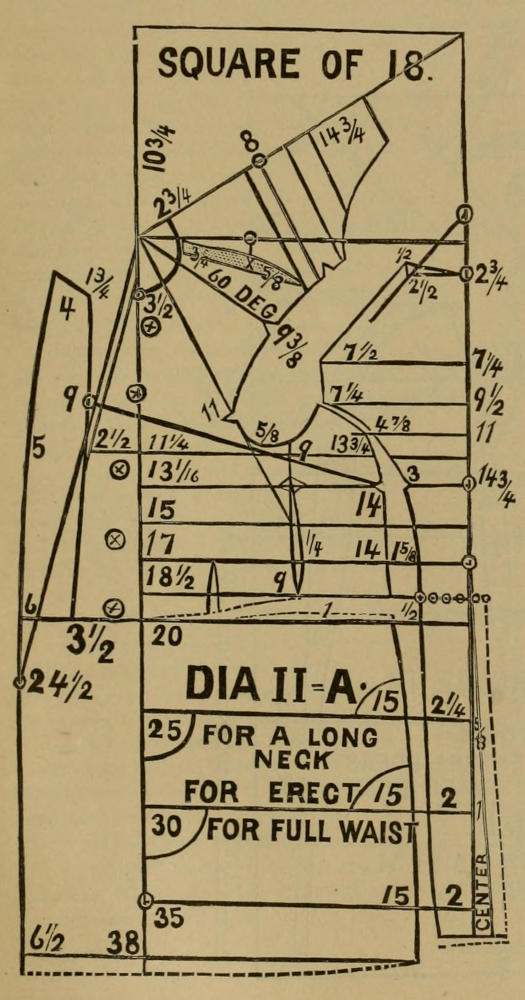

Form a right angle; from its point draw a circle as large as you can, and form two points, as shown in Dias. XI and XII; draw a line from the starting point to the second point of the circle, which will make one angle of one hundred and twenty degrees, to which is added fifteen degrees in front, to make the angle of one hundred and thirty-five degrees. The fifteen degrees are two lines spread one-quarter of their length, as a part of a circle twenty inches long and five inches wide. The angle of one hundred and thirty-five degrees is also one square, and one-half square, and may be found as follows: From the center of back and through the starting point draw a right angle, as shown by the front sleeve bases in all the diagrams, and on that line, go down, and square across and forward at equal distances, say twenty inches, and through that point draw the front line of the angle of one hundred and thirty-five degrees. Forming a right angle, and marking each line at equal distances, and drawing a line through said equally distant points, is equal to cutting a square in two from point to point, and consequently, said points will form an angle of forty-five degrees. The square contains ninety degrees, and the half square contains forty-five degrees, and the whole of it is one hundred and thirty-five degrees. (See Dia. II-A.) In all cases where an angle is to be found, the dimensions should be taken on a large scale, because on a large scale the variations are less than on a small scale.

The form of Dia. I is correct, and may be used as an instrument to measure all shoulders, and the edges of the angle should not be less than eight inches and may be drawn out more. It should be large enough to reach over both shoulders of a full grown person. The application and the use of said angle of one hundred and thirty-five degrees is fully described elsewhere.

How to make a scale: Take one half breast measure and two and one-half inches, in all cases, and divide the result into twenty equal parts. The common inch will produce a breast size of thirty-five, and the same for the seat size. Seventeen and a half inches is one-half of thirty-five, and the two and one-half inches make the twenty units for size thirty-five.

To make the larger or smaller scales: Take the half-breast and two and one-half inches; mark the half, the quarter, and the three-quarters of it, and divide each quarter into five equal parts with a compass, and then divide each unit into halves, quarters and eighths. A cutter should always know just what his scale contains, and should in all cases be able to make his own scales.

The use of fractional scales is not necessary. If the measure indicates a somewhat larger size, say thirty-six and a half, take a scale of thirty-six for a short person, and do not cut away the chalkmarks in width. If the person is tall, take a thirty-seven scale and cut away all the chalkmarks in width. Ordinarily, make small chalkmarks and cut them through in the center. Material which requires large seams should also be cut on the outside of the chalkmarks. It is an easy matter to cut a garment one-half size larger or smaller, without using fractional scales.

A set of scales will accompany each copy of this work; but any graduated set of scales can be used. All we have to do is to select a scale which contains one-half breast and two and a half inches, in twenty units. Such selection may result in a fractional scale by some, but it can be used. There is no other system in existence by which a forcing scale can be used, and give satisfactory results. (See article on “Scientific Calculations.”)

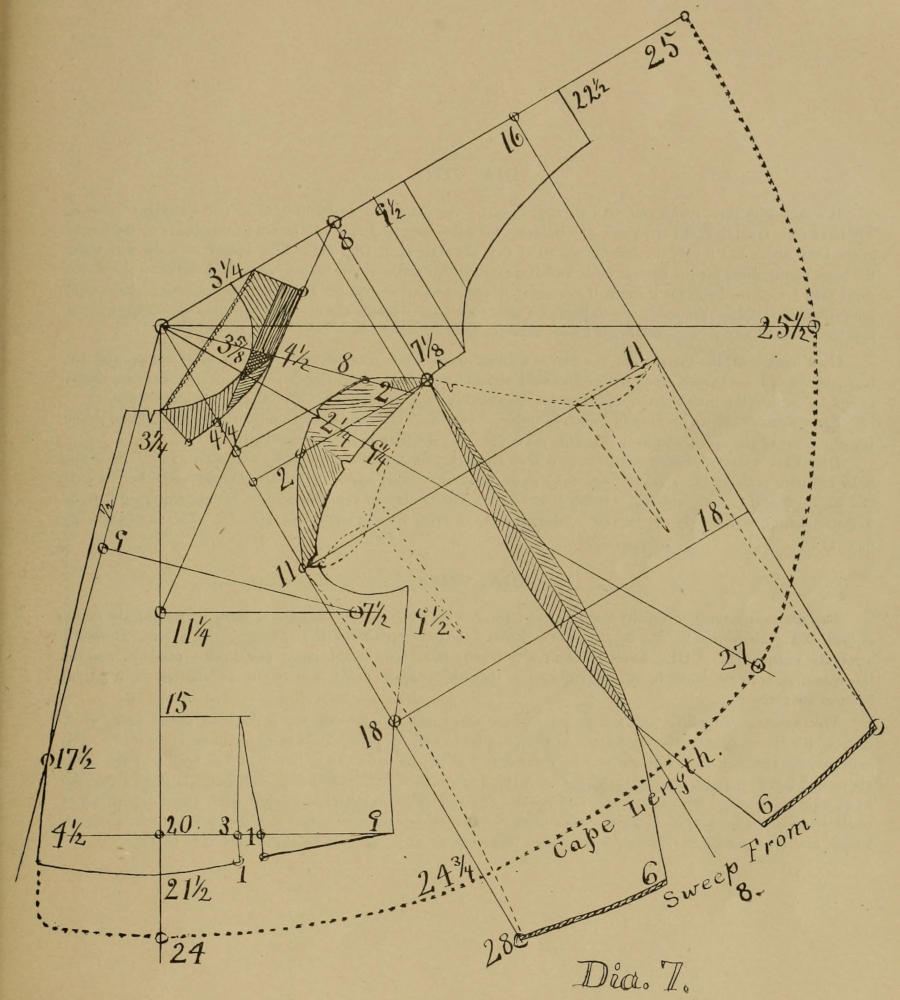

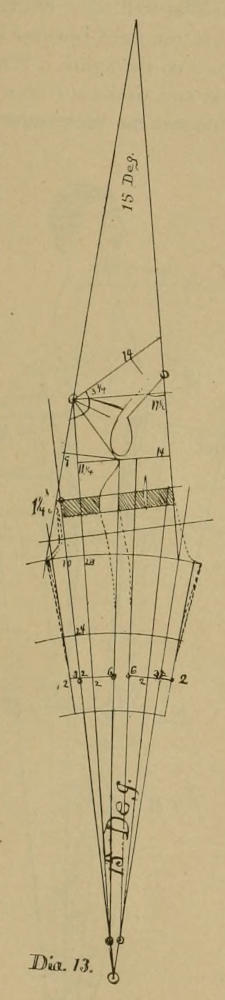

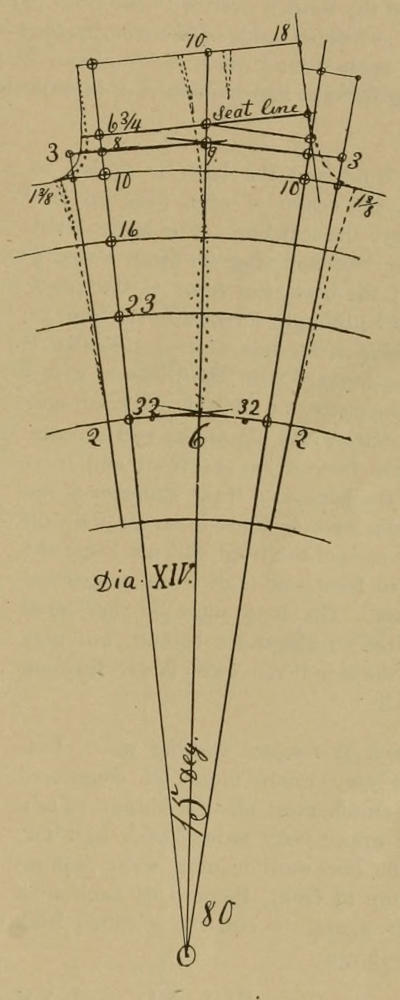

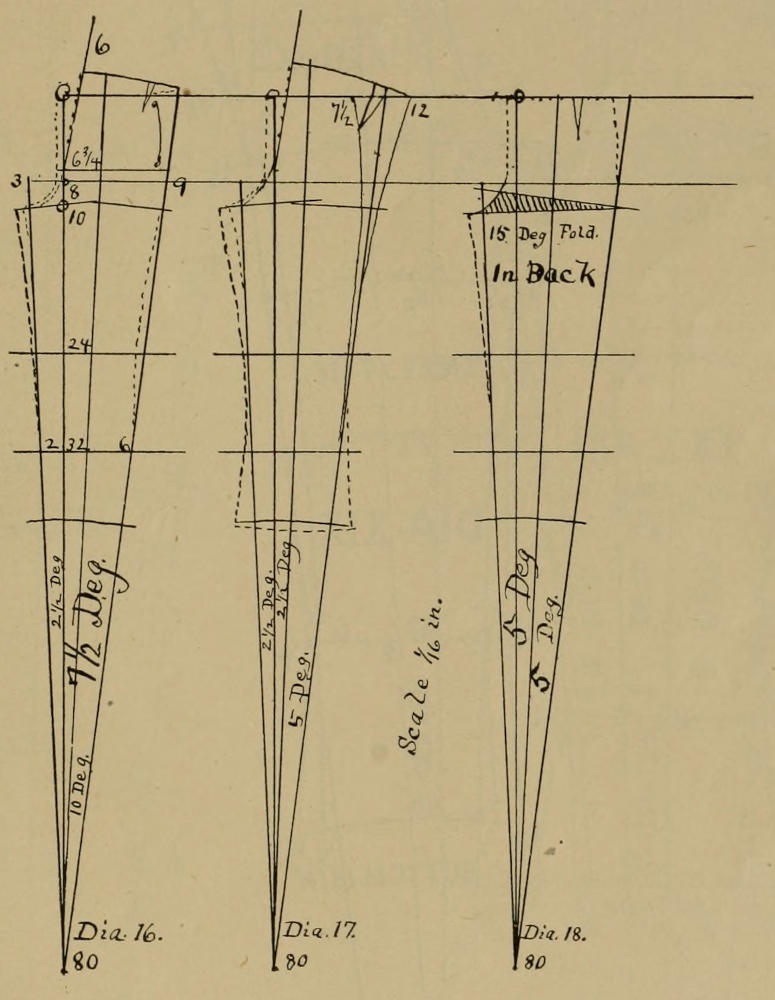

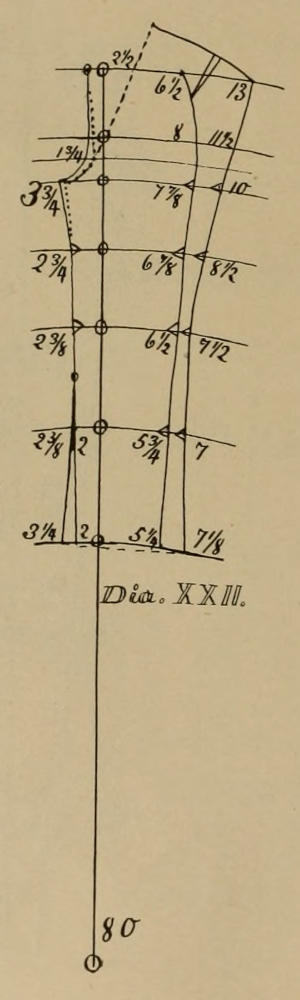

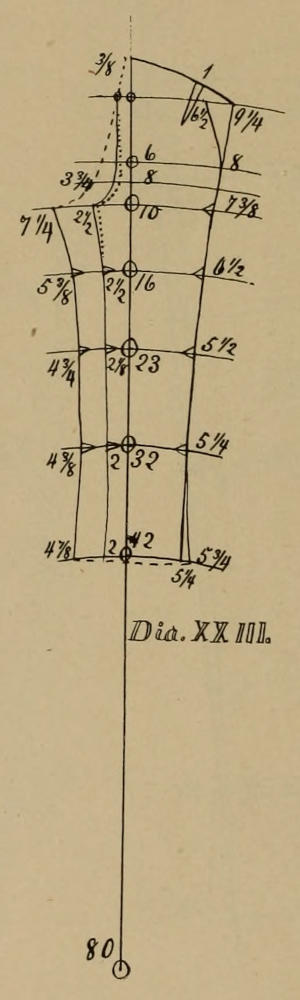

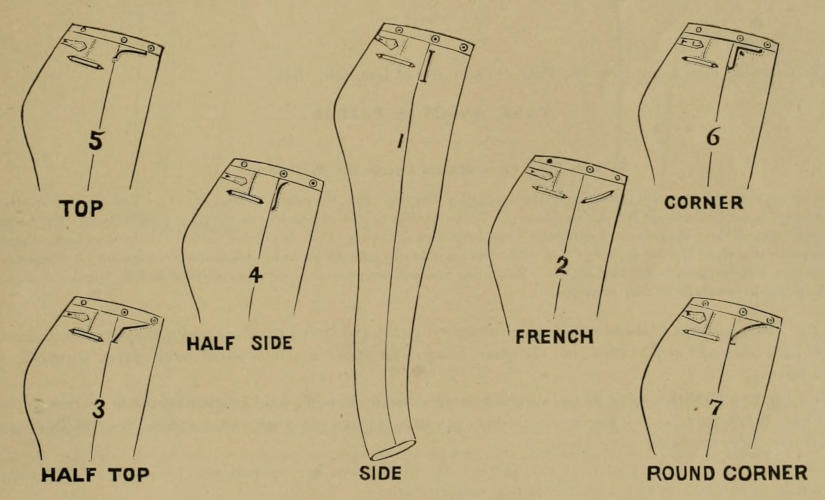

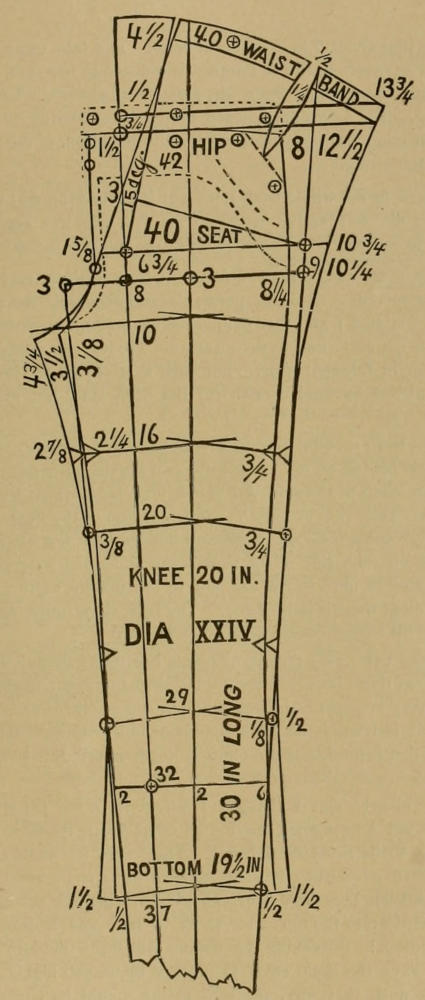

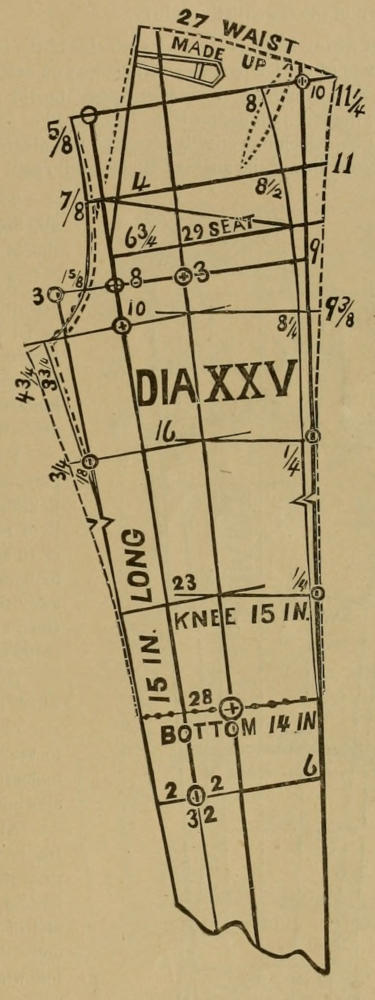

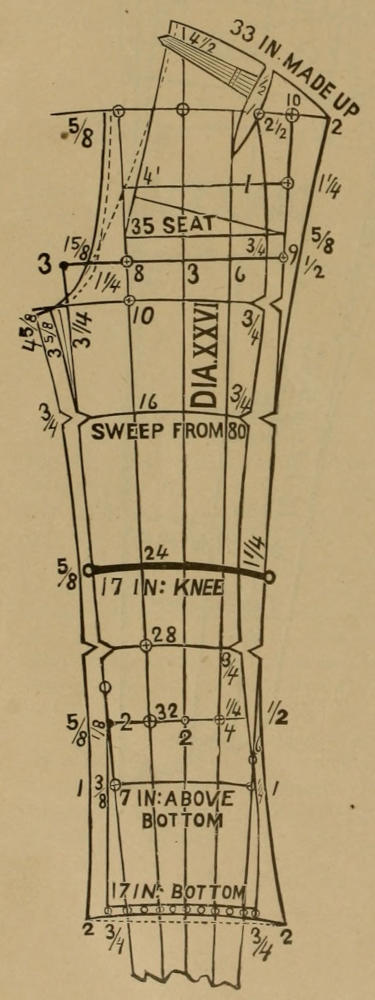

Scale: One-half seat measure and two and a half inches, divided into twenty parts. Form an angle of seven and a half degrees, and mark it ten numbers wide, at a length of eighty numbers, or one-eighth of its entire length.—The angle of seven and a half degrees has a width of one-eighth of its length. At the top of said angle, or at the width of ten numbers, start the top of pants, and go downward ten numbers for the fork or crotch, and continue downward a distance of thirty-two numbers from the top; again mark eight numbers from the top, or two numbers above the crotch; at the points eight and thirty-two is an even division for the purpose of dividing the angle of seven and a half degrees into three equal parts, or two and a half degrees each; at eight go sidewise three, six and nine, and forward three; at thirty-two go sidewise two, four and six, and forward two; strike lines through two and three, four and six, and six and nine sidewise, and through two and three forward. Each line will represent an angle of two and a half degrees. Except for equal divisions, points eight and thirty-two have nothing of importance about them, neither has the line through four and six, which is also only an even division of the angle of seven and a half degrees in three equal parts; but it will be seen that the angle of seven and a half degrees spreads one-eighth of its length; consequently it contracts one inch in eight, and four inches in thirty-two; hence the width of the angle of seven and a half degrees is six inches at a length of thirty-two whenever it is ten inches at the starting point.

The front line of the angle of seven and one-half degrees I use as a base to work from, but either one of the other lines would be just as suitable a base, particularly the line from two and three sidewise, which is to be the center line of the pants leg, and from which line a right angle each way will be nearer horizontal than any other right angle, when the pants are on the body. Consequently it is a good line to square from for both a level top and a level bottom; but for reasons hereafter explained, it is not a sure line to square from to nick the seams when the foreparts are cut smaller and the backs wider; in fact, no square line is sure for that purpose. But a sweep from the point of the angle of seven and a half degrees will make true connections at any point, no matter how narrow the front or how wide the back may be, or if both be even.

After having formed the angle of seven and a half degrees, and having it divided into three equal parts (or in two and a half degrees each), two and a half degrees, or one part, is placed in front of the angle of seven and a half degrees for the crotch or fork. The seven and a half degrees furnish the outside of the pants leg—that is, one front, one side, and one back, except a small fraction of say three-quarters, which is thrown forward on the top of the front of waist, and is further explained elsewhere.

The top and the front edge of all pants is about one-eighth of the whole waist measure, taken close. But if the question should be asked why it is one-eighth of the close whole waist measure, I must say that I can not give any other reason than that it has proven true in years of practice.

The angle of two and a half degrees forms the crotch, to which is added about one and a quarter for dress and extra straddle—as shown in the diagram. The angle of seven and a half degrees, with a width of one-fourth seat and one and a fourth inches, or ten numbers, at the top of waist, will produce three-fourths of one leg; and the angle of two and a half degrees added to the angle of seven and a half degrees will produce the fourth quarter, or enough to cover and to fit one leg, the whole being one angle of ten degrees.

Whatever fashion, or notion, or a larger boot or shoe, may require further at the bottom, must be allowed equally on each side and inside; and again, whatever the forepart may be decreased, must be allowed on the back. Or, in other words, the seams are not placed in the center of either the outside or the inside, but more to the front.

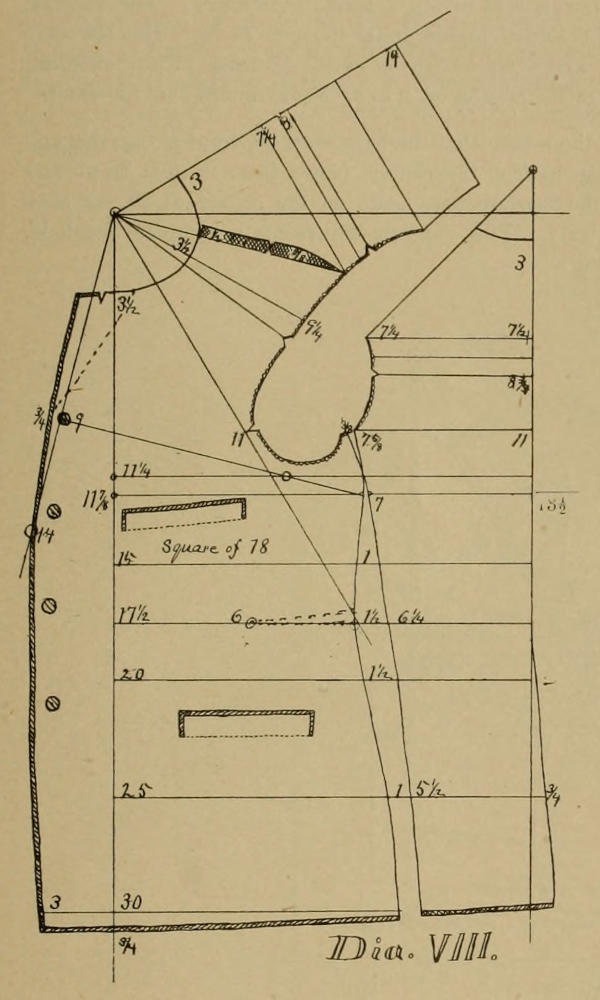

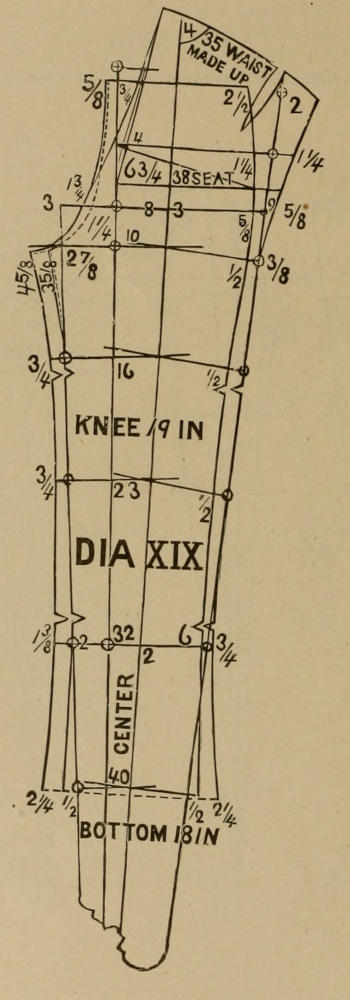

The angle of seven and a half degrees forms the top of the side on a straight line, and the back has from one to one and a half inches gore cut in its center. This gore, however, may be better divided into two small ones—one in the middle of the back and the other at the side seam. The back is sloped off fifteen degrees from the seat line upward, as shown in the diagram. The width of the angle of fifteen degrees is one-fourth of its length, and to draw it, go up ten numbers and sidewise two and a half numbers. Three and a fourth numbers above the crotch is the so-called seat line, from which point the top of the back is sloped off fifteen degrees. The seat line, as shown in Dia. XIV, is a horizontal line over the largest part of the seat when the pants are on the body, and there the seat measure must be taken. It must be taken as tightly as you would measure a stove pipe, or else the pants will become too large.

The angle of seven and a half degrees, with its width of ten at the top of the waist and the back slope of fifteen degrees taken off, and the back seam formed as shown in the diagrams, will produce the two seat lines about nineteen and one-half numbers for the dress side, of which must be used about one and one-quarter inches for all seams, leaving three quarter inches for extra width over the seat for the half pants, which is enough.

Elsewhere it is explained why a narrow tape will record a shorter measure around the fleshy parts of a person than a broad strip of cloth, say ten inches wide. It should also be observed that a broad strip of material, drawn around the seat while standing, will record, say about one and one-half inches more than a narrow tape half an inch wide, both being drawn with the same strain. When a person is sitting, the length of the abdomen contracts, but increases in circumference, and may expand anywhere from one inch, in a person of light build, to five inches in one that is quite fleshy. Therefore, while in a sitting position is the time to make a correct circumference measure over the seat as far as such a measure can be taken, or as far as a correct measure is actually necessary for cutting a garment. This measure, if transferred to the seat line, requires no allowance except for seams. When a person assumes a sitting position, his entire body is on a strain. The seat and abdomen grows very rigid, and in this condition a more correct measure may be taken with a narrow tape. If a pair of pants should be made up as large as such a measure, it will be large enough for a close fit, providing all other parts are correct. There is no question but that a trifle surplus cloth at this point, allowed at the side, will be quite in its place, and will never come amiss, but instead contribute to the comfort of the wearer.

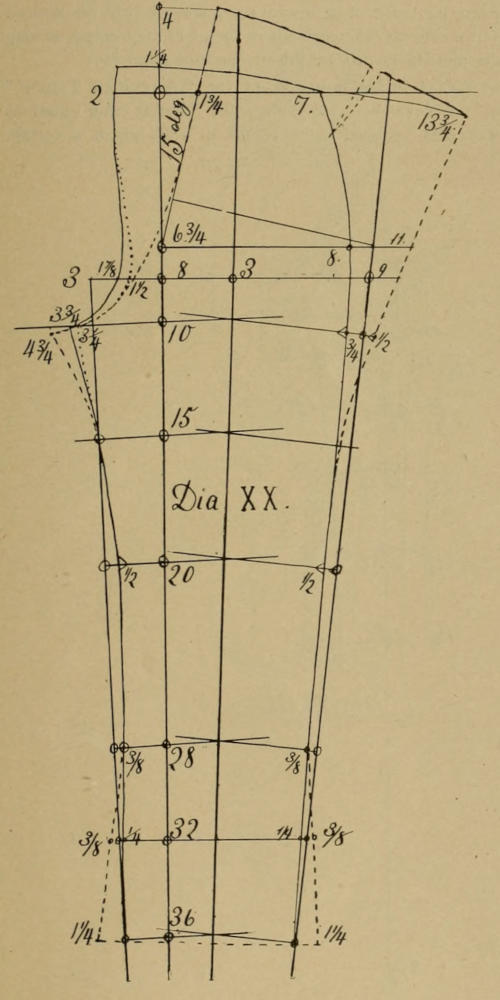

By taking into consideration the sitting or standing position of the body, in connection with the circumference measure of the seat, it is absolutely necessary that the location of the seat line be positively known when the garment is apart and spread upon a flat table, like a pattern. Always bear in mind that the seat line in front will be three and a fourth numbers above the point of the crotch and about two and a half numbers higher on the back, or whatever the spread of the angle of fifteen degrees across the back may be. When the pants are on the body, this extra length in the back of the pants will be taken up in winding around the seat, and pushing backward and downward with the seat; and whatever that takes up must be allowed again on top, as shown in Dia. XIX, or must be obtained from below, as shown in Dia. XIV, which shows the true length as far as necessary. But another inch may be added to the length on the top of the back, in order to make the back that much higher than the front when on the body. In Dia. XX, this extra height of the back is four numbers, and is a permanent thing, even if a larger waist requires the front to be higher. Raising the top of the front for a large-waisted pants is caused by the same principle as raising the top of the back, only less prominent. As the seat requires extra length behind, so does a larger abdomen directly in front require extra length. Hence, large-waisted pants require some extra width at the top of the side in order to throw the fore-part forward and downward, forming a curve over the front of the abdomen; and, that length being supplied from the top of the front, the same must be allowed again from where it was taken. By extra width on the top of the side, I mean an extra width outside of the angle of seven and a half degrees, which is to be the portion thrown forward, and need not in any case be more than an inch. The same amount is enough for the extra length on the top of the front.

To regulate the waist of pants, it is necessary that the waist must be made as wide as the measure indicates when the person is sitting, and it may even be wider if a customer so desires. Some individuals are very sensitive around the waist, and for such pants it will be better that they be two inches too large there, than half an inch too small, or even a close fit. In no case should an extra waist proportion be allowed behind, unless it is to be buckled up or to hang loose; for if it is to be used to supply the waist proportion in front, it must necessarily be drawn forward, consequently will wrinkle the whole pants, and may produce tightness in the crotch. Surplus waist may be allowed behind, as long as it remains under the buckle strap, and such surplus will buckle up[11] straight. But if surplus cloth is allowed in front or at the side, and is drawn backward under the buckle strap, it will draw wrinkles across the seat. Pants too loose at the front or at the side may be all right as long as the wearer will carry them on his suspenders.

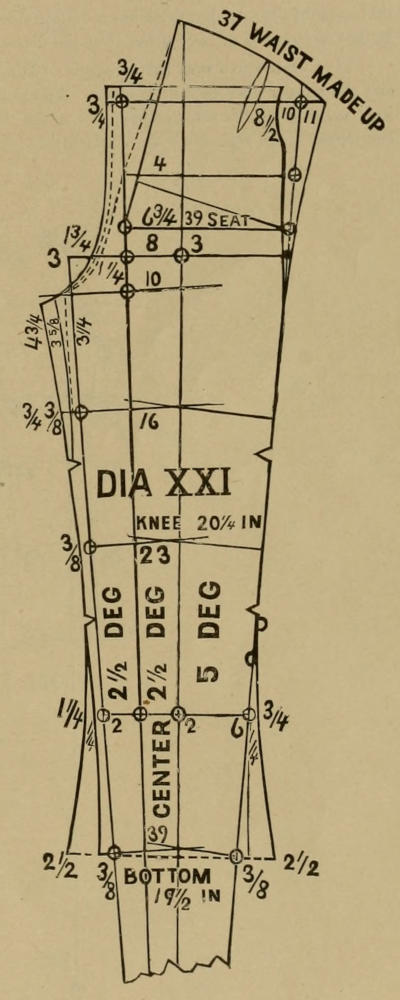

The angle of seven and one-half degrees, with the back sloped off fifteen degrees, and three-quarters allowed in front, must be considered a permanent thing, and within that space and along and around the hollow of the back of the waist, all surplus must be cut away in one or two gores, according to the measure taken in a sitting position. Surplus waist proportion is best allowed by a spring within the back gore, as shown in Dia. XXI, which will remain where it is cut and can not be drawn backward under the buckle strap.

Pants can usually be worn pretty close at the soft, or hollow part of the waist, but they must be plenty large as soon as they come in contact with the short ribs, and such width must be at the sides, as shown in Dia. XXI. Now, if the waist requires more, that amount must be divided into three equal parts, one part being added to the front and two parts to the side; so that when the pants are on the body, the whole will be equally divided,—one part in front, one part on the left side, and one part on the right. The waist, when it grows large, expands forward and sidewise, and extra waist proportion must be supplied accordingly.

The center line of the angle of ten degrees should be perhaps more fully explained. Said center line runs on and along the whole center of the leg when the garment is upon the body, unless, by some miscalculation it is drawn out of shape. From this line all bottoms and tops of the fore-part may be squared, and from it the top and front of the fore-part is one-eighth waist, actual measure. It forms the crease line, and from it the bottom is made an equal distance on each side. The knee also is formed from it as a center. But as the inside of the leg is a straight line and the outside of the leg is hollow at the knee, it follows that, for a close-fitting pants leg at the knee, the outside first requires a reduction of say three-eighths to one-half an inch, on double cloth, which again is allowed at the inside, after which the width may be reduced equally on each side, if such reduction is necessary.

The angle of seven and a half degrees runs in slope with the leg, though on a perfectly straight line, and if the pants leg is to be shaped in accordance with the shape of the leg, as it must be if a close fit is desired, then wherever the leg has a hollow the garment must be reduced, and wherever the leg has a swell the pants also must be enlarged. This is the case with all legs. The side of the knee should be hollowed out, while at the calf the side seam must run outward. If the person be “bow-legged,” then the outside must receive more cloth and the inside less, if the form of the leg is to be followed; but, as a general thing, bow legs in pants should be so formed that the inside is pretty full, in order to hide such a deformity. So-called “knock knees” require more cloth on the inside of the knee, and therefore more must be taken from the outside. Knock knees are not so much a deformity as bow legs, and such pants legs may be cut and made according to the shape of the leg.

There is one more bend in the leg which requires mentioning here, and that is the knee itself. A close-fitting pants must have the shape of the side of the leg and the shape of the knee in front as well. If the pants leg is not cut or worked according to the knee, the knee itself will work it out by stretching the front or wrinkling the back. By fulling the fore part one-fourth to three-eighths of an inch over the knee, and “fulling” the same on both seams, the whole difficulty will be overcome. Or, what is still better, stretch the back that much. If this is to be done correctly, it must not be left to the sweet will of the pants makers to stretch or shrink as much as they please or where they please, but everything must be distinctly notched, say five inches above and five inches below the knee.

This is also true when you cut spring bottoms. Spring bottoms have come and gone regularly for the past forty years, and they will soon come again, and when they come again some cutter or tailor will be glad to know something about them. When spring bottoms were first introduced they were made with a piece or wedge set in the center of the fore part, on the same principle as leggings are made to-day, but it was soon discovered that by allowing that wedge on each side of the back, and by stretching the sides of each fore part toward its center, the side of the fore part would spring forward, and the wedge added at the side of the back filled the vacancy at the stretched side. If there could be a seam in the center of the fore part we would simply add say one-half to three-fourths more on each seam in front, and the spring would be there; or if we could cut our fore part to a point at the bottom, leaving the whole width at the back, the spring would also be there, and all without stretching or shrinking anything, because the spring would be cut where it belongs. But style and economy of material require all seams to be at the side, and for the reason that the spring must be worked toward the center of the front, all such fore parts must be as narrow as possible, because a narrow fore part of six inches will stretch more[12] easily than a fore part of eight inches. Now, in springing the bottom and forcing both seams of the fore part forward as a spring, all must be done by stretching the sides of the fore part before the seams are sewed, and in such manner that the fore parts will fit into the spring on the back. It will be of no practical use to do the stretching at the sides but a part of the way, and attempting to force the spring forward by shrinking the center of the front, as all such shrinking will return. Nor will it do any good to hold the back full on the fore part, and sew the seams, and then attempt to stretch the fore part; for, even if the stretching could be accomplished in this way, the sewed-up seam would soon draw back, because a sewed seam, and particularly a machine-sewed seam, can be stretched but very little, and if it does stretch will soon return to its former condition. The stretching of the side of the fore-part must also be alike on both sides, as well as alike on both legs, or else the springs will not run in the same direction; or they may not spring to the center of the foot, but to one or the other side. The stretching must also be done as far down as possible, and must never be started higher than about five inches above the bottoms, all of which must be indicated by correct nicks in the front and back.

All nicks, and particularly on pants, should be cut small and distinct. It would be best to make just a small, straight cut; and the maker should be required to put them together with the utmost precision, and not one side a quarter of an inch up and the other a quarter of an inch down. Why I claim that the nicking and putting together are very particular features regarding pants, for this reason: All parts of pants are very long, and while a small twist, say in the sleeve of a coat, may not show much, the same twist will show plainly in a pants that is three times as long. In order to convey a correct idea of what I mean by the term “twist,” take a pants pattern and pin it together at each side of the bottom, then throw it out of gear, say one-fourth of an inch at the hips, and see what twist will be at the whole length.

Now, the foregoing points are figured down pretty close, but figuring on paper and practicing on garments are two different things. Fine garment-cutting and making are something more than can be learned from a multiplication table. It requires a practical knowledge of what a customer really requires, and what he ought to have; it also requires practical knowledge of the proportions of the different parts of a garment. It is, for instance, of little importance if a pants leg is half an inch larger or smaller, so long as the garment hangs nicely when on the body, and the bottom corresponds with the knee and thigh, and so on—all of which is something that cannot be learned from the books. If a cutter is what may be termed a “natural-born” cutter, all such things will come to him; but if he is not so gifted, then he must train himself to it, and in no other way will he succeed as a cutter.

On top of front, the pants diagrams are thrown forward from five-eighths to two numbers. Persons who stand very erect, and have small waists, have enough if one-half is thrown out. Large waisted persons stand naturally very erect, and a form of forty-four seat, and forty-six waist, made up, can be fitted with one and one-half, while two numbers, like Dia. XX, is enough for forty-six seat and fifty waist, made up. Forty seat, forty hip and forty waist, made up, can be fitted with one and one-fourth, and the same is true of thirty-seven seat and thirty-seven waist, made up, all such waists to have the angle of seven and one-half degrees complete at the side, or even one inch allowance, as per Dia. XX. The gore in the back is to be one inch at the top of fore-part and running out to nothing at the top of back, and which may be called extra looseness, but which can not be drawn backward under the buckle strap, but will remain at the side and prevent the waistband from striking the short ribs.

Outlets on the waist of a pants would do more good if left on the top of side, running out to nothing at about line sixteen, but the outlet, if left on there, requires too much work to let out, and the outlet is usually left on behind. When such a crotch must be let out, the back crotch seam from line sixteen upward, should be stretched upward say one-quarter to one-half inch, and the whole back seam, above the crotch should be stretched, as much as possible, and that may easily be stretched one full inch, and the stretching should be done mostly at, or near, the seat line, and as far sidewise as possible, and if the seat is lined and the lining is straight, and will not stretch, a wedge must be put in the lining, as shown on the outside of Dia. XVIII. The outside can almost always be stretched any amount desired.

Stretching the back thus, the outlet, left behind, will fall sidewise, where it really belongs, but when said outlet is simply let out behind, it will remain behind, and must be pulled forward, and even if the pants feel wide enough at the waist, the wearer may not feel at home in them when sitting down. On the other hand, when pants have too much seat, but not too much waist, the best way is to rip up the side seam, from line sixteen upward, and stretch the side of the back, say one inch, and cut it off on top, all of which makes the seat shorter[13] behind. Stretching the side of the back upward from the side of the crotch is equal to cutting a larger gore between the front and back on top of side, and allowing it behind. If the pants are lined in the seat, or all the way down, a large fold should be laid in the back lining in place of cutting it in as some do, to imitate the gore, or as others do, who baste the lining flat over the gore, whereby the effect of that gore is destroyed. In short, all linings in the pants should be put in plenty large on both back and front, both in width and in length, on the same principle, as the lining in the back of coats is put in large. The larger it is, the better it will be. The outside of a pants mostly stretches, but the lining does not, and often shrinks from the moisture of the body.

If we should cut two pairs of pants over the same pattern, and make one up with, and the other without lining, we would find that the one without lining feels the larger when on the body. All pants lining should be cut bias.

To shape the crotch seam Dia. XIV should be observed, especially when the fore part is to be cut larger and the back that much smaller, which sometimes may be done to advantage, and may enable the cutter to cut the back without much piecing. In the shape of Dia. XIV the seam may be thrown anywhere, without losing the balance.

Some years ago, Mr. J. B. West brought out what he termed a new style of pants, by cutting the front fork larger than the back fork. But that new style did not last long, for the reason, I suppose, that most of the cutters did not get the points of the forks correct. There is no question but that it can be done satisfactorily. The only objection I could make is this: When the inseam is thrown too far backward, the dress part on that seam locates too far backward, while really the dress requires to be located as far forward as possible, and for this reason I have the undress fork located, near the angle of ten degrees, and it may be made just even with that angle, and all other width allowed on the back.

If for any reason it is necessary to cut a pants with a very large fork on the front, and a small fork on the back, the pattern should be cut like Dia. XI, but the fork should be spread so that whole can be cut without piecing; whereby the crotch seam can be thrown anywhere, by the help of the sweep from point 80, without losing the balance. If the cutter is able to cut that seam anywhere, it may save him a great deal of piecing where such piecing is not desired.

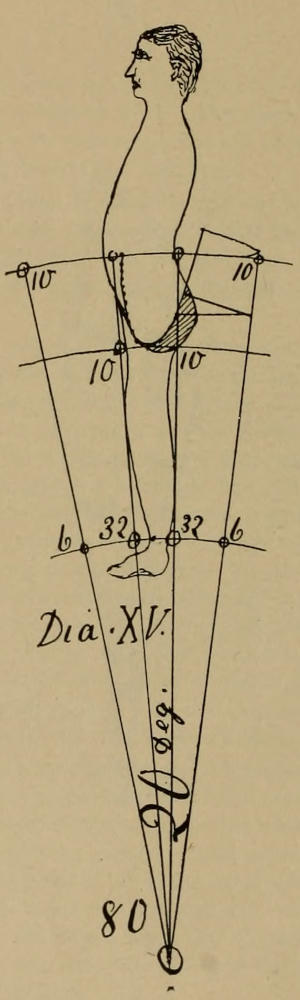

This angle must be further explained. Although I am using the angles two and a half, ten, fifteen and twenty degrees for cutting pants, the angle of seven and a half degrees is the main angle, because it corresponds more nearly to the slope of the legs, at the outside, than an other angle, and the combined outside slopes form an angle of fifteen degrees. I do not claim that the outer sides of a person’s legs actually slope fifteen degrees. In fact, I know they do not, but they come near enough to that to be practical for garment-cutting. It may be fourteen or sixteen degrees, and it may be even more than that, as on short and large-waisted forms, or it may be less than that, as on tall and slim persons, but fifteen degrees is the sixth part of a square and is easily found by spreading two lines one-fourth of their length. Going up from a certain point one yard, and across one-fourth yard, will make the angle of fifteen degrees. By placing a straight edge on each side of the body, on and along the slanting side of each leg, they would form an angle of fifteen degrees. These slopes are certainly the longest and straightest lines that can be drawn on the human form, and there is no reason to contend that they are not good lines to use as bases for cutting pants. The longest and straightest lines are always the best to be used as bases to work from for almost anything. Within these two lines, representing the angle of fifteen degrees, is contained the whole pants, providing the proper circumferences are obtained to go around the entire body. Wrapping a sheet of paper around the body will give the correct idea of what I mean. There is the slope of fifteen degrees, and there is the circumference around the whole body, and represents a cover for both legs as though they were one.

Pants are cut for one side of the body, but on double cloth; so we make our calculation for half of the body only. If we shape that sheet of paper according to the form of the body, it will represent a slope, on the sides, of fifteen degrees, while a straight line in front and center of the body will divide the angle of fifteen degrees into two equal parts, or seven and a half degrees, on each side, which seven and a half degrees are used as a base for this garment, representing a cover of three-fourths of one leg, viz.: one front, one side and one back. The inside of the leg requires as its share one-third of the whole outside, and as the whole outside is the angle of seven and a half degrees, it follows that one-third equals two and a half degrees, which latter, attached to the angle of seven and a half degrees, forms one whole angle of ten degrees.

This angle of ten degrees, with its proper width, will cover a bare leg, and if it does not exactly fit it, it will at least represent the same slopes, and by these, reductions at the knee and additions to the bottom can be made. For the point of the double dress fork one and one-eighth to one and one-quarter is to be allowed, outside of the angle of ten degrees, and three-eighths less for the double undress side, and whatever the forepart is made smaller is allowed again on the back. The points of the forks must be so constructed that they all rest on the same sweep, as shown in Dia. XIV, unless the front and the back are made extremely wide or narrow, in which case the points can not rest on the sweep, but must be put as shown in Dia. XIV. The allowance of one and one-eighth to one and one-quarter for the double dress fork is simply an average quantity and one is enough for a close fit, while a very loose fit, or open cut, may have one and three-eighths allowed. That part of the pants can not be cut to fit close to the body, but must always have some loose cloth there, but it must be cut so that it will hang[15] straight. Years of experience have taught me that one and one-eighth to one and one-quarter is a good average. The same cause, which requires the front of the waist to be thrown forward of the base on 7½ deg., requires the addition to the fork, and to the angle of 10 deg., and the normal form requires about the same amount at the waist and at the undress side. If the front base were moved forward to the front of waist, the angle of 10 deg. would also move forward to the half undress fork. The extra allowance for the dress fork must be considered independent of the body, as it is a one-sided affair.

For a close fitting leg the angle of 10 deg. may have an allowance of ¼ double at the inside of the knee, or the forepart may be placed on the base, and ½ allowed on the back, and a larger leg may have anything more, which a nice slope of the seams allows, but which in no case may be more than ⅝ to ¾ on the double. Large spring bottoms will have to be considered as close fitting at each seam, and the springs thrown forward by stretching the side seams.

The side of the knee may be hollowed out ½ on the double, and in this case may be considered as that portion which is thrown outward on the inside, in order to give the pants leg the natural slope of the body for both inside and outside. For a large leg the side of the knee may have anything more which is consistent with a nice slope of the side seam, starting at the seat line. The above description of a close fitting pants leg at the knee will hold good on a few sizes only, say from 35 to 37. Larger sizes must be reduced more and require less than the angle of 7½ deg., as seen in Dia. XX, and smaller sizes must have more width.

If a large size is to be fitted with a close-fitting leg at the knee, the best way to obtain the correct points is to take the center line of the angle of 10 deg. as a point to measure from, and give the double inside ½ more than the double outside, which will be the same as the above calculation for a medium size. As stated elsewhere, the allowance on top of front of the waist to the angle of 7½ deg., and to the fork and to the knee, is caused by the base being located ⅝ to the side of the center of the body.

In a standing position the base would locate at the supposed inside edge of the front of the leg, but it must be considered that at each step the center of the whole upper body is thrown upon the center of the standing leg, and consequently the bases of a pair of pants change at each step, and the pants is required to set reasonably well in all the different positions in which the leg may be thrown, all of which can only be accomplished by extra width in the fork, and which may be termed the balance of a pants. If said balance is not correct, the pants leg will make a kink or throw a fold somewhere upward to the knee.

This fault of pants can be seen in the muddy streets of a small town, as well as on the fashionable boulevards in large cities, and are even shown on fashion plates. Such may be in style by some reporters of fashions, but I never did like them, and I do not suppose anyone else does, but somebody must cut and make them as long as they are so shown on the fashion plates.

This question will always have to be considered by cutters, and it cannot be explained too much. Careless nicking of the seams, or carelessness in bringing the nicks together when the legs are sewed up, will also cause a twist in the legs, one way or the other. Pants legs which draw from bottom of inside, up and forward, to the knee, may be changed either by giving more width at the inside of the bottom, starting at the fork, or by reducing width at the top and front of waist, and running it out gradually below the knee. If the reduction of the front of the waist makes the waist too small, allow behind what is taken off in front.

If anybody will go to the trouble to open his own pants in front, and draw the front sidewise and the side backward, it will be seen that that twist from the inside angle to front of knee will form, and by twisting the upper portion a great deal, the twist will form all over the leg. Now, if a pants forms that twist itself, it shows that the pants must be altered contrary; that is, by reducing the front and allowing behind, or in other words, by twisting the pants waist from the side forward and from the back sideward. How far that twist is to be made depends upon the condition of the pants, also how far down it is to be made. As to the amount of changing such a pattern or system is not for me to say; I can only point out the way to alter, not the amount. Such pants, when made up, are hard to alter, but by knowing how to alter them, a cutter can, at least, change the next one.

The thigh proper would not require 1¼ addition for the dress side to the angle of 10 deg., but the legs at the fork do not join closely, but are about 1¼ inches apart, and at this point, and in front of the thigh, there is a hollow which is partly filled out with the sexual organ, which must be provided with extra cloth, commonly called “dress” in tailors’ language. The hollow itself forms a bridge from one leg to the other, and for the purpose of fitting pants, cloth to cover that bridge must be allowed for each leg, and is put down in this work as an allowance[16] of ⅝ to the double angle of 10 deg. for the undress side. This allowance for the bridge is made on the same principle as the wedges are, which are put in between the fingers of gloves, and which allow the fingers to move in any direction.

At line 8 the dress fork is placed at 1¾, but 1½ is enough for a close fit, and the dress fork and the back should be even at line 8. The back is even with the front at line 8, and the half dress fork at line 10 is made larger or smaller according to the width at line 8, all of which constitutes the difference between the open and the close cut at that point.

Now I must say something about the 1¼ thrown forward on top of waist, as in Fig. 1. This 1¼ is for such forms which throw their front of waist, say ⅝ forward of a straight line, running parallel with the front slope of the legs, and which is forward on top, and which forms may be called forward leaning waists, but the variations are so great that no positive point can be given; but in order to have something for a standard, I have put it down as ⅝. The ⅝ forward growth of the top of waist and the ⅝ from the base to the center, make a combination of 1¼ and any waist which leans considerably forward, or any waist that is near as large as the seat, requires that amount. All that which has been said above about the amount to be thrown forward of the base for the normal form, as in Dia. XIX, is independent of any consideration for a large waist, and which is further explained in the Article on “Pants.” But I must add this: A large waist, though it grows forward from the back, don’t locate itself forward according to the difference of the diameter from front to back on the same person, as it might be supposed. Whenever the waist becomes larger the body will straighten up, in order to keep in balance, and we can see many large waisted forms whose front of waist is no further forward than that of a small waisted form, and consequently require not much addition to the front, but to the side. Hence 1¼ thrown forward may be plenty for even a large waist, and I find that two numbers are about the most which any pants can stand, or ought to have. It would be folly to attempt to measure the amount in any shape or form, but all this must be made by guess, and it is fortunate for cutters that a quarter or even one half inch, more or less, will not kill the fit. (See description of Fig. 1.)

The angle of 7½ deg. is formed according to the scale of the seat measure, and over that point the side of the pants may have the full width of that angle, while above (at the waist), and below (at the knee), the normal size requires a reduction. On the normal form the seat measure is the largest, and the hips are cut accordingly, and the waist and the knee are cut according to the measure, and it will be seen that whenever the waist becomes larger, the hips also increase, and if we want to cut the waist larger we cannot help cutting the hips larger also, and the hips will mostly follow the waist. It is true there are some extra large hips with small waists, and if this is the case, the hips must receive enough cloth, and to retain a nice slope of the seams, the waist should be cut down again by a larger gore in the middle of the back. Unless the hips and waist are larger than the seat, there is no need of going outside of the angle of 7½ deg., but extremely small waists and small hips require a reduction over the side, the same as extremely large waists and hips require an addition. How much that may be must be left to the cutter, but I will give a rule which works both ways: On a normal 38 seat the hip may be 30 and the waist 34, which requires the full angle of 7½ deg. at the side of line eight; and at, and above, the seat line, but a reduction of say ½ inch at the waist on single cloth, and a small gore in the back. Now, if the hips should be 38 inches too, it is but reasonable to allow over the hips, and outside of the angle of 7½ deg., the difference of such 9½ numbers, at 4 numbers below 0, which is in this case about ⅜ of an inch on both front and back. Still larger hips in proportion to the seat and still larger sizes can be calculated the same way, and though the rule would hold good in the case of quite small hips, the proportionately smaller hips are seldom found, and if found at all, will indicate a smaller waist, and the slope to the smaller waist will regulate the smaller hip, the same as a larger waist will regulate a larger hip.

Some persons are found who are very flat from back to front, and broad from side to side, but of normal circumference, and for such, the pants should be cut full at the top of side, and reduced on top of front, because they are mostly erect forms. In all such cases I would consider the backbone, at the hollow of the waist, as a permanent thing, and regulate the waist for any form at the front and side.

To obtain the correct shape for the depth of the crotch, is clearly shown in Dia. XIII and XIV, or in any diagram with a sweep from point 80, but we can not always go down to point 80, and the next best thing to be done is by squaring from the inside line of the angle of 10 deg. through point 10 on the front base, and it will result in the same thing. At the crotch all faults of the upper part of a pair of pants are recorded. If the pants[17] are too small over the side of waist or hip, the side of the waist or hip will seldom show it, because the solid hip will draw the pants up to the side, and the soft part of the inside thigh will be pinched and sawed by every step. We find plenty of men who will always direct cutters to give them plenty fork, because they always have their pants too tight, and when we look at such persons, we will find that they are always full grown at the sides of hip and waist. True, more fork will help such pants, but they will not set as good as if they were supplied with sufficient cloth over the hips. Too much cloth over the hips will not injure the pants, it will simply make them large there, but not enough will always bring on complaint.

For the following reasons, the base, or the front line of the angle of 7½ deg., was not placed in the center of the front:

1st. The base would not run parallel with the front of the leg.

2d. The center line of the angle of 10 deg. would not run on and along the center of the leg, and consequently would be useless for the crease line.

3d. The center line would not be a reliable point from which to establish the center of the front, at a distance of ⅛ waist, close measure.

4th. The center line would not be the center line for the knee for all widths.

5th. The center line, being used for the running of a stripe, would not run with sufficient correctness, at least not on the back.

All the positions of the lines, angles and bases are placed as indicated, because years of trial have convinced me that they give the best results. There is no way conceivable, that I have not tried, to adjust the angle of 7½ deg. in order to bring the lines in harmony with the body—and the result is here given. What difficulties I have had, to obtain this result, it is not necessary for me to say, neither would anyone believe me, I suppose. But I do say, however, that I spent 8 years in the work of alteration, to adjust this angle of 7½ deg. To some it may seem improbable that I would possess the patience and determination to succeed in solving the problem, and would stick to that determination for 8 long years—but I did.

Now, I will give a description of the seat and compare it with the front, and follow it with a description of the slope of the back, by which the seat is to be fitted. From the crotch forward the front tapers up, and forward, and the normal form can be fitted on a straight line, or with a straight piece of material, by simply turning the crotch backward, but it is not so with the back, or the seat (see Dia. XV). The seat turns in a different way, and from the crotch backward; downward first, say 1 to 1½ inches, then backward, and then upward and forward again. A sheet of paper wrapped around the body will fit well in to the body of the normal form all around the front (see Dia. XV). At the side it will do the same all the way up to the thigh-bone, or the largest part of the seat. But on the back the sheet will not meet the body below, or above the seat, nor will the sheet touch the top of the side; and in order to bring the back to the body, below the seat, the back must be cut through crosswise, when the lower portion can be pushed in, and thus brought in contact with the back of the thigh. Thus cutting the sheet crosswise and below the seat will cause an opening of about 2½ inches directly under the seat, running out to nothing at the side of the thigh, which opening, if minutely examined, will show an angle of 15 deg. This must be closed again by inserting a wedge by some means. This inserted wedge forms a sack for the seat, and is thrown downward and backward just as the seat itself.

But it will not do to cut pants with a piece across the seat, so we must create an artificial wedge by using the surplus cloth on the top of the side, and dipping it backward and downward over the seat, and inward to the back of the thigh. By so doing, the original back center is thrown over the line, and is cut off as back slope; and whatever the back has been thrown downward, and, has lost in length, is allowed again on the top, and is usually termed “extra length of back.”

When the pants are on the body, both front and back are alike in length as far as the fit is concerned, but we may make the back an inch longer for nice appearance, and it is usually so done. That portion which stands off on, or around the back, on such a sheet, is reduced by one or two gores in the back. The extra length of the back is taken up by winding around the seat, and well-adjusted or well-balanced pants will always fit there. I claim that the angle of 7½ deg., with an artificial wedge across the seat, will produce this result every time, as shown in Dia. XIV.

With the help of Dia. XIX, XX and XXI, there should be no difficulty in cutting a pair of pants that will be a pleasure to wear; but, as in all things, there must also be harmony between the cutting and making, and for[18] this purpose I will add, that all diagrams and patterns issued by a reliable publisher of fashions are calculated to be cut from nice material, which requires small seams. Their pants are to be made up without lining, which allows them to give in every direction; and they are also calculated to be worn over nice-fitting under-clothing. In fact, they are calculated for fine trade, and they are made by tailors, who receive about $3.00 pay per pair for making. Therefore, when such a pattern is sent out, and pants are made from cheap goods with large seams, and in all probability lined with heavy muslin, the result is, that the customer cannot wear them. Then, again, one cutter may perhaps allow a little extra here, and another allow a little there, and the pants in the end may be large enough—but where is the city style and the neat fit?

The same is true as to coats and vests. Reports of fashions are intended for fine work, and all that this term implies; and a cutter who uses such patterns to make a pair of pants for a man who works in a ditch must allow more fork and more seat length as well as more width for the upper body—all allowed on the side. Extra looseness for the upper body is best provided by allowing all at the side, where it may hang loose but smooth; but if the extra width is allowed in the fork, it will remain there on a twist, and it may even cut the seat, if only allowed above the fork. Allowing extra width above the fork is almost as bad as to allow extra width at the front of the armhole, which allowance would really make the hole smaller.

From the crotch downward the whole leg must conform to the slope of the angle of 7½ deg., because the relation of the crotch and the ankles change very little except on deformed persons. Some persons may throw their feet a little further apart than others when walking, and the center of the body may be considered at the inside ankles, or one inch from each inside ankle, just as a person may place his feet while standing naturally. But when walking, the center of each half body is in the center of each leg, for by each step one leg makes the whole body must throw itself upon the center of the other leg, or else the body would tumble over. This can be best observed in slow walking, while by fast running it is not noticed. Any person who walks slowly throws his upper body more to a position of standing on one leg, than a fast runner, hence the slow walker is seen wabbling his head from one side to the other by every step, the same as a goose.

In this work the pants are calculated each leg for itself, and each leg has its own base; and they are so adjusted, that a person can stand, walk, jump, run, sit, etc., and it must be understood that when a pants is on the body the base goes with the leg, so that the base runs straight down when the person makes a step, or when he stands on one leg; but when he stands on both legs the base will naturally run a trifle sidewise at the ankles, and consequently a true plumb line pant base can not be found, except for one position of the leg only, and the position of the bases, as given in this work, are as near correct as any can be established, and from which any particular shape of pants may be shaped. As for instance: Riding pants require more fork, so that the rider can spread his legs sidewise. Sailor pants require more width at the bottom, and that width must be allowed on the outside, or else such pants would strike each other at every step. For all such and other changes we have a base to work from, and after all such changes are made we must see that provision is made to sew the parts correctly together, by carefully nicking the seams.

The center of gravitation in a pair of pants may be considered to exist at the points of the angles, which are eighty numbers below the top of the waist, hence a sweep from the point will make a true connection at any point of the leg, and such sweeps can be depended upon no matter how narrow the fore part, or how wide the back is cut, and especially so when laid out like Diagrams XIV and XV. Now, to make a draft from that point for every pants or pattern we cut, would be inconvenient, neither is it required that it should be done, except for practice; but when a cutter knows a center which is infallible, he is certainly better off than if he knows no such center. A sensible person, if he cannot do just as he wants to, will do the best he can; and, so in this case, there are several ways open for operations.

1st. Cut both the front and back of equal width at the knee, and notch there; then measure upward and downward.

2d. Run the inside and the outside lines of the angle of 10 deg. down as far as the cloth or the table allows, and sweep the inside seam from the inside line and the outside from the outside line, each seam separately, from a point as far down as you can reach.

3d. Fold the broader back over to the smaller front, so that both will lay smooth and without twisting, then cut the nicks.

4th. Square from each line of the angle of 10 deg., and at the knee only, because, at the knees, the front and the back are the nearest together, then measure up and down and cut the nicks, and in all cases be careful that the back is not held full behind the knee and upward on either seam....

If the distance between the smaller front and wider back were miles, or rods, even, the result would not be very satisfactory, but in this case the space is never more than 1 inch, and the variations in the several ways are not perceptible. The diagrams in this work are the best illustration of the sweeps from point 80, as well as of the cutting of all seams on a nice slope.

The medium sizes require the top of forepart about ¼ of the whole waist measure, but smaller sizes require the side seam further back and the larger ones more forward on account of the pockets. Another point should be observed: It has been stated that the center line of the angle of 10 deg. is a line to square from for a level bottom as well as for a level top, all of which is true, but the waist of the normal form runs downward in front, and the top of the normal waist should be run in the same direction, and for this reason should be squared from the front base line, and for extremely small waists it may be squared from the front line of the angle of 10 deg. Taking Dia. XIV as a model, we may sink the front of waist ½ inch and raise the back ½, to 1 inch from that top square line.

In conclusion of this article, I will say that, perhaps, I have gone too many times over the same ground, and perhaps I will go over it again and again, but it is always from a different standpoint and connected with something else.

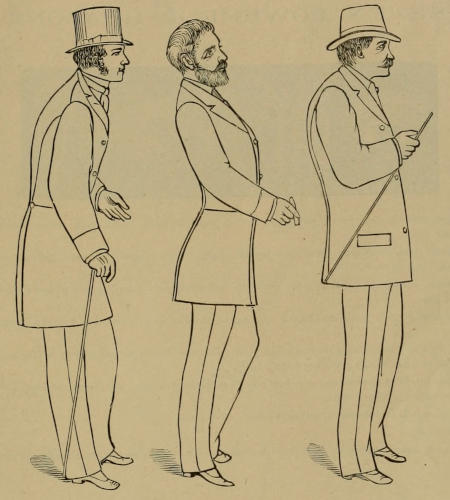

At the present time, the style of pants is loose at the knee, tapering smaller toward the bottom. Pants which are cut wide at the knee must start with extra width at the seat line, and said extra width must be well divided on both seams. All pants must fit the same at the seat line and above, and fashionable width at the knee must be started from the seat line downward. Dia. XIX represents a pants of the present style, and is made over a pattern of 38 seat, actual waist measure 33, and waist made up 34½; about 19½ knee, 18 bottom, and is for a rather small waist. Dia. XX represents a large waist, of about 50 inches, made up; but actual waist measure 47, and seat measure 46 inches; knee 22½, bottom 20½.

For extremely large waists, Dia. XX may be used, and that extra width allowed equal in front and on the side. On all large waists, the seat measure must be taken close, and the fork cut accordingly, no matter what the hip and the waist measure may be. The seat measure is the standard for the scale, and the large waist must be fitted according to the measure, the same as the length of the legs, or the width of the knee. Dia. XXI represents a pants of 39 seat, with a very high waist. The top of waist is made up 37 inches, but at the hollow of the waist it is only 36 inches.

The angle of 7½ deg. has the proper width for all pants, at the seat line, and in no case is a reduction, or an addition required there. Above the seat line, the hip and waist must be made according to the measure, and below, it must be made according to style and measure. As to the top of the side, it may be proper to remark here, that if the top of the side is too small for any pants, the fork balance will be destroyed, because the sides of the body will draw the fork upward, and will cause it to cut the crotch somewhere. The waist is one continuous surface all around and may feel tight all around, but if the crotch is pulled up by a small waist at the top of side, that will saw the crotch on one spot. Therefore I will repeat the true balance for the waist, on the angle of 7½ deg. Reduce the angle of 7½ deg.—from 6¾ upward, 15 deg. for back slope—from the top of the center line of the angle of 10 deg. go forward ⅛ of whole waist circumference, close measure; cut a gore of 1 inch in the center of the back; measure from the front to the side and from the back to the side, and if that gives too much waist, cut another small gore between the forepart and the back. But if the waist requires more than that, divide the addition required into 3 parts, and place 2 parts at the sides and 1 part in front. If the waist is higher than ¼ whole seat measure, run the gore in the back, out to nothing on top, as in Dia. XXI, and the higher the waist is cut upward the more it must be cut like Dia. XIII, both at the side and at the front. Working pants with the front cut clear up to the neck, must have the upper part of the front cut like Dia. XIII, that is, sloped backward 15 deg. from the waist.

Dia. XX has 2 numbers thrown out in front and top of waist, and at line 8 it is 1⅞ while the double dress fork point has 4¼, which produces a good open cut for such pants. The point of the fork may be made ½ inch more or less for the same person, providing allowance or reduction at the point of the fork is run up and down, running out about 5 inches above the fork, and at, or below the knee. I know it is contended that a large-waisted form requires a larger fork in proportion to the seat measure, but this is not the case, as long as the hips and sides of waist have sufficient cloth. The thigh may grow in proportion to a larger seat, but it does not grow in proportion to a larger waist. Large-waisted persons have small seats in proportion to the normal form, and the proportion of the scale of the seat measure is large enough for all forms. That same result may be observed at the knee, and at the bottom; and to better express my ideas, I will say something about the diameter of the thigh, as well as the diameter of the knee and the ankle.

For the purpose of cutting pants, the leg may be considered a straight and round pole, but tapering at the lower end to about ½ of what it is on top. The thigh can be covered and fitted for modern pants, all seams included, if we allow it 4 times its diameter, close measure of the thigh, without compressing it. The circumference of a circle is equal to three and one thousand four hundred and sixteen ten thousandths (3.1416) times its diameter, which is so near to 3½ that we may call it so, at least for the purpose of cutting and fitting pants. Now, if 3½ diameters of the thigh will constitute the circle for the thigh, then that circle will fit the thigh skin tight, but if we allow 4 diameters, we have enough cloth to sew seams and a few inches beside for straddle and general looseness. If the diameter of the thigh were only 1 inch, 4 diameters, or 4 inches, would not give cloth enough to go all around, after 1 inch is used up for seams.

In cutting pants, we may say that a seat size of 36 inches is a medium size; and for the purpose of fitting such a thigh with a modern pants, we will call its actual diameter 6 inches; and its skin-tight circumference just 21 inches, and close investigation will show that this is a fair average. If we give such a pants 4 times 6 inches, and deduct 1 inch for all seams, we have 23 inches left to cover the thigh, which only measures 21 inches, and this would be plenty for the undress side. I do not say that a close-fitting undress side can not stand more than this, but I say it should have that much, and that 1 to 1½ inches more, evenly divided, will not make it too large for a fit, at least not for the present conception of a fit.

At the side of thigh, the angle of 7½ deg. is just ¼ of the whole net seat measure, which may be taken for a medium loose leg, but for a quite close fit, ⅛ to ¼ inch may be deducted, and for a quite loose fit, anything may be allowed there, which will make a nice slope for the seams. For a size 36 the angle of 2½ deg. has a width of 3 inches at the fork, and the double angle of 10 deg. requires double the amount of 4 times 3 inches, making in all 24 inches, to which is added 1¼ inches for the undress side, for extra straddle, and the bridge from one leg to the other, making it 13¼ inches in all for the half undress side.

The above calculation is here given for the purpose of showing how close the diameter and the circumference of the thigh correspond to the angle of 7½ deg. as used in this work. It also shows that a larger thigh, say of 7 inches diameter, produces more cloth in proportion to a smaller thigh of say 5 inches diameter, and that the addition of 2½ inches to each and all half seat measures will give a good balance for all sizes. But for reasons explained elsewhere, boys should have plenty fork, and when we come below size 28, we should give all that is consistent with a very open cut of the fork. The largest sizes may be cut according to the scale and to Dia. XX.